Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Enerpac EVOP12140

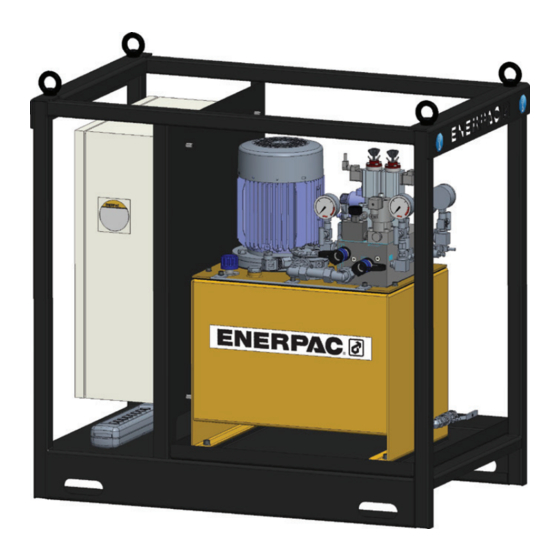

- Page 1 Operation and Maintenance Manual Enerpac EVOP12140, EVOP140150 & EVOP180150 Pump Per Point Lift System Document Number: L4540 Document Revision: A Document Revision Date: 18-NOV-2021 Document Language: ENGLISH EN To reduce the risk of injury, user must read and understand this document before use.

- Page 3 Enerpac for quality tools, services and solutions. For additional information, visit www.enerpac.com. WARRANTY Refer to the Enerpac Global Warranty document for terms and conditions of the product warranty. Such warranty information can be found at www.enerpac.com. NAMEPLATE AVAILABLE LANGUAGES...

-

Page 4: Table Of Contents

Contents 1. SAFETY ................................4 1.1 SAFETY PRECAUTIONS ........................4 2. COMPLIANCE STATEMENT ......................... 6 2.1 EU DECLARATION OF CONFORMITY ....................6 2.2 UL CERTIFICATION ..........................6 3. INTRODUCTION ............................6 3.1 OVERVIEW ............................. 6 3.2 APPLICATION ............................6 3.3 DELIVERY INSTRUCTIONS ........................6 4. - Page 5 10.4 BLEEDING THE PUMP ........................24 10.5 SPARE PARTS ............................ 24 11. ALARM GUIDE ............................25 12. PARTS LIST ..............................26 12.1 EVOP12140 ............................26 12.2 EVOP140150 ............................31 12.3 EVOP180150 ............................36 12.4 DISTRIBUTION MANIFOLD EVOP ....................41 Doc L4540_a...

-

Page 6: Safety

WARNING damage to the product and/or damage to other property. Enerpac cannot be responsible for any damage or injury Failure to observe and comply with the following from unsafe use, lack of maintenance, or incorrect precautions could result in death or serious personal operation. - Page 7 Use of incorrect power source will damage the motor. • Immediately replace worn or damaged parts. Use only genuine Enerpac parts from approved • Do not use electric pumps in an explosive distributors or service centers. Standard grade atmosphere. Adhere to all local and national parts will break causing personal injury and electrical codes.

-

Page 8: Compliance Statement

If damage is found the carrier should be notified at once. Shipping damage is not covered by the Enerpac warranty. The carrier is 2.1 EU Declaration of Conformity responsible for all repair and replacement costs resulting from damage in shipment. -

Page 9: Features & Components

7. Thermo sensor 15. Fast retract valve 23. A line Manometer 8. Reservoir 16. Pressure switch 24. A line safety valve EVOP180150 front view EVOP180150 upper view Figure 2: Major Features and Components of EVOP180150 (similar for EVOP12140 & EVOP140150) Doc L4540_a... -

Page 10: Electric Panel

5.2 Electric Panel 1. Running light/beacon 7. USB connection 13. Power supply wireless 2 2. Main switch 8. Power ok light 14. Pendant control plug 3. Touch screen 9. Emergency stop push-button 15. B line pressure sensor plug 4. Alarm/reset push-button 10. -

Page 11: Hydraulic Scheme

17. Pressure switch 27. Distribution valve 4/2 8. Return filter 18. Relief valve 28. Modular relief valve 9. Electric motor 19. Check valve EVOP12140 150 bar 140 bar Figure 5: Hydraulic Scheme EVOP Doc L4540_a... -

Page 12: Technical Product Data

Maximum pressure -first stage 160 bar 2,320 psi Maximum flow - second stage 8 l/m 488.2 in³/min Figure 6: EVOP180150 dimensions (similar for EVOP12140 & EVOP140150) Maximum flow - first stage 17 l/m 1037.4 in³/min Reservoir 150 l 39.6 gal... -

Page 13: Initial Setup

17. Stroke sensor plug: It is connected to the stroke the distance from the pump to the cylinder. Contact sensor to get the cylinder position value. Enerpac for more details. 7.3 Pendant Control EVOP can be operated in local mode from a pendant Electric schemes for EVOP are available in L4600 control (see Figure 4). -

