Table of Contents

Advertisement

Quick Links

translation of the original instructions for use (also applies to special designs)

BRANO a.s., 747 41 Hradec nad Moravicí

the Czech Republic

tel.: +420/ 553 632 303

http://www.brano-zz.cz; http://www.brano.eu;

zz-info@brano.eu;

info@brano.eu

OPERATION MANUAL

SECURITY PRINCIPLES, OPERATION AND MAINTENANCE

FOR

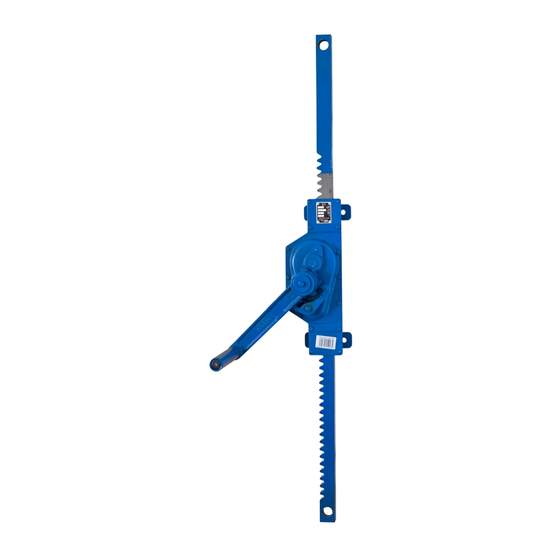

RACK JACK

15-00

2,5t

5t

Type

load capacity

and

15-01

10t

Type

load capacity

CONTAINER WALL-MOUNTED CONSTRUCTION – CON-W

CONTAINER DESIGN – CON

these versions are further available in variants:

DESIGN WITH RATCHET CRANK – RK

DESIGN WITH RATCHET HANDLE-LEVER – RKP

DESIGNED IN EXPLOSIVE ENVIRONMENTS – NEXP

Peruse the operation manual before using the jack. It comprehends substantial security

instructions and instructions for use, installation and maintenance of the product.

Ensure the Operation Manual is available for all responsible persons.

Keep for next usage!

th

Edition 4

JANUARY 2021

Registration number 1-55830-0-1

Advertisement

Table of Contents

Summary of Contents for Brano 15-00-CON-W

- Page 1 (also applies to special designs) BRANO a.s., 747 41 Hradec nad Moravicí the Czech Republic tel.: +420/ 553 632 303 http://www.brano-zz.cz; http://www.brano.eu; zz-info@brano.eu; info@brano.eu OPERATION MANUAL SECURITY PRINCIPLES, OPERATION AND MAINTENANCE RACK JACK...

-

Page 2: Table Of Contents

CONTENTS 1 DEFINITION ........................3 2 DEVICE PURPOSE ......................3 3 SECURITY PRINCIPLES ....................4 3.1 SECURITY PRINCIPLES OVERVIEW ............. 4 3.2. SECURITY PRINCIPLES ................. 4 3.2.1 Prior to use ..................... 4 3.2.2 When in use ....................4 3.2.3 Risk analysis ....................5 3.2.4 Maintenance .................... -

Page 3: Definition

1 DEFINITION ! HAZARD Hazard: it adverts to an imminent hazardous situation, which will inflict death or serious injury, if the operation personnel do not avoid it. ! WARNING Warning: it adverts to a possible hazardous situation, which could inflict death or serious injury, if the operation personnel do not avoid it. ! NOTICE Notice: it adverts to a possible hazardous situation, which could inflict any minor or slight injury, if the operation personnel do not avoid it. -

Page 4: Security Principles

3 SECURITY PRINCIPLES 3.1 SECURITY PRINCIPLES OVERVIEW A hazard exists when handling movable parts of structures especially in the event that the jack is not use in the right way or is badly maintained. Whereas as a result an accident or severe injury could happen, it is necessary to observe the special security measures when handling, assembling, maintaining and checking the jack. -

