Table of Contents

Summary of Contents for vc999 07P Series

- Page 1 Operating Manual Art. no. 527.763 Vali d from machine no. 07891246 Vacuum Packaging Machines 07P ... Inauen Maschinen AG Tel. ++41 (0) 71 35 35 900 Melonenstrasse 2 Fax ++41 (0) 71 35 35 901 CH-9100 Herisau / Switzerland E-mail info@vc999.ch...

- Page 3 Vacuum Packaging Machines 07P ... Hand-over declaration IMPORTANT The following hand-over declaration must be completed by the purchaser. The purchaser shall return the completed hand-over declaration to us. He thereby certifies that he has gained knowledge of the contents of the Operating Manual and that his attention has been drawn to the safety notes for using the machine.

-

Page 5: Table Of Contents

Vacuum Packaging Machines 07P ... Contents Contents Introduction ..................9 General information................9 Definitions..................10 Protection of copyright ..............10 Safety, warranty ................11 General safety instructions............... 11 2.1.1 Use as prescribed ................12 2.1.1.1 Machine with an inert gas system (07PN ...) ........12 2.1.2 Processing materials................ - Page 6 Vacuum Packaging Machines 07P ... Contents Installation of the machine ............23 Electrical installation .................23 Pneumatics installation..............23 Inert gas installation (07PN ...) ............24 Control or fill with oil .................25 Cleaning the machine...............25 Commissioning................26 Initial start-up ..................26 General instructions................26 Operation..................27 10.1 Requirements for operation..............27 10.2 Preparation ..................27 10.3...

- Page 7 Vacuum Packaging Machines 07P ... Contents Service program................45 12.1 Structure of the service program............45 12.1.1 Entry into the service program ............46 12.2 Error diagnosis ................. 46 12.3 Initial settings..................47 12.3.1 Intermediate ventilation ..............47 12.3.2 Gas flush ..................47 12.3.3 Automatic Operation ................

- Page 8 Vacuum Packaging Machines 07P ... Contents Disposal...................66 Pneumatics diagram ..............67 Circuit diagrams ................68 Sequence diagram................72 Index ....................73 Page 8/74 Art. no. 527.763 2003-11-05...

-

Page 9: Introduction

The rating plate is located on the back of the machine. Manufacturer: Inauen Maschinen AG Address: Melonenstrasse 2 CH-9100 Herisau Tel: ++41 (0)71 35 35 900 Fax: ++41 (0)71 35 35 901 E-mail : info@vc999.ch Website : www.vc999.biz 2003-11-05 Art. no. 527.763 Page 9/74... -

Page 10: Definitions

Vacuum Packaging Machines 07P ... Introduction Definitions The following terms are used in this Operating Manual to describe the people who work with or on the machine: Owner Owners are firms which have entered into a contract with the manufacturer or its agent. Owners are legally entitled to sign contracts. -

Page 11: Safety, Warranty

Vacuum Packaging Machines 07P ... Safety, warranty Safety, warranty General safety instructions Pay particular attention to the following instructions: • Anyone in the owner’s factory who is involved in the installation, commissioning, operation and servicing (inspection, maintenance, repairs) of the machine must have read and understood the complete Operating and Maintenance Manual, in particular Chapter 2 "Safety, warranty". -

Page 12: Use As Prescribed

Vacuum Packaging Machines 07P ... Safety, warranty IMPORTANT Before working on any pneumatic components, remove the pressure from the relevant supply line! • When the servicing is complete, check that all the safety equipment is in place and working properly before switching the machine back on. -

Page 13: Processing Materials

Vacuum Packaging Machines 07P ... Safety, warranty 2.1.2 Processing materials 2.1.2.1 Vacuum bags The vacuum bags have to be suitable and permitted for sealing under pressure and heat. They must also conform to hygiene regulations in terms of the handling and packaging of foodstuffs. Obtain a certificate of suitability from the manufacturer. -

