Summary of Contents for All-Flo A100

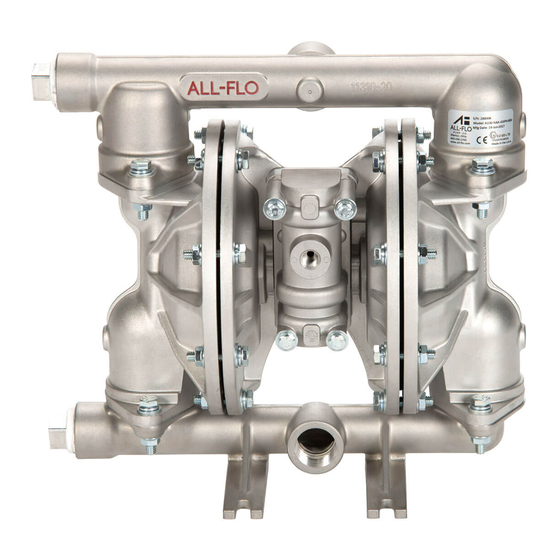

- Page 1 PUMP OPERATIONS & MAINTENANCE MANUAL A100 - 1 INCH AIR OPERATED DOUBLE DIAPHRAGM PUMP all-flo.com...

-

Page 2: Table Of Contents

TORQUE SPECIFICATIONS ............18 SECTION 8 EXPLODED VIEWS AND PARTS LISTS 19-24 ALUMINUM AND STAINLESS ..........STEEL (NON-PTFE DIAPHRAGMS) ......19-21 ALUMINUM AND STAINLESS ..........STEEL (PTFE DIAPHRAGMS) ........22-24 SECTION 9 ELASTOMERS AND REPAIR KITS SECTION 10 WARRANTY AND REGISTRATION all-flo.com... - Page 3 Temperature limits are solely based upon mechanical stress and certain chemicals will reduce the maximum operating temperature. Consult a chemical resistance guide for chemical compatibility and a more precise safe temperature limit. Always use minimum air pressure when pumping at elevated temperatures. all-flo.com...

- Page 4 AIR END REPAIR KIT consist of diaphragms, (back-up diaphragms if required), balls, Air end repair kit contains pilot seats and seat O-rings. sleeve assembly and main air valve. See matrix below. INTERMEDIATE / INNER CHAMBER A = Aluminum Bold indicates recommended options all-flo.com...

- Page 5 Wet end kits are available and Air end repair kit contains pilot consist of diaphragms, (back-up sleeve assembly and main air valve. diaphragms if required), balls, seats and seat O-rings. See matrix below. INTERMEDIATE / INNER CHAMBER A = Aluminum Bold indicates recommended options all-flo.com...

- Page 6 The process of alternating right suction / left discharge (and vice-versa) continues as long as compressed air is supplied to the pump. all-flo.com...

- Page 7 6.3” (160mm) 1.3” (33mm) 4.0” (102mm) 5.2” (132mm) 3/4”-14 FNPT (Exhaust Port) *Note - Suction Center Front / Discharge Center Rear are default ports. See part number matrix option code for additional porting options. **Note - Standard Muffler Shown all-flo.com...

-

Page 8: Performance Curves

*Flow rates indicated on all three charts shown were determined by pumping water at flooded suction. For optimum life and performance, pumps should be specified so that daily operation parameters will fall in the center of the pump performance curve. all-flo.com... -

Page 9: Installation

In the event of a diaphragm failure this will reduce or eliminate the possibility of liquid discharging through the exhaust onto the ground. LOCATION Ensure that the pump is installed in an accessible location, in order to facilitate future service and maintenance. all-flo.com... - Page 10 SUGGESTED INSTALLATION This illustration is a generic representation of an air operated double-diaphragm pump. all-flo.com...

-

Page 11: Troubleshooting

Pump may be cavitating, reduce speed of operation Suction strainer clogged Pump Will Not Prime Air leak in suction pipe Air leak in pump manifold connections Suction strainer and lines clogged Excessive lift conditions Check valve wear Debris in check valve all-flo.com... -

Page 12: Operation

(Closing or partially closing a liquid suction valve restrict the suction line and may cause damage to the diaphragms.) Suction strainers may be employed to reduce or eliminate larger solids, but routine maintenance is necessary in order to prevent a restriction on the suction. all-flo.com... -

Page 13: Repair And Assembly

STEP 4 STEP 5 STEP 6 Using the 1/2 inch wrenches re- Remove the “Suction Manifold”. Remove the “O-Ring”, “Valve Seat” move four “Hex-Head Cap Screws and “Ball”. (5/16”-18 x 1-3/8”)” and four “Compression Washers (5/16”)” from the “Suction Manifold”. all-flo.com... - Page 14 PUMP WET END ASSEMBLY To assemble the wet end of the pump, reverse the order of disassembly. Ensure all hardware is fastened in accordance with torque specifications (see page 18). Inverting one of the diaphragms during reassembly will facilitate ease of assembly. all-flo.com...