Page 5: Risk Analysis

NEVER use the separate jack (not mounted in the structure for which it is destined) to handling free loads NEVER allow the lifted part of the structure would give rise to impacts or vibrations. NEVER leave the loaded jack without supervision or other securing of a raised part of the structure. -

Page 6: Main Specifications

Type-design capacity ting (mm) L = 660 L = 970 L = 1200 tempera- crank (kg) (kg) (kg) ture 15-00-CON-W 12,8 15,2 17,0 345 - 850 15-00-CON 11,4 13,8 15,6 15-00-CON-W 22,1 25,6 28,5 360 – 850 15-00-CON... -

Page 7: Mechanical Classification

Fig.2 Product design – CON 5.1 MECHANICAL CLASSIFICATION Safety and working life of the jack is guaranteed providing that it works in accordance with specified classification. The jack is designed for class 1Bm according to the FEM 9.511 regulation – see table 5.1. -

Page 8: Material And Finish

Load diagram Load diagram Load diagram Load diagram Percentage of operating time 5.2. MATERIAL AND FINISH 5.2.1 All parts of the jack are manufactured from steel and cast iron. 5.2.2. Materials inclinable to creation of an incendiary spark in terms of the annex No. -

Page 9: Jack Installation

6 JACK INSTALLATION ! WARNING ALWAYS before installation check up thoroughly whether the jack is not damaged. NEWER the weight of the jacked up structure or resulting pushing (pulling) force on the rack bar have to exceed the safe working load of the jack. The NEXP product must be installed in such a way as to prevent creeping charges. -

Page 10: Test Prior To Use

6.1.4 Documentation: Method of the container jack anchorage and eventual jack modifications are necessary to be documented by drawing documentation and stress analysis. The equipment manufacturer has to elaborate the operation manual to the equipment, in which the jack is used. ! WARNING The jack anchorage to a structure must be solved so that the ridge bar is not stressed by bend. -

Page 11: Jack Check

8 JACK CHECK 8.1 INSPECTION 8.1.1 Inspections types (1) Introductory inspection: it precedes first use. The responsible competent person must check up all new or repaired jacks to ensure the qualified fulfilment of requirements of this OM. (2) The jack inspections carried out regularly are generally divided to two groups according to inspections intervals. -

Page 12: Inspection Procedure

8.2 INSPECTION PROCEDURE (1) Daily inspection (carried out by operating staff or competent person) Limit / criterion for Part Inspection method putting-out of Remedy operation 1. Jack function Visually, The jack goes To clean up and aurally hardly, stammers, grease the jack. If emits noise etc. -

Page 13: Trouble-Shooting

9 TROUBLE-SHOOTING Situation Cause of trouble Remedy 1. Jack does not hold firmly Brake slipping. Brake adjusting or repair the load. according to Chapter „Maintenance“. 2. Jack jacks up heavily or (1) Jack is overloaded. (1) Remove the cause- does not raise the load. sticking, seizing of (2) Damaged geared equipment mechanism... -

Page 14: Maintenance

11 MAINTENANCE 11.1 SECURITY PRINCIPLES ! WARNING Only qualified persons (service organizations), trained in safety and maintenance of the jacks, can carry out maintenance and professional inspections. ALWAYS use entirely components supplied by the producer. It is not permitted to carry out repairs and maintenance in other way than specified by the producer. -

Page 15: Brake Assembly And Adjusting (Figures 4 And 5)

11.2.2 Brake assembly and adjusting (figures 4 and 5) Proceed in the opposite way when assembling. Slip over the hub (1) the friction insert (2B); ratchet (3) and second friction insert (2A). Set it in the crank arm (7), slide on the spring (4) and screw on the nut (5). -

Page 16: Related Documentation

13 RELATED DOCUMENTATION EC declaration of conformity The Operation Manual was elaborated in accordance with following technical regulations, technical standards and national regulations: Ministerial order No.176/2008 of the Collection of Law as amended (EP and Council • directive 2006/42/EC) No.116/2016 of the Collection of Law as amended (EP and Council •...

Need help?

Do you have a question about the 15-00-CON-W and is the answer not in the manual?

Questions and answers