Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

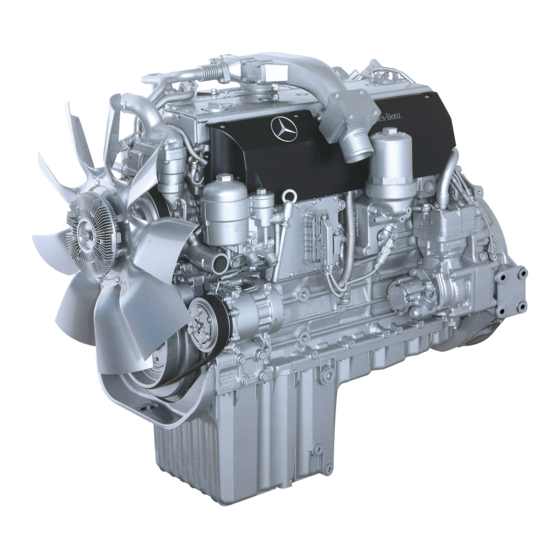

Summary of Contents for Detroit Diesel MBE 900

- Page 3 This manual is to be used in conjunction with the MBE Electronic Controls Troubleshooting Guide, 6SE422. ® ® ® Detroit Diesel , DDC , DDEC and the spinning arrows design are registered trademarks of ® Detroit Diesel Corporation. Diagnostic Link is a registered trademark of the Detroit Diesel Corporation.

-

Page 5: Table Of Contents

MBE 4000 ENGINES WITH EGR SYSTEMS ..............2.1.1 TURBOCHARGER AND EXHAUST MANIFOLD ............2.1.2 EXHAUST GAS RECIRCULATION SYSTEM ............. 2-10 MBE 900 ENGINES WITH EGR SYSTEMS ..............2-15 2.2.1 TURBOCHARGER AND EXHAUST MANIFOLD ............2-20 2.2.2 EXHAUST GAS RECIRCULATION SYSTEM ............ - Page 6 WARM ENGINE WITH NO LOAD ................7.1.3 MBE 4000 ENGINE AT VARIABLE SPEEDS AND LOADS ........7.1.4 MBE 900 ENGINE AT VARIABLE SPEEDS AND LOADS ......... PROBLEM ENGINE OPERATION SNAPSHOTS ............7.2.1 ENGINE WITH NO EGR TEMPERATURE READING ..........7.2.2 ENGINE WITH ABOVE NORMAL EGR TEMPERATURE READINGS ......

-

Page 7: Introduction

STOP, and contact the Detroit Diesel Customer Support Center at 313-592-5800. Once you have discussed your options with a technical support person, you can perform the required tests and evaluations. -

Page 8: Vehicle Inspection

Walk around the vehicle and look for obvious problems such as leaks (air or liquid). Check the fuel filters to ensure they are secure and tight. NOTE: The MBE 4000 has a water separator and a fuel filter. The MBE 900 has a prefilter and main filter. Check for a restricted air filter. -

Page 9: Operator Information

30 minutes? If the concern is repeatable, take the vehicle for a drive with the Detroit Diesel Diagnostic Link (DDDL) connected. Start the snapshot at the beginning of the road test, use the mark user event space to track problems, and end the snapshot at the conclusion of the road test. -

Page 10: Troubleshooting Tips

80 C (176 F). High fuel temp can also cause low power.) Is the exhaust flap fully open and are the exhaust system restrictions eliminated? All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 11: Fuel System

Are the correct fuel filter and water separator installed and clean? Is the Fuel System in proper working order? (Inspect the Fuel System. Refer to MBE 4000 Service Manual, 6SE412 and MBE 900 Service Manual, 6SE414.) Are the overflow valve and fuel pump operating properly? Is the vehicle using fuel with the required specific gravity? (API 34-38 is required for No. -

Page 12: Chassis Dynamometer Testing

Wheel horsepower with vehicle fan on (Wheel horsepower above 80 % of rated power at the wheels is acceptable. Refer to performance curve.) Intake Manifold Pressure (If reading is erratic, take a snapshot.) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 13: Exhaust Smoke