Page 14: Requirements For Operators

Vacuum Packaging Machines 07P ... Safety, warranty 2.1.3 Requirements for operators The machine should only be operated, maintained and repaired by authorised personnel who have received training and instructions on how the machine works. The owner has to point out potential dangers to the personnel. -

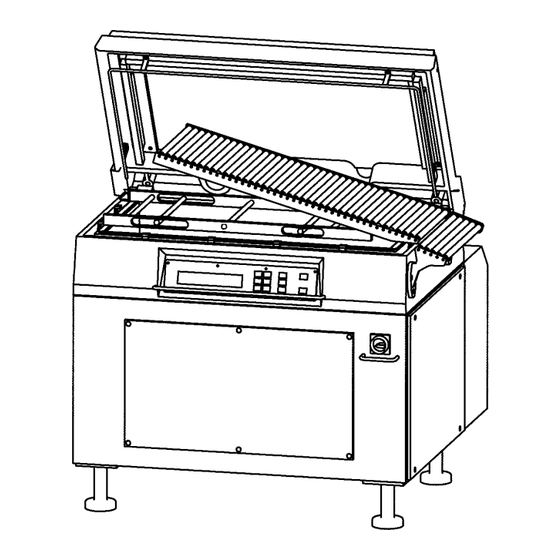

Page 15: Description Of The Machine

Vacuum Packaging Machines 07P ... Description of the machine Description of the machine Functional principle The filled vacuum bag is laid with the opening flat over the sealing pad (or over the sealing beam for 07P+G). The sealing of the vacuum bag is carried out in the vacuum chamber by means of sealing the bag opening under vacuum or in an atmosphere enriched with an inert gas. -

Page 16: Control Panel

Vacuum Packaging Machines 07P ... Description of the machine Control panel The operator console contains the operating buttons and the display. Set values and program numbers can be read off from the display. Fig. 3/3 Display Button PUMP ON Button HELP = Help + Works settings Button DOWN Button UP Button SERVICE SETTINGS... -

Page 17: Ejection Direction

In order to achieve the optimum working conditions, one machine should be provided with product while the other machine creates the vacuum. Thus, two machines can be served optimally with one operator. Please contact the VC999 customer service department if two machines are to be interconnected. 2003-11-05 Art. no. 527.763... -

Page 18: Technical Data

Vacuum Packaging Machines 07P ... Technical data Technical data Electrical connection data (Model to EN 60204-1) 230V/3/50 Hz: 7,5/10/11,5 kW 40 AT 208V/3/60 Hz: 7,5/10/11,5 kW 40 AT 400V/3/50 Hz: 7,5/10 kW 25 AT 440V/3/60 Hz: 7,5/10/11,5 kW 25 AT 11,5 kW 40 AT Vacuum pumps... - Page 19 Vacuum Packaging Machines 07P ... Technical data Dimensioned drawing Fig. 4/1 Legend Vacuum packaging machine 07P ... Extension for an additional roots vacuum pump (Option) Working space for operator 2003-11-05 Art. no. 527.763 Page 19/74...

-

Page 20: Packaging And Transport

Vacuum Packaging Machines 07P ... Packaging and transport Packaging and transport Packaging the machine The machine must be carefully packaged in order to transport it safely. The machine manufacturer recommends you to transport it in the type of packaging which is used to transport it from the factory. Transportation of the machine IMPORTANT Always transport the machine in a horizontal position! The vacuum pump may be damaged if... -

Page 21: Setting Up The Machine

Vacuum Packaging Machines 07P ... Setting up the machine Setting up the machine Criteria for the installation site It must be set up in a dry, well-ventilated room. The machine must be protected against continuous splashes, jets and gushes of water. Foundations A horizontal industrial floor is adequate as a foundation. -

