Table of Contents

Advertisement

Quick Links

MTH DDA4OX DIESEL ENGINE

OPERATING INSTRUCTIONS

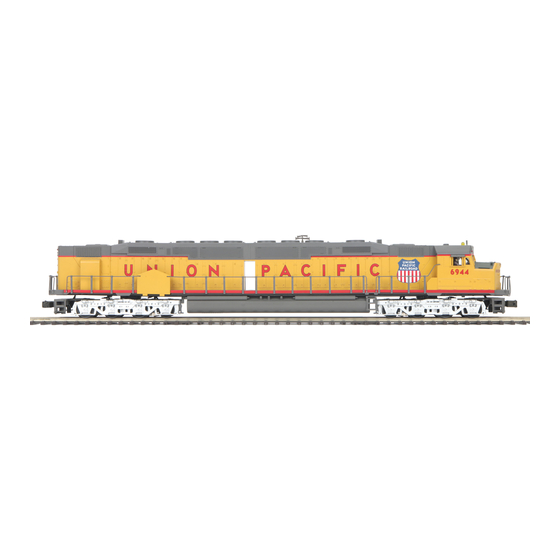

Thank you for purchasing the MTH Electric Trains DDA4OX diesel

locomotive. This ¼" scale reproduction of the famous DDA4OX

locomotive measures over 25" in length and weighs almost 8 pounds.

Despite its scale size, the locomotive is capable of operating on O-72 3-rail

track with any compatible AC transformer, (see page 34 for a complete list

of compatible transformers and wiring instructions) and is completely

compatible with most other 3-rail locomotives, rolling stock and

accessories.

The locomotive is equipped with several deluxe features that are simple

and fun to operate. Each feature is described among the following pages

which should be read before the engine is operated. For those of you who

can't wait to get started, the Quick Start Operating Instructions, found on

page 3, should be read so that you understand the basics of the operating

system.

E L E C T R I C

T R A I N S

R

Advertisement

Table of Contents

Summary of Contents for MTHTrains DDA4OX DIESEL ENGINE

- Page 1 E L E C T R I C T R A I N S MTH DDA4OX DIESEL ENGINE OPERATING INSTRUCTIONS Thank you for purchasing the MTH Electric Trains DDA4OX diesel locomotive. This ¼” scale reproduction of the famous DDA4OX locomotive measures over 25” in length and weighs almost 8 pounds.

-

Page 2: Table Of Contents

Table Of Contents QUICK START - BASIC OPERATION(All 3-Rail Models) PROTOSMOKE™ UNIT OPERATION PROTOSOUNDS® OPERATING INSTRUCTIONS ProtoSound® DCRU® Reverse Unit Operation (All 3-Rail Models) Horn Operation Bell Operation ProtoCoupler™ Operation Cab Chatter Sounds Squeaking Brake Sounds Tips On Using The Squeaking Brake Sounds Freight Yard Sounds (FYS) Activating and Triggering Freight Yard Sounds Tips On Using FYS Features... -

Page 3: Quick Start - Basic Operation(All 3-Rail Models)

QUICK START - BASIC OPERATION The MTH DDA4OX contains state-of-the art electronics with several built-in automatic features for incredibly realistic operation. Despite these advanced features, the DDA4OX is easy to operate with any compatible standard AC transformer (see the compatibility chart on page 34). All models are equipped with an operating smoke system that should be primed with smoke fluid before operating. -

Page 4: Protosmoke™ Unit Operation

PROTOSMOKE™ UNIT OPERATION The DDA4OX contains a self-powered smoke unit that outputs a steady stream of smoke through the smoke stack on the roof of the engine. The ON/OFF switch located next to the power truck must be in the ON position in order for the smoke unit to function. See Fig. 1 on page 3. -

Page 5: Protosounds® Operating Instructions

PROTOSOUNDS® INSTRUCTIONS The MTH ProtoSound® digital sound and train control system provides the operator with unprecedented realistic operation on your model railroad. In addition to actual diesel engine, CD-equivalent 16-bit digital sounds, you get the following features: * Built-In ProtoSound® DCRU® Reverse Unit * Authentic Diesel Horn Sound* Authentic Diesel Bell Sound* Squeaking Brake Sound* Freight Yard Sounds* Operating Remote Controlled ProtoCoupler™* Self-Recharging Battery Back- Up System With Automatic Battery Shut-Off* Remotely Controlled Reverse Unit... -

Page 6: Horn Operation

enter RESET, wait for the diesel startup sounds to begin and then slowly turn the transformer throttle to the off position and then back on again to enter the forward phase. Interrupting the power too quickly may cause the system to re-enter RESET (signaled by two dings of the bell). Should this happen, wait longer before interrupting the power to enter the Forward phase. -

Page 7: Protocoupler™ Operation

button, the bell can be controlled through your transformer’s whistle button whenever the engine is in NEUTRAL. The bell will never ring continuously in RESET (Remember NEUTRAL is the state between Forward and Reverse). Once the bell is turned on, it will continue to ring when the engine is cycled into forward or reverse until you press the bell button or re-enter NEUTRAL and turn the bell off with the whistle button. -