The MBE 4000 uses multiple air manifold gaskets to cover individual cylinder heads. The MBE 900 uses one gasket for every two adjacent cylinders on a single cylinder head. Are there air bubbles in the coolant? (Head gasket failure = vaporized water in exhaust) - Page 14 = incomplete/poor combustion) Has a fuel nozzle failed causing excess fuel delivery? (Excess fuel = incomplete combustion and raw fuel in exhaust) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 15: Coolant Loss

Does the engine miss, drop to idle, quit running, or exhibit hard starting? Is there any pattern related to trip miles or engine temperature? All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 16 INTRODUCTION PRELIMINARY THIS PAGE INTENTIONALLY LEFT BLANK 1-10 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 17: Components

Environmental Protection Agency (EPA) regulations. The key components of an MBE EGR system consists of: EGR Valves EGR Cooler Reed Valves EGR Mixer All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 18 EGR cooler, the EGR control valve, the reed valves (all except the MBE 906), and the EGR mixer in the intake manifold where they are mixed with the charge air. To view the arrangement of these components, see Figure 2-1 for the MBE 4000 engine and Figure 2-2 for the MBE 900 engine. Figure 2-1 Schematic of MBE 4000 EGR System All information subject to change without notice.

- Page 19 PRELIMINARY MBE EGR TECHNICIAN'S GUIDE Figure 2-2 Schematic of MBE 900 EGR System All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 20 The EGR systems for the MBE 900 and MBE 4000 engines are similar but differ in their specific components. The EGR components are listed in Table 2-1.

-

Page 21: Mbe 4000 Engines With Egr Systems

Unit (DDEC-ECU) utilizes algorithms and several sensor inputs for management of the fuel injection and EGR systems. See Figure 2-3 and Figure 2-4 for sensor locations. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 22 Combination Sensor the DDEC-ECU) 3. Camshaft Position Sensor 7. DDEC-ECU 4. Crankshaft Position Sensor Figure 2-3 MBE 4000 EGR Sensor Locations (Left Side) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 23 1. EGR Temperature Sensor 2. Engine Oil Pressure and Engine Oil Temperature Combination Sensor Figure 2-4 MBE 4000 EGR Sensor Locations (Right Side) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 24 The MBE 4000 engines for NAFTA On-Highway 2004 applications use a liquid-cooled EGR system. Exhaust from the front three cylinders is routed through the EGR system. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 25: Turbocharger And Exhaust Manifold

Cross Section of MBE 4000 Exhaust Manifold with EGR Due to the compressor characteristics, it is not possible to use EGR at low engine speeds. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 26: Exhaust Gas Recirculation System

EGR flow during steady state and transient modes. EGR control is optimized for maximum NOx control with consideration for particulate emission levels. 2-10 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 27 8. Reed Valves 4. EGR Cooler 9. EGR Cooler Coolant Return 10. Exhaust Manifold 5. EGR Mixer Figure 2-6 MBE 4000 EGR System Components 2-11 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 28 The EGR shutoff valve, located before the EGR cooler, closes the EGR system during the engine braking mode to prevent EGR cooler damage from high exhaust pressures. See Figure 2-7. Figure 2-7 MBE 4000 EGR Shutoff Valve 2-12 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 29 See Figure 2-9. Figure 2-8 Reed Valves Figure 2-9 MBE EGR System Operating Pressure Characteristics 2-13 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 30 The EGR control valve meters the exhaust flow into the EGR mixer. The DDEC-ECU controls the actuator position to determine the amount of valve opening. See Figure 2-10. Figure 2-10 MBE 4000 EGR Control Valve 2-14 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 31: Mbe 900 Engines With Egr Systems

MBE EGR TECHNICIAN'S GUIDE MBE 900 ENGINES WITH EGR SYSTEMS The MBE 900 is a four-stroke, high speed electronically-controlled diesel engine. Key emissions systems components include an EGR system that includes a gas-to-liquid cooler for hot EGR, a divided turbine housing turbocharger design, reed valves to prevent reverse gas flow, and a rotary valve that modulates EGR flow. - Page 32 2-16 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 33 PRELIMINARY MBE EGR TECHNICIAN'S GUIDE The MBE 900 engine utilizes electronically controlled fuel injection and cooled exhaust gas recirculation as the primary emission control technologies. The engine’s DDEC-ECU utilizes algorithms and several sensor inputs for management of the fuel injection and EGR systems.

