Troy-Bilt series 650 Operator's Manual

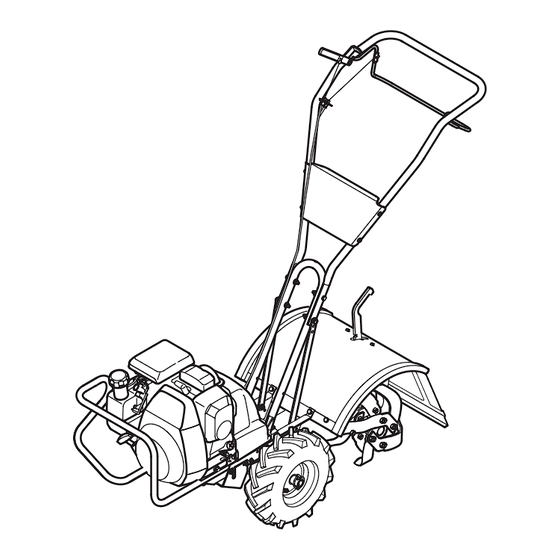

Rear tine tiller

Hide thumbs

Also See for series 650:

- Illustrated parts manual (12 pages) ,

- Operator's manual (24 pages)

Advertisement

Table of Contents

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

O

'

M

peratOr

s

anual

Rear Tine Tiller — 650 Series

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-03621

(January 23, 2008)

Advertisement

Table of Contents

Summary of Contents for Troy-Bilt series 650

- Page 1 READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE THIS MACHINE. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 Printed In USA Form No. 769-03621...

-

Page 2: Table Of Contents

Call a Customer Support Representative at (800) 828-5500 or (330) 558-7220 ◊ Write us at Troy-Bilt LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019 This product has met the rigid safety standards of the Outdoor Power Equipment Institute and an independent testing laboratory. -

Page 3: Safe Operation Practices

Important Safe Operation Practices WARNING! This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. - Page 4 When practical, remove gas-powered equipment from the truck or trailer and refuel it on the ground. If this is not possible, then refuel such equipment on a trailer with a portable container, rather than from a gasoline dispenser nozzle. Keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete.

-

Page 5: Spark Arrestor

If the fuel tank has to be drained, do this outdoors. Observe proper disposal laws and regulations for gas, oil, etc. to protect the environment. Notice Regarding Emissions Engines which are certified to comply with California and federal EPA emission regulations for SORE (Small Off Road Equipment) are certified to operate on regular unleaded gasoline, and may include the following emission control systems: Engine Modification (EM), Oxidizing Catalyst (OC), Secondary Air... -

Page 6: Assembly & Set-Up

Assembly & Set-Up Contents of Carton • One Tiller • One Operator’s Manual WARNING! To prevent personal injury or property damage, do not start the engine until all assembly steps are complete and you have read and understand the safety and operating instructions in this manual. - Page 7 Using two 5⁄16”-18 x 1-3⁄4” screws and 5⁄16”-18 hex nuts, loosely attach the handlebar support using the upper holes. Tighten the two screws securely. See Fig. 3-2. Hex nut Figure 3-2 There are three height adjustment holes in the two handlebar support brackets.

- Page 8 Reverse Clutch Cable Carefully unwrap the reverse clutch cable (Red) from its shipping position. Pull the cable up through the top hole in the cable bracket and push the cable connector up through the hole in the bracket until the groove in the connector snaps into place.

-

Page 9: Controls & Features

Controls and Features Gasoline Fill Recoil Starter Engine Controls For detailed information on all engine controls refer to the seperate Engine Operator’s Manual. Wheel Drive Pins Each wheel is equipped with a wheel drive click pin that secures the wheel to the wheel shaft. The wheels can be positioned in either a WHEEL DRIVE or a FREEWHEEL mode. -

Page 10: Operation

Operation Starting the Engine Pre-Start Checklist With the spark plug wire disconnected from the spark plug, perform the following checks and services before each use. Read the Safe Operation Practices and the Features & Controls Section in this manual. Read the separate Engine Operator’s Manual provided with the tiller. - Page 11 To Engage Drive & Tines NOTE: The tiller pictured on the following pages is used to demonstrate the operation of the tiller and may not look exactly like your tiller. For forward motion of the wheels and power to the tines pull the Forward Clutch Bail up against the handlebar.

- Page 12 Clearing the Tines The tines have a self-clearing action which eliminates most tangling of debris in the tines. However, occasionally dry grass, stringy stalks or tough vines may become tangled. Follow these procedures to help avoid tangling and to clean the tines, if necessary.

- Page 13 Suggested Tilling Patterns • When preparing a seedbed, go over the same path twice in the first row, then overlap one-half the tiller width on the rest of the passes. See Fig. 5-5. Figure 5-5 • When finished in one direction, make a second pass at a right angle, as shown in Fig.

- Page 14 Terrace Gardening To create a terrace, start at the top of the slope and work down. Go back and forth across the first row as shown in Fig. 5-8. UPHILL 12" UNTILLED REPEAT DOWNHILL Figure 5-8 Each succeeding lower terrace is started by walking below the terrace you’re preparing.

-

Page 15: Maintenance & Adjustments

Maintenance & Adjustments Maintenance Schedule Check Motor Oil Level Clean Engine Check Nuts and Bolts Change Motor Oil Lubricate Tiller Service Engine Air Cleaner System Check Tines for Wear Check Air Pressure in Tires Service Spark Plug WARNING! Before inspecting, cleaning or servicing the machine, shut off the engine, wait for all moving parts to come to a complete stop, disconnect the spark plug wire and move the wire... - Page 16 Lubrication After every 10 operating hours, oil or grease the lubrication points shown in Fig. 6-1 and described below. Handlebar Attaching Screws Wheel Shaft Figure 6-1 Use a clean lubricating oil (#30 weight motor oil is suitable) and a clean general purpose grease (grease containing a metal lubricant is preferred, if available).

-

Page 17: Service

Service Belt Replacement If the drive belt needs to be replaced, see your local authorized dealer or refer to the Replacement Parts Section for ordering information. Use only a factory-authorized belt as an “over- the- counter” belt may not perform satisfactorily. The procedure requires average mechanical ability and commonly available tools. -

Page 18: Troubleshooting

Troubleshooting Problem Engine does not start Engine runs poorly Engine overheats Engine does not shut off Wheels/Tines will not turn Tines turn, but wheels don’t Wheels turn, but tines Don’t Poor tilling performance Cause Spark plug wire disconnected. Engine Throttle Control Lever incorrectly set. Fuel tank empty. -

Page 19: Replacement Parts

Replacement Parts Component Phone (800) 828-5500 to order replacement parts or a complete Parts Manual (have your full model number and serial number ready). Parts Manual downloads are also available free of charge at www.troybilt.com. Part Number and Description 754-04090 Forward Drive Belt 754-04091 Reverse Drive Belt... -

Page 20: Replacement Parts

MANUFACTURER’S LIMITED WARRANTY FOR The limited warranty set forth below is given by Troy-Bilt LLC with respect to new merchandise purchased and used in the United States and/or its territories and possessions, and by MTD Products Limited with respect to new merchandise purchased and used in Canada and/or its territories and possessions (either entity respectively, “Troy-Bilt”).

Need help?

Do you have a question about the series 650 and is the answer not in the manual?

Questions and answers