Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Idex Godiva GV10000

- Page 1 Vehicle Mounted Fire Pump GV10000 Model Installation Manual Operation Manual Workshop Manual Parts List Godiva Ltd A Unit of IDEX Corporation Charles St Warwick CV34 5LR England Tel +44 (0)1926 623600 Fax +44 (0)1926 623666 GP/180/02 Issue 2021 www.godiva.co.uk godiva@idexcorp.com...

-

Page 2: Amendment Record

AMENDMENT RECORD Model: GV10000 Date Page/s Amendment New Issue No. July 2002 New Issue Sep 2021 Insertion of installation manual with corresponding drawings. Addition of shipping details and lifting locations. Layout manual also updated; previous content remains the same. ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. -

Page 3: Table Of Contents

CONTENTS AMENDMENT RECORD ..........................2 CONTENTS ..............................3 SAFETY ................................ 4 ............................. 4 N OPERATION ..............................4 RAINING ............................4 AINTENANCE ........................4 NVIRONMENTAL ROTECTION ............................4 SSESSMENT ........................ 4 RANSPORTATION AND TORAGE ......................5 PRODUCTION LEANING LUID ..............................5 ARRANTY ........................ -

Page 4: Safety

SAFETY Please read this manual before operating the machinery. Safety notices - = Non-compliance could affect safety IMPORTANT = In case of damage to pump ATTENTION = In case of personal hazards In operation Rotating parts must be guarded against accidental contact. ... -

Page 5: Post-Production Cleaning Fluid

cardboard box is not suitable for storage outside, or when open to the elements. The pump is sprayed internally with a moisture inhibitor when leaving the factory, this treatment may be required if the pump is in long term storage (6 months or more) before use. -

Page 6: Essential Installation Data

Essential installation data Fastening bolts, pump to chassis Use 3/4” UNC or M18 fasteners four off, cross-member minimum strength grade 8.8. Alignment of pump drive lines 7° Effective joint angle – maximum. Tank to suction pipework No tank to pump connection. Pump speed sensor (accessory) A mechanical tachometer is available Godiva part UFP2568. -

Page 7: Installation

INSTALLATION 1) Before installation check the pump for any transit damage. 2) Water Ring Primer (WRP) This type requires a header tank (4.5 litres, 1 gallon capacity minimum) to be installed by the vehicle builder. Information sheet ref. DS325 (page 22) provides details. -

Page 8: Lifting Points

LIFTING POINTS Weight: Mk21 – Gunmetal 321Kg. Use lifting straps that can support the respective weights above. Mount strap around the pump driving shaft. Mount strap around the suction tube flange. ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. -

Page 9: Operation

OPERATION Basic Operation The Godiva Prima pump is designed for extinguishing fires with an unrestricted water source. Water must be as clean as possible and can be fresh water or sea water. Operator Controls Operation of the pump is by two basic controls – discharge valve and pump speed control. After use: If pump has been used with foam, stale water or contaminated water, flush after use. -

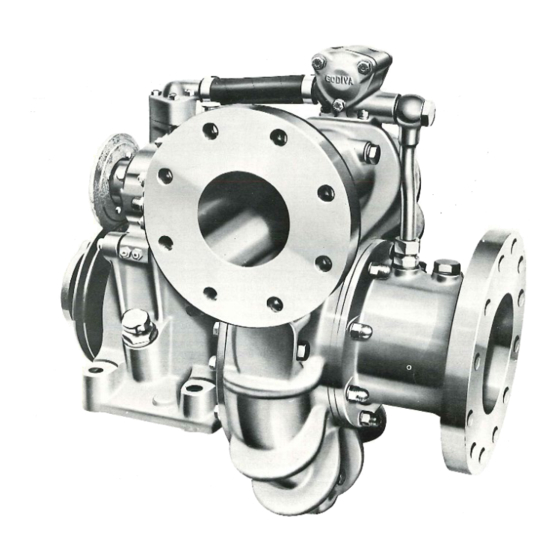

Page 10: General Description

GENERAL DESCRIPTION The Godiva single-stage centrifugal pump is driven in a clockwise direction as viewed from the drive end. The pump drive shaft is stainless steel and runs on ball bearings in an oil bath. Shaft sealing is by a special mechanical face seal ensuring efficiency and long life without adjustment. -

Page 11: Performance Curve

PERFORMANCE CURVE ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. -

Page 12: Pump Overhaul

PUMP OVERHAUL CHAPTER 1 SUCTION TUBE & SUCTION TUBE SEALING RING Removing and Refitting To remove the suction tube, undo the union nuts at each end of the priming suction pipe and take off the pipe. Remove the eight bolts and sealing washers securing the suction tube to the volute body and take off the suction tube. -

Page 13: Volute Body

CHAPTER 3 VOLUTE BODY Removing & Refitting Slacken the clips and disconnect the rubber hose from the priming valve to the primer. Remove the sixteen bolts and sealing washers which attach the volute body to the pump head and remove the volute body. When re-assembling, ensure that the flange faces are clean. -