Page 22: Interface Definition

Vacuum Packaging Machines 07P ... Interface definition Interface definition Electrical connection See section 4 "Technical data". • The connection data of the machine can be found on the rating plate (Fig. 3/1, Pos. 5) at the back of the machine. Pneumatic connection The pneumatic connection is situated at the back of the machine. -

Page 23: Installation Of The Machine

• Wire a CEE round system plug to the electrical cable. CAUTION The machine may only be switched on for the first time by VC999 Customer Service personnel! Pneumatics installation • Remove the back wall or the cover of the pump extension (Fig. -

Page 24: Inert Gas Installation (07Pn

Vacuum Packaging Machines 07P ... Installation of the machine Inert gas installation (07PN ...) The inert gas connection point is located in the bottom part of the machine. Remove the front cover for access (Fig. 3/1, Pos. 11) The inert gas valve with the hose connection nozzle (50) is situated in the lower right region. -

Page 25: Control Or Fill With Oil

Vacuum Packaging Machines 07P ... Installation of the machine Control or fill with oil Rotary slide vacuum pump The oil level must be visible in the level tube (55) between the Min. and Max. markings Recommended oil: BP Energol RC 100 ESSO Teresso 100 Mobil DTE Oil extra heavy Shell Corena Oil H100... -

Page 26: Commissioning

Commissioning Initial start-up The initial start-up should only be carried out by VC999 Customer Service personnel! Unauthorised initial start-up can result in injuries or damage to equipment and property! The customer’s personnel will also receive thorough training during initial start-up. -

Page 27: Operation

Vacuum Packaging Machines 07P ... Operation Operation This chapter is directed at machine operators. It contains all the information necessary to operate the machine; from starting the machine to operating and stopping it. 10.1 Requirements for operation The following requirements have to be met before the machine can be put into operation: •... -

Page 28: Machine Preparation

Vacuum Packaging Machines 07P ... Operation 10.4 Machine preparation 10.4.1 Switching on the machine • Turn main switch to position “ “.The machine switches on. CAUTION The vacuum chamber opens automatically! − The machine version appears at the display for a few seconds. −... -

Page 29: Packaging

Vacuum Packaging Machines 07P ... Operation 10.5 Packaging IMPORTANT The vacuum chamber must be dry. If possible, package cooled products! The warmer moist products are, the less is the achievable vacuum due to the evaporation. Strong evaporation can be prevented with the aid of evaporation steps (see Chapter 10.6 “Programming”). -

Page 30: Start Packaging Cycle (Single Cycle)

Vacuum Packaging Machines 07P ... Operation 10.5.1 Start packaging cycle (single cycle) • Press the START button (single cycle). CAUTION The vacuum chamber closes automatically. The working process − Vacuuming − Possibly intermediate ventilation − Possible gas flushing − Sealing/separating −... -

Page 31: Programming

Vacuum Packaging Machines 07P ... Operation 10.6 Programming 10.6.1 Selecting the packaging programs The internal memory has space for 30 packaging programs. In the initial position, the parameters of each program are shown; see also Chapter 10.6.13 “Sequence diagram – program level. In order to change from one program to the next, press the PROGRAM and UP or DOWN buttons. -

Page 32: Inert Gas Supply (07Pn

Vacuum Packaging Machines 07P ... Operation Vacuuming in stages to the set value (for sensitive and porous products) With these products there is the danger, with too-quick vacuuming, that they explode of swell up as they can evacuate only slowly (e.g. cheese, bread, etc). The vacuuming in stages starts with 500 ‰. -

Page 33: Sealing And Cutting

Vacuum Packaging Machines 07P ... Operation 10.6.6 Sealing and cutting The programmed sealing and cutting times refer to the operating heat of the sealing bars. In order to obtain an optimum sealing quality independently of the operating temperature, a sensor measures the heating bar temperature. -

Page 34: 10.6.10 Transport Time

Vacuum Packaging Machines 07P ... Operation The setting shows up to what remaining vacuum, a slow preventilation can take place. After that the main valve opens. IMPORTANT Enter 999 to deactivate the preventilation function. Preventilation extends the packaging cycle! 10.6.10 Transport time After the end of the packaging cycle the products are automatically transported out of the vacuum chamber. - Page 35 Vacuum Packaging Machines 07P ... Operation Open key switch: • Press the SERVICE SETTINGS button 4 times. • Press the button combination HELP-CONTINUE-HELP. • Press the UP button to open the key switch. • Press the STOP button to return to the initial position. Making locked programs accessible: •...

