Advertisement

Table of Contents

- 1 Read before Using

- 2 Table of Contents

- 3 To Know Your Engraving Machine

- 4 Composition Name of the Machine

- 5 Sketch Map of Installation and Wiring

- 6 To Test Your Engraving Machine

- 7 Trial Run and Manual Control Test for the Machine

- 8 Definition of Triaxial Coordinate

- 9 To Use Your Engraving Machine

- 10 Primary Engraving Practice

- 11 Install Auxiliary Operating Platform for Your Engraving Machine

- 12 Secondary Engraving Practice

- 13 Application of Tool Setting Gauge

- 14 Control the Spindle Motor through Software

- Download this manual

Advertisement

Table of Contents

Summary of Contents for CNC 3020Z-DQ

- Page 1 Web site: www.lybga.cn official agency: www.usbearth.cn Three-axis CNC engraving machine USER GUIDE (F OR:3020Z-DQ/3040Z-DQ)...

-

Page 2: Read Before Using

Congratulations! Y ou already have your own numerical control engraving machine, but you need to carefully know it and master it, in order to make it your good assistant as soon as possible. ■Read before using: ●This machine is only designed for the surface engraving of plastics, bamboo and timber, and non- ferrous soft metal, so the application with other purposes may damage it;... - Page 3 ■Requirements for the configuration of master control computer: ①The desktop computer must possess parallel ports; Notebook PC or USB parallel port cannot be used normally. ②Minimum configuration of the computer: CPU/1G, 512M memory, 20G hard disk, mainboard with parallel port, WIN-XP operating system. ■Introduction to control software and design software: ①Control software: Mach3 is recommended (EMC2 and Kcam4 can also be applied, and consult software providers for detailed information);...

-

Page 4: Table Of Contents

3020Z/3040Z-DQ CNC Engraving Machine CONTENTS ■Read before using----------------------------------------------------------------1 ■To know your engraving machine------------------------------------------4 · Composition name of the machine · Sketch map of installation and wiring ■To test your engraving machine--------------------------------------------5 · (Mach3) Software settings · Trial run and manual control test for the machine ·... -

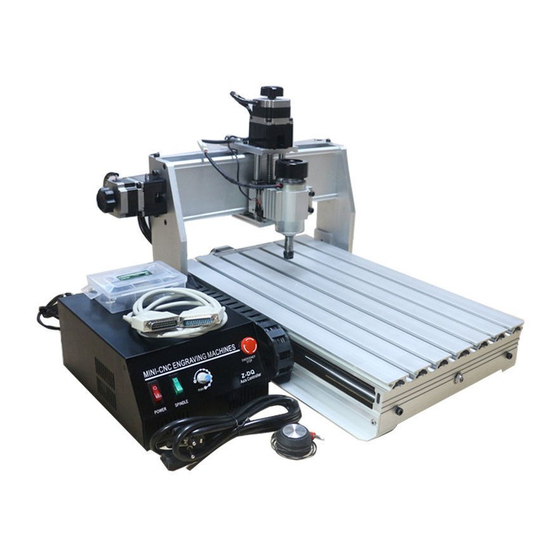

Page 5: To Know Your Engraving Machine

■To know your engraving machine ◆Composition name of the machine ◆Sketch map of installation and wiring... -

Page 6: To Test Your Engraving Machine

■To test your engraving machine ◆Installing the control software · Software is not included in this machine, so please purchase appropriate software in line with your fondness; It is recommended to use Mach3 to control it; · Please carefully read the instructions about installation in the Mach3 software manual before installing the software. - Page 7 ② ③ ④...

- Page 8 ⑤ ⑥...

-

Page 9: Trial Run And Manual Control Test For The Machine

⑦ Please carefully read the above picture for setup, and the mistake of any number or option will lead to the failure of the engraving machine, or even lead to accident when operating the machine. ◆Trial run and manual control test for the machine ①Check and confirm: whether the connection among computer→control box→engraving machine is correct;... -

Page 10: Definition Of Triaxial Coordinate

④Now press the direction key on the keyboard, there may be some response actions from the X or Y axis, and the digital coordinate of corresponding axis on the screen may be changed. The left and right keys control the X axis, while the up and down keys control the Y axis, the Page-UP and Page-DOWN keys control the Z axis;... -

Page 11: To Use Your Engraving Machine

methods: ①Uninstall MACH3 software, change the MACH3 of other version, and do installation test (because some main board parallel ports are not compatible with MACH); ②Check whether your parallel port is normal, and please change another set of qualified desktop computer and do test. - Page 12 ①First, we operate the XY axis through manual control, and move the principal axis close to the initial point; Install a flat base pointed knife. ②Turn off the power switch of electric cabinet (the phase step motor will not be self-locked when the power is cut off), and then slowly wring the hand wheels for fine control on three stepping motor, to move the tool nose to the initial point.

-

Page 13: Install Auxiliary Operating Platform For Your Engraving Machine

Attention: at the time engraving, prevent the hand from getting too close to the cutter with highly revolving speed, and do not observe it in close distance. After finishing the engraving, first turn down the revolving speed of the principal axis to the minimum; then rise Z axis in Mach3 through manual control, and move the spindle motor outside the engraving materials;... -

Page 14: Secondary Engraving Practice

◆Secondary engraving practice Now, we can use the auxiliary operating platform. Double color plate is one of the most commonly used engraving materials, which is shown as the following picture: ①Stick double-faced adhesive tape on the back of the double color plate; ②Paste it on the milled plane of the auxiliary operating platform, and press it to make it stickfast;... -

Page 15: Application Of Tool Setting Gauge

pasted on the auxiliary operating platform, the size of the material should within the scope of 90X90mm. Meanwhile, the initial point of this file is on the top left corner. The application of engraving machine is easy, which can be summarized as: clamping materials, tool setting, and engraving. -

Page 16: Control The Spindle Motor Through Software

Using method: ① Just shown in the picture, put the tool setting gauge on the materials to be engraved, and then adjust Z axis to an appropriate position manually. When the tool setting is triggered, Z axis may arise 5mm automatically;... - Page 17 ① Move the control switch on the back of the control box to the M position. (Attention: M position means that the spindle motor is controlled by MACH3 software; H position means that it is controlled by the electric control panel; no matter which method is used, you must first press the SPINDLE switch, and otherwise the principal axis is not electrified.) ②...

- Page 18 ◆Notice for maintenance of the machine: ①Each time after engraving, you should first close the principal axis and power switch, and then clean the scraps produced by engraving in time. ②Lubricate the guide way, bearing, and screw mandrel of the machine per time every month; Use clean cotton fabric with white oil (sewing-machine oil) to clean the guide way, smear some white lubricating grease on the screw mandrel, and then turn on the machine to operate for several times.

Need help?

Do you have a question about the 3020Z-DQ and is the answer not in the manual?

Questions and answers