- Page 34 1. Engine Oil Pressure Sensor 3. Engine Oil Temperature Sensor 2. EGR Temperature Sensor Figure 2-13 MBE 900 EGR Sensor Locations (Left Side) 2-18 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 35 The DDEC-ECU is one of two electronic controllers that make up the IES that is used in commercial vehicles with the MBE 900 engine. The separation of functions of each controller is such that the DDEC-VCU senses and controls the vehicle-influencing parameters such as cruise control, while the DDEC-ECU covers engine operating parameters as described above.

-

Page 36: Turbocharger And Exhaust Manifold

EGR flow into the intake manifold. See Figure 2-14. 1. EGR Outlet Figure 2-14 EGR Exhaust Manifold for MBE 906 and 926 Engines 2-20 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 37 EGR outlet is located on the end. See Figure 2-15. 1. EGR Outlet Figure 2-15 EGR Exhaust Manifold for MBE 904 and 924 Engines 2-21 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 38: Exhaust Gas Recirculation System

The MBE 900 EGR system utilizes a combination of two EGR valves to control the exhaust gas flow. The first valve is a rotary plate valve located in the end cover of the EGR cooler. This valve is electro-magnetically actuated to control EGR flow. - Page 39 Back flow could otherwise occur since the average intake manifold pressure is higher than the average exhaust manifold pressure. See Figure 2-18. Figure 2-17 Reed Valves 2-23 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 40 COMPONENTS PRELIMINARY Figure 2-18 MBE EGR System Operating Pressure Characteristics 2-24 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 41: Egr Operation

If coolant temperature, barometric pressure, engine speed, and percent torque are below certain limits, the EGR will be disabled. Excessively high charge air temperature will disable the EGR to prevent engine damage. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 42 If the EGR temperature sensor fails, the EGR is shut off. If the self-diagnostics indicate a malfunction of the EGR control valve, the EGR is shut off. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 43: Codes

“normal”. Example: For SID 146, DDEC Engine Control Unit (DDEC-ECU) uses the EGR temperature sensor to monitor EGR temperature. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 44: Code Descriptions

Accelerator Pedal — Voltage Above Normal or Shorted High — Accelerator Pedal — Voltage Below Normal or Shorted Low Table 4-1 SAE Codes and Descriptions (Sheet 1 of 6) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 45 Engine Coolant Temperature Sensor — Short to Ground — Engine Coolant Temperature — Very High Table 4-2 SAE Codes and Descriptions (Sheet 2 of 6) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 46 Injector Cylinder #3 — Shorted Circuit — Injector Cylinder #3 — No Plunger Table 4-3 SAE Codes and Descriptions (Sheet 3 of 6) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 47 Injector Cylinder #8 — Idle Smoothness Governor at Limit — Injector Cylinder #8 — Single Cylinder Correction at Limit Table 4-4 SAE Codes and Descriptions (Sheet 4 of 6) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 48 Aux PWM Driver #3 — Open Circuit — Aux PWM Driver #3 — High Side Line Short to Ground Table 4-5 SAE Codes and Descriptions (Sheet 5 of 6) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 49 Propriety Data Link — Communication Failure — Engine Brake Calibration —Parameters Invalid — DDEC-VCU — Internal Error Table 4-6 SAE Codes and Descriptions (Sheet 6 of 6) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 50: Troubleshooting Of Performance Codes

NOTE: The EGR systems in the MBE 4000 and MBE 900 engines contain fewer components and use simpler control logic than the other series of Detroit Diesel engines. Therefore, using the DTCs should be the primary means of solving troubleshooting problems. -

