Advertisement

Quick Links

Advertisement

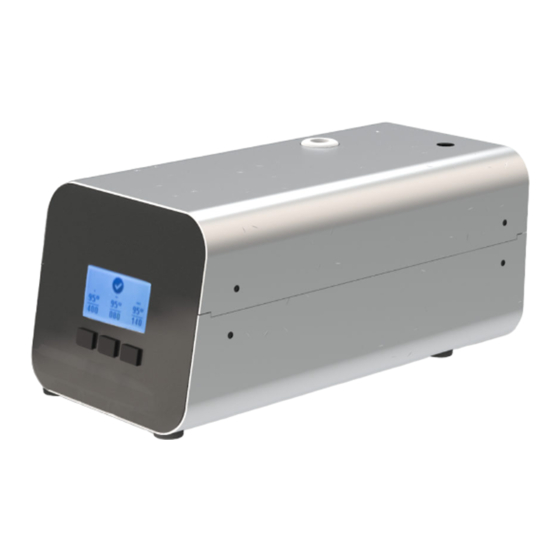

Summary of Contents for Marco POURD

- Page 1 Instruction Manual: 1900940 Machine P/N: 1000940#...

-

Page 2: Table Of Contents

Contents 1. Box Contents.......................2 2. Connections......................3 3. Connecting to BIB....................3 4. Installation......................6 POUR’D 3 Button font with boiler (Hot water, ambient concentrate, concentrate shot)....................6 POUR’D 3 Button font with Chiller (CHILLED water, cold concentrate, concentrate shot)....................7 POUR’D 3 Button/ 1 button font (3 volumes or ratios) ..........8 POUR’D 3 Button font Ready to drink (3 volumes)............10 POUR’D 1b Font (Concentrate or Ready to drink) ........... -

Page 3: Connections

Connections This equipment must be installed with adequate backflow protection to comply with all applicable federal, state and local codes. Connect to boiler Connect to font IEC Power or another control box cable (if applicable) Beverage tube to beverage source 5/16 to 3/8 barbed connector for soft tubing to BIB) - Page 4 Introduction The information provided in this manual is intended to assist in the installation and maintenance of the POUR’D Control Box. Please read the instructions carefully to prevent accidents and ensure an efficient installation. This manual is not a substitute for any safety instructions or technical data affixed to the machine or its packaging.

- Page 5 CAUTION SANITISATION Before sanitising the equipment, carefully read the instructions given by the sanitisation product manufacturer and put on all the necessary personal protective equipment (gloves, masks, etc.). Ensure that the premises are well ventilated. The sanitisation operations should only be carried out by specialised technical assistance personnel. DANGER ELECTRICAL MAINS Always disconnect the equipment from the electricity supply before doing any work on it, to prevent...

- Page 6 HOT/AMBIENT WATER, DILUTED CONCENTRATE & CONCENTRATE SHOT 3 button connections (1000942 3b concentrate) For use with Boiler Never place beverage source above control box to avoid (Plummed to mains) concentrate spilling on machine Hot water from Cold water hard 1/4” tube boiler 8mm tube Beverage tube control box to Din connector to font...

- Page 7 Control box setup 3 finger press short hold COLD MODE 000% 020% % CONCENTRATE 200ml P&H 30ml DISPENSE VOLUME (P&H = push and hold) Next MODE DESCRIPTION Hot Water (set ratio to 0% ) COLD Cold / ambient water mixed with concentrate (set ratio to 0% for just cold water) Ready to drink, undiluted concentrate Sparkling water...

- Page 8 CHILLED WATER, DILUTED CONCENTRATE & CONCENTRATE SHOT 3 button connections (1000942 3b concentrate) For use with chiller Cold water hard 1/4” tube Din connector to font Beverage tube control box to font hard 1/4” tube Beverage tube control box to font hard 1/4”...

- Page 9 Control box setup Calibrate conc pump Calibrate Hot water Calibrate Cold water RTD speed 3 finger press Calibrate Hot water long hold Chiller present RTD speed Next Next 3 finger press short hold COLD MODE 000% 020% % CONCENTRATE P&H 200ml 30ml DISPENSE VOLUME...

- Page 10 POUR’D DILUTED CONCENTRATE (3B/1B font, 3 volumes or ratios/ 1 volume or ratio) BIB beverage source Mains or chiller water Din connector to font Beverage tube control box to font hard 1/4” tube Cold water hard 1/4” tube Power cable Beverage source Mains water...

- Page 11 Control box setup 3 finger press short hold COLD COLD COLD MODE 025% 020% 050% % CONCENTRATE 200ml 200ml 100ml DISPENSE VOLUME (P&H = push and hold) Next MODE DESCRIPTION Hot Water (set ratio to 0% ) COLD Cold / ambient water mixed with concentrate (set ratio to 0% for just cold water) Ready to drink, undiluted concentrate Sparkling water...

-

Page 12: Concentrate Shot)

Connecting Hoses POUR’D Ready to Drink (3B font, 3 volumes) Power font to control box Power cable BIB coffee source Concentrate Shot/ Ready to Drink (1B Font, 1 Volume) Power font to control box BIB coffee source... - Page 13 POUR’D Multiple Source Ready to Drink 5/16 to 3/8 barbed connector Power cable Control box setup 3 finger press short hold MODE COLD COLD COLD 020% 025% 050% % CONCENTRATE 200ml 200ml 100ml DISPENSE VOLUME (P&H = push and hold) Next Control box directly in line with font must be set to PRIMARY...

-

Page 14: Engineering Setup & Calibration

Engineering Setup & Calibration 3 finger press long hold Calibrate conc pump Calibrate Cold water Calibrate Hot water RTD speed Next OPTION DESCRIPTION Calibrate conc pump Will pump concentrate using FAST speed for 10 seconds and ask for weight to be entered – then again the same at SLOW speed. (for accurate results make sure system is primed / tubes are full with liquid) Calibrate Cold water Will dispense water until flowmeter clicks 200 pulses and then will ask to... - Page 15 Button Setup Programmable buttons Program and change buttons accordingly...

-

Page 16: Cleaning

Cleaning CLEANING PROCEDURE MUST BE DONE DAILY Clean 1. Disconnect tubing from beverage source. 2. Put tubing into a bucket of cleaning solution. Cleaning solution recommended: Start cleaning? URNEX RINZA (follow Urnex instructions) 3. Press cleaning option on control box. 4. - Page 17 Operating Font 2. Push & Release 1. Push & Hold RISK OF SCALDING If using a boiler, turn off before cleaning to prevent accidental triggering of a dispense. Beware of accidentally operating the control box especially when cleaning around the push buttons. Do not use abrasive cloths or creams, as this will spoil the finish of the control box.

- Page 18 Marco Beverage Systems Limited. 63d Heather Road, Sandyford Industrial Estate, Dublin 18 t: +353 (0)1 295 2674 f: +353 (0)1 295 3715 e: sales@marco.ie www.marcobeveragesystems.com NSF/ANSI 4...

Need help?

Do you have a question about the POURD and is the answer not in the manual?

Questions and answers