Summary of Contents for AMCOL 6000E

- Page 1 AMCOL CORPORATION 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual...

-

Page 2: Table Of Contents

Yearly ............................13 10 Recommended Fluids ......................... 14 11 Schematics and Drawings ......................15 AMCOL Corporation 21435 Dequindre, Hazel Park, MI 48030 248-414-5700 fax: 248-414-7489 www.amcolcorp.com 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 1... -

Page 3: Introduction

This operator’s manual describes the installation, operation, and maintenance of your new AMCOL 6000E Precision Applicator. For more information on the system and the individual components, please refer to the preceding document: “AMCOL 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM - Technical Description.”... -

Page 4: Included Components

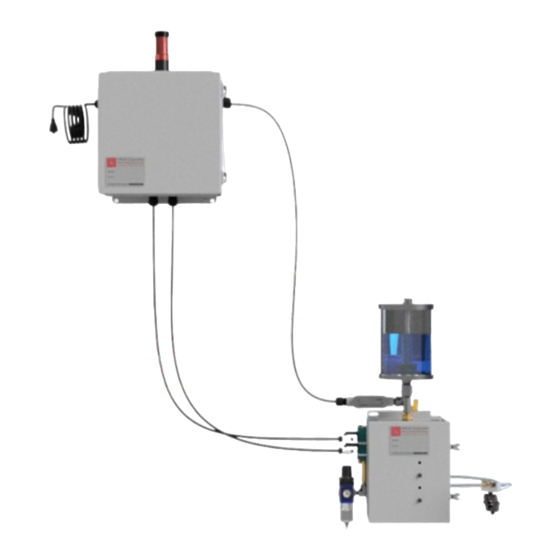

3. Air/Liquid Hose to Spray Point 4. Air/Liquid Spray Assembly Shown is a 6000E Precision Applicator System with a two injector T60A Posi-pump, ½ Gallon Reservoir with Low Level Indicator, urethane bonded biaxial hose, and B2 Manifold with Air Propelled Wet Tips on a Compact Multifunctional Mounting Bracket. -

Page 5: Assembly And Installation

3 Assembly and Installation PRIOR TO GETTING STARTED • WARNING! The AMCOL 6000E series applicator is serviced by a high-pressure air source. Pressurized air is inherently dangerous and only qualified individuals should be allowed to work on these systems. •... -

Page 6: Recommended Settings

Settings with SMART Metering All 6000E systems include a dual solenoid control package that eliminates the variability of traditional pneumatic controls. Fixed position hex caps and non- adjustable regulators remove variability associated with spray volume and pattern. -

Page 7: Operation

Injection Pulse Rate Solenoid closed for 80ms • If using a 6000-ETC, simply press the up or down buttons on the PLC to modify Injection Rate without any changes to programming. See the AMCOL 6000 ETC Technical Description and Operator’s Manual for more information. Proper Operation System Timing Correct system timing can be seen to the left. - Page 8 Manual operation should be used to verify current settings, test spray coating, and troubleshoot. Automatic Actuation To automatically use the 6000E system, it should be interfaced with the control PLC, which should contain the following sequence: •...

-

Page 9: Priming/Re-Priming The System

Manifolded dispensing air pressure set too high: adjust. • Individual spray point flow set too high: adjust. Liquid from Back of Injector • Injector contact seals leaking: clean injector and replace O-ring. 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 8... -

Page 10: T60A Posi-Pump Troubleshooting

Exit fitting is leaking: replace. • Evacuation valve is ineffective: clean or replace. • Biaxial hose is trimmed incorrectly: be sure hose is cut straight with no burrs or deformities. 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 9... - Page 11 Liquid Leaking from Pump Body O-ring seals are worn: replace. • • Piston sleeve is not tight: tighten. • Piston sleeve is worn: rebuild complete injector 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 10...

-

Page 12: Maintenance

* Number of injectors on replacement pump must match current system Recommended Tools Description Part Number Quantity O-ring repair tool ORT-T60 T-60A repair tool RT-T60 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 11... -

Page 13: Repair Of The T60A Posi-Pump

6. Clean and observe all components, both internally and externally. 7. Using the liquid to be pumped as a lubricant, replace and install all associated components in reverse order. 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 12... -

Page 14: T60A Posi-Pump Bill Of Materials

Observe system settings • Observe system for damage Quarterly • Empty, clean, and refill reservoir • Replace liquid and air hose Yearly • Rebuild or replace T60A Posi-pumps 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 13... -

Page 15: Recommended Fluids

10 Recommended Fluids AMCOL offers a variety of CANMIST High Performance Lubricants to meet your specific needs. With your new 6000E Electronically Controlled Precision Lubrication System, the properly matched fluid is of critical importance. Only CANMIST fluids are recommended and fully compatible with 6000 Spray Systems. Contact an AMCOL representative to select the right CANMIST fluid for your operation. -

Page 16: Schematics And Drawings

11 Schematics and Drawings General schematic for dual air source Sample System with Components (6000E-24-3-D-D-3-B-A) 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 15... - Page 17 T60A-2B-1AX-NAR15 Complete Assembly System Actuation Assembly 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 16...

- Page 18 Top Mounted Reservoir Assemblies Wall Mounted Reservoir Assemblies 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 17...

- Page 19 6000E Enclosure Assembly (2 Injector Shown) AMCOL Corporation 21435 Dequindre, Hazel Park, MI 48030 248-414-5700 fax: 248-414-7489 www.amcolcorp.com 6000E ELECTRONICALLY CONTROLLED PRECISION LUBRICATION SYSTEM Operator’s Manual P A G E | 18...

Need help?

Do you have a question about the 6000E and is the answer not in the manual?

Questions and answers