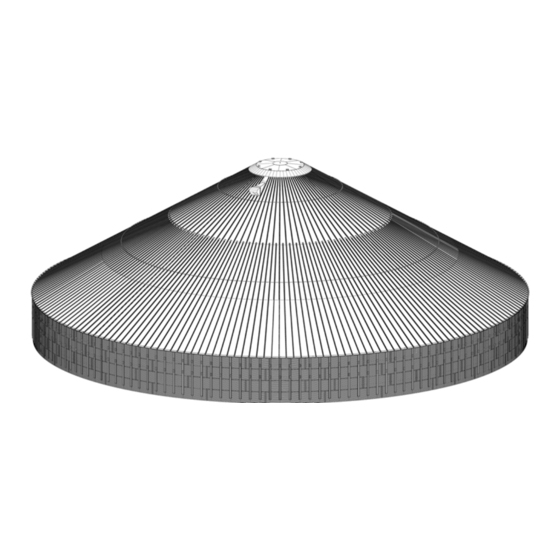

GSi EVO-50 Z-TEK ROOF BINS Construction Manual

Hide thumbs

Also See for EVO-50 Z-TEK ROOF BINS:

- Construction manual (224 pages) ,

- Construction manual (218 pages) ,

- Construction manual (172 pages)

Summary of Contents for GSi EVO-50 Z-TEK ROOF BINS

- Page 1 135' Diameter Models: EVO-50 Z-TEK ROOF BINS - 11 RINGS AND TALLER Construction Manual PNEG-54135-2X Version 1.0 Date: 03-14-22 PNEG-54135-2X...

- Page 2 All information, illustrations, photos, and specifications in this manual are based on the latest information available at the time of publication. The right is reserved to make changes at any time without notice. PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 3: Table Of Contents

Contents Chapter 1 Safety Precautions ........................7 Safety Guidelines ........................7 Cautionary Symbol Definitions......................8 Safety Cautions...........................9 Safety Decals ...........................14 Safety Sign-off Sheet.........................16 Chapter 2 General Overview ........................17 General Information........................17 Tools Required for Construction....................17 Guidelines for Proper Storage of Grain Bin Materials Prior to Construction........18 Overview for a Typical Bin Installation ..................18 Guidelines for Construction Procedures and Lifting Jack Usage............19 Anchor Bolt Detail ........................21... - Page 4 Chapter 6 Stiffeners..........................53 Stiffener Starting Location ......................54 Stiffener Splice Location ......................55 Stiffener Part Number Description ....................56 Color Codes for Stiffener Gauge Identification ................56 Standard Stiffeners........................57 Top Stiffeners..........................58 Stiffeners Splice ........................59 Base Stiffeners .........................60 Base Boots ..........................61 One-Ring Top Stiffener (15-18 Ga.) to a One-Ring Stiffener (15-18 Ga.) ........62 One-Ring Top Stiffener (15-18 Ga.) to a Two-Ring Stiffener (15-18 Ga.) ........62 One-Ring Top Stiffener (15-18 Ga.) to a Two-Ring Stiffener (8-14 Ga.) ..........63 One-Ring Stiffener (15-18 Ga.) to a Two-Ring Stiffener (15-18 Ga.) ..........63...

- Page 5 Assembling the Purlin Number 3....................129 Assembling the Purlin Number 2....................131 Assembling the Purlin Number 1....................133 Assembling a Double A-Frame ....................135 Assembling the Outer Center Collar..................137 Assembling the Lower Stand-Off Bracket to the Outer Center Collar..........138 Center Collar Placement ......................

