Summary of Contents for Unimotion MCE

- Page 1 MAINTENANCE AND ASSEMBLY INSTRUCTIONS MCE and MSCE MINI ELECTRIC CYLINDERS and SLIDERS...

-

Page 2: Table Of Contents

Electrical connection of the system ........ 22 Initial start-up Operation Maintenance Lubrication ................. 24 Cleaning ................24 Repair MCE / MSCE ..............25 Motor and drive ..............25 Disassembly and replacement Disassembly ..............25 Replacement ..............25 Disposal Technical data... -

Page 3: General Information

(with or without the preassembled standard motor together with the cables and drive) are designated as product. There are also an abbreviations MCE and MSCE used, by which the mini electric cylinder and mini electric slider is defined, respectively. -

Page 4: General Safety Instructions

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS PRODUCT DESCRIPTION GENERAL SAFETY INSTRUCTIONS To ensure the right functionality of the product, it must be MODIFICATION OF THE PRODUCT handled with care. It is not allowed to put any tools or any other items which can cause damage to the product on the product. -

Page 5: Operating Conditions

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MINI ELECTRIC SLIDER – MSCE / CHARACTERISTICS OPERATING CONDITIONS Ambient temperature 0 °C ~ +50 °C Ambient temperature without a preassembled standard motor 0 °C ~ +60 °C... -

Page 6: Product Description

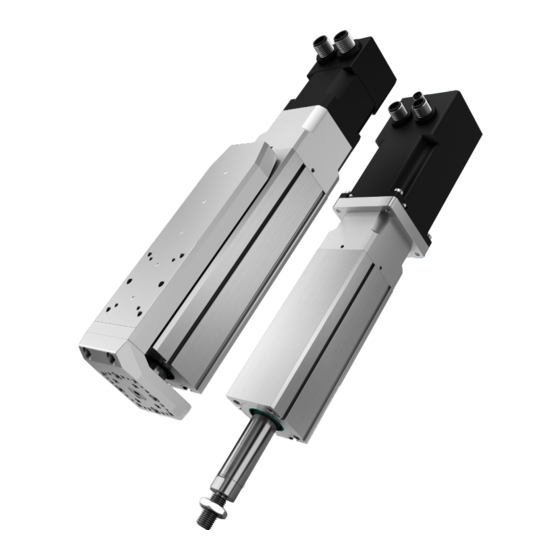

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS PRODUCT DESCRIPTION PRODUCT DESCRIPTION STRUCTURAL DESIGN With a standard motor, motor adapter VK, drive and cables 1 – Compact aluminium cylinder profile 2 – Piston rod (stainless steel) with an anti-rotation device 3 –... - Page 7 MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS PRODUCT DESCRIPTION MSCE With a standard motor, motor adapter VK, drive and cables 1 – Aluminium slide with an integrated linear guiding system 2 – Front plate 3 –...

-

Page 8: Identification Label

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS PRODUCT DESCRIPTION IDENTIFICATION LABEL 1 – ID number 2 – Serial number 3 – Product ordering code The label must be fully visible and must ensure compliance with all the instructions it contains. -

Page 9: Transport And Storage

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS TRANSPORT AND STORAGE TRANSPORT AND STORAGE TRANSPORT STORING THE PRODUCT The product is carefully packed for its safe transportation. The product needs to be stored in a dry and roofed place and protected against corrosion and humidity. -

Page 10: Mounting

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING MOUNTING MOUNTING OPTIONS Mounting the product For the mounting accessories, please refer to the Avoid from collision of the mounting screws and the product product catalogue MCE and MSCE (mini electric cylinders and sliders). - Page 11 MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING The piston rod must not be subjected to torsion when tightening or loosening the hex nut In order to avoid torsion, use one wrench to hold the piston rod accessory in proper position, then tighten or loosen the hex nut with the second wrench, see Figure 9.

- Page 12 MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING Mounting the attachment Never use other mounting points as it is presented Avoid from collision of the mounting screws and the product The attachments can be mounted only on the presented...

-

Page 13: Orientation

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING MSCE The attachments can be mounted as follows (see Figure 13): 1 – on the slide 2 – on the front plate Figure 13: Mounting the attachments to the MSCE. -

Page 14: Permissible Loads

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING PERMISSIBLE LOADS For the values of the maximum permissible axial load, Overloading lateral load, drive torque, travel and rotational speed Overloading the product can lead to the product being and acceleration (of the product and the product damaged. -

Page 15: Accessories - Overview

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING ACCESSORIES – OVERVIEW For information about materials, dimensions and the Accessories are not pre-assembled to the product in the maximum permissible loads of the accessories, please factory before shipment. - Page 16 MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING Compatible with MCE size Accessories Motor adapter VK • • • • • • Motor adapeters Coupling • • • • • • Elastomer couplings Motor side drive MSD •...

- Page 17 MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING MSCE Figure 17: Overview of the MSCEs accessories. In order to improve the products in this catalogue the specifications are subject to change without notice.

-

Page 18: Magnetic Field Sensor

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING Compatible with MSCE size Accessories Motor adapter VK • • • • • • Motor adapeters Coupling • • • • • • Elastomer couplings Motor side drive MSD •... - Page 19 MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING MSCE MCE/MSCE Position of the magnets [mm] LP [mm] Position of the magnets [mm] LP [mm] Abs. position + 37,0 LP - E + 27,0 Abs. position + E + 10,0 Abs.

-

Page 20: Motor Adapter With A Coupling

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING Magnetic field sensor with an HMG sensor holder Valid for the MCE/MSCE size of 25. STEP 1: The magnetic field sensor 1 must be placed STEP 4: Adjust the sensor holder 2 together with the in the slot of the sensor holder 2. -

Page 21: Motor Side Drive With A Timing Belt

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING MOTOR SIDE DRIVE WITH A TIMING BELT For assembly instructions for the motor side drive MSD with a timing belt, please refer to the assembly instructions for MSD MG (motor side drive with a timing belt). -

Page 22: Electrical Connection Of The System

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS MOUNTING ELECTRICAL CONNECTION OF THE SYSTEM 1 – Motor 2 – Drive 3 – Motor cable 4 – Encoder cable 5 – Brake cable 6 – Signal cable 7 –... -

Page 23: Initial Start-Up

• direction of the movement of the piston rod (MCE) or the slide (MSCE) depending on the motor shaft rotation, • homing procedure (by the limit switch or physical end position, where the maximum permissible drive torque of the product and homing travel speed of 10 mm/s are not exceeded), •... -

Page 24: Maintenance Lubrication

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS OPERATION / MAINTENANCE OPERATION The product must not be put into operation until the final machinery into which it is installed has been declared in conformity with the provisions of the machinery directives, where appropriate. -

Page 25: Repair

MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS DISPOSAL / TECHNICAL DATA REPAIR MCE / MSCE Mini electric cylinder MCE and mini electric slider MSCE can not be repaired. It can be only replaced with an identical MCE or MSCE. - Page 26 MAINTENANCE AND ASSEMBLY INSTRUCTIONS / MCE AND MSCE MINI ELECTRIC CYLINDERS AND SLIDERS TECHNICAL DATA DISPOSAL At the end of the product service life the product and its components must be disposed in accordance with the applicable national and international directives.

- Page 27 GE R MAN Y NO RT H A ME RI CA Unimotion GmbH Unimotion North America, Inc. Waldstrasse 20 3952 Ben Hur Ave, Unit 5 D - 78736 Epfendorf Willoughby, OH 44094...

Need help?

Do you have a question about the MCE and is the answer not in the manual?

Questions and answers