Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Johnson Controls SABROE NS-HPAC

- Page 1 Operating manual NS-HPAC/DualPAC with reciprocating compressors...

- Page 3 Manual for DualPAC heat pump Unit type Compressor types Designations Compressor nos. Refrigerant R717 Oil type Other: PAO 100 Level control Mechanical float valve Electronic valve Approval Other: PED (2014/68/EU) Motor: 3 x ______ V / ____ Hz Supply voltage Control: 1 x ______ V / ____ Hz IP23 IP55...

- Page 4 Vessel data External surface Design pressure Type [bar] Condenser HP Condenser LP Evaporator Oil separator HP Oil separator LP Oil cooler Safety valve: Data for calculation of Intermediate vessel downstream line accord- ing to EN 13136 Economiser Desuperheater Subcooler Other Pressure loss, if any, from safety valve to customer connection (based on design pressure) [bar] _____________ Safety valve type:...

-

Page 5: Table Of Contents

Contents Introduction ..................8 Definition of safety precautions used in this manual ..... 9 Requirements for competent persons ........9 Safety ....................10 Area of application ..............10 2.1.1 Application of the DualPAC pump ........10 2.1.2 Application of combustion engines ........ 10 Identification ................. - Page 6 3.2.9 Automatic oil recovery system from evaporator ... 30 3.2.10 Automatic oil return from oil separator ......31 3.2.11 By-pass function during start-up ........31 3.2.12 WHC circulation system ..........31 3.2.13 Discharge check valve ............ 33 3.2.14 Function of CVP valves ........... 34 Installation information ..............

- Page 7 Shutdown and alarms ............45 5.6.1 Operating state ............... 45 5.6.2 Troubleshooting .............. 45 5.6.3 Testing of DualPAC units ..........46 Maintenance instructions ............47 Maintenance of DualPAC units ..........47 Selecting lubricating oil for DualPAC units ......48 R717 charge ................48 Final disposal .................

-

Page 8: Introduction

Copyright © Johnson Controls Denmark This manual must not be copied without the written permission of Johnson Controls Denmark and the contents must not be imparted to a third party nor be used for any unauthorised purposes. Contravention will be prosecuted. -

Page 9: Definition Of Safety Precautions Used In This Manual

Introduction Definition of safety precautions used in this manual Danger! Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning! Indicates a potentially hazardous situation or practice which, if not avoided, will result in death or serious injury. -

Page 10: Safety

However, check with the local authorities as exemptions to this rule may be granted. Warning! Johnson Controls Denmark is not liable for injuries to personnel or damage to equipment resulting from using the equipment for other purposes than the ones stated above. Operating manual – DualPAC with reciprocating compressors 10/63 0012201 en 2021.04... -

Page 11: Identification

Safety Identification 2.2.1 Identification of equipment All equipment from Johnson Controls Denmark can be identified by one or several name plates positioned as illustrated in the following drawings: Fig. 1: Positioning of name plates on DualPAC Designation Pos. no. Compressor name plate... -

Page 12: Compressor Name Plates

Test pressure Test pressure bar g bar g Fig. 2: Name plate for standard compressor Fig. 3: Name plate for ATEX compressor Johnson Controls Denmark ApS 2516-347 Christian X's Vej 201 8270 Højbjerg, Denmark www.sabroe.com Year Compressor Type... - Page 13 Safety The compressor name plate is positioned on the compressor and contains this information: Compressor no. Identification no. (serial no). Year of manufacturing. Year Type Manufacturer's type designation. Allowable refrigerant or refrigerants for the compressor. Refrigerant (The actual refrigerant for the unit is stated on the unit name plate).

-

Page 14: Vessel Name Plate

Safety 2.2.3 Vessel name plate Johnson Controls D e n m ar k ApS Johnson Controls Denmark ApS Christian X 's V e j 201 Christian X's Vej 201 2516-331 8 270 Højbj e rg, D e n m ark 8270 Højbjerg, Denmark... -

Page 15: Unit/Pipe System Name Plate

Safety 2.2.4 Unit/pipe system name plate Johnson Controls Denmark ApS 2516-343 Johnson Controls Denmark ApS 2516-342 Christian X's Vej 201 Christian X's Vej 201 8270 Højbjerg, Denmark 8270 Højbjerg, Denmark www.sabroe.com www.sabroe.com Refrigeration unit Year Refrigeration unit Year Type Type... - Page 16 Safety The unit name plate is positioned on the frame and contains this information: Refrigeration unit No. Identification no. (serial no.) Year of manufacturing. Year Type Manufacturer's type designation. For EC PED/EAC approval: ‘Unit & Piping’ means that the CE/EAC mark applies to the complete unit including the piping system.