- Page 6 NOTES PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 7: Chapter 1 Safety Precautions

Safety Precautions Topics Covered in this Chapter ▪ Safety Guidelines ▪ Cautionary Symbol Definitions ▪ Safety Cautions ▪ Safety Decals ▪ Safety Sign-off Sheet Safety Guidelines Safety guidelines are general-to-specific safety rules that must be followed at all times. This manual is written to help you understand safe operating procedures and problems that can be encountered by the operator and other personnel when using this equipment. -

Page 8: Cautionary Symbol Definitions

Chapter 1: Safety Precautions Cautionary Symbol Definitions Cautionary symbols appear in this manual and on product decals. The symbols alert the user of potential safety hazards, prohibited activities and mandatory actions. To help you recognize this information, we use the symbols that are defined below. Table 1-1 Description of the different cautionary symbols Symbol Description... -

Page 9: Safety Cautions

Chapter 1: Safety Precautions Safety Cautions Use Personal Protective Equipment • Use appropriate personal protective equipment: Respiratory Foot Protection Protection Protection Hearing Head Fall Protection Protection Protection Hand Protection • Wear clothing appropriate to the job. • Remove all jewelry. •... - Page 10 Chapter 1: Safety Precautions Maintain Equipment and Work Area • Understand service procedures before doing work. Keep area clean and dry. • Never service equipment while it is operating. Keep hands, feet, and clothing away from moving parts. • Keep your equipment in proper working condition. Replace worn or broken parts immediately.

- Page 11 Chapter 1: Safety Precautions Unload the Bin Correctly • Use CENTER FLOOR OUTLET ONLY until NO grain remains above this outlet. • Side floor outlets to be used ONLY when above condition is satisfied. • Lock all side floor outlets to avoid accidental premature use.

- Page 12 Chapter 1: Safety Precautions Rotating Auger Hazard • Keep clear of rotating augers and moving parts. • Do not remove or modify guards or covers. • Lock-out power source before making adjustments, cleaning, or maintaining equipment. • Failure to follow these precautions will result in serious injury or death.

- Page 13 Chapter 1: Safety Precautions Store Bin Sheets Properly • Sidewall bundles or sheets must be stored in a safe manner. The safest method of storing sidewall bundles is by laying them horizontally with the arch of the sheet upward, like a dome.

-

Page 14: Safety Decals

The safety decals on your equipment are safety indicators which must be carefully read and understood by all personnel involved in the installation, operation, service and maintenance of the equipment. To replace a damaged of missing decal, contact us to receive a free replacement. GSI Decals 1004 E. Illinois Street Assumption, IL 62510 Phone: 1–217–226–4421... - Page 15 Chapter 1: Safety Precautions Description Location Decal No. Decal Warning Keep Clear of On bin door DC-GBC-1A Augers covers On bin door Warning Unload Instructions DC-GBC-2A covers PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 16: Safety Sign-Off Sheet

Chapter 1: Safety Precautions Safety Sign-off Sheet Below is a sign-off sheet that can be used to verify that all personnel have read and understood the safety instructions. This sign-off sheet is provided for your convenience and personal record keeping. Date Employee Name Supervisor Name... -

Page 17: Chapter 2 General Overview

These include, but may not be limited to: • A stiffener and sidewall gauge layout chart is required. If such a chart is not included with this manual, contact GSI. • Roof instructions must be followed. Roof instructions are included in this manual. -

Page 18: Guidelines For Proper Storage Of Grain Bin Materials Prior To Construction

Chapter 2: General Overview • 1/2" Drive impact socket set • Lifting jacks • Center pole roof support • Step ladders • Large C-clamp or welding V-grip for clamping NOTE: Quantities required will depend on the number of workers and size of the bin. Guidelines for Proper Storage of Grain Bin Materials Prior to Construction Storage of the build materials prior to construction is important. -

Page 19: Guidelines For Construction Procedures And Lifting Jack Usage

Chapter 2: General Overview Assembly • Build one ring of sidewall and make sure to caulk all seams. • Add top outside stiffeners and inside stiffeners at the same time to the rings of the sidewall sheets NOTE: These top stiffeners are the lightest gauge stiffeners and will get heavier as the bin is raised. Therefore, the heaviest stiffeners are located at the bottom of the bin and are installed last. - Page 20 11.Lower the tank and secure to the foundation before leaving the job site. 12.At the completion of the tank, set stiffeners over the anchor bolts and measure the tank to ensure it is in a round condition. Consult with GSI for questions on tolerances. PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 21: Anchor Bolt Detail