Page 51: Description Of Sid 146

Data Erratic (146/2), refer to section 4.3.2.3. EGR Valve not Responding (146/7), refer to section 4.3.2.4. Bad Component (146/12), refer to section 4.3.2.5. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 52: Troubleshooting Sid 146

Control of the EGR valve is routed through pins 11, 42, and 50 of the 55-pin connector. See Figure 4-1. 1. 55-Pin Connector Figure 4-1 Pin Locations on 55-Pin Connector The following procedures will troubleshoot SID 146. 4-10 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 53: 146/0 - Egr Temperature Above Normal

[b] If fault code s 146/0 is no longer active, erase fault code memory and verify repairs. Refer to section 4.3.2.6. [c] If fault code s 146/0 is still active, go to step 3. 4-11 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 54 [b] Look for heavy soot deposits on the valves. If necessary, clean valves. Erase fault code memory and verify repairs. Refer to section 4.3.2.6. [c] If fault code s 146/0 is still active, contact the Detroit Diesel Customer Support Center at 313-592-5800.

-

Page 55: 146/1 - Egr Temperature Below Normal

[a] If resistance is less than 3 , repair the short in the wire. Erase the fault code memory and verify repairs. Refer to section 4.3.2.6. [b] If resistance is greater than 3 , go to step 4. 4-13 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 56 [a] If the cooler is damaged and leaking, repair or replace cooler as required. Erase the fault code memory and verify repairs. Refer to section 4.3.2.6. [b] If fault code s 146/1 is still active, contact the Detroit Diesel Customer Support Center at 313-592-5800.

-

Page 57: 146/2 - Erratic Data

Refer to section 4.3.2.6. [b] If fault code s 146/2 is still active, go to step 4. 4-15 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 58 [b] If coolant usage is normal and fault code s 146/2 is still active, contact the Detroit Diesel Customer Support Center at 313-592-5800. 4-16 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 59: 146/7 - Egr Valve Not Responding

[c] Check all contacts and connections. Remove corrosion as required. If fault code s 146/7 is still active, go to step 3. 4-17 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 60 [b] If coolant usage is normal and fault code s 146/2 is still active, contact the Detroit Diesel Customer Support Center at 313-592-5800. 4-18 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 61: 146/12 - Bad Component

[c] If fault code s 146/12 is still active, replace EGR valve. Erase fault code memory and verify repairs. Refer to section 4.3.2.6. [d] If fault code s 146/12 is still active, go to step 2. 2. Contact the Detroit Diesel Customer Support Center at 313-592-5800. 4-19 All information subject to change without notice. (Rev. 5/05) -

Page 62: Verifying Repairs

6. Check active codes. [a] If no codes are displayed, troubleshooting is complete. [b] If a fault code other than SID 146 is logged, refer to Detroit Diesel MBE Electronic Controls Troubleshooting Guide, 6SE422. [c] If a fault code in SID 146 is logged, refer to: Section 4.3.2.1 for code s 146/0... -

Page 63: Engine Protection

The Low Engine Oil Level fault cannot be enabled on a DDEC system of a NAFTA MBE engine because the engine oil level sensor is not offered in the NAFTA market. 4-21 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 64 CODES PRELIMINARY THIS PAGE INTENTIONALLY LEFT BLANK 4-22 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 65: Testing

MBE EGR TECHNICIAN'S GUIDE TESTING The following operational events and diagnostic recommendations are based on conditions identified by the Detroit Diesel Customer Support Center. The recommended troubleshooting procedures are accurate as of April 2005. Troubleshooting SID 146: Refer to section 4.3.2: Fault Code s 146/0 —... - Page 66 TESTING PRELIMINARY THIS PAGE INTENTIONALLY LEFT BLANK All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 67: Detroit Diesel Diagnostic Link/Snapshots

