Subscribe to Our Youtube Channel

Summary of Contents for StoneAge AUTOBOX ABX-3L-V3

- Page 1 AUTOBOX TRACTOR (ABX-3L-V3) ® LIGHTWEIGHT POSITIONER (LWPS-100-NS) & CONTROL BOX (CBX-ABX-PL) USER MANUAL PL 702 REV D (04/2022)

-

Page 2: Table Of Contents

TABLE OF CONTENTS MANUFACTURER’S INFORMATION ..............SPECIFICATIONS . -

Page 3: Manufacturer's Information

Drive belt has durable polyurethane cover to ensure traction in all • exchanger tube cleaning applications. It is recommended operation conditions it be used with the StoneAge® Banshee line of self-rotary Can run any hose size from 3/2 to 8/4 without any component changes. • waterblast tools. -

Page 4: Ec And Ukca Declarations Of Conformity

The Technical File for AutoBox® Hose Tractor (ABX-3L-V3) and Control Box (CBX-ABX-PL) is maintained at: StoneAge Incorporated, 466 South Skylane Drive, Durango, CO 81303, USA and was compiled by the Engineering Manager. The Technical File is available through the Authorized Representative. - Page 5 The Technical File for AutoBox® Hose Tractor (ABX-3L-V3) and Control Box (CBX-ABX-PL) is maintained at: StoneAge Incorporated, 466 South Skylane Drive, Durango, CO 81303, USA and was compiled by the Engineering Manager. The Technical File is available through the Authorized Representative.

-

Page 6: Warning And Safety Instructions

Aerosols • StoneAge WILL NOT accept responsibility for the results of misuse. Biological and microbiological (viral or bacterial) agents • IT IS THE RESPONSIBILITY OF THE INSTALLER/OPERATOR Combustible materials •... -

Page 7: Pre-Run Safety Check

The back-out prevention device is the Hose Stop Collet Ensure the doors of the AUTOBOX® (ABX-3L-V3) Hose Tractor • located within the Hose Guide Assembly. StoneAge offers sev- are closed and securely latched. eral different size Hose Stop Collets. The Collet Size Reference... -

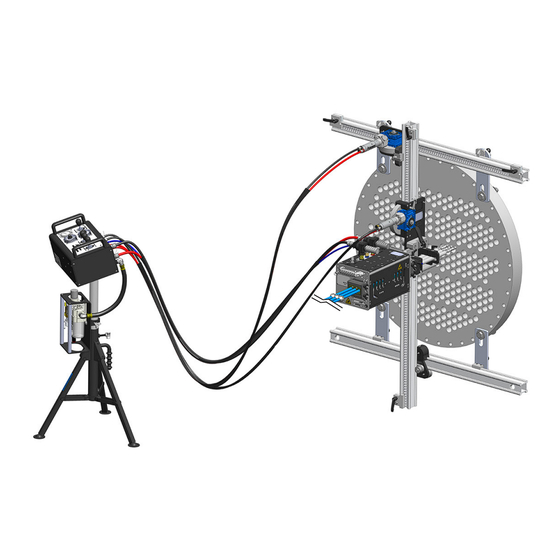

Page 8: System Assembly - Overview

SYSTEM ASSEMBLY - OVERVIEW AUTOBOX® (ABX-3L-V3) HOSE TRACTOR, LIGHTWEIGHT POSITIONER, GUIDE ASSEMBLY, AND CONTROL BOX (CBX-ABX-PL) SYSTEM ASSEMBLY LIGHTWEIGHT POSITIONER (LWPS-100-NS) AUTOBOX ® HOSE TRACTOR (ABX-3L-V3) CONTROL BOX (CBX-ABX-PL) GUIDE ASSEMBLY (ABX-301) HIGH PRESSURE WATER HOSES NOT INCLUDED HOSE STOPS (HS-121.1-XX) NOTICE Heat exchanger tube bundle face, shown for graphic... -