Chapter 2: General Overview Anchor Bolt Detail The following is the minimum requirement for anchoring of standard tanks. • 3/4" diameter anchor bolt (1) is the minimum allowed, 1" diameter anchor bolt (1) is the minimum with sidedraw flume system. •... -

Page 22: Anchor Bolt Charts

Chapter 2: General Overview Anchor Bolt Charts Prior to setting any anchor bolts, you must be sure to have the correct anchor bolt placement. This is very critical for stiffener alignment during bin erection. NOTE: Refer to proper chart to find the anchor chord dimensions that correspond to the bin that is being built. -

Page 23: Chapter 3 Hardware Requirements

Hardware Requirements Topics Covered in this Chapter ▪ Bolt and Nut Pairings ▪ Hardware for 2-Post Sidewall Sheets ▪ Hardware for 3-Post Sidewall Sheets ▪ Bolt Torque Specifications ▪ Identifying Bolt Grades ▪ Color Chart for Bin Hardware Buckets ▪ Bolt Identifications Bolt and Nut Pairings This chart lists shows the correct nut to use with each size of bolt. -

Page 24: Hardware For 2-Post Sidewall Sheets

Chapter 3: Hardware Requirements Hardware for 2-Post Sidewall Sheets Refer to the below chart for the hardware requirements for 2-post sidewall sheets on commercially stiffened bins that are 21'-78' in diameter. Table 3-1 Hardware for 2-post sidewall sheets Horizontal Seam Vertical Seam Bolt Stiffener to Sidewall Overlap Seam Bolt... -

Page 25: Hardware For 3-Post Sidewall Sheets

Chapter 3: Hardware Requirements Hardware for 3-Post Sidewall Sheets Refer to the below chart for the hardware requirements for 3-post sidewall sheets on commercially stiffened bins that are 21'-78' in diameter. Table 3-2 Hardware for 3-post sidewall sheets Horizontal Seam Vertical Seam Bolt Stiffener to Sidewall Overlap Seam Bolt... -

Page 26: Bolt Torque Specifications

CAUTION Grade 2 Bolts Grade 2 bolts are designated with a plain head and are not used in GSI grain bins. Grade 5 Bolts Grade 5 bolts are designated by three slash marks on the head. All 5/16" diameter bolts are to be grade 5 or higher. -

Page 27: Color Chart For Bin Hardware Buckets

Chapter 3: Hardware Requirements Color Chart for Bin Hardware Buckets For ease of identification, hardware is separated and identified by buckets with color coded lids or labels. Use the following chart to help identify the correct hardware. Hard- Lid/ ware Description JS Part # YDP Part # Color... -

Page 28: Bolt Identifications

Chapter 3: Hardware Requirements Bolt Identifications Use the following information to identify the bolts and where each must be used during installation. Bolt (S-7485) An S-7485 is a 3/8" x 1" JS flange bolt without a sealing washer. Bolt (S-7485) is used in the following locations: •... -

Page 29: Bolt (S-10260)

Chapter 3: Hardware Requirements Bolt (S-10260) An S-10260 is a 5/16" x 1" JS flange bolt that is pre-assembled with a sealing washer. Bolt (S-10260) is used in the following locations: • Use to connect the roof panels together, where they overlap. •... -

Page 30: Bolt (S-10779)

Chapter 3: Hardware Requirements Bolt (S-10779) An S-10779 is a M10 x 25 flange bolt that is pre-assembled with a conical HDPE sealing washer. Bolt (S-10779) is used in the following locations: • Use to connect the horizontal, vertical and overlap seams on 20 gauge to 15 gauge sidewall connections. -

