Summary of Contents for Envent 330S

- Page 1 Total Sulfur Option User’s Manual (Addendum to Model 330S & 331S H2S Analyzers User’s Manual) Last Updated: October 14, 2022 Revision: 2.0...

-

Page 3: Table Of Contents

331S/330S TS Only _________________________________________________________________________ 8 330S/331S H2S & TS with Mode Switching _______________________________________________________ 8 4.2.1 330S/331S H2S & TS with Mode Switching and Hydrogen Saver ___________________________________ 9 330SDS/331SDS H2S & TS with Hydrogen Saver __________________________________________________ 9 APPENDIX A – Drawings and Diagrams ________________________________________________________10 330S with Mode Switching Outline &... - Page 4 Table of Figures Figure 1. Total Sulfur Oven Cutaway ____________________________________________________________ 4 Figure 2. High Temperature O-Rings and Ultra Tor Elbow/Fittings ____________________________________ 7...

-

Page 5: Introduction

INTRODUCTION About this Manual The Total Sulfur Operator’s Manual should be used in addition to the Model 330S & 331S Hydrogen Sulfide Analyzer Operator’s Manual. This manual contains a comprehensive overview of Envent Engineering’s total sulfur addition to their hydrogen sulfide (H2S) analyzers as well as descriptive installation and startup instructions. -

Page 6: Warnings And Cautions

Total Sulfur Option User Manual – Revision 1.0 Warnings and Cautions CAUTION: Hydrogen is extremely flammable. Use Caution when handling. CAUTION: Quartz reaction tube is fragile and is removed during shipping, handle with care. CAUTION: Do not apply power or hydrogen to the total sulfur furnace until the reaction tube is installed and leak tested. -

Page 7: Total Sulfur Option Overview

H2S. The total sulfur option involves the addition of a total sulfur reaction furnace (pyrolysis furnace) to a Model 330S or 331s. The furnace converts all sulfur compounds into H2S, allowing the H2S analyzer to read total sulfur as per the ASTM D 4468-85 “Standard Test Method for Total Sulfur in Gaseous Fuels by Hydrogenolysis and Rateometric... -

Page 8: Hydrogen

Total Sulfur Option User Manual – Revision 1.0 Figure 1. Total Sulfur Oven Cutaway WARNING: Quartz reaction tube located in total sulfur furnace ii) Dual Seal maximum working pressure is 2 PSI iii) Leaks are indicated by monitoring the ball in the H2/Sample Flow meter during a pressure test. - Page 9 (9.25” x 60”) without any leaks or calibration runs. Our calculations based on a 200 /min (flow of 2 on a A-157-1 flow meter). Each analysis will run 3 times. Envent suggests that the bottle should be checked at least 10 days prior to estimated end of life.

-

Page 10: Installation And Start-Up

Total Sulfur Option User Manual – Revision 1.0 INSTALLATION AND START-UP Note 1: The furnace power should be disabled by removing fuse on the main board. Note 2: The power should be left off until the leak testing is complete. CAUTION: Quartz reaction tube is fragile and is removed during shipping, handle with care when installing. -

Page 11: Connecting Vacuum Fitting To Quartz Tube

Total Sulfur Option User Manual – Revision 1.0 Figure 2. High Temperature O-Rings and Ultra Tor Elbow/Fittings 3.1.1 Connecting Vacuum Fitting to Quartz Tube • With quartz tube inside ceramic furnace, slide Ultra Torr nut, ferrule, and Kalrez O-ring over the end of quartz tube. (1, 2, 3) •... -

Page 12: Hydrogen Flow And Sample Flow

The Process Flow Diagrams in Appendix A, show the typical sample conditioning system used for the 330S & 331S Total Sulfur Analyzers. The total sulfur reaction furnace and an extra flowmeter, used to control the flow of hydrogen, are added to the standard sample conditioning system for H2S Analyzers. -

Page 13: 330S/331S H2S & Ts With Mode Switching And Hydrogen Saver

Total Sulfur Option User Manual – Revision 1.0 4.2.1 330S/331S H2S & TS with Mode Switching and Hydrogen Saver A second solenoid may be added to shut off the hydrogen gas when in H2S mode. This configuration saves hydrogen usage by a large margin (see table 1). The analyzer is typically programmed to run every 6 hours or alternate between H2S mode and TS mode each analysis;... -

