Table of Contents

Advertisement

BRANO a.s., 747 41 Hradec nad Moravicí

Česká republika

tel.: +420/ 553 632 303

http://www.brano-zz.cz; http://www.brano.eu;

zz-info@brano.eu;

info@brano.eu

OPERATION MANUAL

SECURITY PRINCIPLES, OPERATION AND MAINTENANCE

FOR

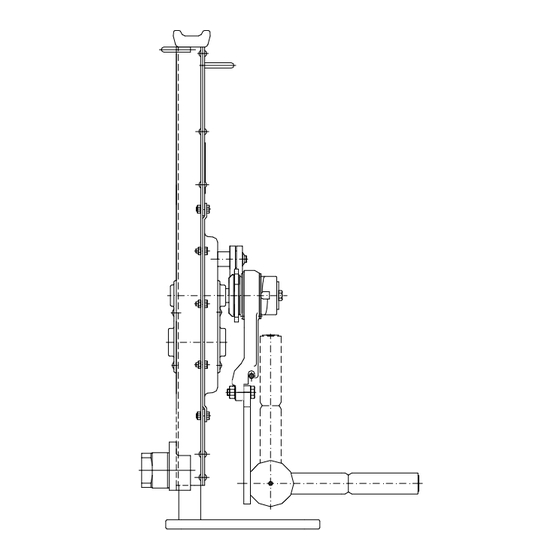

RACK JACK

WITH A RATCHET CRANK-LEVER

type 15-00-CM / 5t, 15-01-CM / 10t

Peruse the operation manual before using the jack. It comprehends substantial

security instructions and instructions for use, installation and maintenance of the

product. Ensure the Operation Manual to be available for all responsible persons.

Keep for next usage!

Edition 5th

APRIL 2018

Registration number 1-57012-0-0

1

Advertisement

Table of Contents

Summary of Contents for Brano 15-00-CM

- Page 1 SECURITY PRINCIPLES, OPERATION AND MAINTENANCE RACK JACK WITH A RATCHET CRANK-LEVER type 15-00-CM / 5t, 15-01-CM / 10t Peruse the operation manual before using the jack. It comprehends substantial security instructions and instructions for use, installation and maintenance of the product.

-

Page 2: Table Of Contents

CONTENT 1 DEFINITION ........................... 3 2 DEVICE PURPOSE ......................3 3 SECURITY PRINCIPLES ....................4 3.1 SECURITY PRINCIPLES OVERVIEW ................4 3.2. SECURITY PRINCIPLES ....................4 3.2.1 Prior to use ........................4 3.2.2 When in use ......................... 5 3.2.3 Risk analysis ........................ 5 3.2.4 Maintenance ......................... -

Page 3: Definition

Competent person: is the person determined by the equipment user 2 DEVICE PURPOSE 2.1 The rack jack of type 15-00-CM / 5t, 15-01-CM / 10t with modification for ISO container (hereinafter referred to as jack) is designed entirely for manual raising, lowering and pushing of free loads in the workplace. -

Page 4: Security Principles

3 SECURITY PRINCIPLES 3.1 SECURITY PRINCIPLES OVERVIEW A hazard exists when handling loads especially in the event that the jack is not use in the right way or is badly maintained. Whereas as a result an accident or severe injury could happen, it is necessary to observe the special security measures when handling, assembling, maintaining and checking the jack. -

Page 5: When In Use

3.2.2 When in use ALWAYS attend to the jack would stay vertically when jacking up. ALWAYS make sure the load is fitly put on the jack. ALWAYS pay increased attention, if the jack is drawn up to maximum position. ALWAYS work with the jack only with manpower. -

Page 6: Storage

Load Actuating capacity Main dimensions (mm) Weight force on (kg) Type crank- lever 15-00-CM 612 / 352 202 225 222 39 15-01-CM 540 / 324 263 256 222 39 Working temperature range -30° to +55° Main dimensions Producer label Position transport... -

Page 7: Mechanical Device

5.1 MECHANICAL DEVICE Safety and working life of the jack is guaranteed if it works in accordance with specified classification. The jack is designed for class 1Bm according to the FEM 9.511 regulation – see table 5.1. (it corresponds to mechanism classification M3 according to the ISO 4301/1). Average daily operating time is specified in the load diagram. -