Page 31: Bolt (S-10800)

Chapter 3: Hardware Requirements Bolt (S-10800) An S-10800 is a M10 x 75 flange bolt that is pre-assembled with a conical HDPE sealing washer. Bolt (S-10800) is used in the following locations: • Use to connect the overlap seams on 6 gauge and heavier triple laminated sidewall connections. -

Page 32: Nut (S-10784)

Chapter 3: Hardware Requirements Nut (S-10784) An S-10784 is a M10 flange nut. Nut (S-10784) is used in the following locations: • Use to connect all non-laminated sidewall connections and stiffener splice connections. • Use to connect the base angles to the sidewall sheets. •... -

Page 33: Nut (S-9281)

Chapter 3: Hardware Requirements Nut (S-9281) An S-9281 is a 7/16" hex nut. Nut (S-9281) is used in the following locations: • Use in wind ring splice and over pipe connections. 0.385" (0.977 cm ) Grade 5 PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin... - Page 34 NOTES PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 35: Chapter 4 Assembling The Sidewall Sheets

Assembling the Sidewall Sheets Topics Covered in this Chapter ▪ Guidelines for Constructing the Sidewall Sheets ▪ Color Codes for Sidewall Gauge Identification ▪ Orientation Detail for Sidewall Sheets (2-Post) ▪ Orientation Detail for Sidewall Sheets (3-Post) ▪ References for Sidewall Sheets and Caulkings ▪... -

Page 36: Orientation Detail For Sidewall Sheets (2-Post)

Chapter 4: Assembling the Sidewall Sheets Orientation Detail for Sidewall Sheets (2-Post) To avoid the misalignment of the holes, it is necessary to use the correct orientation of the top sidewall sheet during installation. Figure 4-1 Orientation details of 2-post sidewall sheets PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin... -

Page 37: Orientation Detail For Sidewall Sheets (3-Post)

Chapter 4: Assembling the Sidewall Sheets Orientation Detail for Sidewall Sheets (3-Post) To avoid the misalignment of the holes, it is necessary to use the correct orientation of the sidewall sheet during installation. Figure 4-2 Orientation details of 3-post sidewall sheets PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin... -

Page 38: References For Sidewall Sheets And Caulkings

Chapter 4: Assembling the Sidewall Sheets References for Sidewall Sheets and Caulkings To avoid the misinterpretation of callouts during installation, follow the references for sidewall sheets and caulkings used in this section as below. Table 4-2 For Non-Laminated Sheets Callout Description Part Number Reference... -

Page 39: Caulking And Assembling The Standard (Non-Laminated) Sheets

Chapter 4: Assembling the Sidewall Sheets Caulking and Assembling the Standard (Non-Laminated) Sheets To keep out moisture from overlapping the sheets, apply caulking to each sidewall sheet prior to installation. 1. Apply strip caulk (2) near the outside edge of the outer sheet and then apply 13" (33 cm) long strip caulk (3) along the top horizontal seam. - Page 40 Chapter 4: Assembling the Sidewall Sheets 3. Before bolting the next ring into place, apply one 13" (33 cm) long strip of caulk (3) along the lower horizontal edge of the lapping sheet (1) at every vertical seam. This will fill the space that occurs between the holes caused by the overlapping sheets.

-

Page 41: Outer Sheet Caulking Instructions For Laced Lamination

Chapter 4: Assembling the Sidewall Sheets Outer Sheet Caulking Instructions for Laced Lamination To help keep the moisture out between the laminated sidewall sheets, it is necessary to apply caulking over each set of stiffener holes and at the ends of the laminated outer sidewall sheet. 1. - Page 42 Chapter 4: Assembling the Sidewall Sheets 4. For 9-5 gauge laminates: a. Extend the caulk (3) horizontally 18" (45.7 cm) between the edge of the sheet and second horizontal seam hole at the top right of outer sheet (1O). b. Apply a horizontal strip of caulk (5) between the overlapping vertical seam edge and second horizontal seam hole at both the ends of the outer sheet (1O).