-

Page 36: 10.6.13 Sequence Diagram Program Level

Vacuum Packaging Machines 07P ... Operation 10.6.13 Sequence diagram Program level Fig. 10/3 Page 36/74 Art. no. 527.763 2003-11-05... -

Page 37: 10.6.14 Program Table

Vacuum Packaging Machines 07P ... Operation 10.6.14 Program table 2003-11-05 Art. no. 527.763 Page 37/74... -

Page 38: Service Settings

Vacuum Packaging Machines 07P ... Operation 10.7 Service settings For certain servicing and cleaning work, it is necessary to bring the machine to a certain service setting, see Chapter 10.7.5. “Sequence diagram service settings”. IMPORTANT The service settings are exited with the STOP button and the machine returns to the initial setting. -

Page 39: Close Lid

Vacuum Packaging Machines 07P ... Operation • In order to lower the platform again press the STOP (35) button 2 x. CAUTION During this procedure do not reach into the chamber. There is a danger of jamming the hands! After the platform has been lowered, the machine is in the initial position. 10.7.2 Close lid For cleaning purposes (spraying down) it is necessary to switch off the machine with the vacuum... -

Page 40: Sequence Diagram Service Settings

Vacuum Packaging Machines 07P ... Operation 10.7.5 Sequence diagram service settings Fig. 10/5 Page 40/74 Art. no. 527.763 2003-11-05... -

Page 41: Malfunctions

Vacuum Packaging Machines 07P ... Malfunctions Malfunctions DANGER Before the removal of malfunctions always separate the machine from the electrical power supply with the main switch. Repairs may only be carried out by the VC999 customer service department. Faults and their remedies 11.1 Fault... - Page 42 Vacuum Packaging Machines 07P ... Malfunctions Fault Cause Remedy CHECK PUMP Measuring switchover valve Call VC999 Customer Service Dept. AND/OR VACUUM defective, pressing membrane of MEAS. SYSTEM the sealing bar not tight, Measuring hose has loosened itself from sensor. OPEN LOOP AT...

-

Page 43: Sealing Current Monitoring

If the error is not corrected immediately, it is displayed again when the machine has been switched off and started again. Please check sealing bar, possibly a mains automatic circuit breaker (Fig. 3/2, Pos. 18) has been triggered. Possibly contact VC999 customer service department. 2003-11-05 Art. no. 527.763... -

Page 44: Possible Operating Malfunctions

Fine wire fuse (Fig. 3/2, Pos.6) burnt Replace fine wire fuse 2 AT through Interruption in 48 VAC supply Call the VC999 Customer Service Dept. Excess temperature switch at the Allow sealing transformer to cool off sealing transformer has been... -

Page 45: Service Program

Vacuum Packaging Machines 07P ... Service program Service program The service program contains various information important for the service. Basic settings for optimum machine running and test programs are also included. IMPORTANT The service program is only of use to trained personnel. Therefore it is only accessible with key switch "OPEN"... -

Page 46: Entry Into The Service Program

Vacuum Packaging Machines 07P ... Service program 12.1.1 Entry into the service program Call up the service program as follows: • If a packaging cycle is running press the STOP button. The started cycle is completed nut no further cycle is started. •... -

