Summary of Contents for Reyco Granning 23AR

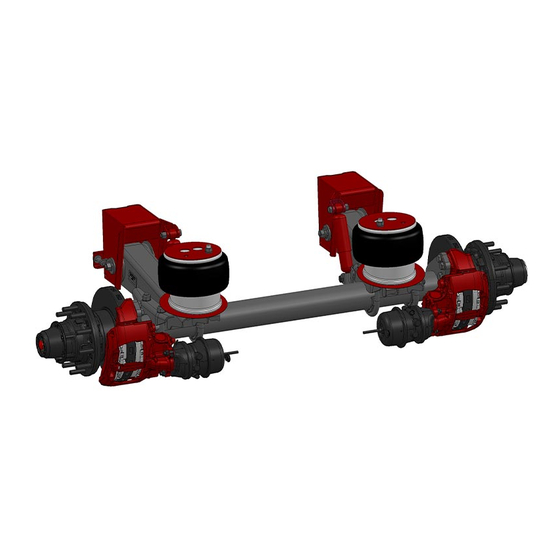

- Page 1 MODELS 23AR, 25AR, 30AR TRAILER AIR-RIDE SUSPENSION SYSTEMS IMPORTANT This booklet MUST ACCOMPANY the trailer when delivered to the end user. MAINTENANCE INSTRUCTIONS...

-

Page 2: Table Of Contents

MODELS 23AR, 25AR, 30AR TRAILER AIR-RIDE SUSPENSION SYSTEMS MAINTENANCE INSTRUCTIONS SAFETY PROCEDURES / INFORMATION Welding, Welding Specs ..................2 Lifting, Overloading, Torque, Air Supply, Air Springs ........... 3 MAINTENANCE INFORMATION U-Bolts........................4 Air Control......................5 Alignment......................6 Rey-Align Details....................7 Trouble Shooting Guide................... -

Page 3: Safety Procedures / Information

SAFETY PROCEDURES SAFETY IS FIRST Be sure to read and follow all installation and maintenance procedures. WARNING If these procedures and specifications are not followed damage to the suspension or axle could occur. Failure to follow these procedures helmet could result in accident with consequent injury. WELDING When welding, be sure to wear all personal protective equipment for face and eyes, and have... -

Page 4: Lifting, Overloading, Torque, Air Supply, Air Springs

PERSONAL LIFTING Practice safe lifting procedures. Consider size, shape, and weight of assemblies. Obtain help or the assistance of a crane when lifting heavy assemblies. Make sure the path of travel is clear. OVERLOADING Overloading of the suspension system or its components is the practice of transporting car- gos that surpass the specified vehicle’s ratings. -

Page 5: U-Bolts

U-BOLT INSTALLATION U-BOLT 1. U-BOLT installation and torquing should be Torquing Sequence done only after completion of axle weld. Be sure to provide sufficient cooling time before applying torque wrench. FIRST ..205 NM (150 ft lbs) 1*2*3*4 (shown below) SECOND ..410 NM (300 ft lbs) 4*3*2*1 THIRD..650 NM (480 ft lbs) 4*3*2*1... -

Page 6: Air Control

AIR CONTROL HEIGHT CONTROL VALVE Height Control Valves regulate the mounting height (ride height) of the suspension. Ride Height (Inches) 1. One height control valve (HCV) is used, regardless of the number of axles. The air springs on each side of the trailer are connected by 9.5 mm (3/8”) minimum diameter tubing (customer supplied). -

Page 7: Alignment

ALIGNMENT Alignment Procedure ALIGNMENT 1. Release the brake system and pull the trailer forwards and backwards several times in a straight line to free the suspen- sion from binding and tension. NOTE: This procedure must be performed on a smooth level surface. 2. -

Page 8: Rey-Align

REY-ALIGN DETAILS Care must be taken to ensure that the Rey-Align option is installed correctly. Adjustment Shaft (#5) Optional NOTE: IMPORTANT! When installing the Weld Location disc spring washers, the “CONCAVE” side MUST FACE the surface of the hanger, and the “CONVEX” side MUST FACE the nut. -

