Summary of Contents for KSB EMV Series

- Page 1 Control Valve Actuators For the BOA-Control PIC Type Series Installation/Operating Manual...

- Page 2 All rights reserved. The contents provided herein must neither be distributed, copied, reproduced, edited or processed for any other purpose, nor otherwise transmitted, published or made available to a third party without the manufacturer's express written consent. Subject to technical modification without prior notice. © KSB SE & Co. KGaA, Frankenthal 11/10/2021...

-

Page 3: Table Of Contents

Contents Contents General.............................. 5 Principles ................................ 5 Target group.............................. 5 Symbols ................................ 5 Key to safety symbols/markings........................ 5 Safety .............................. 7 General................................ 7 Intended use .............................. 7 2.2.1 Prevention of foreseeable misuse....................... 7 Personnel qualification and training....................... 7 Consequences and risks caused by non-compliance with this operating manual........ 8 Safety awareness .............................. 8 Safety information for the user/operator ....................... 8 Safety information for maintenance, inspection and installation .............. 8... - Page 4 Contents Commissioning/Start-up/Shutdown.................... 30 Prerequisites for commissioning/start-up...................... 30 Commissioning/Start-up .......................... 30 6.2.1 Commissioning / starting up the EMV211/146 and EMV211/147 actuators ........ 30 6.2.2 Commissioning / starting up the EMV212/146 and EMV212/147 actuators ........ 30 6.2.3 Commissioning / starting up the EMV212/144 and EMV212/145 actuators ........ 30 6.2.4 Commissioning / starting up the EMV212/148, EMV212/150, EMV213/145, EMV213/147, EMV213/148, EMV213/150 actuators .................... 32 6.2.5 Commissioning / starting up the EMV311 and EMV312 actuators .......... 33...

-

Page 5: General

The serial number uniquely describes the product and is used as identification in all further business processes. In the event of damage, immediately contact your nearest KSB service facility to maintain the right to claim under warranty. - Page 6 1 General Symbol Description Electrical hazard In conjunction with one of the signal words this symbol indicates a hazard involving electrical voltage and identifies information about protection against electrical voltage. Machine damage In conjunction with the signal word CAUTION this symbol indicates a hazard for the machine and its functions.

-

Page 7: Safety

2 Safety 2 Safety All the information contained in this section refers to hazardous situations. DANGER In addition to the present general safety information the action-related safety information given in the other sections must be observed. 2.1 General ▪ This operating manual contains general installation, operating and maintenance instructions that must be observed to ensure safe operation of the system and prevent personal injury and damage to property. -

Page 8: Consequences And Risks Caused By Non-Compliance With This Operating Manual

2 Safety 2.4 Consequences and risks caused by non-compliance with this operating manual ▪ Non-compliance with this operating manual will lead to forfeiture of warranty cover and of any and all rights to claims for damages. ▪ Non-compliance can, for example, have the following consequences: –... -

Page 9: Transport/Storage/Disposal

1. On transfer of goods, check each packaging unit for damage. 2. In the event of in-transit damage, assess the exact damage, document it and notify KSB or the supplying dealer and the insurer about the damage in writing immediately. -

Page 10: Disposal

3 Transport/Storage/Disposal EMV213/145, EMV213/147 Table 8: Ambient conditions for storage Ambient condition Value Storage temperature -20 °C to +55 °C Humidity 5 % to 95 % rH EMV213/148, EMV213/150 Table 9: Ambient conditions for storage Ambient condition Value Storage temperature -15 °C to +55 °C Humidity 5 % to 95 % rH ▪... -

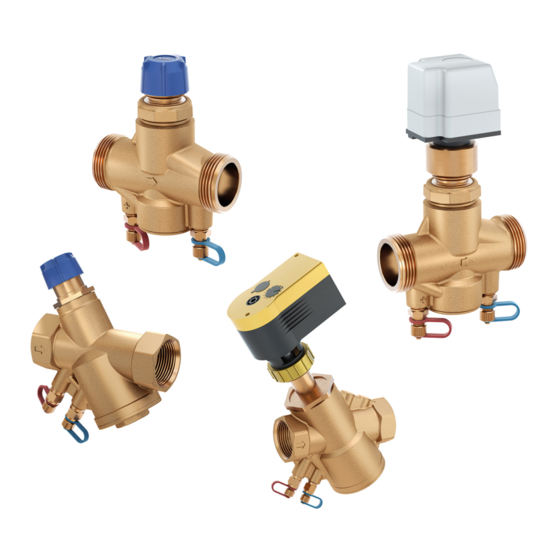

Page 11: Description

4 Description 4 Description 4.1 General description ▪ Electric actuator for the automation of a control valve The electric actuators are used for actuating control valves in building services systems and industrial plants. Continuous-action actuator EMV 211/145, EMV212/148, EMV212/144: The electric actuator provides continuously variable actuation for control valves. The input signal, the characteristic curve and the control value (voltage/current) can be set via DIP switches. -