-

Page 43: Lacing Overview Of Double Laminated Sidewall Sheets

Chapter 4: Assembling the Sidewall Sheets Lacing Overview of Double Laminated Sidewall Sheets Figure 4-7 Lacing overview of double laminated sheets PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin... -

Page 44: Caulking And Assembling The Double Laminated Sheets

Chapter 4: Assembling the Sidewall Sheets Caulking and Assembling the Double Laminated Sheets Each outer sidewall sheet (1O) must be layered and caulked prior to assembling sidewall sheet seams together. The inner sidewall sheets (1I) do not have any caulking. 1. - Page 45 Chapter 4: Assembling the Sidewall Sheets 5. Before bolting the next ring into place, apply a strip of caulk (3) along the horizontal edge of the overlapping sheet at every overlapping seam. This will fill the space that occurs between the holes caused by the overlapping sheets.

-

Page 46: Lacing Overview Of Triple Laminated Sidewall Sheets

Chapter 4: Assembling the Sidewall Sheets Lacing Overview of Triple Laminated Sidewall Sheets Figure 4-10 Lacing overview of triple laminated sheets PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin... -

Page 47: Caulking And Assembling The Triple Laminated Sheets

Chapter 4: Assembling the Sidewall Sheets Caulking and Assembling the Triple Laminated Sheets Each outer sidewall sheet (1O) must be layered and caulked prior to assembling sidewall sheet seams together. The inner sidewall sheets (1I) do not have any caulking. 1. - Page 48 Chapter 4: Assembling the Sidewall Sheets 5. Before bolting the next ring into place, apply a strip of caulk (3) along the horizontal edge of the overlapping sheet at every overlapping seam. This will fill the space that occurs between the holes caused by the overlapping sheets.

-

Page 49: Chapter 5 Installing The Base Angle

Installing the Base Angle Topics Covered in this Chapter ▪ Installing the Base Angle ▪ Installing the Base Angle Shims ▪ Installing the Anchor Bolt Washer Installing the Base Angle Installing the base angle ring will help reinforce and seal the final ring of the sidewall. What You Should Know The base angle overlap should be offset two holes from the stiffener. - Page 50 Chapter 5: Installing the Base Angle Figure 5-1 Installing the base angle M10 x 25 flange bolt with HDPE sealing washer (S-10779) Base angle (B-7031) M10 flange nut (S-10784) Base angle offset example Sidewall sheet (final ring assembly) Optional mastic sealer (or equivalent) PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 51: Installing The Base Angle Shims

Chapter 5: Installing the Base Angle Installing the Base Angle Shims A section of the base boot plate will rest on top of the base angle, therefore causing the base boot to rest unevenly on the foundation. To offset this, base angle shims are required to ensure the base boot sets evenly on the foundation. -

Page 52: Installing The Anchor Bolt Washer

Chapter 5: Installing the Base Angle Installing the Anchor Bolt Washer Anchor bolt washers help to cover the oversized hole in the base plate. Before You Begin Make sure the anchor bolts are secured and the base plates are installed. 1. -

Page 53: Chapter 6 Stiffeners

Stiffeners Topics Covered in this Chapter ▪ Stiffener Starting Location ▪ Stiffener Splice Location ▪ Stiffener Part Number Description ▪ Color Codes for Stiffener Gauge Identification ▪ Standard Stiffeners ▪ Top Stiffeners ▪ Stiffeners Splice ▪ Base Stiffeners ▪ Base Boots ▪... -

Page 54: Stiffener Starting Location

Chapter 6: Stiffeners Stiffener Starting Location 1. All stiffeners should be installed on the exterior of the bin. 2. Install the top stiffener (29) to the top sidewall sheet (30) at a distance of 4" from the top hole in the bin wall. -

