Table of Contents

Advertisement

Quick Links

LED Newel Cap Installation Instructions

Before Getting Started

Installation may vary based on the circumstances at the installation site. Retrofitting an existing deck or patio will

require a different method than installing lighted caps in an area where posts and railing have yet to be installed. Please

contact your local Sales representative or reach out to INTEX Millwork Solutions for assistance in planning your

installation. It is generally recommended to estimate about 10-20' of wiring per cap required depending on the

installation scenario. It is also recommended to purchase a few extra gel connectors (INTEX Part # LED-SPLICE) for field

adjustments and corrections during installation.

Warranty Disclosure

INTEX Millwork Lighted Cap Warranty will not be honored if 3

rd

party parts and accessories are substituted during

installation. INTEX Millwork supplied Lighted Caps, wires, connectors, and transformers must be installed in accordance

with INTEX Millwork Lighted Cap Installation Instructions in order maintain warranty coverage. Using any accessories or

electrical equipment not specified by INTEX Millwork in this instruction will void all warranties associated with the

product. Please see full warranty information at

www.intexmillwork.com

1. Planning your Installation

Determine the number of lights required and plan your layout. The 150W Transformer supports up to 40 lights in total,

but it is recommended that these are split over several output terminals. For best results, limit installation to no more

than 12 caps per output terminal, and evenly distribute the number of caps per output terminal. See Figure 1 at the end

of this instruction for reference.

Plan the location of the transformer. Bear in mind that if a Timer/Photocell combo is being used, the power supply will

need to be located in a position where there is sufficient ambient light to trigger the sensor (i.e. not under a deck or

inside an enclosure.)

Determine the method required to run the wiring from post to post. It is generally advised to run wiring underneath the

deck or structure and up through the newel posts to make a connection. If posts are already installed or there is no

access underneath the structure, wiring can be run through top railing sections. This will require drilling holes in the

newel posts faces to run the wiring, which will then be covered once the top rail is installed. Refer to the images below

for hole locations and sizes if running cabling through INTEX railing.

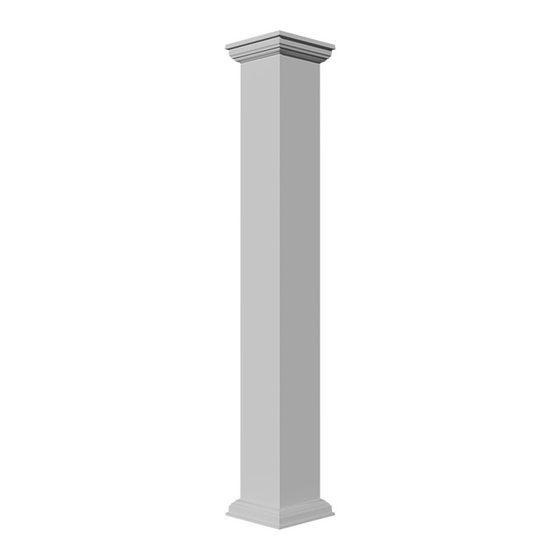

RS35 Dartmouth

RS40 Hampton

RS60 Liberty

Drill 5/16" hole in newel and pass

Drill two 3/16" holes

Drill 5/16" hole in newel just above bracket, centered

wire through notch at bracket.

to split wire and pass

or offset depending on which rail cap is being used.

leads over bracket.

Requires making small

notches in the rail cap

for clearance.

LEDINST | REV B

Advertisement

Table of Contents

Summary of Contents for Intex Newel

- Page 1 This will require drilling holes in the newel posts faces to run the wiring, which will then be covered once the top rail is installed. Refer to the images below for hole locations and sizes if running cabling through INTEX railing.

- Page 2 Using a pair of wiring strippers, strip the source leads about ½” back before inserting them into the terminals and snapping them in place. Note: INTEX Millwork Solutions recommends using the 15V terminals only on the power supply. If you are unable to evenly balance the number of lights per terminal, you may wish to connect the smaller run of lights to the 12V terminal to more evenly balance the brightness.

- Page 3 Figure 1 – Planned Layout Figure 2 – Wire Under Deck Example LEDINST | REV B...

- Page 4 Typical Lighted Cap Material Take-Off for Deck Example Above Suggested Item with INTEX SKU Description Quantity 150W unit can support 40 total Lighted Caps across 4 separate Transformer (LEDPOWER-150) circuits Timer & PhotoCell (LEDPOWER-TP) This item is optional but recommended Also available in Pyramid;...

- Page 5 LEDINST | REV B...

Need help?

Do you have a question about the Newel and is the answer not in the manual?

Questions and answers