Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Taktomat RTX350

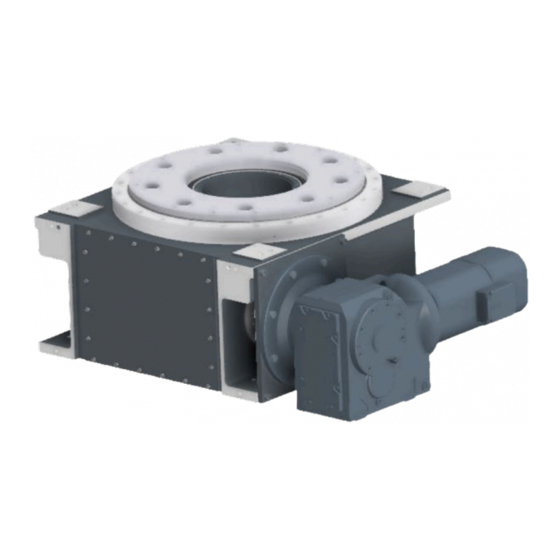

- Page 1 Rotary indexer Version 1.0 Assembly instructions 2022-05-30...

-

Page 2: Table Of Contents

Assembly instructions Table of contents About these instructions ................................. 3 Purpose ........................................3 Contact information ....................................3 Product designation ....................................3 Symbols ......................................... 4 Safety ........................................5 Safety instructions ....................................5 Warnings ....................................... 5 Requirements for personnel ................................. 7 Personal protective equipment ................................7 Requirements for incorporation into a complete machine ......................... -

Page 3: About These Instructions

Purpose The purpose of these Assembly Instructions is to provide users with all the information necessary for proper and safe installation of the rotary indexer in a complete machine. Contact information TAKTOMAT GmbH Rudolf-Diesel-Straße 14 86554 Pöttmes Tel.: +49 (0) 8253-9965-0... -

Page 4: Symbols

Assembly instructions About these instructions Symbols The following symbols are used in these instructions: Instructions and directions Requirements for performing an instruction are indicated by a check mark. The action steps to be executed are numbered. The results of individual action steps are indicated by a black arrow. The overall result of an instruction is marked by a white arrow in a black circle. -

Page 5: Safety

Assembly instructions Safety Safety Safety instructions General safety instructions • Read through these instructions completely • Observe the information and instructions in these instructions • Keep unauthorized persons away from the working area • Work on electrical systems may only be carried out by qualified electricians •... - Page 6 Assembly instructions Safety 2.2.2 Meaning of the signal words and symbols The following signal words are used in this document: Signal word Meaning DANGER Indicates a hazardous situation which will result in death or serious injury. WARNING Indicates a potentially hazardous situation which may result in death or serious injury. CAUTION Indicates a potentially hazardous situation which may result in minor or moderate injury.

-

Page 7: Requirements For Personnel

Assembly instructions Safety Wear foot protection Wear hand protection Requirements for personnel The activities described in these instructions may only be performed by qualified personnel. Qualified personnel are persons who are able to carry out the work assigned to them due to their technical training, knowledge and experience. -

Page 8: Product Description

40 to 70 Media do not expose to aggressive media Storage period > 6 months provide additional corrosion protection 3.2.2 Dimensions The dimensions of the different versions are given on the TAKTOMAT website: https://www.taktomat.de/. 8 / 27 Rotary indexer RTX Version 1.0... -

Page 9: Product Overview

Assembly instructions Product description Product overview Fig. 2: Rotary indexer structure – basic type with closed circuit Roll star / output flange Middle part (fixed) in basic type Drive unit Housing Position indicator Fig. 3: Rotary indexer structure – distance type with closed circuit Roll star / output flange Middle section (fixed) in distance type Drive unit... -

Page 10: Transport

Assembly instructions Transport Transport Required personal protective equipment WARNING Tipping or falling loads Suspended loads can tip or fall down. This can cause serious or fatal injuries to persons. • Do not step under suspended loads • Keep unauthorized persons out of the danger zone •... -

Page 11: Transport With Slings

Assembly instructions Transport Transport with slings 4.1.1 Slings on the middle section (RTX350/RTX450) Transport the rotary indexer with the slings as follows: Fig. 4: Transport with slings Attach the slings in the threaded holes as shown below and check their function. - Page 12 Assembly instructions Transport 4.1.2 Slings on the housing (RTX 550-RTX900) Transport the rotary indexer with the slings as follows: Fig. 5: Transport with slings Attach the slings in the threaded holes as shown below and check their function. The angle between the vertical and the chain sling or sling strap must be between 0 and 45°. Fig.

- Page 13 Assembly instructions Transport Recommended slings Quantity Manufacturer Designation Type CODIPRO Swivel eyebolt M6 DSR M6 UP - 0.15t CODIPRO Swivel eyebolt M8 DSR M8 UP - 0.40t CODIPRO Swivel eyebolt M8 DSR M8 UP - 0.40t CODIPRO Swivel eyebolt M10 DSR M10 UP - 0.70t Version 1.0 Rotary indexer RTX...

