Summary of Contents for schmalenberger Fluvo WK Series

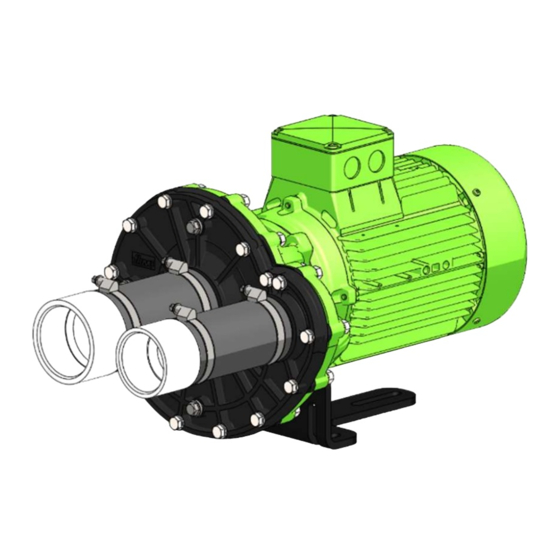

- Page 1 Centrifugal pump Type WK/SMK Operating / Assembly manual Translation of the original Entwurf 27.10 .2020...

- Page 2 Operating / Assembly manual EU-Declaration of Conformity Manufacturer: Schmalenberger GmbH + Co. KG Strömungstechnologie Im Schelmen 9-11 D-72072 Tübingen / Germany The manufacturer hereby declares that the product: Centrifugal pump type: WK, WK-Vario, SMK (identification numbers: all) Serial number range: 2018000001 - 2023999999 has been manufactured in accordance with the following directives: Directive 2006/42/EC "Machinery"...

-

Page 3: Table Of Contents

Type WK ..........................24 8.2. Typ SMK ..........................25 Maintenance / Repair ....................26 9.1. Generel Information ......................26 9.2. Maintenance / Inspection ..................... 27 Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... - Page 4 11.3. Explosion Drawing type WK6513 ..................33 11.4. Explosion Drawing type WK6013 Vario ................34 11.5. Explosion Drawing type SMK- 5013 ..................35 Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany Version: 27220 - E...

-

Page 5: General Information

"birth certificate" and must be treated assuch. The confirmation of order together with the delivery slip can be used as a replacement as proof of technical data. Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 6: Technical Data Wk5013

Operating / Assembly manual 1.5. Technical Data WK5013 DN50 | G2“ DN65 | G2½“ Speed Nominal current Voltage Frequenz Output Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany Version: 27220 - E... -

Page 7: Technical Data Wk6013

1.6. Technical Data WK6013 DN65 DN50 | G2“ | G2½“ DN80 DN65 | G2½“ | G3“ Speed Nominal current Voltage Frequenz Output Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 8: Technical Data Smk-5013

Operating / Assembly manual 1.7. Technical Data SMK-5013 DN50 | G2“ DN65 | G2½“ Speed Nominal current Voltage Frequenz Output Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany Version: 27220 - E... -

Page 9: Safety Instructions

(at least DN 40). There must not be any conducting connection between the metallic components of the motor and a liquid. Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 10: Safety Instructions For Connection And Commissioning

The suction connection (strong suction effect) The pressure connection (high discharge speed of objects that may have been sucked in) The pump housing (heating) Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany... -

Page 11: Transport, Storage And Assembly

Before initial commissioning and after an extended down time, or after installation of a new mechanical seal, always check for smooth operation (see chapter 10.1.3 Recommissioning). Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 12: Unpacking, Cleaning And Assembly

Note: Check to ensure the centrifugal pump is running easily and freely before starting assembly. Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany Version: 27220 - E... -

Page 13: Setting Up And Connecting

For short pipelines, the nominal widths should at least match those of the pump connections. For longer pipelines, determine the most cost-effective nominal width from case to case. Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... - Page 14 Loctite 5331. The inobservance of these instructions can lead to damages to the plastic parts and with that for the loss of all rights to claim under warranty! Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany...

- Page 15 After the pump is started, the air from the suction pipe will be completely pumped away. The air disappears in the discharges pipes i.e. the pump can only vent through the open discharge pipes. Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E...

-

Page 16: Electrical Connection

Equipotential bonding with a cross-section of 10 mm² must be applied on the connection terminal so identified (on the motor mount or next to the terminal box). The pump must only be operated with the terminal box cover closed! Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany... - Page 17 For additional information, see the Operator's Manual Pump Control (27122). Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E...