PRELIMINARY MBE EGR TECHNICIAN'S GUIDE DETROIT DIESEL DIAGNOSTIC LINK/SNAPSHOTS The Detroit Diesel Diagnostic Link (DDDL) can record snapshots of the electronic controls input and output to resolve the engine operating concerns. WORKING WITH DDDL SNAPSHOTS Create a snapshot using the following procedure: 1. - Page 68 6. When recording of the desired data is completed, click once with the left mouse button on the Stop Recording ESC box. See Figure 6-2. Figure 6-2 Stop Recording ESC Box All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 69 Yes option. To discard the data recorded by the snapshot, click on the NO option. See Figure 6-3. Figure 6-3 Stop Recording ESC Options All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 70 Save In box. For example, the file may be saved to the A:\ drive. Once the file has been saved, the process is complete. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 71: Using Snapshot Replay Controls

1. Go to the Snapshot drop-down menu and select Open. Do not have the computer connected to a vehicle when replaying a snapshot. See Figure 6-5. Figure 6-5 Snapshot Drop-Down Menu All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 72 Snapshot Dialog Box NOTE: The default folder that snapshot files are saved in is C:\Detroit Diesel\Diagnostic and the files have an extension of “.ddl”. 3. Highlight the desired the file with one click of the left mouse button. The selected file name will now appear in the File Name box.

- Page 73 7. To stop the replay at a particular point of interest, click on Pause. The instruments will show the values at the time the replay was stopped. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 74 See Figure 6-9, Figure 6-10, Figure 6-11, and Figure 6-12 for samples of windows that may be activated. All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 75 PRELIMINARY MBE EGR TECHNICIAN'S GUIDE Figure 6-9 Diagnostic Instrumentation Window Figure 6-10 Graph Window All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 76 DETROIT DIESEL DIAGNOSTIC LINK/SNAPSHOTS PRELIMINARY Figure 6-11 User Window Figure 6-12 Fault Codes Window 6-10 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 77: E-Mailing Snapshot Files

1. Identify the filenames of snapshots to send. Typically the snapshot files a user creates are saved in the C:\Detroit Diesel\Diagnostic folder. If this folder was used to store snapshots, view the snapshots available by going to Diagnostic Link, opening up the Snapshot drop-down menu, and selecting Open. - Page 78 DETROIT DIESEL DIAGNOSTIC LINK/SNAPSHOTS PRELIMINARY 3. Open up the file manager on the C:\ drive, and locate the Detroit Diesel folder. See Figure 6-15. NOTE: The user may choose a different location when the files are created so this location is not always used.

- Page 79 PRELIMINARY MBE EGR TECHNICIAN'S GUIDE 4. Click on the + sign in front of Detroit Diesel. Two more folders appear. Click twice on the Diagnostic folder. This folder is the default location of all the snapshot files for Diagnostic Link. See Figure 6-16.

- Page 80 E-mail and select Paste from the menu. See Figure 6-19. Figure 6-19 Pasting the Files in the E-mail Message 6-14 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 81 11. Open up Diagnostic Link and choose the Open selection from the File drop-down menu. The files recently copied should appear in the list. 6-15 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 82 DETROIT DIESEL DIAGNOSTIC LINK/SNAPSHOTS PRELIMINARY THIS PAGE INTENTIONALLY LEFT BLANK 6-16 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 83: Snapshot Examples

Engine Warming Up With No Load — Refer to section 7.1.2. MBE 900 Engine at Low but Varied Loads and Speeds — Refer to Section 7.1.4. MBE 4000 Engine at Low but Varied Loads and Speeds — Refer to Section 7.1.3. -

Page 84: Normal Engine Operation Snapshots

For a cold engine at idle, the EGR valve is closed and the EGR temperature after the EGR cooler is well below the engine coolant temperature. See Figure 7-1 and Figure 7-2 for an MBE 900 engine operating at idle. - Page 85 PRELIMINARY MBE EGR TECHNICIAN'S GUIDE Figure 7-2 Cold MBE 900 Engine at Idle — Graph Window All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 86: Warm Engine With No Load