-

Page 14: Assembly

Assembly instructions Assembly Assembly Required personal protective equipment DANGER Electric shock Touching live parts poses an immediate danger to life • Work on electrical systems may only be carried out by qualified electricians • Before starting work, disconnect the system, secure it against being switched on again and make sure that no voltage is present WARNING Crushing during assembly and dismantling... -

Page 15: Drive Attachment

Damage to components Improper attachment of the drive can cause material damage • The type of drive, e.g. a servomotor or three-phase a.c. motor must be agreed with TAKTOMAT • On attaching the drive, note and follow the manufacturer’s operating instructions •... - Page 16 Note the following regarding attachments on the roll star / output flange: • Maximum weight moved (according to TAKTOMAT project planning). • Minimum time until positioning (according to TAKTOMAT project planning). • Maximum overhang (tipping moment) (according to TAKTOMAT project planning).

-

Page 17: Guidelines For Drive Control Of Indexing Tables

Assembly instructions Assembly Guidelines for drive control of indexing tables The specified switching time must be reached for correct operation of the indexing table. The switching time is the time required for the output flange to move from station to station (circuit) at a constant rated motor speed (50 Hz). The switching time does not include any times for the motor movement in the dwell area, as well as the time for motor acceleration and delay. - Page 18 Assembly instructions Assembly Delayed reaction to sensor signal: Immediate reaction to sensor signal: Motor remains stopped outside the dwell area Motor remains stopped in the dwell area Dwell area Speed, output flange Speed, output flange Sensor Sensor Motor speed Motor speed Fig.

-

Page 19: Operation

This mode is frequently used in fast-running machines with short machining times. The partly completed machinery is synchronised mechanically with the rest of the machine via the free drive shaft. The ration between the dwell and step time can be adjusted within certain limits by TAKTOMAT when producing the curve. Reversing operation (reciprocating operation) In this mode the roll star / output flange oscillates (shuttles) continuously, back and forth between two positions. - Page 20 The cylinder is unable to accelerate and decelerate the accumulated load gently. As a result, high accelerations occur, which impact the mechanics. Inching may only be carried out with a suitable universal controller. A suitable controller is, for example, the TIC controller (TAKTOMAT Indexing Controller). Emergency stop The emergency stop stops the movement of the roll star / output flange immediately.

-

Page 21: Maintenance

Assembly instructions Maintenance Maintenance Required personal protective equipment DANGER Electric shock Touching live parts poses an immediate danger to life • Work on electrical systems may only be carried out by qualified electricians • Before starting work, disconnect the system, secure it against being switched on again and make sure that no voltage is present CAUTION Harmful substances... -

Page 22: Maintenance Tasks

Assembly instructions Maintenance Maintenance tasks 7.1.1 Maintenance plan Interval Activity Personnel Daily Operator • General visual inspection and check for noises • Check the rotary indexer for oil leakage Monthly Operator • Check the function of the seals • Check for damage (visual inspection) •... -

Page 23: Lubricating

Assembly instructions Maintenance Lubricating 7.2.1 Lubricant requirements Careful lubrication is necessary to ensure operating reliability and a long life of the partly completed machinery. All lubricating points must be supplied with the specified oils and greases. Clean soiled lubricating points carefully with petroleum or an appropriate means and then lubricate with new lubricant. After lubricating, the surplus lubricant must be removed and disposed of properly. -

Page 24: Troubleshooting

• Check sensor setting on position cam • Check sensor cable on sensor • Brake not released • Worm gear malfunction • Contact TAKTOMAT GmbH The drive turns but the rotary indexer does not turn and the • Safety clutch overload / disengaged •... -

Page 25: Disposal

Assembly instructions Disposal Disposal Required personal protective equipment NOTICE Environmental damage Improper disposal may result in environmental damage • Dispose of components and operating materials in accordance with local regulations • Observe the safety data sheets of the operating materials Materials used The components are mainly made of the following materials: •... -

Page 26: Spare And Wear Parts

• Check spare parts for faults or defects prior to installation Spare and wear parts are always order-specific. A corresponding spare and wear parts list is available from TAKTOMAT on request. When ordering spare parts, always specify the serial number. The serial number is located on the nameplate. -

Page 27: Annexes

(The original declaration of incorporation is included in the documentation) Translation of the original declaration of incorporation (in German) for partly completed machinery (Machinery Directive 2006/42/EC, Annex II 1 B) Manufacturer: TAKTOMAT GmbH Rudolf-Diesel-Straße 14 D-86554 Pöttmes Description and identification of the partly completed machinery: Your order No.: Our order No.:...

Need help?

Do you have a question about the RTX350 and is the answer not in the manual?

Questions and answers