Summary of Contents for Talon TP-60BA

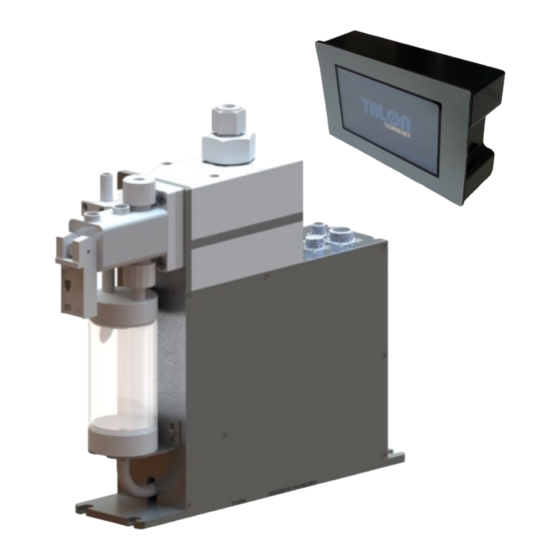

- Page 1 TP-60BA (Rev 2.2) HIGH VISCOSITY PR PUMP Pump & Controller – Built-in type MODEL : TP-60BA TALON TECH CO. LTD. TALON TECH CO. LTD.

-

Page 2: Table Of Contents

TP-60BA (Rev 2.2) CONTENTS 1. System Configurations……………………………………………………….……………..………………………………………………. 2. System Specifications…………………………………………………………………………………………………………..……………. 2-1. Pump [TP-60BA]……..……………………………………………………………………………………………………...……………... 2-2. Touch Pad [TTP-6008]……………………………………………………...……………………………………………………………. 3. System In/Exterior Names.……………………….……………………………………………………………………………………….. 3-1. Pump In/Exterior Names.…………………………………………………...…………………………………….…………………… 3-1-1. Pump Name Explanation..……….……….……………………………………………………………….………………..…. 3-2. Touch Pad Exterior Names……………..……….……………………………………………………………………………..…….. 3-2-1. Touch Pad Name Explanation………………………………………………………………………………………..……... 4. Wiring & Signal Interface……………………………………………………………………………………………………..………….. - Page 3 7-1. Pump Parts Dis/Assembly.………..………………………………………………………….…..…………………………………... 7-1-1. Pump Cover Dis/Assembly..……..………………………………………………………..………………………………….. 7-1-2. Driving Shaft Condition Check & Grease up on Ball Screw.…...………..…………………………………. 7-2. Suck-Back Setting………………………………………………………………………………………..……………………………….. 8. Recommended Spares/Mechanical Dimensions……………………………………………..……………………………… 8-1. TP-60BA Spare Parts……………………………………………………………………………….……..…………………………….. 8-2. Pump Dimensions…………………………………………………………………………………………..……………………………. 8-2-1. Front View…………………………………………………………………………………………………..…………………….…… 8-2-2. Side View……………………………………………………………………………………………………..………………………… 8-3. Touch Pad Dimensions………………………………………………………………………………………..………………………..

-

Page 4: System Configurations

RS422 Multi Drop method. By synchronizing with Windows CE Operating System, Touch Pad MMI Software operates TP-60BA pump. Be careful to use the pump by following this manual or Talon Tech’s acceptance. Or, other defects should be paid even under the warranty period. -

Page 5: System Specifications

TP-60BA (Rev 2.2) System Specifications 2-1 Pump [ TP-60BA ] ITEM SPEC REMARKS Dispense Volume Range 1.0cc ~ 10.0cc Dispense / Reload Rate 0.3 cc/sec ~ 1.2cc/sec Dispense Volume Resolution 0.05 cc Dispense Repeatability ≤±0.05 (0.8cp, 23℃) Viscosity 50cp ~ 10,000cp Step Angle Degree 0.3deg / step... -

Page 6: Touch Pad [Ttp-6008]

TP-60BA (Rev 2.2) 2-2 Touch Pad [ TTP-6008 ] ITEM SPEC REMARKS Main CPU 32Bit ARM920T 64Mb (OS:32Mb/App:32Mb) Flash NAND Flash 64Mb (OS:32Mb/App:32Mb) LCD Size 4.3 Inch TFT Wide (480*272) RTC Function Built-in Exchangeable Coin Battery Max. Connecting Pump No. -

Page 7: System In/Exterior Names

TP-60BA (Rev 2.2) System In/Exterior Names 3-1 Pump In/Exterior Names ② PR Out ⅜” ③ PR Drain ⅜” ① PR In ⅜” ⑥ Pump Connector ④ Toggle Valve ⑤ Buffer Tank 3-1-1 Pump Name Explanation ① PR In - Chemical supply. (⅜ Inch Teflon) ②... -

Page 8: Touch Pad Exterior Names

TP-60BA (Rev 2.2) 3-2 Touch Pad Exterior Names ① Touch Panel ② Power Source (DC12~24V) ④ Com Port (RS422) ③ Com Port (RS422) 3-2-1 Touch Pad Name Explanation ① Touch Panel - Touching area ② Power Source - Touch Pad Power DC12~24V Connector. -