Page 9: Trouble Shooting Guide

TROUBLE SHOOTING GUIDE ROUGH RIDE Check the suspension ride height. Be sure the suspension is operating at the proper height. If too high, over inflation of the bags will be evident. Ensure the opposite is not occurring (no air in air springs) and correct as required. Normal Operation Air Bag Over-Inflated Air Bag LOOSE PIVOT CONNECTION... - Page 10 TROUBLE SHOOTING GUIDE Typical Plumbing Diagram Air Suspension with Trailer Air Supply Height Control Valve 1. Bags won’t inflate (A) Check air supply at the height control valve. If supply is good, (B) check to see if air is going thru the valve Filter when it is actuated.

- Page 11 TROUBLE SHOOTING GUIDE DUMP VALVE PROBLEMS BUSHING WALK CAUTION: Due to the geometry of all trailing This is indicated by the trailing beams shifting beam air ride suspensions, the trailer will move off of the bushings. forward when the air is exhausted. Check alignment.

-

Page 12: Maintenance Instructions, Torque Requirements

MAINTENANCE INSTRUCTIONS Model 23AR/25AR/30AR Suspensions, by design, require a minimum of maintenance. All suspension systems require periodic checks to assure continued, trouble-free performance. REYCO RECOMMENDED MAINTENANCE SCHEDULES 1. Pre-service inspection. 2. First service inspection, after 1600-4,800 km, (1,000-3,000 miles). 3. PM inspections, concurrently with required annual inspection. -

Page 13: Common Parts

COMMON PARTS MODEL BUSHING REY-ALIGN DISC SPRING REY-ALIGN SHOCK SHOCK U-BOLT U-BOLT U-BOLT WASHER BOLT BOLT SPACER 23AR 23421-01 24403-01 23952-01 23948-01 24539-01 11010-01 23423-01 23939-01 20688-02 25AR 23421-01 24403-01 23952-01 23948-01 24539-01 11010-01 23423-01 23939-01 20688-02 30AR 23421-01 24403-01... - Page 14 25ARU RIDE LEFT BEAM HUCKBOLT ® REY-ALIGN UPPER SHOCK HEIGHT RIGHT SPRING HANGER HANGER SHOCK ASSEMBLY 165 mm (6.5”) LEFT 23764-01 12882-01 23960-11 24001-11 23926-01 23553-01 RIGHT 23764-02 12882-01 23960-11 24001-12 23926-01 23553-01 191 mm (7.5”) LEFT 23764-01 23521-01 23960-213 24001-213 23639-01 23553-01...

-

Page 15: Installation Supplement

INSTALLATION SUPPLEMENT INSTALLATION SUPPLEMENT #IS-CA121599 (rev b) REF: 23/25/30 AR DATE: December 15, 1999 SUBJECT: SUSPENSIONS Rey Align™ Pivot Shaft Sleeve Part Number 23674-01 EFFECTIVE: Immediately Tuthill Transport Technologies is continuing to improve their products. Through continued testing of compo- nents to improve their effectiveness and integrity, Tuthill Transport Technologies recommends the following pro- cedure be followed before assembly and final torque of all Rey Align™... -

Page 16: Warranty

LIMITED WARRANTY REYCO-GRANNING 23AR/25AR/30AR SERIES AIR SUSPENSION SYSTEMS AND COMPONENTS Tuthill Transport Technologies (The Company) warrants suspension products manufactured by it to be free from defect in material and workmanship which occur under normal use and service subject to the following conditions and limita- tions: 1. - Page 17 7. Retention of possession or use of the product for the warranty period shall constitute an unconditional acceptance thereof and fulfillment of all warranties and obligations of The Company and no assistance rendered by The Company in operating the product or remedying any defect either before or after that time shall operate to extend the warranty period.

- Page 18 905.945.5906 1.800.811.4011 Fax: CANADA Tel: 417.837.0404 1.800.753.0050 Fax: Tel: 417.837.0485 417.837.0423 Fax: INTERNATIONAL Tel: Form# MM-23-25-30AR Rev. 020200...

Need help?

Do you have a question about the 23AR and is the answer not in the manual?

Questions and answers