Page 8: Cab Chatter Sounds

the air lines coming apart. It can best be described as a CHA-CHUSHHH sound. The coupler doesn’t have to be fired in NEUTRAL. Once the coupler is armed it can be fired in Forward, Neutral or Reverse. However, you may find that the coupler Lubricate doesn’t open when firing the ProtoCoupler™... -

Page 9: Tips On Using The Squeaking Brake Sounds

found later in this manual. The sound itself is a stored record on the ProtoSounds® software chip and will always play the same brake sound for the same three second length each time the voltage is reduced from high to low. -

Page 10: Freight Yard Sounds (Fys)

FREIGHT YARD SOUNDS (FYS) ProtoSounds® comes equipped with operator controlled Freight Yard Sounds, hereby referred to as FYS. This easy to use feature plays digitally reproduced freight yard sounds whenever your engine stops on your layout and is parked in the Neutral position. No additional wires or modifications are needed on your layout to enjoy these amazing sound effects. - Page 11 carefully, you should hear an air release sound after three seconds have passed. At this time you can release the bell button. (Note: because the air release sound may be difficult to hear, we recommend that you count out a full three seconds before releasing the bell button.) The bell will continue to chime, so if you want to turn off the bell ringing, simply press and release the bell button a second time.

- Page 12 ACTIVATING THE FREIGHT YARD SOUNDS Before FYS can be heard, the feature must be armed as described on the proceeding pages. Once armed, activating the FYS effects is accomplished by simply interrupting the transformer throttle and parking the engine in the Neutral position with track power remaining on.

- Page 13 B. After entering Neutral, ProtoSounds® will immediately play an air release sound followed approximately 2 seconds later by a radio arrival message (cab chatter). Immediately following the radio arrival Listen For Air Release Sound And Cab Chatter Message message, the sound of freight car doors can be heard opening, followed by the sounds of freight loading and unloading.

-

Page 14: Tips On Using Fys Features

Event 5: (Forward) The operator now interrupts the transformer throttle again to enter the next reverse unit phase; Forward. FYS confirms to the operator that it has entered the Forward phase by playing a radio messagne followed by the freight car door closing. Within 2 seconds of the door closing, the locomotive bell begins chiming. - Page 15 Tip #4: You can utilize FYS even if you are double-heading with another engine regardless of whether the second engine is equipped with an FYS programmed ProtoSound® module. If the second engine isn’t equipped with FYS, the only thing to remember is that you not turn up the transformer throttle very high when entering the Reverse phase found in Event 3.

-

Page 16: Self-Recharging Battery Backup System

SELF-RECHARGING BATTERY BACKUP ProtoSounds® state-of-the-art design includes a self-recharging battery backup system for improved performance at any speed. The battery ensures that power to the sound system will remain on during directional changes, setting RESET options or when travelling over dirty track and switches. The self-recharging battery backup system is automatically turned on or off whenever track power is turned on or are off. -

Page 17: Protosound® Volume Adjustment

substituted as a temporary fix, but since alkaline batteries can’t take a charge, it will eventually wear down. Regardless, it should give you a week to a couple of months use while you wait for your replacement ProtoSound® battery to arrive. PROTOSOUND®... -

Page 18: Using "Reset" To Program Protosounds

USING “RESET" TO PROGRAM PROTOSOUNDS® As mentioned earlier, there are several programmable options in each ProtoSound®-equipped engine that can be remotely set from any compatible standard AC transformer equipped with a whistle button. For a list of compatible transformers, see the chart on page 34. This hands-off approach gives you unprecedented control of your railroad empire’s motive power never before seen in model railroading. -

Page 19: Setting The Engine Volume

times the throttle is advanced by playing back the number of “Clinks" and “Clanks" to confirm the feature you’ve selected. SETTING THE ENGINE VOLUME Of all the sounds that come with each ProtoSound®-equipped locomotive, the one most often turned down is that of the engine volume because it is the one sound normally heard whenever the engine is running and is what usually can become tiresome to the ear over prolonged running sessions. -

Page 20: Programming For A Separate Bell Button Controller

PROGRAMMING FOR A SEPARATE BELL BUTTON CONTROLLER To operate ProtoSounds® with a separate bell button controller, like the Lionel® No. 5906 bell button, you will need to wire up the controller to your Common transformer and track as shown in Fig. 5. Once the button is RED Wire BLACK Wire wired, ProtoSounds®... -

Page 21: Programming For Horn In Neutral Operation

Feature 45. (See the section Using RESET To Program ProtoSounds® on page 18). Once in Feature 45, press the whistle button and wait for the module to sound a bell ding(s). Continue pressing the whistle button until the module plays back one ding for option 1 - Squeaking brakes are activated by the bell button. -

Page 22: Programming For Protocoupler™ Operation

ProtoSounds® has been programmed to sound the horn in neutral). Turn the throttle off and then on again to “Lock-In" your selection. Now, whenever you are in neutral, you can blow the horn with the transformer whistle button. To reset ProtoSounds® to its original factory setting of no horn in neutral, repeat the above procedure but keep pressing the whistle button in Feature 25 until ProtoSounds®... -