Page 9: Wiring & Signal Interface

TP-60BA (Rev 2.2) Wiring & Signal Interface 4-1 Track Interface Signal [Input Signal] [Output Signal] - 6 - TALON TECH CO. LTD. -

Page 10: Track Timing Chart

TP-60BA (Rev 2.2) 4-2 Track Timing Chart 4-3 Dispense Trigger Select “0” Trigger Off “1” Trigger On Recipe Start1 Start2 Start3 Remark Select Not supported Cycle Recipe - 7 - TALON TECH CO. LTD. -

Page 11: Con1 Pin Assign [Track Cable]

TP-60BA (Rev 2.2) 4-4 CON1 Pin Assign [Track Cable] Standard Type Pin Assign Pin NO. Signal Name Description +24V Input Pump Main Power Source Input EX_+5V Input Home/End signal Power Home Output Pump Ready Signal Output Pump End Signal N.C EXH... -

Page 12: Con2 Pin Assign [Start Sol Cable]

TP-60BA (Rev 2.2) 4-5 CON2 Pin Assign [Dispense Trigger Cable] Standard / ACT / Mark Type Pin Assign Pin NO. Signal Name Description 12V~24V Input Recipe Select(+) Track Start1 Input Track Start2 Input Recipe Select(-) Track Start3 Input Not Use... -

Page 13: External Cable Length

TP-60BA (Rev 2.2) External Cable Length 5-1 CON1 Cable Standard Mark Type 5-2 CON2 Cable Standard Mark Type 5-3 422 In Cable 5-4 422 Out Cable - 10 - TALON TECH CO. LTD. -

Page 14: Touch Pad Operation

TP-60BA (Rev 2.2) Touch Pad Operation 6-1 Operation 6-1-1 Initial Screen The pumps’ ID, which are cable-connected to touch pad, are auto-searched every 5 sec. On every lower menu, if there isn’t any input for 1 min, the initial screen is back. The pump, which is not searched, cannot be chosen. -

Page 15: Select Function

TP-60BA (Rev 2.2) 6-1-3 Select Function When ID is chosen, the above screen is shown. Go to the previous menu. Dispense Dispense by touching the pad. Recipe Run Recipe & Dispense Recipe Setting. Config Pump Mode, Reset, Error & ID Setting. - Page 16 TP-60BA (Rev 2.2) 6-1-5 Recipe Setting For Recipe Setting, touch # under No. and input recipe # that you want to go in and touch ‘Ent’. At this time, Recipe Data is automatically shown on the screen. And you can input the data that you want and touch ‘set’...

-

Page 17: Configuration Of Pump

TP-60BA (Rev 2.2) 6-1-6 Configuration of Pump On Config Pump, the password needs for the important items’ set. The password is set as ‘0901’. Vital Check pump’s response and in case of response, ‘vital’ window activates and disappears right away. At the left window, the response data is shown. -

Page 18: Maint Mode, Run Mode, Pump Reset Setting

TP-60BA (Rev 2.2) On Config Pump screen, when you touch ‘Set ID’, Password input screen shows and input ‘0901’and touch Ent. And then, ‘Check ID’ ‘Set ID’ screen shows and disappears right away so the initial starts. If there is no response from the pump, the window keeps showing. If there is already the same pump ID, the window –... -

Page 19: Calibration

TP-60BA (Rev 2.2) 6-1-9 Calibration Calibration – Per each Recipe, it is possible to set the calibration value. If there is the differences between the real value and the setting value, set the calibration value higher or lower % at the standard- 100. - Page 20 TP-60BA (Rev 2.2) After clicking Set, the window goes to Password window. The setting value is adopted after inputting “2580”. Cancel button means no application even Limit change & Count Zero click. When dispense # goes over Limit Setting value, “Count Over” shows on Main Menu and also shows on Touch pad.

-

Page 21: Example

TP-60BA (Rev 2.2) 6-2 Example 6-2-1 Dispense If you want to dispense one time, use Start Run. This recipe is Run recipe which set on Recipe menu. Start Cycle below is 4 Recipe. Stop Cycle only works the case of using Start Cycle. Keep touching Stop Cycle button. -

Page 22: Recipe Setting

TP-60BA (Rev 2.2) 6-2-2 Recipe Choose the recipe # and touch ‘Ent’ button. The chosen recipe data is automatically read from the pump. Set the recipe’s volume & time and touch ‘Set’ button. - 19 - TALON TECH CO. LTD. -

Page 23: Id Setting

TP-60BA (Rev 2.2) 6-2-3 ID Setting Choose ID # which you want to change from 11~44. ID consists of 2 digits. The 2 digit means Coater# and the 1 digit means Nozzle#. Total 16 ID setting is possible. [Password : 0901] - 20 - TALON TECH CO. -

Page 24: Name Setting

TP-60BA (Rev 2.2) When ID changes, check the automatic pump initialization and the change is applied on Main Menu. 6-2-4 Name Setting The pump name can be changed on Main Menu and the max digit is 18~25. - 21 -... -