Page 12: Name Plate

4 Description 4.3 Name plate EMV212/144 24V ~ 50/60 Hz – 3,6VA -5T55 - IP43 100s @ 9mm 300N SN:********* Made in **** Fig. 1: Example of an EMV212/144 Manufacturer Symbol for disposal/recycling in accordance with environmental guidelines Appliance class CE marking Product name Supply voltage Frequency... -

Page 13: Function

4 Description EMV211: ▪ 13 s/mm EMV212: ▪ 9.4 - 15 s/mm EMV213: ▪ 60 s and 120 s Design Continuous-action actuators and 3-point actuators, 24 V AC/DC version (linear / part- turn function depending on the design variant) ▪ Positioning function ▪ Active feedback function ▪... -

Page 14: Installation

5 Installation 5 Installation 5.1 Safety regulations DANGER Electrical connection work by unqualified personnel Risk of fatal injury due to electric shock! ▷ Always have any work on the connection to the power supply performed by a trained electrician. WARNING Improper handling of an electric actuator Crushing of fingers! Damage to the actuator or the valve! -

Page 15: Dimensions And Weights Of Actuators

5 Installation 5.2.1 Dimensions and weights of actuators Fig. 2: Actuator dimensions a) EMV211/146 /147 b) EMV212/144 /145 /146 /147 c) EMV212/148 /150 d) EMV213/145 /147 e) EMV213/148 /150 f) EMV311/XXX EMV312/XXX Table 11: Dimensions and weights of actuators Actuator type [kg] [mm] [mm] [mm]... -

Page 16: Installation Position

5 Installation 5.3 Installation position CAUTION Incorrect installation position Valve function impaired! ▷ Always observe the valve's operating manual and the permissible installation position. EMV 211/146 /147 EMV 311/XXX, EMV312XXX EMV 212/148 /150 EMV 212/144 /145 /146 /147 360° 360° 360°... -

Page 17: Manual Override

5 Installation 5.4 Manual override A manual override is provided on versions EMV212/148 and EMV212/150 as well as EMV213/145 and EMV213/147 for operating the actuator in the event of a power failure or for making adjustments when mounting the actuator on the valve. EMV212/148, EMV212/150 Fig. 4: Actuators EMV212/148, EMV212/150: Using the manual override of the actuator... - Page 18 5 Installation EMV213/145, EMV213/147 Fig. 6: Actuators EMV213/145, EMV213/147: Using the manual override of the actuator 1. Slide the safety device downwards. ð The manual override has been enabled. 2. Rotate the actuator coupling until the actuator has reached the required position.

-

Page 19: Mounting The Emv211 Actuator

5 Installation 5.5 Mounting the EMV211 actuator 5.5.1 Mounting the actuator ü The actuator has been de-energised. ü The actuator is in its upper limit position. CAUTION Incorrect installation/removal of the actuator with tools Damage to the actuator! ▷ Only tighten or loosen the threaded ring by hand. ▷... - Page 20 5 Installation Fig. 8: Removing the actuator cover 1. For EMV211/147: Undo the fastening screw at the actuator cover. 2. Insert a flat-head screwdriver into the edges of the cover to lever off and remove the actuator cover. Fig. 9: Plugging the connector into the socket 3.

- Page 21 5 Installation Fig. 11: Closing the actuator cover 5. Hold the strain relief device in place with a finger, and close the actuator cover. 6. For EMV211/147: Fasten the fastening screw at the actuator cover. For the wiring refer to the “Wiring diagrams” section. (ð Section 9.1, Page 44) . 21 of 54...