Page 14: Appendix A - Drawings And Diagrams

Total Sulfur Option User Manual – Revision 1.0 APPENDIX A – DRAWINGS AND DIAGRAMS 330S with Mode Switching Outline & Dimensional pg. 11 330SDS with H2 Saver and H2 Pressure Switch Outline & Dimensional pg. 12 331S Total Sulfur Outline and Dimensional pg.13... -

Page 15: 330S With Mode Switching Outline & Dimensional

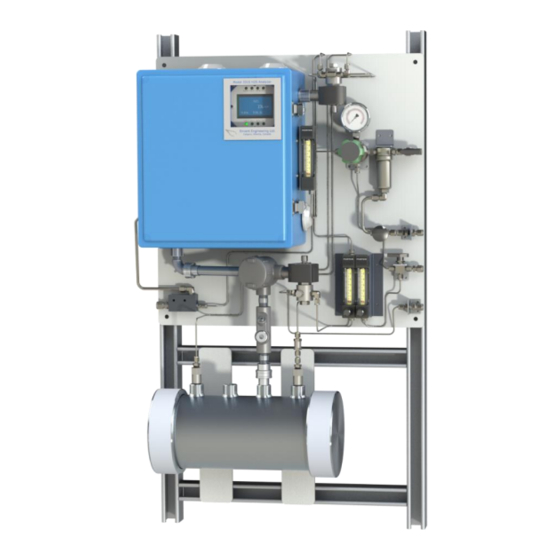

Total Sulfur Option User Manual – Revision 1.0 330S with Mode Switching Outline & Dimensional... -

Page 16: 330Sds With H2 Saver And H2 Pressure Switch Outline & Dimensional

Total Sulfur Option User Manual – Revision 1.0 330SDS with H2 Saver and H2 Pressure Switch Outline & Dimensional... -

Page 17: 331S Total Sulfur Outline And Dimensional

Total Sulfur Option User Manual – Revision 1.0 331S Total Sulfur Outline and Dimensional... -

Page 18: Total Sulfur Oven Break Down

Total Sulfur Option User Manual – Revision 1.0 Total Sulfur Oven Break Down... -

Page 19: H2S Total Sulfur With Ethernet Card, Pressure Switch And Powered A/O Electrical & Connection

Total Sulfur Option User Manual – Revision 1.0 H2S Total Sulfur with Ethernet Card, Pressure Switch and Powered A/O Electrical & Connection... -

Page 20: 330Sds With H2 Saver And H2 Pressure Switch Process Flow Diagram

Total Sulfur Option User Manual – Revision 1.0 330SDS with H2 Saver and H2 Pressure Switch Process Flow Diagram 331S Total Sulfur Process Flow Diagram... -

Page 21: Appendix B - Recommended Spare Parts List

Total Sulfur Option User Manual – Revision 1.0 APPENDIX B - Recommended Spare Parts List Part Number Quantity Description 1000123 Ultra Torr Elbow 2000052 Kalrez O-Ring 1000065 ¼” Elbow 1100107 Flex Tube 1100115 Total Sulfur Temperature Switch 1000051 1/8” 1/3PSIG Check Valve 1300281 Group BCD Flame Arrestor 2000050... -

Page 22: Appendix C - Faq & Troubleshooting

The analyzer can be calibrated using strictly H2S calibration gas, however, the operation of the oven cannot be verified. Does Envent sell calibration Total Sulfur gas? Contact Envent How long does a hydrogen bottle last? Check table in section 2.3... -

Page 24: Contact Us

Tel: 1 (713) 567 – 4421 13219 B Stafford Road Missouri City, Texas, USA 77489 China Tel: 86 (138) 0119 – 1148 Room 305, Bld. No.9, Greenland Qihangguoji Email: julie.lu@enventengineering.com Shunyi District, Beijing, China International Sales Tel: (403) 253-4012 Email: international@envent-eng.com...

Need help?

Do you have a question about the 330S and is the answer not in the manual?

Questions and answers