Page 23: Programming For Fys Operation

want to stop at a yard and have both engines playing their FYS sound effects. To In RESET Mode Move The Throttle Push The Whistle Button Up & Down From Until You Hear turn off FYS, enter RESET High Voltage To Low 2 Bell Dings 28 Times and go to Feature 28. -

Page 24: Programming For Cab Chatter Sounds

To lock in the setting, simply turn the throttle all the way off and then back on again. To turn the Remote Lockout Control setting back off, go back to Feature 40 and press the whistle button until only one bell ding sounds. To lock in the setting, simply turn the transformer throttle off and then back on again. -

Page 25: Reverse Unit Lock-Out Operation

REVERSE UNIT LOCK-OUT OPERATION ProtoSounds® unique design eliminates the need for a lock-out switch on the locomotive by allowing the customer to lock the engine into any directional state (forward, neutral or reverse) from the transformer. This will allow users to run the engine on layouts equipped with block signals or stop stations which would normally cycle the engine back into neutral. - Page 26 of the horn. QUICKLY TURN THE POWER BACK ON AGAIN. Your engine is now locked into NEUTRAL. : When locking the engine in the Forward or Reverse positions, the whistle button will NOTE blow the whistle. But when locking the engine into the NEUTRAL position, the whistle button may turn on or off sounds of the bell, coupler arming or coupler firing depending on the transformer throttle voltage settings prior to the user’s attempt to lock out the engine.

-

Page 27: Oil & Lubrication Instructions

OIL & LUBRICATION INSTRUCTIONS In order for the engine to perform correctly and quietly, it is important that the chassis be lubricated before operation. Lubrication should include all Lubricate Pickups (L) Lubricate Blind Wheel Axle (L) Grease Gears (G) Figure 6: Lubricating The Locomotive Chassis gears, axles and pickup rollers to prevent them from squeaking. -

Page 28: Traction Tire Replacement Instructions

Periodically, check the locomotive wheels and pickups for dirt buildup as this can significantly affect the engine’s ability to perform properly. Dirty track and dirty wheels can cause both poor electrical contact as well as poor traction, especially on elevated track sections. Finally, dirt and oil build up can prematurely wear out the neoprene traction tires. -

Page 29: Light Bulb Removal & Replacement

fully seated inside the groove. Any portion of the tire extending out of the groove can cause the engine to wobble. A razor blade can be used to trim away any excess tire that doesn’t seat itself inside the groove properly. Replacement tires are available directly from MTH Electric Trains. -

Page 30: Trouble Shooting Protosound® Problems

TROUBLE SHOOTING PROTOSOUND® PROBLEMS Although ProtoSound® has been designed and engineered for ease of use, some questions may arise during initial operation. The following table should answer most questions. If you find that your problem can’t be resolved with this manual, contact MTH ProtoSound® Electronics (7020 Columbia Gateway Drive, Columbia, MD 21046, 410-381-2580) for additional assistance. - Page 31 COUPLER PROBLEMS REMEDY DIESEL START/CAB CHATTER REMEDY LOCKOUT PROBLEMS REMEDY VOLUME PROBLEMS REMEDY MTH DDA4OX Diesel Operating Manual...

- Page 32 BATTERY PROBLEMS REMEDY RESET PROBLEMS REMEDY BRAKE SOUND PROBLEMS REMEDY MTH DDA4OX Diesel Operating Manual...

-

Page 33: Protosound Reset Feature Chart

FYS PROBLEMS REMEDY PROTOSOUND RESET FEATURE CHART The following chart lists the available features found in your ProtoSound® equipped engine. The default settings are listed for each feature as well as the operation of the feature. You can reset all features to their original factory settings by accessing Feature 18 in RESET and then pressing and holding the transformer whistle button until you hear a soft, warbled bell sound. -

Page 34: Transformer Wiring Chart

TRANSFORMER COMPATIBILITY AND WIRING CHART ProtoSounds® is designed to work with any standard AC transformer that uses a “Pure Sine-Wave" format. The chart below lists the many Lionel® compatible transformers, such as the Lionel KW or ZW models. In addition, the chart details how the terminals on these compatible transformers should be attached to your layout. - Page 35 O-72 OPERATION While the DDA4OX engine is more than capable of operating on O-72 curves and switches, you may find that certain light freight cars are prone to derailing when being pulled or pushed by the DDA4OX through O-72 switches. Should this occur, we suggest adding weight to the cars making them heavier and less likely to derail.

-

Page 36: Service And Warranty Information

SERVICE & WARRANTY INFORMATION HOW TO GET SERVICE UNDER THE TERMS OF THE LIMITED ONE YEAR WARRANTY For warranty repair, do not return your product to the place of purchase. Instead, follow the instructions below to obtain warranty service as our dealer network is not prepared to service the product under the terms of this warranty.

Need help?

Do you have a question about the DDA4OX DIESEL ENGINE and is the answer not in the manual?

Questions and answers