Page 14: Screens

ID and Password to log into the user profile. The system is submitted with the default user profile which is recorded with the user name: enerpac and password: 100. 8.2 Main Screen Figure 10: Movements Pop Up Details In this pop up the user can access Manual, Preload, Automatic, Fast Retract and Depressurize screens. -

Page 15: Work Parameters Screen

8.3 Work Parameters Screen 8.2.3 Others Pop Up Figure 11: Others Pop Up Details Figure 13: Work Parameters Screen Details In this pop up the user can access Data Recording, In this screen the user must define some features and Language, Users, Inverted Speed, Instructon Manual, security parameters of the system. -

Page 16: Spans Screen

These are the buttons shown in this screen: Position sensor scale: Depending on where the Calibration operation must be carried out depending on stroke sensor is placed, the user must select one how the hook of the stroke sensor is attached. If the of these two options (see Figure 15). -

Page 17: Offset Screen

A line (big chamber) and B line (small chamber) of Information of sensors and cylinders is available either the hydraulic circuit. on the product label or online at www.enerpac.com. Manual button: Select this button to activate For single acting cylinders, B line parameters are the manual mode operation. -

Page 18: Calibration Screen

The user must push and hold for 3 seconds this button to make the value effective. The offset value does not disappear when the equipment is turned off or there is a power failure. This value is CAUTION maintained until the operator performs a reset of the Offset value. -

Page 19: Pressure Sensor Calibration Screen

8.8 Pressure Sensor Calibration Screen Figure 26: Pressure Sensor Calibration Screen Details This screen is used when the operator needs more accuracy when reading the load in the cylinder. The user can type manually the minimum and maximum analogical values given by the calibration certificates of pressure transducers. -

Page 20: Manual Screen

100% of the total flow. It corresponds to the speed of the motor. Movement values: There are some values that the Enerpac recommends setting the final load value to less system can show during the movement. These are: than 10% of the expected load. -

Page 21: Automatic Screen

8.12 Automatic Screen Through this mode the operator can retract the cylinder faster after the load has been secured by another mechanical means. Pushing the button and start cycle in the console, oil will be redirected to tank through the shortest and fastest way to reduce the time for retracting the plunger of the cylinder. -

Page 22: Data Recording Screen

To access this user, it is required to Time period: The user must type the frequency of enter the ID “enerpac” and password “100”. the data recording. The units used are seconds. - Expert: The expert has same access rights as... -

Page 23: Inverter Speed Screen

8.18 Inverter Speed Screen 8.19 Hour Counter Screen Figure 38: Hour Counter Screen Details Figure 37: Inverter Speed Screen Details This screen shows the status of the inverter speed in In this screen the user can have a record of the services the current moment. -

Page 24: Cylinder Calibration

This mode allows to have a real reference of the position of the load, and avoid unladen work. Enerpac recomends to always set the layout of the In order to work with this mode, follow the steps below: cylinders in such a way that the calibration is allowed. -

Page 25: Fast Retract Mode

Type Delta Position parameter. Delta Position is the The system will require a second check to be sure distance that the plunger of the cylinder must be there is no load on the cylinder. Refer to Figure 39. moved. This distance can be positive or negative, depending on the movement sense (extending or retracting). -

Page 26: Maintenance

10.2 Change Oil and Clean Reservoir Bleed screw Enerpac HF oil is a crisp blue color. Frequently check oil condition for contamination by comparing pump oil to new Enerpac oil. Replace oil and return filter cartridge when return filter is clogged (pressure sensor will trigger an alarm in the system). -

Page 27: Alarm Guide

Only qualified hydraulic technicians should service the common problems. For repair service, contact your pump or system components. To determine the cause local Authorized Enerpac Service Center. of the problem, the complete system must be included in any diagnostic procedure. -

Page 28: Parts List

Parts List Product Date Code Beginning With: A 12.1 EVOP12140 Figure 42: EVOP12140 Frame Figure 43: EVOP12140 Reservoir Doc L4540_a... - Page 29 NOTES Torque to 23 Nm Torque to 46 Nm Figure 44: EVOP12140 Hydraulic part NOTES Torque to 23 Nm Torque to 5.5 Nm Figure 45: EVOP12140 Powerpack components Doc L4540_a...

- Page 30 Torque to 70 Nm Torque to 120Nm Torque to 180 Nm Torque to 100 Nm Torque to 10-16Nm Torque to 80 Nm Torque to 46 Nm Torque to 60 Nm Figure 46: EVOP12140 Assemby cover reservoir with main components Doc L4540_a...

- Page 31 12.1.1 EVOP12140 Table of Parts Repair Parts List - Figure 42 Item Description Qty. Part number Eyebolt 24D0209 ISO lifting point DB9449226 Washer CCE1120108-5A Nut-lock CBE1120120-2A Weld housing Blind rivet nut DB0120020 Repair Parts List - Figure 43 Item Description Qty.