Page 9: Lightweight Positioner - Overview

LIGHTWEIGHT POSITIONER - OVERVIEW LIGHTWEIGHT POSITIONER AND ACCESSORIES RAIL STOP ASSEMBLIES HORIZONTAL DRIVE ASSEMBLY RAIL EXTENSIONS (2,4, OR 6 FT LENGTHS) (.61 , 1.2 , OR 1.8 VERTICAL SLOTTED RAIL POSITIONER CONTROL LINES HORIZONTAL SLOTTED RAIL CLAMP TYPES (LWP 625 KIT IN- CLUDES ALL KITS 25 FT / 7620 SHOWN HERE) -

Page 10: Lightweight Positioner Clamp Selection

LIGHTWEIGHT POSITIONER CLAMP STYLES CLAMP SELECTION is dependent upon the heat exchanger geometry, bolt holes, hole spacing, and flange accessibility. QUICK CLAMPS (LWP 518) are for use with heat exchanger flanges that provide a robust clamping surface or if flange holes are inac- cessible. -

Page 11: Lightweight Positioner Set-Up

LIGHTWEIGHT POSITIONER SET-UP LIGHTWEIGHT POSITIONER STEP BY STEP SET-UP Mount the appropriate frame Positioner Clamps to the tube bundle as shown in Figure 1. (Shown with Plate Clamps) Po- sitioner Clamps should be Parallel to the direction of the tube rows. -

Page 12: Shotgun Mount

LIGHTWEIGHT POSITIONER SET-UP Replace the Quick Release Pin into the locked position. (Figures 4 & 5) Angle the Idler Carriage as shown to allow the Idler Carriage to engage with the lower rail properly. Rotate it back to the vertical position and slide it towards the lower Rail Clamp. - Page 13 OPTIONAL SHOTGUN MOUNT INSTALLATION INSTALL SHOTGUN MOUNT (FOR USE WITH BARRACUDA OR SPITFIRE TOOL) 1. Set the desired Clamp Angle. The Clamp Assembly on the Shotgun Mount can • be rotated 30° Up or Down by removing the two SHCS Screws with a 5/16” Allen Key, rotating the Clamp into the desired position, and fastening the Screws in the desired location.

-

Page 14: Guide Assembly - Overview

AVAILABLE) PITCH ADJUST LEVERS MOUNTING BRACKET TUBE CLAMP HOSE STOP CLAMPS (MULTIPLE SIZES AVAILABLE) QUICK RELEASE PIN StoneAge (SA) PART NUMBER COLLET AND HOSE STOP REFERENCE CHART COLLET PART HOSE STOP HOSE O.D. SPIR STAR PARKER COLLET SIZE NUMBER HOSE STOP SIZE... -

Page 15: Guide Assembly Set-Up

HOSE GUIDE ASSEMBLY SET-UP HOSE GUIDE ASSEMBLY Select the appropriate Guide Tube size for the application from the chart at the bottom of the previous page. • The length of the Guide Tubes for an exchanger bundle with no channel head is 12.5 in. (318 mm). •... -

Page 16: Guide Assembly To Lightweight Positioner Set Up

HOSE GUIDE ASSEMBLY TO LIGHTWEIGHT POSITIONER SET UP ATTACH GUIDE ASSEMBLY TO LIGHTWEIGHT POSITIONER Pull Quick Release Handle open and slide the Guide Tube Assembly onto the Vertical Carriage. Adjust position until the Guide Tubes are approximately 1/2 in. (13 mm) away from the face of the heat exchanger. Lock the Quick Release Handle in place when the mount is in position. -

Page 17: Autobox ® (Abx-3L-V3) Hose Tractor - Overview

ABXS-3L HOSE TRACTOR - OVERVIEW AUTOBOX ® HOSE TRACTOR (ABX-3L-V3) COLOR CODED PUSH CONNECT FITTINGS WITH DUST CAPS QUICK EXHAUST WITH SILENCER FORWARD SPEED REVERSE SPEED CONTROL CONTROL COLLET REFERENCE CHART HANDLE DOOR PIN MOUNTING BRACKET QUICK RELEASE PINS *DRIVE BELT DOOR ASSEMBLY MOUNTING BRACKET... -