-

Page 17: Signs

Safety 2.2.5 Signs All signs which may be found on your equipment are shown below. The number of signs, however, may vary from one product to another. High surface High voltage/ The compressor may be temperature Risk of electric shock High pressure top-heavy (about 70°C) -

Page 18: Safety Precautions

Safety Safety precautions 2.3.1 General precautions These precautions should be used as a supplement to the safety precautions and warnings in- cluded in: • All other manuals pertaining to the compressor/unit • Local, plant and shop safety rules and codes •... -

Page 19: Water System

Use the prescribed tools, and check that they are properly maintained and in good work- ing condition. In explosion-proof areas, use tools suited for this specific purpose. • Use only Johnson Controls Denmark original spare parts; other parts may impair the safety of the compressor/unit. •... -

Page 20: Lubricating Oils

Safety • When the cause of the shutdown has been removed, the motor may restart. This can be dangerous for machines and installations, and it is therefore important that the user takes adequate precautions against restarting if the motor makes an unscheduled stop. •... - Page 21 Safety Note: The occurrence of air is usually an indication of poor maintenance or lack of thoroughness at installation. Note: R717 systems should be purged on a regular basis to avoid atmospheric air and other non- condensable gases. Operating manual – DualPAC with reciprocating compressors 0012201 en 2021.04 21/63...

-

Page 22: First Aid For Accidents With Ammonia

Safety 2.3.10 First aid for accidents with ammonia (Chemical formula: NH , refrigerant no.: R717) General Ammonia is not a cumulative poison. It has a distinctive, pungent odour that even at very low, harmless concentrations is detectable by most people. As ammonia is self-alarming, it serves as its own warning agent so that no person stays voluntar- ily in hazardous concentrations. -

Page 23: Protecting The Operator As Well As The Environment

Safety 2.3.11 Protecting the operator as well as the environment Industrialisation affects our environment, and it is therefore essential that we do what we can to minimise the harmful effect on nature. Many countries have passed legislation in an effort to reduce pollution and preserve the environ- ment. -

Page 24: Emergency Stop

Safety 2.3.12 Emergency stop In case of an accident, push the emergency stop button on the Unisab III controller. Emergency stop Fig. 11: Unisab III built into the electrical panel Emergency stop Fig. 12: Unisab III as a separate device For resetting and further information, please see the Unisab III manual. -

Page 25: Design And Function

DualPAC is controlled by Johnson Controls Denmark’s UniSAB III control and capacity regulating system and before start-up, the settings must be checked by a refrigeration engineer to make sure they are in accordance with the Sabroe settings list (U-set document). -

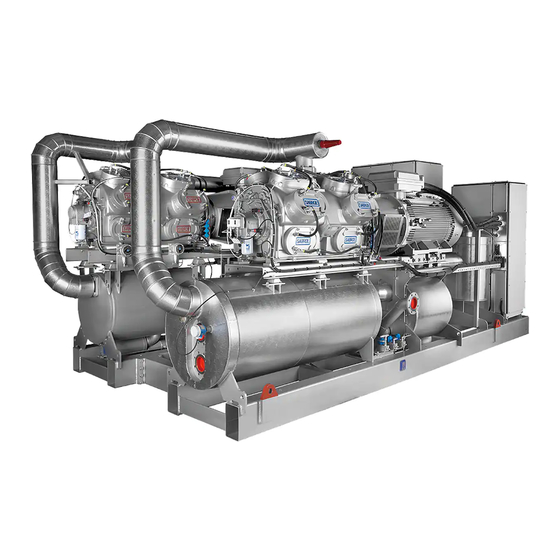

Page 26: Dualpac Description

Design and function 3.1.2 DualPAC description Fig. 13: Components on a DualPAC heat pump Note: Evaporator manifolds, which are illustrated on the left drawing, are not standard equipment. Pos. no. Description Evaporator/Liquid separator Oil separator Condenser GHUR intermediate cooler Brine inlet evaporator Brine outlet evaporator Water inlet condenser Water outlet condenser... -