WARM ENGINE WITH NO LOAD As the engine warms up, the EGR valve opens and the EGR temperature after the EGR cooler approaches the engine coolant temperature. See Figure 7-3 and Figure 7-4 for an MBE 900 engine warming up with no load. - Page 87 PRELIMINARY MBE EGR TECHNICIAN'S GUIDE Figure 7-4 MBE 900 Engine Warming up at Intermediate Speeds — Graph Window All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 88: Mbe 4000 Engine At Variable Speeds And Loads

In this snapshot, the engine coolant is at operating temperature. See Figure 7-5. NOTE: The EGR temperature slowly builds while the coolant temperature remains steady. Figure 7-5 MBE 4000 Engine at Low Vehicle Speed All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 89: Mbe 900 Engine At Variable Speeds And Loads

7.1.4 MBE 900 ENGINE AT VARIABLE SPEEDS AND LOADS This snapshot is an MBE 900 engine operating at low vehicle speeds but variable engine speeds and loads. In this snapshot, the engine coolant is at operating temperature. See Figure 7-6. -

Page 90: Problem Engine Operation Snapshots

If an engine runs with no EGR temperature reading, such as a bad EGR temperature sensor or open EGR temperature circuit; then there will be no value for EGR temperature after cooler. See Figure 7-7 and Figure 7-8 for an MBE 900 engine with no EGR temperature reading. Figure 7-7 MBE 900 Engine Running with No EGR Temperature Reading —... - Page 91 PRELIMINARY MBE EGR TECHNICIAN'S GUIDE Figure 7-8 MBE 900 Engine Running with No EGR Temperature Reading — Graph Window All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 92: Engine With Above Normal Egr Temperature Readings

EGR temperature circuit; then the fault description, fault ID (SID or PID), and FMI will appear in the fault codes window. See Figure 7-9. Figure 7-9 MBE 900 Engine Running with Above Normal EGR Temperature — Fault Codes Window 7-10 All information subject to change without notice. -

Page 93: Appendix A: List Of Acronyms

Engine Control Module (Pump and Nozzle Control Unit, aka DDEC-ECU) Pounds per Square Inch Power Take Off Pulse Width Modulation Revolutions per Minute Red Stop Lamp (aka SEL) All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 94 APPENDIX A: LIST OF ACRONYMS PRELIMINARY Society of Automotive Engineers Stop Engine Light (aka RSL) System Identification Turbocharger Boost Sensor (aka IMP Sensor) Vehicle Speed Sensor All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 95: Appendix B: Mbe Ddec Wiring Schematics

MBE EGR TECHNICIAN'S GUIDE APPENDIX B: MBE DDEC WIRING SCHEMATICS MBE 900/4000 DDEC Vehicle Interface Wiring Diagram — See Figure B-1. MBE 4000 DDEC-ECU Engine Wiring Diagram — See Figure B-2. MBE 900 DDEC-ECU Engine Wiring Diagram — See Figure B-3. - Page 96 APPENDIX B: MBE DDEC WIRING SCHEMATICS PRELIMINARY All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 101: Appendix C: Service Information Letters

Subject: MBE 4000 EGR System — EGR Cooler Inspection See Figure C-2, Figure C-3, Figure C-4, Figure C-5, and Figure C-6. Service Information Letter 04 TS-57, Subject: MBE 900 Model Year 2004 EGR Overheat Condition See Figure C-7 and Figure C-8. Service Information Letter 04 TS-61, Subject: MBE 4000 —... - Page 102 APPENDIX C: SERVICE INFORMATION LETTERS PRELIMINARY All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 104 APPENDIX C: SERVICE INFORMATION LETTERS PRELIMINARY All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 106 APPENDIX C: SERVICE INFORMATION LETTERS PRELIMINARY All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 120 APPENDIX C: SERVICE INFORMATION LETTERS PRELIMINARY C-20 All information subject to change without notice. (Rev. 5/05) 7SE940 0505 Copyright © 2005 DETROIT DIESEL CORPORATION...

Need help?

Do you have a question about the MBE 900 and is the answer not in the manual?

Questions and answers