-

Page 22: Mounting The Actuator

5 Installation 5.6 Mounting the EMV212/144, EMV 212/146 and EMV212/147 actuators 5.6.1 Mounting the actuator ü The actuator has been de-energised. ü The actuator is in its upper limit position. CAUTION Incorrect installation/removal of the actuator with tools Damage to the actuator! ▷... -

Page 23: Electrical Connection

5 Installation CAUTION Improper electrical connections Damage to the device! ▷ Check the electrical connection. ▷ Observe the wiring diagrams. Fig. 13: Removing the strain relief device B Hole Strain relief device 1. Remove the cross recessed head screw with a screwdriver. Remove the strain relief device B. -

Page 24: Mounting The Emv212/148 And Emv212/150 Actuators

5 Installation 5.7 Mounting the EMV212/148 and EMV212/150 actuators 5.7.1 Mounting the actuator ü The actuator has been de-energised. ü The actuator is in its upper limit position. CAUTION Incorrect installation/removal of the actuator with tools Damage to the actuator! ▷... -

Page 25: Electrical Connection

5 Installation 5.7.2 Electrical connection DANGER Unintentional contact with live parts Danger of death from electric shock! ▷ De-energise the mains connection. ▷ Take steps to ensure that the mains connection cannot be re-energised unintentionally. CAUTION Improper electrical connections Damage to the device! ▷... -

Page 26: Mounting The Emv213/145 And Emv213/147 Actuators

5 Installation 5.8 Mounting the EMV213/145 and EMV213/147 actuators 5.8.1 Mounting the actuator ü The actuator has been de-energised. Fig. 16: Mounting the EMV213/145 and EMV213/147 actuators 1. Place the actuator on the fixing plate of the valve. Check that the valve stem slides into the opening of the actuator until you can hear its snap-fit connection engage. -

Page 27: Mounting The Actuator

5 Installation 5.9 Mounting the EMV213/148 and EMV213/150 actuators 5.9.1 Mounting the actuator ü The actuator has been de-energised. ü The control valve is in the middle position. Fig. 17: Mounting the EMV213/148 and EMV213/150 actuators: Removing the circlip, fastening piece and metal sheet with directional arrow 1. - Page 28 5 Installation 5.9.2 Electrical connection DANGER Unintentional contact with live parts Danger of death from electric shock! ▷ De-energise the mains connection. ▷ Take steps to ensure that the mains connection cannot be re-energised unintentionally. CAUTION Improper electrical connections Damage to the device! ▷...

-

Page 29: Mounting The Actuator

5 Installation 5.10 Mounting the EMV311 and EMV312 actuators 5.10.1 Mounting the actuator ü The actuator has been de-energised. CAUTION Incorrect installation/removal of the actuator with tools Damage to the actuator! ▷ Only tighten or loosen the threaded ring by hand. ▷... -

Page 30: Commissioning/Start-Up/Shutdown

6 Commissioning/Start-up/Shutdown 6 Commissioning/Start-up/Shutdown 6.1 Prerequisites for commissioning/start-up NOTE Never operate the actuator electrically or pneumatically before it has been mounted onto a valve. Before commissioning/starting up the actuator, make sure the following conditions are met: ▪ The actuator has been properly mounted and positioned ▪... - Page 31 6 Commissioning/Start-up/Shutdown Fig. 21: Standard setting of the DIP switches for an EMV212/144 actuator mounted on a BOA-Control PIC DN 10-25 valve Fig. 22: Standard setting of the DIP switches for an EMV212/144 actuator mounted on a BOA-Control PIC DN 32-50 valve Table 12: Possible settings of DIP switches 1 - 6 DIP switch Description ✘...

-

Page 32: Commissioning / Starting Up The Emv212/148, Emv212/150, Emv213/145, Emv213/147, Emv213/148, Emv213/150 Actuators

6 Commissioning/Start-up/Shutdown 6.2.4 Commissioning / starting up the EMV212/148, EMV212/150, EMV213/145, EMV213/147, EMV213/148, EMV213/150 actuators ü The actuator has been de-energised. Fig. 23: Actuators EMV212/148, EMV212/150 and EMV213/145, EMV213/147: Removing the cover 1. For EMV212/148, EMV212/150, EMV213/145, EMV213/147: Lever off the rubber cover with a flat-head screwdriver and fingers. -