Page 27: Main Components

Design and function Main components 3.2.1 Compressors The compressors on the DualPAC are Sabroe standard compressors, complete with stop valves, motor, oil separator etc. For further information, please see the compressor operating manual. 3.2.2 Control system The DualPAC is delivered with two UniSAB III monitoring, safety and capacity regulating systems. The control system is described in the UniSAB III manual. -

Page 28: Receiver

Design and function 3.2.6 Receiver The outlet of the condenser is connected to a small receiver, see Fig. 14. The receiver is equipped with two sight glasses, pos. 1, a purge valve, pos. 2, an electronic level transmitter, pos. 3, and a drain valve, pos. 4. The outlet pipe, pos. -

Page 29: Pressure Regulation System (Electrical)

Design and function 3.2.8 Pressure regulation system (electrical) The DualPAC unit has two electrical expansion systems. The high-pressure system is connected to the condenser outlet and regulates the liquid level in the GHUR cooler and controls the expan- sion between the high and intermediate pressure sides. The liquid level in the condenser is controlled by the level sensor, pos. -

Page 30: Automatic Oil Recovery System From Evaporator

Design and function 3.2.9 Automatic oil recovery system from evaporator Fig. 17: System for reciprocating compressor Pos. no. Component Compressor Evaporator Level float switch Stop valve Stop valve Stop valve Solenoid valve combined with filter and stop function Solenoid valve combined with filter and stop function Oil recovery pot Discharge gas line The relatively small amount of oil leaving the compressor and oil separator with the discharge gas... -

Page 31: Automatic Oil Return From Oil Separator

Design and function Discharge gas Oil / R-717 Fig. 18: Oil recovery pot When the oil level in the recovery pot, Fig. 18, is high, the float switch is activated. The switch turns on the solenoid valve in the oil recovery system. Incoming discharge gas pushes down the piston, pos. - Page 32 Design and function The SABROE WHC circulation system is a complete system with built-in control. The system has two functions: • At standstill the water is circulated and heated in the circuit to prevent condensing of re- frigerant in the compressor while at the same time keeping the oil in the compressor crankcase warm for operation.

-

Page 33: Discharge Check Valve

Design and function 3.2.13 Discharge check valve In the discharge line to the GHUR cooler, there is a controlled check valve, see Fig. 20. The valve opens when it has 2 bar differential pressure and stays open at a differential pressure of approximately 0.02 bar. -

Page 34: Function Of Cvp Valves

Design and function 3.2.14 Function of CVP valves The ICS main valve with pilot valves EVM (NC) and CVP in parallel is mounted downstream from the ICM expansion valve in order to avoid flash gas. This introduces the risk of trapped liquid when the DualPAC is stopped. The CVP valve will open the ICS valve if the pressure rises to above 20 bar. -

Page 35: Installation Information

Installation information 4. Installation information Installation 4.1.1 General information For assistance or information about installation, please contact your local Johnson Controls product representative. 4.1.2 First start-up procedure Installation in terms of mechanical work (refrigeration system and piping), electrical work and in- stallation of safety equipment must be performed in accordance with local codes/rules and/or ac- cording to EN 378-3 and EN 378-4 as a minimum requirement. -

Page 36: Sound And Vibrations

Installation information 12. Turn on power. 13. Check the UniSAB III control system settings including calibration according to the Uni- SAB III manual. 14. Check the direction of rotation of the compressor motor. 15. Check alignment of coupling. 16. Carry out the pre-start check, see section 5.2, and run the compressor in 100% capacity. Check that the oil is not foaming and check for low oil temperature. -

Page 37: Vibration Dampers

70% vertical isolation (100% capacity). For installation on decks, special dampers are often required. Please consult a vibration expert or a Johnson Controls representative for further information. To ensure optimum effect of each individual anti-vibration machine foot, the load on the feet must result in roughly the same deflection of all machine feet, see Fig. -

Page 38: Cleaning In Place

It is therefore important to keep brine and water under observation for both evaporator and con- denser. Consult a water treatment expert concerning additives to the system. The liability of Johnson Controls Denmark does not include any damage that may occur due to harmful impur- ities in the system. -