Page 8: Data On The Product

5.3 DATA ON THE PRODUCT Each product is equipped with the label with specified data as follows: Standard finish: Finish to environment with explosion risk: Mark of the producer Mark of the producer Address of the producer Address of the producer Product type Product type Load capacity... -

Page 9: Raising Or Lowering

Lowering position Neutral position Changeover lever Lifting position Fig.4 6.2 RAISING OR LOWERING Before raising hitch up the changeover lever and set on the mark of raising – up-arrow (see fig. 4). Carry out the raising by oscillating (eventually rotation) motion of the ratchet crank. At the beginning of the raising before the loading of the rack jack will take place, hold the knurled nut so that it would not be carried away by the crank at its backwards motion. -

Page 10: Bearing Surface Check-Up

6.4 BEARING SURFACE CHECK-UP /floor, rough ground/ ! NOTICE ALWAYS make sure that the bearing surface is sufficiently firm to hold tightly supposed loading for all time of handling. The installation must not be carried out on the surface where it is not possible to determine the load-bearing capacity or that is instable. -

Page 11: Safety Work Environment

Usage to ISO containers All jacks of load capacity 5t and 10t can be used to ISO containers raising. Get the jack by the handle and hang it on the container lock. The operating personnel put the head in the corner element of the container (see Fig. 5a). Having put the head in the corner element of container, the operating personnel can start raising or lowering of the container (see chapter 6). -

Page 12: Check-Up On The Jack

8 CHECK-UP ON THE JACK 8.1 INSPECTION 8.1.1 Inspections types (1) Introductory inspection: it precedes first use. The responsible competent person must check up all new or repaired jacks to ensure the qualified fulfillment of requirements of this OM. (2) The jack inspections carried out regularly are generally divided to two groups according to inspections intervals. -

Page 13: Inspection Procedure

8.2 INSPECTION PROCEDURE (1) Daily inspection (carried out by operating staff or responsible person) Limit / criteria for Part Inspection method putting-out of Remedy operation 1. Jack function Visually, The jack goes To clean up and aurally hardly, stammers, grease the jack. If emits noise etc. -

Page 14: Trouble-Shooting

9 TROUBLE-SHOOTING Situation Cause of trouble Remedy 1. Jack does not hold firmly Brake slipping. Brake adjusting or repair the load. according to the chapter „Maintenance“. 2. Jack jacks up heavily or (1) Jack is overloaded. (1) Lower the load weight does not raise the load. -

Page 15: Maintenance

11 MAINTENANCE 11.1 SECURITY PRINCIPLES ! WARNING Only qualified persons (service organizations), trained in safety and maintenance of the jacks, can carry out maintenance and professional inspections. ALWAYS use entirely components supplied by the producer. It is not permitted to carry out repairs and maintenance in other way than specified by the producer. -

Page 16: Brake Assembly And Adjusting (Figures 6 And 7)

11.2.2 Brake assembly and adjusting (figures 6 and 7) Proceed in the opposite way when assembling. Slip over the hub (1) the friction insert (2); ratchet (3) and second friction insert (2) and the carrier segment (7A) slide on the spring (4). Screw on the nut (5) and tighten the nut so that the clearance in the dent is from 4 to 6 mm (see fig. -

Page 17: Related Documentation

13 RELATED DOCUMENTATION EC declaration of conformity The Operation Manual was elaborated in accordance with following technical regulations, technical standards and national regulations: Ministerial order No.176/2008 of the Collection of Law as amended • (EP and Council directive 2006/42/EC) Ministerial order No.116/2016 of the Collection of Law as amended (EP and Council directive •... -

Page 18: Ec Declaration Of Conformity

TIN: CZ45193363 We declare under our sole responsibility that the product Name: Rack jack Type: 15-00-CM; 15-01-CM Parameters: Load capacity 5t; 10t Description and purpose of use: Jacking equipment destined entirely for underposable raising and lowering of free loads at normal atmospheric conditions in the workplace when observing the specified maximum load capacity.

Need help?

Do you have a question about the 15-00-CM and is the answer not in the manual?

Questions and answers