Page 33: Commissioning / Starting Up The Emv311 And Emv312 Actuators

6 Commissioning/Start-up/Shutdown Actuating time at Switch setting 8 mm stroke / 90° angle of rotation 60 s ± 2 120 s ± 4 Fig. 25: Setting the actuating time 3. Set the actuating time via DIP switch S1. Stroke Signal Signal Stroke Signal Signal Stroke Signal... -

Page 34: Operating Limits

6 Commissioning/Start-up/Shutdown 6.3 Operating limits 6.3.1 Ambient temperature Observe the following parameters and values during operation: Table 14: Permissible ambient temperatures Ambient condition Value Ambient temperature EMV211 0 °C to +50 °C Ambient temperature EMV212 0 °C to +50 °C Ambient temperature EMV213 0 °C to +50 °C Ambient temperature EMV311 -5 °C to +50 °C Ambient temperature EMV312... -

Page 35: Servicing/Maintenance

▷ Secure the actuator against tilting or tipping over during installation/ dismantling. NOTE All maintenance work, service work and installation work can be carried out by KSB Service or authorised workshops. Never use force when dismantling and reassembling the actuator. -

Page 36: Removing The Emv212/144, Emv 212/146 And Emv212/147 Actuators

7 Servicing/Maintenance Fig. 27: Removing the EMV211 actuator Threaded ring 1. Unscrew the threaded ring A from the external thread of the valve by hand. 2. Remove the actuator from the valve. 7.2.2 Removing the EMV212/144, EMV 212/146 and EMV212/147 actuators ü The actuator has been de-energised. CAUTION Incorrect installation/removal of the actuator with tools Damage to the actuator! -

Page 37: Removing The Emv212/148 And Emv212/150 Actuators

7 Servicing/Maintenance 7.2.3 Removing the EMV212/148 and EMV212/150 actuators ü The actuator has been de-energised. CAUTION Incorrect installation/removal of the actuator with tools Damage to the actuator! ▷ Only tighten or loosen the threaded ring by hand. ▷ Do not use any tools for tightening or loosening the threaded ring. Fig. 29: Removing the EMV212/148 and EMV212/150 actuators 1. -

Page 38: Removing The Emv213/145 And Emv213/147 Actuators

7 Servicing/Maintenance 7.2.4 Removing the EMV213/145 and EMV213/147 actuators ü The actuator has been de-energised. Fig. 30: Removing the EMV213/145 and EMV213/147 actuators 1. Use an Allen key (4 mm) to remove the valve stem from the actuator. 2. Use an Allen key (3 mm) to undo the fastening element between the actuator and the fixing plate of the control valve. -

Page 39: Removing The Emv311 And Emv312 Actuator

7 Servicing/Maintenance 7.2.6 Removing the EMV311 and EMV312 actuator ü The actuator has been de-energised. CAUTION Incorrect installation/removal of the actuator with tools Damage to the actuator! ▷ Only tighten or loosen the threaded ring by hand. ▷ Do not use any tools for tightening or loosening the threaded ring. Fig. 32: Removing the EMV311 and EMV312 actuators 1. -

Page 40: Mounting The Actuator

7 Servicing/Maintenance 7.6 Mounting the actuator After maintenance / inspection, the actuator must be mounted back on the valve. EMV211/...: (ð Section 5.5.1, Page 19) EMV212/144, EMV 212/146 and EMV212/147: (ð Section 5.6.1, Page 22) EMV212/148 and EMV212/150: (ð Section 5.7.1, Page 24) EMV213/145 and EMV213/147: (ð Section 5.8.1, Page 26) EMV213/148 and EMV213/150: (ð Section 5.9.1, Page 27) EMV311/..., EMV312/... : (ð Section 5.10.1, Page 29) Connect the power cable and the control cable. -

Page 41: Trouble-Shooting

If problems occur that are not described in the following table, consultation with the KSB service is required. 8.1 Display of EMV211/145 A Green LED lit continuously... -

Page 42: Display Of Emv211/146 And Emv211/147

8 Trouble-shooting 8.2 Display of EMV211/146 and EMV211/147 A Green LED lit continuously B Green LED flashing C Green LED OFF Table 16: Trouble-shooting for statuses A B C Status Possible cause Remedy - ✘ - Actuator moving into limit position ✘... -

