Summary of Contents for rc3Dprint Micro Velocity

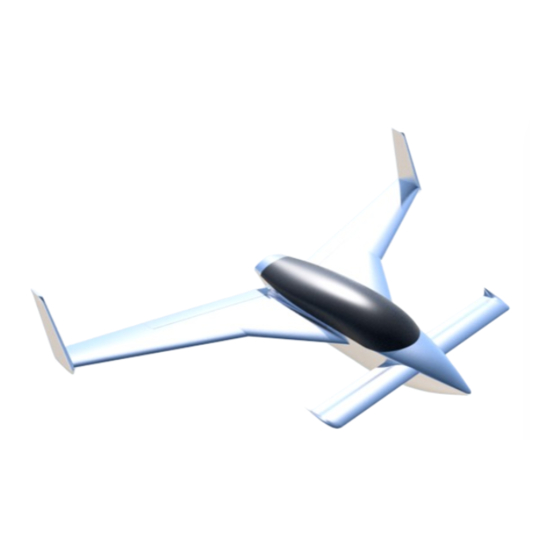

- Page 1 Micro Velocity P R I N T I N G A N D A S S E M B L Y I N S T R U C T I O N B O O K...

- Page 2 T H A N K Y O U Thank you for downloading this Micro Velocity XL. These models take many hours of work to make available to you so please don’t share the STL files with others. Send them to www.rc3print.com where they can download the models themselves.

-

Page 3: Parts List

P A R T S L I S T R E Q U I R E D I recommend UMX electrics, specifically from the UMX Cessna 182, for this model however you can use any lightweight rx/esc and servos you like. RX ESC and integrated servo - EFLA5864 SPMA3065 Programming cable LIPO 2S 7.4v - EFLB2802S30... - Page 4 I N C L U D E D S T L . F I L E S F U S E L A G E W I N G...

- Page 5 C A N A R D V E R T I C A L S T A B...

-

Page 6: Other Parts

O T H E R P A R T S... -

Page 7: Specifications

S P E C I F I C A T I O N S Wing Span & Area 710mm span Flying Weight 709.93 169g Wing Loading 16.9g/m 5.6oz/sq ft Wing Cube Loading Channels Centre of Gravity - behind fuselage join... - Page 8 P R I N T I N G P R O F I L E S * If printing in LW-PLA from Colorfabb we recommend following the calibration process suggested by the manufacturer regarding nozzle temp and flow, below are suggestions L W - P L A P R O F I L E Save this profile as LW-PLA.

- Page 9 A W O R D O N R E T R A C T I O N S With regular PLA a common problem is under extrusion at layer change - to fix this increase the setting extra prime amount in Cura. With LW-PLA it is recommended to switch retractions OFF since trying to retract the foaming filament can cause problems.

- Page 10 A S S E M B L Y 1. T H R O U G H O U T T H E B U I L D , A D H E S I O N S S H O U L D B E C A R E F U L L Y R E M O V E D A N D F A C E S T O B E G L U E D T O G E T H E R S H O U L D B E S A N D E D F I R S T T O E N S U R E G O O D C O N T A C T .

- Page 11 Glue together the aileron pieces, careful not to have any glue fill up the hinge space. When gluing the hinges into he wings you can line the aileron up with the wings to give enough space for the hing to move. The front of the hinge should be about 1mm away from the wing.

- Page 12 The rx/esc should be mounted onto the tray ( I used double sided foam tape) then the tray screw into place as far forward as you can (checking the wires reach the motor). This means you can move the rx between models).

- Page 13 P R O G R A M M I N G If you are using the Cessna 182 UMX board (EFLU5864) then you will need to reprogram the board for elevon mixing. Whilst this can be achieved inside your transmitter, the AS3X will interfere with your controls, I.e.

- Page 14 To set up the elevon mixing follow the settings in the screenshots...

- Page 16 A D V I C E F O R M A I D E N F L I G H T Make sure the control surfaces are moving correctly! The battery should be positioned such that it won’t move, I tend to use sticky velrco for this. Check the CG.

-

Page 17: Component Placement

C U R A C O M P O N E N T P L A C E M E N T C O W L I N G “Spiralize outer contour” F U S E L A G E F R O N T F U S E L A G E B A C K If using a motor that will need to affix to the firewall, increase the... - Page 18 V E R T I C A L S T A B T O P Unique Setting: None V E R T I C A L S T A B B O T T O M Unique Settings: None C A N O P Y 1 Unique Settings: None...

- Page 19 C A N O P Y 2 Unique Settings: None W I N G 1 Unique Settings: None W I N G 2 Unique Settings: None...

- Page 20 W I N G 3 Unique Settings: None C A N A R D T I P Unique Settings: None C A N A R D Unique Settings: None...

- Page 21 I N B O A R D E L E V O N Unique Settings: None Can be printed with 1% infill O U T B O A R D E L E V O N Unique Settings: None Can be printed with 0% infill T P U P A R T S The hinges sit at a 2 degree angle when loaded into Cura.

- Page 22 P L A M O T O R M O U N T Print in a standard PLA profile.

Need help?

Do you have a question about the Micro Velocity and is the answer not in the manual?

Questions and answers