Page 18: Autobox ® (Abx-3L-V3) Hose Tractor To Guide Assembly

ABXS-3L HOSE TRACTOR TO GUIDE ASSEMBLY ATTACH AUTOBOX (ABX-3L-V3) HOSE TRACTOR TO GUIDE ASSEMBLY ® Remove the lower quick release pin from the AUTOBOX (ABX-3L-V3) Hose Tractor. ® Slide the mounting bracket over the block on the Guide Assembly and lay the pin onto the top slot on the Guide Assembly block. Install the lower pin through the mounting bracket on the Hose Tractor and the block on the Guide Assembly. -

Page 19: Control Box - Overview

CONTROL BOX - OVERVIEW CONTROL BOX TOP VIEW HOSE FEED FORCE MOMENTARY PNEUMATIC DUMP CONTROL HOSE FEED LEVER HOSE CLAMP POSITIONER HOSE CLAMP PRESSURE CONTROLS PRESSURE GAUGE REGULATOR CONTROL BOX CONTROL BOX BACK VIEW FRONT VIEW DUMP CONTROL CONTROL FITTING PANEL BOX VERTICAL POSITIONER FITTINGS... -

Page 20: Control Box Set-Up

CONTROL BOX SET-UP ASSEMBLE CONTROL BOX, FRL, AND TRIPOD BASE Setup the tripod base in a location with good visibility to the bundle face, but at a safe distance away from high pressure nozzles. Slide the vertical tube into the tripod base. Secure with the supplied thumbscrew knob. Slide the Filter, Regulator, Lubricator (FRL) assembly over the vertical tube down to the tripod base. -

Page 21: Control Box Air Supply Fitting

CONTROL BOX AIR SUPPLY FITTING AIR SUPPLY AND LUBRICATOR SETTING The Control Box is supplied with a twist claw style inlet coupling (Chicago style) located on the side of the FRL Assembly. Connect a com- patible compressed air line (not included) according to the Manufacturer’s instructions. Using the regulator adjust the operating air pressure to 100 psi (6,8 bar) for the application. -

Page 22: Control Box To Autobox ® (Abx-3L-V3) Hose Tractor

CONTROL BOX TO ABX-3L-V3 TRACTOR PNEUMATIC SUPPLY LINE CONNECTIONS Connect hoses to the Hose Tractor Remove the dust caps from the Joint Industry Council (JIC) fit- Two 8 mm diameter tubing (FWD-BLACK & REV-RED) • tings of the Control Box and the AUTOBOX (ABX-3L-V3) Hose ®... -

Page 23: Operation

OPERATION - DOORS AND PINS DOOR Always run the AUTOBOX (ABX-3L-V3) Hose Tractor with the doors closed and locked. ® DOOR PIN The Door Pin is a spring plunger with a pull ring. To unlock the door, pull and twist the pull ring. -

Page 24: Collet Insertion, Hose, And Hose Stop Installation

OPERATION COLLET INSERTION, HOSE, AND HOSE STOP INSTALLATION COLLET Remove Quick Release Pin and pull out existing Collet. Select the appropriate Collet size for the diameter of the hoses. (See the “Recommended Collets For Common Hose Sizes” plaque on the top plate of the AUTOBOX (ABX-3L-V3) Hose Tractor.) (Figure 1) ®... -

Page 25: Control Box And High Pressure Hose

OPERATION CONTROL BOX The HOSE FEED LEVER will move the hose in the forward (feeding) and reverse (retracting) directions. The OFF position is at the spring • centered middle position and will stop the Drive Belt from turning. The speed controls are located on the AUTOBOX (ABX-3L-V3) Hose Tractor. -