Page 43: Display Of Emv212/144, Emv212/145, Emv212/146 And Emv212/147

8 Trouble-shooting 8.3 Display of EMV212/144, EMV212/145, EMV212/146 and EMV212/147 A Yellow LED lit continuously B Yellow LED flashing slowly C Yellow LED OFF D Red and green LEDs flashing in alternation (fast) E Red and green LEDs flashing in alternation (slowly) F Red LED OFF G Red LED flashing slowly H Red LED lit continuously... -

Page 44: Related Documents

9 Related Documents 9 Related Documents 9.1 Wiring diagrams EMV211/146, EMV211/147 EMV211/146 24 V AC EMV211/147 230 V AC Fig. 33: Wiring diagram EMV211/146 and EMV211/147 (3-point) Blue Orange EMV212/144, EMV212/145, EMV212/146, EMV212/147 Open/Stop/Closed 24 V AC Input signal EMV 212/146: 24 V AC EMV 212/147: 230 V AC Output signal Fig. 34: Wiring diagrams a) EMV212/146 and EMV212/147 (3-point) b) EMV212/144... - Page 45 9 Related Documents EMV212/148, EMV212/150 EMV 212/148: 24 V AC/DC 24 V AC/DC EMV 212/150: 230 V AC Open/Stop/Closed Fig. 35: Wiring diagrams a) EMV212/148 (continuous-action) b) EMV212/148 and EMV212/150 (3-point) Blue Brown Blue Grey EMV213/147, EMV213/150 230 V AC Open/Stop/Closed Fig. 36: Wiring diagram EMV213/147 and EMV213/150 Blue Brown...

- Page 46 9 Related Documents EMV213/145, EMV213/148 24 V AC/DC 24 V AC/DC Open/Stop/Closed Fig. 37: Wiring diagrams a) EMV213/145 and EMV213/148 (continuous-action) b) EMV213/145 and EMV213/148 (3-point) Blue Brown Blue Grey EMV311/NC24, EMV311/NO24, EMV311/NC230, EMV311/NO230, EMV312/NO24, EMV312/NO230 Electrothermal Thermostat Fig. 38: Wiring diagram EMV311/NC24, EMV311/NO24, EMV311/NC230, EMV311/ NO230, EMV312/NO24, EMV312/NO230 Blue Brown...

- Page 47 9 Related Documents EMV311/PRO 24 V AC Input signal Fig. 39: Wiring diagram EMV311/Pro Brown Blue White 47 of 54...

-

Page 48: Eu Declaration Of Conformity

10 EU Declaration of Conformity 10 EU Declaration of Conformity Manufacturer: KSB SE & Co. KGaA Johann-Klein-Straße 9 67227 Frankenthal (Germany) The manufacturer herewith declares that the product: EMV311 ▪ is in conformity with the provisions of the following directives / regulations as amended from time to time: –... -

Page 49: Eu Declaration Of Conformity

11 EU Declaration of Conformity 11 EU Declaration of Conformity Manufacturer: KSB SE & Co. KGaA Johann-Klein-Straße 9 67227 Frankenthal (Germany) The manufacturer herewith declares that the product: EMV212/144, EMV212/145, EMV212/146, EMV212/147, EMV212/150, EMV212/148, EMV213/147, EMV213/145 ▪ is in conformity with the provisions of the following directives / regulations as amended from time to time: –... -

Page 50: Eu Declaration Of Conformity

12 EU Declaration of Conformity 12 EU Declaration of Conformity Manufacturer: KSB SE & Co. KGaA Johann-Klein-Straße 9 67227 Frankenthal (Germany) The manufacturer herewith declares that the product: EMV211/145, EMV211/146, EMV211/147, EMV213/150, EMV213/148 ▪ is in conformity with the provisions of the following directives / regulations as amended from time to time: –... -

Page 51: Index

Index Index Commissioning/start-up 30 Design 12 Designation 11 Disposal 10 Event of damage 5 Faults Causes and remedies 41, 42, 43 Key to safety symbols/markings 5 Maintenance 35 Operating limits 34 Operating modes 12 Personnel 7 Preservation 9 Qualification 7 Returning to service 34 Safety 7 Safety awareness 8 Specialist personnel 7 Storage 9 Training 7 Warnings 5 Warranty claims 5 51 of 54... - Page 54 KSB SE & Co. KGaA Johann-Klein-Straße 9 • 67227 Frankenthal (Germany) Tel. +49 6233 86-0 www.ksb.com...

Need help?

Do you have a question about the EMV Series and is the answer not in the manual?

Questions and answers