Page 25: Reset On Pump Error

TP-60BA (Rev 2.2) 6-3 Reset on Pump Error 1. Choose the alarmed pump. [PIC 1] 2. Touch Config button on Select Function menu. [PIC 2] 3. Push Pump Reset button - Push OK button “Are you Sure?” window. - Right after touching OK, Reset progresses and Alarm is clear. -

Page 26: Log Data

1. Set the date to check out. 2. Set ID to check out. (In case of ‘ 0 ‘, search all ID) 3. Click Query. The contents are shown as Text /Code. Contact Talon for detail. - 23 - TALON TECH CO. LTD. -

Page 27: Log Data Analysis

TP-60BA (Rev 2.2) 6-4-1 Log Data Analysis At the right of date & time, there are ' O ' , ' I ' , & ' U '. 1. [ O ] Touch Pad (Command) -> Controller. 2. [ I ] Touch Pad <- Controller. (Response) 3. -

Page 28: Touch Pad Menu Tree

TP-60BA (Rev 2.2) 6-5 Touch Pad Menu Tree 6-5 Notice 6-5-1 Dispense Cycle During the system or the manual dispense, the pump doesn’t save Recipe changes and setting changes. At this time, ‘Busy’ window is shown normally. 6-5-2 Pump ID Setting The basic ID is ‘11’. -

Page 29: Notice On Pump Operation

TP-60BA (Rev 2.2) 6-6 Notice on Pump Operation 1. During Pump is under process (RUN OR CYCLE) don’t try to modify the data. (Please do it after Pump had stop properly) ▶ In this term of “modify data” means changing recipe, cycle, CAL value etc. If you modified the data during pump operation, BUSY screen will be pop-up and it will be not saved. -

Page 30: Maintenance

TP-60BA (Rev 2.2) Maintenance 7-1 Pump Parts Dis/Assembly 7-1-1 Pump Cover Dis/Assembly 1. As per the below [PIC 1], use 2mm wrench to release Pump Cover Mounting M3 Screw(14ea) to open the cover. 2. The assembly is the reverse order of the disassembly. -

Page 31: Suck-Back Setting

TP-60BA (Rev 2.2) Don’t disassemble the moving parts, which can be the root cause of any problems. 7-2 Suck-Back Setting ③ Suck-Back Volume (Adjust PR volume) ③-① Lock Nut ② Cut Off (PR Cut Timing) ②-① Lock Nut ④ Suck-Back Speed (Adjust Suck-back speed) ④-①... - Page 32 TP-60BA (Rev 2.2) 2mm in 1 sec to rotate the speed control knob②. 7. If Suck-Back Speed ④ is too fast, turn it CW, too slow, turn it CCW. 8. Fasten every knob’s lock nut. (①-①, ②-①, ③-①, ④-①) 9. Dispense resist again to final check.

-

Page 33: Recommended Spares/Mechanical Dimensions

TP-60BA (Rev 2.2) Recommended Spares / Mechanical Dimensions 8-1 TP-60BA Spare Parts Division Part NO. Description TL-60BA-TA-001 Cylinder TL-60BA-TA-002 Outer Type Edgeless Bellows TL-60BA-CA-001 Toggle Valve TL-60BA-TA-003 TL-60BA-TA-004 ⅜” Fitting Nut TL-60BA-TA-005 Out Cap TL-60BA-TA-006 Buffer Tank Ass’y TL-60BA-MA-001 Ball Screw... -

Page 34: Pump Dimensions

TP-60BA (Rev 2.2) 8-2 Pump Dimensions 8-2-1 Front View 8-2-2 Side View - 31 - TALON TECH CO. LTD. -

Page 35: Touch Pad Dimensions

TP-60BA (Rev 2.2) 8-3 Touch Pad Dimensions 8-3-1 Front View 8-3-2 Rear View 7-3-3 Side View - 32 - TALON TECH CO. LTD. -

Page 36: Installation Method

TP-60BA (Rev 2.2) 8-4 Installation Method 8-4-1 Pump Installation Sequence 1. Prepare the space for the pump installation. 2. As per the below picture, tighten the panel base plate with 4 pieces of M4 screw. Make 3.4mm hole and Tap M4. -

Page 37: Touch Pad Installation Method

TP-60BA (Rev 2.2) 8-4-3 Touch Pad Installation Method Back Cover [PIC 1] Equipment-side Panel Touch Pad [PIC 2] [PIC 3] 1. As per [PIC 1], peel the sticker a little until the screw is seen. And loose the screw to take the back cover apart. -

Page 38: Suggested Recipe Setting Value

TP-60BA (Rev 2.2) 3. As per [PIC 2], install the touch pad on the equipment. 4. The panel type can be changed up to the equipment’s position. 8-4-4 Suggested Recipe Setting Value (PR viscosity: 1,800cP) Volume(g) Data Input Dispense/Time Data Input... - Page 39 TP-60BA (Rev 2.2) <THE END> - 36 - TALON TECH CO. LTD.

Need help?

Do you have a question about the TP-60BA and is the answer not in the manual?

Questions and answers