Page 14: Impeller

CHAPTER 5 IMPELLER Removing & Refitting In order to remove the impeller, take off the volute body as in Chapter 3. Undo the impeller nut and remove the impeller from the splined shaft, carefully levering between the impeller and the pump head if necessary. When refitting the impeller, use a new split pin to secure the slotted nut. -

Page 15: Carbon Seal & Sealing Ring Etc

CHAPTER 7 CARBON SEAL & SEALING RING ETC Maintenance Attention With the impeller removed, (see Chapter 5), access is gained to the carbon seal seating ring, its spring, the carbon seal and the wearing ring. In the event of excessive leakage past the carbon seal or from the drain hole in the pump head, first examine the two O-rings (one under the carbon seal, and one in the carbon seal seating ring). -

Page 16: Wearing Ring

CHAPTER 8 WEARING RING Maintenance Attention Check diameter ‘C’ (Fig. 3) of the wearing ring. If it exceeds 205. 9mm (8.107”), fit a new wearing ring. This entails the removal of six bolts and washers. Two 5/16” UNC jack bolts may be used. -

Page 17: Drive Shaft Bearings

Press out the old oil seal towards the stepped face of the housing. Press in the new oil seal in the opposite direction, making sure that the open end of the seal is towards the stepped face of the housing. To remove the oil seal from the impeller end of the bearing housing it is necessary to remove the volute body (see Chapter 3), the impeller (Chapter 5), and the carbon seal, undo the six nuts and washers which join the pump head to the bearing housing and... -

Page 18: Water Ring Primer

On refitting the primer, it is advisable to rotate the fulcrum shaft from its original position so that the grubscrews bear on a new part of the shaft. Before tightening the grubscrews, ensure that both sides of the primer fibre wheel bear on the sides of the groove in the pump pulley. -

Page 19: Primer Disengaging Unit

CHAPTER 14 PRIMER DISENGAGING UNIT Maintenance Attention To remove the disengaging unit, slacken the hose clips and remove the rubber priming hose. Disengage the primer return spring, and swing the primer upwards and clear of the disengaging unit. Disconnect the pipe union on the underside of the disengaging unit and unscrew the disengaging unit from the bracket. -

Page 20: Spare Parts List

SPARE PARTS LIST TO ORDER SPARE PARTS: ALWAYS QUOTE: The pump serial number as identified on the unit. The serial number is stamped on the volute casing, near the delivery flange. The item number, part number and the description, as given in the parts list below. -

Page 21: How To Read The Spare Parts List

HOW TO READ THE SPARE PARTS LIST The lay-out of this spare parts list enables the composition of the various assemblies to be ascertained immediately. It should be noted that in some cases the parts listed under a particular assembly are not all parts used to make up the assembly concerned. -

Page 22: Gvb10000 Spare Parts

GVB10000 Spare parts ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. - Page 23 ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation.

- Page 24 ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation.

- Page 25 ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation.

-

Page 26: Pump Head And Pump Drive Shaft

Pump Head and Pump Drive Shaft ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. -

Page 27: Volute Body And Suction Tube Assembly

Volute Body and Suction Tube Assembly ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. -

Page 28: Water Ring Primer

Water Ring Primer ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. -

Page 29: Priming Valve

Priming Valve ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. -

Page 30: Primer Disengaging Unit

Primer Disengaging Unit ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. -

Page 31: Gv10000 Pump Assembly Drawing

GV10000 Pump Assembly Drawing ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation. - Page 32 ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation.

-

Page 33: Installation Points

Installation points Pump Mounting Holes with a 20.62mm diameter. Use 3/4” UNC or M18 fasteners four off, minimum strength grade 8.8. Pump Mounting Holes with a 20.62mm diameter. Use 3/4” UNC or M18 fasteners four off, minimum strength grade 8.8. ©Godiva Ltd. - Page 34 ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation.

- Page 35 ©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the right to amend specifications without notice or obligation.

-

Page 36: Specification

SPECIFICATION The UFPM Mk20 and UFPM Mk21 pumps are identical except that in the UFPM Mk20 the impeller and casings are in aluminium alloy, while in the UFPM Mk21 these parts are in gunmetal. This is a single-stage centrifugal pump. The impeller is mounted on a stainless-steel shaft, which runs on two heavy-duty ball bearings continuously lubricated in an oil bath. -

Page 37: Godiva Customer Support Documents

To find these Godiva documents, scan these QR codes - Contact Customer Service Click here for details www.godiva.co.uk/customer-support/ Warranty Statement Click here for details www.godiva.co.uk/warranty_statement Warranty Claim Form Click here for details www.godiva.co.uk/customer-support-warranty- claim/ Godiva terms and Conditions of Sale GODIVA CUSTOMER SUPPORT DOCUMENTS Click here for details https://www.godiva.co.uk/customer-support-terms-...

Need help?

Do you have a question about the Godiva GV10000 and is the answer not in the manual?

Questions and answers