Page 26: Test Run, And Run Procedures And Hose Clamp

OPERATION TEST RUN PROCEDURE Perform the PRE-RUN SAFETY CHECK (SEE PAGE 7). • Ensure appropriate Collet is installed and set initial hose clamp pressure to 20 - 30psi (1.4 - 2.0 bar) • Operate the high-pressure hose and waterjet tool at full pressure to test the clamp force. Optimal clamp force will provide good control of the •... -

Page 27: Maintenance And Storage, Transportation, And Handling

A heavy film indicates over-lubrication and the drip rate should be reduced by turning knob to a lower setting. Contact StoneAge for Safety Data Sheets for material usage, a complete list of spare part numbers, and service instructions for the AUTO- (ABXS-3L) Hose Tractor and Controller. -

Page 28: Abx-3L-V3 Belt Replacement Instructions

ABX-3L-V3 HOSE TRACTOR - DRIVE BELT REPLACEMENT WARNING Always de-energize the system before servicing or replacing any parts. Failure to do so can result in severe injury and/or death. Keep hands, hair, and clothing clear of rotating parts. If the performance of the belt is not functioning well for the conditions, try replacing it with an alternate durometer belt. TECH TIP: BELTS INCLUDED: BELT OPTIONAL:... -

Page 29: Parts Diagrams

PART DIAGRAM AUTOBOX (ABX-3L-V2) HOSE TRACTOR BELTS INCLUDED: BELT OPTIONAL: ABX 305-50 Green ABX 305-70 Green (50 durometer – softest – better grip , (70 durometer – medium) NOTE: but fastest wear) 1. APPLY BLUE LOCTITE 242 TO ALL THREADED HARDWARE. ®... - Page 30 PART DIAGRAM AUTOBOX (ABX-3L-V3) HOSE TRACTOR MANIFOLD ASSEMBLY PART NUMBER QTY. ABX 346 PLATE, FLOW CONTROL ABX 382 QUICK EXHAUST VALVE, P6 ABX 383 SILENCER, P6 ABX 392 FTG, MANIFOLD 90 P6M 2XPL5 ABX 394 FTG, INLINE FILTER P6M P6M ABX 397 FTG, ADAPTER P6M PL6 ABX 399 FTG, MANIFOLD 90 P4M 3XPL4 ABXS 270 FTG, ADAPTER P6M PL10 EISELE...

- Page 31 PART DIAGRAM AUTOBOX (ABX-3L-V3) HOSE TRACTOR INSIDE AND OUTSIDE PLATE ASSEMBLIES PART NUMBER QTY. ABX 375 BUSHING, PEEK .375 ID X .375 LG ABX 139 COLLET REFERENCE PLATE ABX 566-001 SPRING PLUNGER ASSY ABX 215 PULL HANDLE GREY ABXS 357 MOUNTING BRACKET, INLET ABX 303-002 CE SERIAL PLATE GN 337-HJ NUT, HEX JAM .37-16 SS ABX 342 SIDE PLATE OUTLET...

- Page 32 PART DIAGRAM AUTOBOX (ABX 310-001) BELT TRACK DRIVE ASSEMBLY NOTE: 1. APPLY BLUE LOCTITE ® 242 TO ALL THREADED HARDWARE. 2. BLUE GOOP IS A SWAGELOCK BRAND ANTI-SEIZE AN EQUIVALENT ALTERNATIVE ® IS ACCEPTABLE. PART NUMBER QTY. ABX 323 IDLER, TENSIONING ABX 228 BEARING .500 ID X 1.125 OD SEALED PERMALUBE ABX 324 ECCENTRIC SHAFT ABX 267 RETAINING RING, SL EXTERNAL SS...

- Page 33 PART DIAGRAM AUTOBOX (ABX 350) REAR MOUNT INSIDE ASSEMBLY PART NUMBER QTY. ABX 230 SPIRAL INTERNAL RETAINING RING, .625 BORE, SS ABX 294 ORING, SHOCK ABSORBING ABX 351 REAR MOUNTING BRACKET, INSIDE ABX 352 SPACER, O-RING ABX 354 HOSE GUIDE PLATE, OUTER GSF 319-025 FHCS .19-24 X .62 SS 866-795-1586 •...