Page 47: Initial Settings

Vacuum Packaging Machines 07P ... Service program Entry into the error diagnosis • Press the UP button. This brings up the error diagnosis. With the CONTINUE button, all the conditions which were set at the time of the last error display can be called up sequentially. The displayed settings and values cannot be edited. -

Page 48: Automatic Operation

Vacuum Packaging Machines 07P ... Service program 12.3.3 Automatic Operation The automatic operation is only switched on when the START button (Automatic operation) is to be activated. CAUTION In Automatic operation special care must be exercised with manual loading. After the completion of the set delay time, the vacuum chamber closes automatically. -

Page 49: Cooling Time

Vacuum Packaging Machines 07P ... Service program 12.3.8 Cooling time Before the sealing bar is lifted from the sealing position, a cooling period of the seal must occur or the cooling time must elapse. The setting range is between 0 and 5 seconds. The time is set to the default setting by pressing the HELP button. -

Page 50: 12.3.13 Tolerance Conveyor Levelling

Vacuum Packaging Machines 07P ... Service program 12.3.13 Tolerance conveyor levelling The tolerance value defines the positioning accuracy of the platform. With normally functioning platform, this value should not be changed. If the tolerance is set too low, then the platform cannot reach the set value in a useful time and thus triggers an error message. -

Page 51: Test Programs

Error in the VCP base module With measuring values outside the limiting values, the VC999 customer service must be contacted. • To exit from the test program press the STOP button until the initial position is shown at the display. -

Page 52: Check: Chamber / Pressure Below

Vacuum Packaging Machines 07P ... Service program 12.4.2 Check: chamber / pressure below This test program checks the tightness of the vacuum chamber and the pressing cushion. Procedure: • Start the test program, by pressing the UP button. The query to start the pump appears if this is not running already. -

Page 53: Check Procedure: Platform Adjustment

Vacuum Packaging Machines 07P ... Service program 12.4.3 Check procedure: platform adjustment This test program controls the platform positioning. The displayed cycle value is used by the service technician (expert) for setting and controlling position pickup. The cycle value must be between 17 (upper position) and 193 (lowest position). -

Page 54: 12.4.4.1 Calibration Of The Sealing Time Adjustment

Vacuum Packaging Machines 07P ... Service program 12.4.4.1 Calibration of the sealing time adjustment After installation of a new VCP extension module undertake the calibration of the sealing time calibration as follows: • Switch the machine off. • On the VCP extension module (20) in the switch box, pull out the plug of the temperature sensors (21) and insert in its place the calibration plug supplied with the... -

Page 55: Sequence Service Program

Vacuum Packaging Machines 07P ... Service program 12.4.6 Sequence service program Fig. 12/2 2003-11-05 Art. no. 527.763 Page 55/74... -

Page 56: Maintenance

Vacuum Packaging Machines 07P ... Maintenance Maintenance Service the machine regularly in order to ensure that it works properly. Maintenance includes all work which serves to keep the vacuum packaging machine in good working order, including the following: • checks •... -

Page 57: Checking Platform

Vacuum Packaging Machines 07P ... Maintenance Every month • Check whether both ends of the lid seal touch and seal. IMPORTANT If an end piece has cone out of the slot, simply press it in lightly with the fingers. 13.1.3 Checking platform Every month •... -

Page 58: Cleaning

Vacuum Packaging Machines 07P ... Maintenance 13.2 Cleaning The machine can be sprayed down with the vacuum chamber closed; see Chapter 10.7.2 "Close lid". 13.2.1 Detergent Do not use anything that will scour or scratch! Use standard detergents which conform to hygiene regulations, for: Vacuum chamber Platform... -

Page 59: Maintenance Work

13.3 Maintenance work We recommend that the machine has a full service once a year at least. The VC999 Customer Service Department is available for all service and servicing, on request. 13.3.1 Displayed servicing works The machine monitors the required services intervals itself. The following messages appear at the display. - Page 60 Insert the cutting wire and clamp it with a flat pliers taut with the threaded pins (74). IMPORTANT The sealing bar can also be sent to the VC999 customer service department for renewal of the Teflon strips or the sealing and cutting wires.

