Summary of Contents for Holland Green Science Hephaestus V094

- Page 1 User Manual 10310001/10310002 Hephaestus V094/V213 Vacuum Ovens User Manual Version 1.0...

-

Page 2: Table Of Contents

Table of Contents Disclaimer & Warranty ....................3 LIMITED WARRANTY & DISCLAIMER ..................3 LIMITATION OF LIABILITY ....................... 6 Safety ..........................7 Hephaestus V094/V213 Vacuum Ovens – Introduction..........9 III. Vacuum Oven Overview .....................10 Technical Specifications ....................12 Standards and Conformity ...................13 Inspection ........................14... -

Page 3: Disclaimer & Warranty

User Manual I. Disclaimer & Warranty • The intellectual property rights for this manual belongs to Holland Green Science Corporation (hereinafter referred to as “the Company”). • Products of the company are under the patent protection of China and other countries and regions (inclusive of obtained patents and patents currently under application). - Page 4 User Manual conformance with said published specifications; provided that Buyer shall (a) promptly notify the Company in writing upon the discovery of any defect, which notice shall include the product model and serial number (if applicable) and details of the warranty claim; and (b) after the Company's review, the Company will provide Buyer with service data and/or a Return Material Authorization ("RMA"), which may include biohazard decontamination procedures and other product-specific handling instructions, then, if applicable, Buyer may return the defective...

- Page 5 User Manual THE OBLIGATIONS CREATED BY THIS WARRANTY STATEMENT TO REPAIR OR REPLACE A DEFECTIVE PRODUCT SHALL BE THE SOLE REMEDY OF BUYER IN THE EVENT OF A DEFECTIVE PRODUCT. EXCEPT AS EXPRESSLY PROVIDED IN THIS WARRANTY STATEMENT, THE COMPANY DISCLAIMS ALL OTHER WARRANTIES, WHETHER EXPRESS OR IMPLIED, ORAL OR WRITTEN, WITH RESPECT TO THE PRODUCTS, INCLUDING WITHOUT LIMITATION ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE OR USE.

-

Page 6: Limitation Of Liability

User Manual For claims under the warranty please contact your local supplier. You may also send the instrument directly to manufacturer, enclosing the invoice copy and by giving reasons for the claim. LIMITATION OF LIABILITY NOTWITHSTANDING ANYTHING TO THE CONTRARY CONTAINED HEREIN, THE LIABILITY OF THE COMPANY UNDER THESE TERMS AND CONDITIONS (WHETHER BY REASON OF BREACH OF CONTRACT, TORT, INDEMNIFICATION, OR OTHERWISE, BUT EXCLUDING LIABILITY OF THE COMPANY FOR BREACH OF WARRANTY (THE SOLE... -

Page 7: Safety

User Manual Safety IMPORTANT Safety Items to be Observed. Safety Warnings ! DANGER (may cause serious damage to property and or casualties) 1. Please carefully read this user manual prior to operating the instrument and observe the instructions on safe operation. 2. - Page 8 User Manual ! ATTENTION (may affect operational performance or service life) 17. When pulling the power plug out from a power source, do not pull out using the power cord directly. 18. Only accredited and qualified professional repair technicians can open the instrument or conduct required repairs.

-

Page 9: Hephaestus V094/V213 Vacuum Ovens - Introduction

User Manual Hephaestus V094/V213 Vacuum Ovens – Introduction III. The Hephaestus V vacuum ovens are designed to efficiently process raw materials in a temperature controlled vacuum environment. This process has the following advantages: • The partial vacuum decreases the boiling point of water and thereby decreases the process temperature and increases the rate of moisture evaporation. -

Page 10: Vacuum Oven Overview

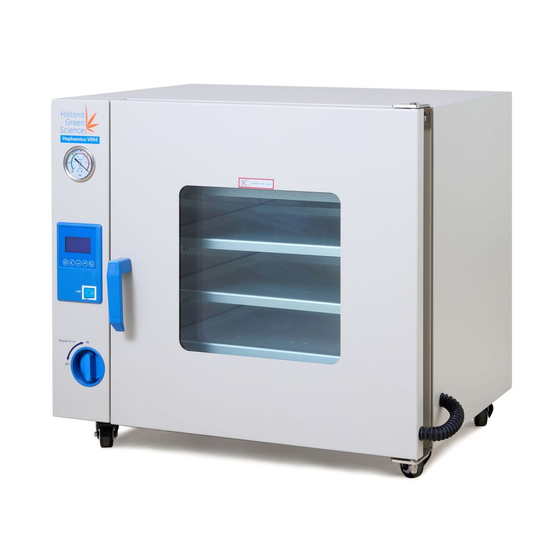

User Manual Vacuum Oven Overview vac-gauge controller LED switch vac-valve handle 6) LED inlet outlet/kf25 power switch 10) power cord 11) gas/air The Hephaestus V094/V213 vacuum oven uses 5-15P power plug (see figure below). Version 1.0... - Page 11 User Manual After Sales Support If problems are encountered or technical assistance support is required, when installing or using the instrument, please immediately contact the service department at ServiceUSA@hollandgreenscience.com. The Company may provide technical assistance and information regarding the instrument or equipment or service without charge at its sole discretion.

