Summary of Contents for Master FVS25

- Page 1 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com OPERATION MANUAL FVS25 Vibratory screed Machine P E R F O R M A N C E · E F F I C I E N T · R E L I A B L E...

- Page 2 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com Master sincerely thanks you for selecting the Concrete Cutting Machine. For your Safety and proper operation, before you start to operate or carry out any maintenance on this equipment, YOU MUST READ and STUDY this manual carefully.

- Page 3 After reading through this manual thoroughly you will find that you can do some of the regular maintenance yourself. However, when in need of parts or major service be sure to see your Master dealer. For your convenience we have provided this space to record relevant data about your ride-on Trowel.

-

Page 4: Safety Precautions

Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com inches in depth. Multiple blade lengths and variable exciter weight positions allow for optimum compaction and production of the slab placement. SAFETY PRECAUTIONS 1. Before starting operation, the operator has to check that all control and safety devices function properly. -

Page 5: Service Safety

Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com death. 2. DO NOT smoke while operating the machine. 3. DO NOT smoke when refueling the engine. 4. DO NOT refuel a hot or running engine. 5. DO NOT refuel the engine near an open flame. -

Page 6: Operation

Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com hard-to-read labels. Labels provide important operating instructions and warn of dangers and hazards. 7. ALWAYS check all external fasteners at regular intervals. 8. ALWAYS handle blades carefully. The blades can develop sharp edges which can cause serious cuts. -

Page 7: Stopping Engine

Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com 2. Press the primer bulb repeatedly until fuel can be seen in the clear plastic return tube. 3. Choke engine if necessary (you may not need to choke a warm engine). 4. Pull starter rope repeatedly until engine starts. - Page 8 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com 2. Run the Screed between the wet pads to create two parallel strips (B) that define the grade for the remainder of the wet screeding. These strips should be 300-500 wide. Place one end of the float blade on each of the parallel strips (B) and screed the concrete (C) in between the strips.

-

Page 9: Maintenance Schedule

Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com TRANSPORTING It is recommended to transport the Screed with the float bar removed. The float bar is more likely to be damaged if attached to the main unit during transport. STORAGE The following steps should be taken to prepare your Screed for extended storage. -

Page 10: Engine Maintenance

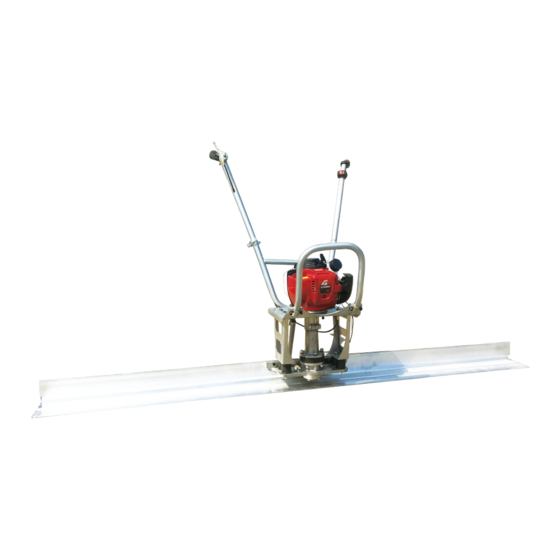

Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com Each Every Every Each Item Maintenance year hours hours Refer to engine Engine operator/owner × manual Part Check tighten × × needed Shockmount Check for cracks × × or tears ENGINE MAINTENANCE Refer to the engine owner’s manual for maintenance intervals and procedures. - Page 11 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com 4. Start engine and run the exciter for about 10 seconds. 5. Shut down the engine. DIAGRAM 1. VS25 screed assembly...

- Page 12 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com Item Part no. part name 10001 Lock Nut M8 10002 Washer8 10003 Shock mount 10004 Kickstand 10005 Bushing 10006 Handle assembly 10007 Gasket8 10008 Bolt M8x30 10009 Lock Nut M8 10010 Washer8 10011...

- Page 13 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com 2.Handle assembly Item Part no. part name 1000601 Bushing φ25 1000602 Throttle Control assembly 1000603 Handle 1000604 Gasket10 1000605 Bolt M10x90 1000606 Bolt M8x16 1000607 Gasket8 1000608 Engine-mounting plate 1000609 Nut M10 1000610...

- Page 14 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com Throttle control assembly Item Part no. part name 100060201 Screw M6×16 100060202 Washer 100060203 Bushing 100060204 Lever 100060205 Screw M4×6 100060206 Screw M5×6 100060207 Lock washer5 100060208 Plate 100060209 Gasket 6 100060210 Lock nut M6...

- Page 15 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com Exciter assembly Item Part no. part name 1001701 Shaft pin 1001702 Rubber ring 1001703 Flange 1001704 Gasket 6...

- Page 16 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com 1001705 Screw 6×20 1001706 Retaining ring 52 1001707 Washer 12 1001708 Bearing 6205-2RS 1001709 Lock Nut 12 1001710 Shaft 1001711 Shaft pin 1001712 Bearing 6204-2RS 1001713 Exciter mount 1001714 Washer 8 1001715 Gasket 8 1001716 Bolt 8×20...

- Page 17 Henan Master Machinery Co., Ltd Tel:(+86)17737606271 www.mastermachinerys.com 1001732 Bearing 6204-2RS 1001733 Retaining ring 47 1001734 Shaft pin...

Need help?

Do you have a question about the FVS25 and is the answer not in the manual?

Questions and answers