-

Page 15: Air Valve Removal

“Air-Valve Assembly”. main “Air-Valve Assembly”. the “Air Valve End Plug” from the main “Air-Valve Assembly”. Note: The smooth shinny side of the shuttle plate should be toward Ensure the “O-Ring” is installed the shuttle car. when reassembling. all-flo.com... - Page 16 Note that if the lip-seals are installed incorrectly, they will be unable to rotate. Insert the spool, the spool’s shorter piston is to be on the plug side, ensure O-ring is enstalled, and then the air-valve end plug into position. all-flo.com...

-

Page 17: Pilot Valve Removal

Using two 7/16 inch wrenches, Remove the “Pilot Sleeve” from (Pilot Sleeve)” and four “O-Rings disassemble the “Diaphragm Rod the disassembled “Diaphragm (Pilot Sleeve)” from the pilot Assembly” into its two parts. Rod Assembly”. sleeve assembly. Note they are installed with thread locker. all-flo.com... -

Page 18: Torque Specifications

Manifold Bolts 115 in-lbs (13 N-m) 1/2” Chamber Bolts 85 in-lbs (9.6 N-m) 1/2” Air Valve Bolts 40 in-lbs (4.5 N-m) 7/16” Diaphragm plate 70 in-lbs (7.9 N-m) 3/4” Diaphragm plate (PTFE) 70 in-lbs (7.9 N-m) 3/4” IN/FT-LBS (N•m) all-flo.com... -

Page 19: Exploded Views And Parts Lists

SECTION EXPLODED VIEW & PARTS LIST ALUMINUM & STAINLESS STEEL A100-*A*-****-*** (NON-PTFE DIAPHRAGM) all-flo.com... - Page 20 PARTS LIST - ALUMINUM & STAINLESS STEEL A100-*A*-****-*** (NON-PTFE DIAPHRAGM) ITEM DESCRIPTION PUMP MODEL PART NO. MATERIAL PILOT SLEEVE All Models 10105-31 Acetel INNER SPACER (PILOT SLEEVE) All Models 10203-40 Polyproplyene END SPACER (PILOT SLEEVE) All Models 10209-40 Polyproplyene 4 & 5 DIAPHRAGM ROD ASSEMBLY...

- Page 21 PARTS LIST - ALUMINUM & STAINLESS STEEL A100-*A*-****-*** (NON-PTFE DIAPHRAGM) ITEM DESCRIPTION PUMP MODEL PART NO. MATERIAL LIP SEAL (AIR VALVE) All Models 12003-76 Nitrile AIR VALVE GASKET All Models 12125-19 Nitrile WASHER (1/4”) A100-*AA-****-*** 12300-25 Plated Steel A100-*A3-****-*** 12300-26...

- Page 22 EXPLODED VIEW & PARTS LIST ALUMINUM & STAINLESS STEEL PUMPS A100-*A*-T***-*** (PTFE DIAPHRAGM) all-flo.com...

- Page 23 PARTS LIST - ALUMINUM & STAINLESS STEEL A100-*A*-T***-*** (PTFE DIAPHRAGM) ITEM DESCRIPTION PUMP MODEL PART NO. MATERIAL PILOT SLEEVE All Models 10105-31 Acetel INNER SPACER (PILOT SLEEVE) All Models 10203-40 Polyproplyene END SPACER (PILOT SLEEVE) All Models 10209-40 Polyproplyene 4 & 5 DIAPHRAGM ROD ASSEMBLY...

- Page 24 PARTS LIST - ALUMINUM & STAINLESS STEEL A100-*A*-T***-*** (PTFE DIAPHRAGM) ITEM DESCRIPTION PUMP MODEL PART NO. MATERIAL LIP SEAL (DIAPHRAGM ROD) All Models 12000-76 Nitrile LIP SEAL (AIR VALVE) All Models 12003-76 Nitrile AIR VALVE GASKET All Models 12125-19 Nitrile WASHER (1/4”)

-

Page 25: Elastomers And Repair Kits

Geolast is a registered trademark of ExxonMobil Chemical Co. ® Santoprene is a registered trademark of ExxonMobil Chemical Co. Teflon ® is a registered trademark of DuPont Performance Elastomers L.L.C. Magnalube ® is a registered trademark of Carleton-Stuart Corp. all-flo.com... - Page 26 IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, AND ANY IMPLIED WARRANTIES OTHERWISE ARISING FROM A COURSE OF DEALING OR TRADE. All-Flo will not, in ANY event, be liable for any loss of profit, interruption of business or any other special, consequential or incidental damages suffered or sustained by Customer.

- Page 27 all-flo.com...

- Page 28 ALL-FLO is committed to the pursuit of designing and manufacturing the highest quality product available to industry. Since the beginning in 1986, All-Flo engineers have used their extensive knowledge of today’s engineered materials, advanced air system logic and manufacturing techniques to develop the superior group of lube-free, air-operated diaphragm pumps found in this catalog.

Need help?

Do you have a question about the A100 and is the answer not in the manual?

Questions and answers