- Page 34 PART DIAGRAM AUTOBOX (ABX 360-001) BELT TRACK DRIVE ASSEMBLY NOTE: 1. CENTER PIN WHEN INSTALLING SHAFT 2. APPLY BLUE LOCTITE 242 TO ALL THREADED HARDWARE. ® 2. APPLY TEFLON TAPE OR EQUIVALENT TO THREADS OF ALL PNEUMATIC FITTINGS. PART NUMBER QTY.

- Page 35 PART DIAGRAM AUTOBOX (ABX 370-001) DOOR ASSEMBLY PART NUMBER QTY. ABX 371-001 DOOR ABX 372 PIN PLATE, DOOR ABX 373 PIVOT PLATE, DOOR ABX 374 PLATE, WEDGE ABX 376 PLATE, BELT GUIDE GSB 319-02 BHCS 10-24 X .50 SS GSB 325-02 BHCS .25-20 X .50 SS GSF 319-0225 FHCS .19-24 X .56 SS PL 164 WARNING, DOOR OPEN CLAMP ENGAGED...

- Page 36 PART DIAGRAM AUTOBOX (ABX-301) GUIDE ASSEMBLY NOTE: ® 1. BLUE GOOP IS A SWAGELOK BRAND ANTI-SEIZE AN EQUIVA- LENT ALTERNATIVE IS ACCEPTABLE. ® 2. BLUE LOCTITE 242 OR EQUIVALENT. 3. COLLET AND GUIDE TUBE SIZES WILL NEED TO BE CHOSEN AND PURCHASED SEPARATELY BY THE CUSTOMER AT TIME OF ORDER.

- Page 37 PART DIAGRAM AUTOBOX ABX-3L-V2 HOSE GUIDE ASSEMBLY ACCESSORIES ® GUIDE TUBES, COLLETS, ANTI-TWIST CLAMPS AND HOSE STOPS StoneAge (SA) PART NUMBER GUIDE TUBE REFERENCE CHART ABX GUIDE TUBES ABX 11X-XX GUIDE TUBE BANSHEE INSIDE DIAMETER, LENGTH ABX 115-12 BN9.5 .459 in / 12 mm, 12.5 in. / 318 mm ABX 115-36 BN9.5...

- Page 38 PART DIAGRAM LIGHTWEIGHT POSITIONER ASSEMBLY (LWPS-100-X-NS) NOT INCLUDED IN PACKAGE, SEE LWPS-100-X MANUAL FOR MORE DETAILS DESCRIPTION BU 002-6-001 2.5 BOX RAIL EXTRUSION LWPS-100-NS LIGHTWEIGHT POSITIONER PARTS (SEE BELOW) PL 160 WARNING PINCH POINT 1.25 X 3.0 DECAL 866-795-1586 • WWW.STONEAGETOOLS.COM...

- Page 39 PART DIAGRAM AUTOBOX (CBX-ABX-PL) CONTROL BOX ASSEMBLY NOTES: 1. ALIGN FRL ASSY AND CONTROL BOX WITH DECAL ON FRONT LEG AS SHOWN. PART NUMBER QTY. CB 310 FRL ASSEMBLY CBL A025F-2PL10-1PL5 ABX CABLE ASSEMBLY, TRACTOR CBX 300-PL CONTROL BOX ASSEMBLY CBX 301 CB STAND ASSEMBLY 866-795-1586 •...

- Page 40 PART DIAGRAM AUTOBOX (CBX 300-PL) CONTROL BOX ASSEMBLY (CONTINUED ON NEXT PAGE) PART NUMBER QTY. CBX 321 CBX FRAME, ABX-3L CBX 322 SIDE PLATE CBX 323 CB BRACE REAR GPTB 0375-PUR95A-BL 3/8 OD URETHANE TUBING, BLUE GTB 319-02-32 BHTS, TORX 10-32 X .50 SS 866-795-1586 •...