Page 39: Operating Instructions

Operating instructions 5. Operating instructions Personnel qualification requirements Note: Read chapter 2. Safety carefully before operating the unit. Before operating the DualPAC unit, all personnel must have studied the unit manuals carefully. The operator must be confident operating a UniSAB III controller. Prior to start-up and running of the DualPAC, the pre-start check must be accomplished. -

Page 40: Normal Start-Up Procedure

Operating instructions Top bar Content area Info bar F-key area Fig. 22: Unisab III front 5.3.2 Normal start-up procedure Confirm that the system conditions permit the DualPAC to start. Press the start button on UniSAB III. Allow the compressor to start up and stabilise. Check the following on the DualPAC: Mechanical tightness of the external piping, bolts and valves. -

Page 41: Valve Positions During Operation

Operating instructions 5.3.3 Valve positions during operation Designation Qty. Position during operation Pos. no. Compressor suction stop valve Open Open Compressor discharge stop valve Stop valve for oil recovery/oil return Open Purging valve Closed Open Stop valve for liquid by-pass (start-up) Open Stop valve for oil recovery, discharge gas Stop valve for oil drain, oil separator... -

Page 42: Restarting Dualpac After Power Interruption

Operating instructions Fig. 23: Principle P&I diagram for DualPAC 5.3.4 Restarting DualPAC after power interruption When the power supply returns after a short power interruption, restarting depends on the Uni- SAB III settings. If UniSAB III is set in AUTO running mode, the heat pump will normally start up when needed by the automatic control and when the relevant timer/delay has expired. -

Page 43: Stopping For A Brief Period

Operating instructions 5.3.6 Stopping for a brief period In automatic mode Unisab III will occasionally stop the heat pump depending on the heating re- quirement. This is normal and does not require any action by the operator of the plant. The heat pump can be stopped manually on Unisab III at any capacity setting. -

Page 44: Shutting Down For A Long Standstill Period

Operating instructions Caution! Wire connections to the motor and VSD must not be touched immediately after the DualPAC unit is powered down as the capacitors in the VSD may still be charged. Read the warning label on the VSD. 5.5.2 Shutting down for a long standstill period Follow the Stopping for a brief period instructions and: Turn off the oil heater and heat tracing. -

Page 45: Shutdown And Alarms

Operating instructions Shutdown and alarms 5.6.1 Operating state Experience has shown that variations in pressures and temperatures within the cooling cycle can provide information about the operating state of a DualPAC. In particular, suction and condensing pressures, as well as the temperatures of suction and pres- sure gas, can provide important information. -

Page 46: Testing Of Dualpac Units

5.6.3 Testing of DualPAC units DualPAC units supplied by Johnson Controls Denmark have, as far as possible, been function and performance tested. A performance test consists of simultaneous measurements of cooling or heating capacity, power consumption and condenser capacity. -

Page 47: Maintenance Instructions

Maintenance instructions 6. Maintenance instructions Maintenance of DualPAC units Read chapter 2. Safety carefully before performing any maintenance on the DualPAC unit. To ensure that the DualPAC unit operates without problems throughout a long service life, the system of maintenance presented in the following instructions must be followed. Daily maintenance is normally performed by operating personnel. -

Page 48: Selecting Lubricating Oil For Dualpac Units

PAO oil is a synthetic oil with low vapour pressure. Usually, the DualPAC is charged with oil from factory. Do not switch to a different oil type or brand without first consulting your local Johnson Controls representative. Oil changes are described in detail in the compressor manual. -

Page 49: Final Disposal

Final disposal 7. Final disposal Safety precautions Danger! Before dismantling the plant, read the safety precautions carefully. Dismantling a refrigeration unit to be scrapped must be carried out safely. Only competent refrigeration personnel must perform the dismantling as fundamental knowledge of refrigeration systems and the risks involved are required. -

Page 50: Appendices

Appendices 8. Appendices Monitoring of operation To ensure satisfactory operation, it is required that you enter certain routines in a logbook on a regular basis. You can use the items listed in the Start-up log, which is page 2 of the Checklist il- lustrated in Fig. -

Page 51: Control Description - Dualpac

Appendices Control description - DualPAC Start-up Cold side control The ChillPAC UniSAB control regulates according to the Water temperature out on evaporator. When the temperature gets outside range, UniSAB III will initiate a start request for the ChillPAC. The ChillPAC is not allowed to start until the HeatPAC is running, but it initiates that the setpoint for suction pressure in the HeatPAC UniSAB III is changed to setpoint 2 (normally 10°C) and this will start the HeatPAC. -

