Table of Contents

Summary of Contents for Jema Autolifte JA3500F

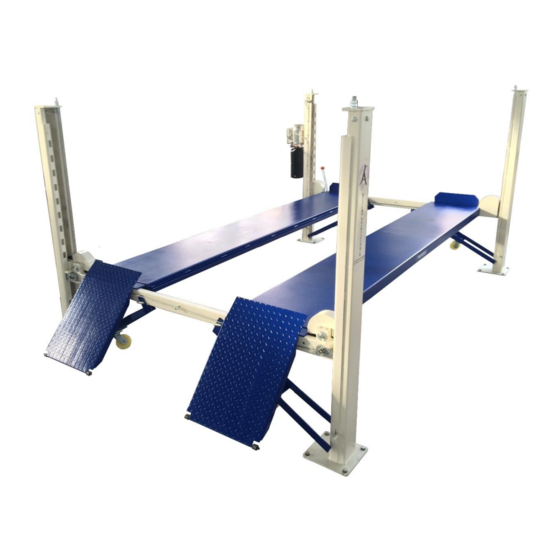

- Page 1 Jema Autolifte A/S ORIGINAL JA3500F FOUR POST LIFT Capacity: 3500KG Manual Release INSTALLTION, OPERATION AND MAINTENANCE MANUAL Read this entire manual carefully and completely before installation and operation of the lift.

- Page 2 INDEX 1. Important safety instructions……………………………….………. 5~7 1.1 Important notices 1.2 Qualified personnel 1.3 Danger notices 1.4 Warning signs 1.5 Sound level 1.6 Training 2. Overview of the lift……………………………………………….…… 7~8 2.1 General descriptions 2.2 Construction of the lift 2.3 Optional parts 3.

- Page 3 User’s Records Fill the following blanks with the information on the nameplate. Model No. ____________________________ Serial No.___________________________ Production Date ______________________ The following specially trained people have permitted to operate and maintain this lift.

-

Page 4: Installation Records

Installation Records Model No. _________________________ Serial No. _ _ ____________________ _ __ Customer’s Name: ______________________ ___ _ _ _ Installation Date: __________________ ________ _ _ Declaration The above mentioned lift has been correctly installed and all its functions including the reliability of safety locks have passed strict tests. -

Page 5: Important Safety Instructions

1.1 Important notices Jema Autolifte A/S will offer one-year's quality warranty for the whole machine,during which any quality problem will be properly solved to the user's satisfaction. However, we will not take any responsibility for whatever bad consequence resulted from improper installation and operation, overload running or unqualified ground condition. - Page 6 1.4 Warnings (Read and understand all safety warnings before operation) All safety warning signs attached on the lift are for the purpose of drawing the user’s attention to safety operation. The labels must be kept clean and need to be replaced when they are worn-out or have dropped. Read the explanations of the labels carefully and try to memorize them.

- Page 7 1.5 Sound Level The sound emitted from the lift should not exceed 75DB. For the sake of your health, we suggest putting a noise detector in your working area. 1.6 Training Only properly trained people are allowed to operate the lift. We are quite willing to provide professional training for the users when necessary.

-

Page 8: Optional Parts

Unfold the package and check if any parts missed as per Annex 1. Do not hesitate to contact us in case any parts missed, but if you do not contact us and insist installing upon the lack of some parts, Jema Autolifte A/S as well as our dealers will not bear any responsibility for this and will charge for any parts subsequently demanded by the buyer. -

Page 9: Precautions For Installation

3.2 Precautions for installation 3.2.1 Make sure the four posts stand paralleled and are vertical to the ground. No slanting. 3.2.2 Joints of oil hose and steel cable must be firmly connected in order to avoid the looseness of steel cable and leakage of oil hose. - Page 10 Step 7: Position the four posts according to the dimensions show in the picture.. Step 8: Connect the platforms and beams Connect the assistant platform to the beam. Pay attention that the runway for jack should be placed inside. Mount the car protection in front of the platform.

- Page 11 Length of wire 1=6800 mm. 2=8265 mm. 3=4140 mm. 4=2670 mm. Step 11: Mount the hydraulic pump and oil hose onto the main post. Pull out the oil hose and air hose (if applicable) from the main platform and connect to the hydraulic block. Then fix the hydraulic pump on to the plate by M10*30 hex bolts, spring and flat washers.

- Page 12 4.1.3 The machine shall not lift or lower an automobile if its center of gravity is not positioned midway of the platforms. Otherwise, Jema Autolifte A/S as well as our dealers will not bear any responsibility for any consequence resulted thereby.

-

Page 13: Flow Chart For Operation

4.2 Descriptions of control panel Description Function Alarm buzzer Low height alarm UP button Control UP movement DOWN I button Control DOWN movement DOWN II button Control DOWN movement 4.3 Flow chart for operation Raising Lowering Switch on Switch on Press the UP button Press the DOWN button Motor drives the gear pump... -

Page 14: Emergency Lowering In Case Of No Power

Lower the lift 1. Switch on. When the power indicating light is on, press the DOWN I and DOWN II button and then platforms of the list will go down gradually. 2. Drive away the vehicle when platforms have lowered to the lowest position. 3. -

Page 15: Troubleshooting

2. Press the release bar and screw loose counter-clockwise the unloading valve to lower the platform. 5. Trouble Shooting ATTENTION: If the trouble could not be fixed by yourself, please do not hesitate to contact us for help .We will offer our service at the earliest time we can. -

Page 16: Maintenance

The seal of the cylinder is abraded. Replace the seal. Inside surface of the posts is not well greased. Add grease. The throttle valve jammed. Clean or replace. The hydraulic oil is dirty. Change the oil. Lowering too slow The anti-surge valve jammed. Clean it. - Page 17 6.1 Daily checking items before operation The user must perform daily check. Daily check of safety latch system is very important – the discovery of device failure before action could save your time and prevent you from great loss, injury or casualty. ·Before operation, judge whether the safety latches are engaged by sound.

- Page 18 7. Annex Annex 1:Packing list of the whole lift...

- Page 19 Annex 2:Overall diagram...

- Page 20 Annex 3:Floor plan Annex 4: Steel cable connection...

- Page 21 Annex 5:Hydraulic working system 1. Oil cylinder 3. Electrical unloading valve 4. Throttle valve 5. Motor 6. Coupling 7. Gear pump 8. One way valve 9. Overflow valve 10. Anti-surge valve 11. Cushion valve 12. Emergency unloading valve Annex 6:Size and weight requirements on vehicles...

Need help?

Do you have a question about the JA3500F and is the answer not in the manual?

Questions and answers

My lift 3500F takes the fuse, when i try to lower it, it can raise but wont go down.

@Richard . My lift blows the fuse, only when trying to lower the lift.