-

Page 61: Maintenance Vacuum Pumps

Vacuum Packaging Machines 07P ... Maintenance 13.3.3 Maintenance vacuum pumps 13.3.3.1 Rotary slide vacuum pump See oil change label on the machine. Every week The oil level in the level glass (55) must be between Min. and Max. • Top up with oil. Oil recommendation: BP Energol RC 100 ESSO Teresso 100... - Page 62 Vacuum Packaging Machines 07P ... Maintenance Suction filter The suction filter of the vacuum pump must be cleaned more or less frequently depending on the amount of dirt in the sucked in air. Procedure: • At the suction nozzle, unscrew the cover (80). The suction filter is behind the cover.

-

Page 63: Roots Vacuum Pump (07P

Vacuum Packaging Machines 07P ... Maintenance 13.3.3.2 Roots vacuum pump (07P... / 220W500) The oil level must be visible in the sight glass (60+62). Top up with oil if necessary. Oil recommendations: BP Energol RC 100 ESSO Teresso 100 Mobil DTE Oil extra heavy Shell Corena Oil H100 Oil changes IMPORTANT... -

Page 64: Replace Fuses

• After replacing the fine wire fuses replace the lid of the electrical switch box. Fig. 13/8 13.3.5 Replace the electronics board IMPORTANT In order to replace electronic components contact the VC999 customer service department. Page 64/74 Art. no. 527.763 2003-11-05... -

Page 65: Repairs

15.1 Ordering spare parts The VC999 Customer Service Department can provide you with a separate list of spare parts, on request. Comply with the following instructions when you order spare parts: • Check the machine to ascertain which part you need to order. -

Page 66: Disposal

Vacuum Packaging Machines 07P ... Disposal Disposal When you purchase lubricant and bag material, check that they are environmentally friendly and are not harmful to people. Also check the disposal regulations and the possibilities for disposing of these properly in your local area. The owner is responsible for disposing of the machine. -

Page 67: Pneumatics Diagram

Vacuum Packaging Machines 07P ... Pneumatics diagram Pneumatics diagram 2003-11-05 Art. no. 527.763 Page 67/74... -

Page 68: Circuit Diagrams

Vacuum Packaging Machines 07P ... Circuit diagrams Circuit diagrams Page 68/74 Art. no. 527.763 2003-11-05... - Page 69 Vacuum Packaging Machines 07P ... Circuit diagrams 2003-11-05 Art. no. 527.763 Page 69/74...

- Page 70 Vacuum Packaging Machines 07P ... Circuit diagrams Page 70/74 Art. no. 527.763 2003-11-05...

- Page 71 Vacuum Packaging Machines 07P ... Circuit diagrams 2003-11-05 Art. no. 527.763 Page 71/74...

-

Page 72: Sequence Diagram

Vacuum Packaging Machine 07P ... Sequence diagram Sequence diagram Page 72/74 Art. no. 527.763 2003-11-05... -

Page 73: Index

Vacuum Packaging Machines 07P ... Index Index Inert gas nozzles 17 Automatic operation 52 Inert gas quality 24 Autostart interval 36 Inert gas supply 34 Inert gas system 12 Initial settings 49, 51 Calibr. of the sealing time adjustment 58 Initial start-up 28 Calibration plug 58 Insertion frame 16... - Page 74 Vacuum Packaging Machines 07P ... Index Structure of the machine 16 Raise platform 41 Suction filter 66 Raise sealing bar time 53 Switch pump on 30 Rating plate 16, 69 Switching off the machine 32 Repair work 11, 68, 69 Switching on 30 Replace the electronics board 68 Replacing the sealing pads 64...

Need help?

Do you have a question about the 07P Series and is the answer not in the manual?

Questions and answers