Page 52: Spare Parts List For Cvua 1201 Oil Recovery Pot

Appendices Spare parts list for CVUA 1201 oil recovery pot NO: 3247--128 Fig. 25: Oil recovery pot Pos. Pcs. Part no. Description 3247.128 Complete pot 3445.508 Float switch 1331.433 Seal ring 3413.038 Piston 3411.009 Oil reservoir 2144.049 Spring 3411.039 Cover 1331.571 O-ring 1425.018... -

Page 53: Declaration Of Conformity

Appendices Declaration of conformity Johnson Controls Denmark declares on the signed declaration of conformity that the unit is manu- factured and CE-marked in conformity with relevant directives and standards. The printed version of this operating manual, which is delivered with the unit, contains a trans- lated version of the declaration, however not filled in with the specific data for your unit. -

Page 54: Set-Up Guide - Aks 4100 280 Mm For Ammonia Heat Pump Application

Appendices Set-up guide — AKS 4100 280 mm for ammonia heat pump application Set-up guide for AKS 4100 280 mm Set-up and calibration of the AKS 4100 280 mm level sensor must be performed by competent personnel only. The guide is in English only. Warning! Incorrect set-up may cause the compressor to break down. - Page 55 Appendices Open the tightening screw (pos. 1) on the meta glass connector and the fixing screw (pos. 2), see Fig. 26. Fit it carefully on the process connector. The loose screw (pos. 1) gives way for the trap- ped air so the signal converter can be installed. It should be pressed down carefully, yet with some force, to fit over the o-ring.

- Page 56 Appendices Check the settings You can check your settings by pressing twice. AKS 4100 COAX D22 280 mm (0%) 4 mA 210 mm 060 mm (100%) 20 mA Press to return to default screen. After running the quick set-up, go to the supervisor menu and change the following parameters: •...

- Page 57 Appendices Press Arrow up (no. 4) once to change the digit to 2. Press Arrow right (no. 1) again → passcode required → press the buttons: 1-2-3-4-1-2, see Fig. 30. Fig. 30 Example: how to change a parameter in the supervisor menu Change of gas constant 2.5.3 to value according to the list in Fig.

- Page 58 Appendices • Press Arrow up (no. 4) until 1 has turned to 3, see Fig. 33. Fig. 33 Change the gas constant: • Press Arrow right (no. 1) – the bottom line is marked. • Change the digit to wanted number by pressing Arrow right (no. 1), Arrow down (no.

- Page 59 Appendices Fig. 36 Change to ‘STORE YES’ with Arrow down (no. 3) or Arrow up (no. 4) and Confirm (no. 2). You will then return to the standard display and the AKS 4100 is now running with optimised parameters. Note: After changing the parameters, do NOT run a quick set-up. If you do so, you will need to fill in the parameters again.

- Page 60 Appendices Set point z on e Fig. 37: AKS 4100-280 mm installed in a DN150 receiver. Operating manual – DualPAC with reciprocating compressors 60/63 0012201 en 2021.04...

- Page 61 Appendices Extended list – Gas constant for ammonia heat pump application Fig. 38 Operating manual – DualPAC with reciprocating compressors 0012201 en 2021.04 61/63...

-

Page 62: Index

Index Ammonia accidents - first aid ..................... 22 Automatic oil recovery ....................... 30 Batteries ............................ 49 Brine ............................38 Cleaning in place ........................38 Combustion engines - application ....................10 Competent persons - requirements....................9 Compressor name plates......................12 Control description ........................51 CVP valves .......................... - Page 63 Power supply ..........................19 Protecting the operator ......................23 Refrigerants ..........................20 Safety during maintenance and service..................19 Safety signs ..........................17 Sound and noise data ......................... 36 Spare parts list ........................... 52 Starting procedures ........................39 Stopping for a brief period ......................43 Testing ............................

- Page 64 Johnson Controls Denmark ApS Sabroe Factory Christian X's Vej 201 ∙ 8270 Højbjerg Denmark Phone +45 87 36 70 00 Version 2 www.sabroe.com...

Need help?

Do you have a question about the SABROE NS-HPAC and is the answer not in the manual?

Questions and answers