- Page 41 TOP ASSEMBLY BOTTOM ASSEMBLY SIDE VIEW PART NUMBER QTY. CBX 326 212.53 2 120PSI 1/4 B FF STONEAGE BR 167 DUST CAP, J8 CBX 331 POLE MOUNT WELDMENT CB 314 3-LOBE KNOB CBX 335 REGULATOR ASSEMBLY (CLAMP PRESSURE) CB 327-001-PL COUPLER PLATE, REAR ASSEMBLY...

- Page 42 PART DIAGRAM AUTOBOX (CB 327-001-PL) COUPLER PLATE, REAR ASSEMBLY PART NUMBER GP 011-B ID WASHER, RUBBER, MED, BLUE ABX 397 FTG, ADAPTER P6M PL6 GP 011-BK ID WASHER, RUBBER, MED, BLACK ABXS 270 FTG, ADAPTER P6M PL10 EISELE GP 011-R ID WASHER, RUBBER, MED, RED ABXS 273 FTG, ADAPTER P4M PL5 EISELE GP 012-BK ID WASHER, RUBBER, LARGE, BLACK CB 327.1-001-PL COUPLER PLATE, REAR WELDMENT...

- Page 43 PART DIAGRAM AUTOBOX (CBX 301) CB STAND ASSEMBLY PART NUMBER QTY. CB 301.1 CUSTOM SUMNER STAND CB 303 MTG POLE CB 314 3-LOBE KNOB PL 163 DECAL, LEG TOWARD OPERATOR 866-795-1586 • WWW.STONEAGETOOLS.COM...

- Page 44 PART DIAGRAM AUTOBOX (CB 310) FRL ASSEMBLY SEE NEXT PAGE FOR CB 312-001 PARTS LIST NOTE: 1. CLEAN ALL DEBRIS & OILS BEFORE INSTALLING. INSTALL AT APPROXIMATE ORIENTATION AND LOCATION & AT ROOM TEMP. 2. APPLY BLUE LOCTITE (PN: 242 OR EQUIVALENT) TO ALL STRAIGHT THREADED FASTENERS. 3.

- Page 45 PART DIAGRAM AUTOBOX (CB 312-001) GEN 3 FILTER, REGULATOR, LUBRICATOR WITH Y400T-D CLAMP PART NUMBER QTY. CB 312.1.1 FILTER REGULATOR BOWL CB 312.1.3 FILTER BODY CB 312.1.6 REPLACEMENT SMC FILTER CB 312.1.7 SMC GAUGE WITH LENS CB 312.1.8 ORING FOR AW40-A REGULATOR CB 312.2.1 LUBRICATOR BODY CB 312.2.2 LUBRICATOR BOWL CB 312.3-001MODIFIED Y400T-D BRACKET ASSEMBLY, FRL...

-

Page 46: Terms And Conditions

STONEAGE TRADEMARK LIST UNDER NO CIRCUMSTANCES SHALL SELLER HAVE ANY LIABILITY WHATSO- View the list of StoneAge’s trademarks and service marks and learn how the EVER FOR LOSS OF USE OR FOR ANY DIRECT OR CONSEQUENTIAL DAMAG- trademarks should be used. Use of StoneAge trademarks may be prohibited, ES RESULTING FROM DELAY REGARDLESS OF THE REASON(S). -

Page 47: Warranty Information

(4) allows the Product to be operated under more severe conditions or beyond StoneAge or a waiver or modification to any of the provisions hereof or create any the rated capacity specified for the Product; or (5) otherwise negligently operates liability for StoneAge. - Page 48 1-866-795-1586 • www.STONEAGETOOLS.com © 2022 StoneAge, Inc. All Rights Reserved...

Need help?

Do you have a question about the AUTOBOX ABX-3L-V3 and is the answer not in the manual?

Questions and answers