-

Page 18: Device Units

B =160 mm Screw Mount the support in the place provided for it. Fasten the support in place with 3 screws (S). Fig. 6 Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany Version: 27220 - E... -

Page 19: Assembly Of The Control Box

8 m. Connection information for Control box, refer to the corresponding operating instructions 27248. Fig. 7 Control Box Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 20: Assembly Of Wk-Vario Combination With Massage Jets Or Water Curtain

Flow losses in the pipeline (pressure- and suction side) must be noted. Flow losses must be kept low in the components that are used. Sample flow values are listed in Fig. 9. Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany... - Page 21 Rohrverengung 0,278 bar 2,562 m/s DN 80 auf DN 50 Kantiger Einlauf unter 0,027 bar 2,562 m/s Winkel Fig. 9 Example flow values Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E...

-

Page 22: Operating The Centrifugal Pump

To avoid large temperature increases in the motor and excessive load on the centrifugal pump, motor and bearings, one switching-on process per minute must not be exceeded. Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany... -

Page 23: Notices Of Incorrect Operation

If there is danger of freezing and/or for extended periods of standstill, the pump must be emptied and/or protected against being emptied or freezing (auxiliary heating). Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 24: Emptying The Pump

4. Motor protection switch is Wrong setting Set the correct current value triggered +10% (see Data Sheet p. 5) Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany Version: 27220 - E... -

Page 25: Typ Smk

Suction pipe not properly Check vibrates immersed in the liquid Air in the suction pipe Blocked suction pipe Suction pipe too long Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 26: Maintenance / Repair

Only original spare parts may be used for repairs. This applies especially to the mechanical seal. When working on the motor, the instructions of the relevant motor manufacturer and instructions must be followed. Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany... -

Page 27: Maintenance / Inspection

After disassembly, clean all the individual parts of the centrifugal pump. Check the individual parts for wear and damage. Parts that are not in flawless condition must be reworked or replaced. Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 28: Die Sassembly / Dismantling The Pump

Use only original spare parts for repairs! Observing these instructions is a precondition for problem-free operation of the pump and for honouring any warranty claims that may be submitted. Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany... -

Page 29: Appendix

9.2 Maintenance / Inspection must be performed. Before using the pump again, all the points listed in chapter 7.1 Initial Commissioning must be observed. Special feature of mechanical seals: Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 30: Disposal

The confirmation of order or motor number may also be helpful. This will help us deliver the right spare part for your pump! 10.3.3.Customer Service: Address of main office: +49 (0)7071 70 08 – 0 Schmalenberger GmbH + Co. KG +49 (0)7071 70 08 - 10 (Fax) www.schmalenberger.de Im Schelmen 9 – 11 D-72072 Tübingen / Germany info@schmalenberger.de... -

Page 31: Spare Parts

11. Spare parts 11.1. Explosion Drawing type WK5013 Fig. 11 exemplary presentation Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 32: Explosion Drawing Type Wk6013

Operating / Assembly manual 11.2. Explosion Drawing type WK6013 Fig. 12 exemplary presentation Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany Version: 27220 - E... -

Page 33: Explosion Drawing Type Wk6513

11.3. Explosion Drawing type WK6513 Fig. 13 exemplary presentation Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... -

Page 34: Explosion Drawing Type Wk6013 Vario

Operating / Assembly manual 11.4. Explosion Drawing type WK6013 Vario Fig. 14 exemplary presentation Schmalenberger GmbH + Co. KG Pump type WK/ SMK D-72072 Tübingen / Germany Version: 27220 - E... -

Page 35: Explosion Drawing Type Smk- 5013

11.5. Explosion Drawing type SMK- 5013 Fig. 15 exemplary presentation Pump type WK/ SMK Schmalenberger GmbH + Co. KG D-72072 Tübingen / Germany Version: 27220 - E... - Page 36 +49 (0)7071 70 08 - 10 (Fax) www.fluvo.de Im Schelmen 9 – 11 info@schmalenberger.de D-72072 Tübingen / Germany © 2020 Schmalenberger GmbH + Co. KG; All Rights reserved This Document is subject to change without notice Pump type WK/ SMK 27220 - E...

Need help?

Do you have a question about the Fluvo WK Series and is the answer not in the manual?

Questions and answers