-

Page 12: Technical Specifications

User Manual Technical Specifications Model Index 10310001 10310002 Name AC 120V 60Hz Voltage Input Power 1350W 1550W Control Scope RT+10~200 RT refers to Environment Temperature (℃) Fluctuating Degree (℃) Attainable 133Pa Vacuum Degree Number of Shelves per Model (Layer) Inner Chamber 304 Stainless Steel Material Inner Chamber... -

Page 13: Standards And Conformity

User Manual Standards and Conformity Construction in Accordance with the following Safety Standards: UL 61010-1:2012 CSA C22.2#61010-1-12:2012 UL 61010-2-010:2015 CSA C22.2#61010-2-010:2015 Construction in Accordance with the following EMC Standards: EN 61326-1 Version 1.0... -

Page 14: Inspection

User Manual Inspection 6.1 Packing List Unpack the equipment carefully and check for any damage which may have arisen during transport. In the event of identified damage, please contact serviceusa@hollandgreenscience.com Type Item Description Quantity Main Unit Vacuum Oven Fittings Vacuum Connection Pipe Fittings Spanner Quick Setup Card... -

Page 15: Operating Instructions

User Manual VII. Operating Instructions 7.1 Temperature Controller Panel Description of Controller Panel Keys Press and hold the key for 3s or more to control the run/stop of the program. In the setup mode, press this key to add one number and hold the key to increase numbers successively. -

Page 16: Functions

User Manual 7.2 Functions • F1: first layer measurement temperature • F2: second layer measurement temperature • F3: third layer measurement temperature • F4: fourth layer measurement temperature • RUN/STOP: display of running status • 14: 09: time display of controller system •... -

Page 17: Priming The Vacuum Pump

User Manual 7.3 Priming the Vacuum Pump • Priming of the vacuum pump requires that the connecting tube provided is securely (airtight sealed) placed between the vacuum pump and the vacuum oven. • The oven door should be securely shut and the door handle secured in a closed position (this will prevent air from entering the chamber by causing the hole in the rubber plug and the hole in the pipe core to be 180 °... -

Page 18: Setting The Deviation Alarm And Timer

User Manual upper right comer, the system is in the running state and the screen will display values like timer, temperature measured inside the chamber. • At any time, you can always manually stop running by pressing the button for 4-5 seconds. -

Page 19: Setting The Pre-Set Start Function

User Manual Press the key so, that Timer numerical value is back lit displayed, indicating the timer can now be set as required, by pressing either the key. NOTE: If no operation is performed for a long time, the system automatically returns to the home screen. -

Page 20: Unit, Systm Timer And Password Settings

User Manual 7.10 Unit, SYSTM Timer and PASSWORD Settings • Unit:”0” ℃,”1” ℉ • YY: year; MM: month; DD: day; HH: hour; MM: minute; SS: second; (this is the apparatus system time setting) • PASSWORD: for direct input and changing of new password. 0: ℃... -

Page 21: Cautions

User Manual VIII. Cautions • Combustible materials and corrosive liquids or gases should not be placed in the vicinity of the drying cabinet. • If the product is excessively damp before drying, add a “precipitation” filter between the vacuum pump and the cabinet to avoid steam entering the pump. •... -

Page 22: Fault Diagnosis

User Manual Fault Diagnosis Fault Possible Causes Solution External power supply outlet has no Check power outlet power. The power plug is not correctly inserted Re-insert the power plug into the No Power into the socket socket check switched ‘ON’ Failed fuse Check the fuse. - Page 23 User Manual The vacuum pumping speed The vacuum pump is not the correct size should not be less than 2 Litres for the volume within the vacuum oven per second Various connecting flanges and pipes are Check all are securely fitted if not secured or coming loose not replace applicable fittings.

-

Page 24: Maintenance And Cleaning

User Manual Maintenance and Cleaning Proper maintenance and operation of the vacuum oven is required to ensure good working condition and extend the oven’s service life. Keep the vacuum oven dry and clean in routine operations. Clean the exterior of the vacuum oven with a non-abrasive cleanser and only connect the power supply when the oven surface is dry.

Need help?

Do you have a question about the Hephaestus V094 and is the answer not in the manual?

Questions and answers