- Page 32 Repair Parts List - Figure 46 Item Description Qty. Part number Coupling motor 3KW 002-A6011-3KW Coupling motor 3KW 002-C6011-3KW Suction filter 023-0025S125W Bonded seal 030-JMB-G14 Washer-flat, 10.50, 20.00, 2.00 CAE1100108-1A Screw-SHCS, M10X25 CBA1023028-1A Screw-SHCS, M12X20 CBA1221028-1A Screw-SHCS, M6X20 CBA621028-1A Cap screw CBB1223046-1B Lock washer, 6.10, 11.80, 1.60 CCE1060108-5A...

-

Page 33: Evop140150

12.2 EVOP140150 NOTES Torque to 46 Nm Torque to 135 Nm Torque to 25 Nm Figure 47: EVOP140150 Frame NOTES Torque to 38 Nm Torque to 46 Nm Torque to 25 Nm Torque to 80 Nm Torque to 135 Nm Figure 48: EVOP140150 Reservoir Doc L4540_a... - Page 34 NOTES Torque to 9.5 Nm Figure 49: EVOP140150 Powerpack components Figure 50: EVOP140150 Upper view Doc L4540_a...

- Page 35 NOTES Torque to 35 Nm Torque to 210 Nm Torque to 90 Nm Torque to 120 Nm Torque to 55 Nm Torque to 9.5 Nm Torque to 13 Nm Torque to 100 Nm Torque to 320 Nm Torque to 10-16Nm Torque to 80 Nm Torque to 46 Nm Torque to 70 Nm...

- Page 36 12.2.1 EVOP140150 Table of Parts Repair Parts List - Figure 47 Item Description Qty. Part number Eyebolt 24D0209 Washer-flat CAE1080108-1A Screw-SHCS CBA825028-1A Cabinet panel DB0113201-11 Frame DB0113201 Plate register reservoir DB9091900 Blind rivet nut DB0120020 Nut-lock CBE1120120-2A Lock washer CCE1120108-5A Repair Parts List - Figure 48 Item Description...

- Page 37 Repair Parts List - Figure 51 Item Description Qty. Part number Screw-SHCS, HEX, M6X12.00 CBA617028-1A Screw-HHCS, HEX, M12X1.75x30 CBB1225046-1B Lock washer CCE1100108-5A Assembly reservoir cover DB0112420-99 Fitting 1/4” BSP DB2099095 Plug 1/2”BSP DB2141006 Fitting 3/8” BSP 10S without nut DB2213095 Hexagonal head plug 3/4”BSP DB2227091 Elbow...

-

Page 38: Evop180150

12.3 EVOP180150 NOTES Torque to 46 Nm Torque to 135 Nm Torque to 25 Nm Figure 52: EVOP180150 Frame NOTES Torque to 38 Nm Torque to 46 Nm Torque to 25 Nm Torque to 80 Nm Torque to 135 Nm Figure 53: EVOP180150 Reservoir Doc L4540_a... - Page 39 NOTES Torque to 9.5 Nm Figure 54: EVOP180150 Powerpack components Figure 55: EVOP140150 Upper view Doc L4540_a...

- Page 40 NOTES Torque to 35 Nm Torque to 210 Nm Torque to 90 Nm Torque to 13 Nm Torque to 55 Nm Torque to 9.5 Nm Torque to 70 Nm Torque to 100 Nm Torque to 320 Nm Torque to 10-16Nm Torque to 80 Nm Torque to 46 Nm Torque to 120 Nm...

- Page 41 12.3.1 EVOP180150 Table of Parts Repair Parts List - Figure 52 Item Description Qty. Part number Eyebolt 24D0209 Washer-flat CAE1080108-1A Screw-SHCS CBA825028-1A Cabinet panel DB0113201-11 Frame DB0113201 Plate register reservoir DB9091900 Blind rivet nut DB0120020 Nut-lock CBE1120120-2A Lock washer CCE1120108-5A Repair Parts List - Figure 53 Item Description...

- Page 42 Repair Parts List - Figure 56 Item Description Qty. Part number Screw-SHCS, HEX, M6X12 CBA617028-1A CBB1625046-1B.prt CBB1625046-1B Lock washer CCE1100108-5A Lock washer CCE1160108-5A Assembly reservoir cover DB0115420-99 Fitting 1/4” BSP DB2099095 Plug 1/2”BSP DB2141006 Hexagonal head plug 3/4”BSP DB2227091 Elbow DB2315095 Elbow swivel DB2315095-1...

-

Page 43: Distribution Manifold Evop

12.4 Distribution Manifold EVOP Figure 57: Distribution manifold Doc L4540_a... - Page 44 12.4.1 Distribution Manifold Table of Parts Repair Parts List - Figure 57 Item Description Qty. Part number Manifold DB5150840 Pressure switch DG365 Relief valve MVP4A Check valve Distribution valve 4/3 24V DB1132660 Relief valve MVP4AR Compensated flow control valve DB1105662 Valve 2/2 NC GR2-22 X24 Modular relief valve...

- Page 45 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 46 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 47 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 48 NOTES ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________...

- Page 49 © 2020 Enerpac Tool Group, All Rights Reserved.

Need help?

Do you have a question about the EVOP12140 and is the answer not in the manual?

Questions and answers