Page 55: Stiffener Splice Location

Chapter 6: Stiffeners Stiffener Splice Location 1. All stiffeners should be installed on the exterior of the bin. 2. Align the stiffener splice (32 or 33) with the holes at the ends of the two stiffeners (29 and 31). NOTE: Make sure the center of the stiffener splice (stiffener ends) is at 10" above the horizontal seam. -

Page 56: Stiffener Part Number Description

Chapter 6: Stiffeners Stiffener Part Number Description The part numbers in the following tables use an “XX” at the end of the number to represent the gauge of the material. Color Codes for Stiffener Gauge Identification Refer to the below charts toto identify the stiffener gauge based on the color code painted on the ends of the stiffeners. -

Page 57: Standard Stiffeners

Chapter 6: Stiffeners Standard Stiffeners Refer to the below information to determine the differences between the types of standard two-ring stiffeners. Figure 6-3 Standard stiffeners Description Length Available Gauges Call Out Part Number Two-ring stiffener 87.938" (223 cm) 2, 5, 6 CTS-4002XX Two-ring stiffener 87.938"... -

Page 58: Top Stiffeners

Chapter 6: Stiffeners Top Stiffeners Refer to the below information to determine the differences between the two types of top stiffeners. Figure 6-4 Top stiffeners Description Length Available Gauges Call Out Part Number CTS-4012XX Inside top stiffener 28.938" (73.5 cm) 2, 5, 6, 8, 10, 12, 14 CTS-4016XX Outside top stiffener... -

Page 59: Stiffeners Splice

Chapter 6: Stiffeners Stiffeners Splice Refer to the below information to determine the gauge of the splice needed to connect the stiffeners. Figure 6-5 Stiffener splice Description Length Available Gauges Call Out Part Number 12, 14 CTS-4035XX Stiffener splice 9.938" (25.24 cm) CTS-4073XX Stiffener splice 15.906"... -

Page 60: Base Stiffeners

Chapter 6: Stiffeners Base Stiffeners Refer to the below information to determine the differences between the base stiffeners. Figure 6-6 Base stiffeners Description Length Available Gauges Call Out Part Number CTS-4033XX Base stiffener 98.126" (249 cm) 2, 5, 6 CTS-4034XX Laminated base stiffener 98.126"... -

Page 61: Base Boots

Chapter 6: Stiffeners Base Boots Refer to the below information to determine the differences between the base boots. Figure 6-7 Base boots Description Length Available Gauges Call Out Part Number Base boot weldment for 8 Ga. through 6" x 9" x 3/4" 11.391"... -

Page 62: One-Ring Top Stiffener (15-18 Ga.) To A One-Ring Stiffener (15-18 Ga.)

Chapter 6: Stiffeners One-Ring Top Stiffener (15-18 Ga.) to a One-Ring Stiffener (15-18 Ga.) Refer to the below information for a standard connection of a one-ring top stiffener (CTS-4016XX) to a one-ring stiffener (CTS-4006XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) One-ring stiffener (CTS-4006XX) One-ring top stiffener (CTS-4016XX) -

Page 63: One-Ring Top Stiffener (15-18 Ga.) To A Two-Ring Stiffener (8-14 Ga.)

Chapter 6: Stiffeners One-Ring Top Stiffener (15-18 Ga.) to a Two-Ring Stiffener (8-14 Ga.) Refer to the below information for a standard connection of a one-ring top stiffener (CTS-4016XX) to a two-ring stiffener (CTS-4074XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) Two-ring stiffener (CTS-4074XX) One-ring top stiffener (CTS-4016XX) -

Page 64: One-Ring Stiffener (15-18 Ga.) To A Two-Ring Stiffener (8-14 Ga.)

Chapter 6: Stiffeners One-Ring Stiffener (15-18 Ga.) to a Two-Ring Stiffener (8-14 Ga.) Refer to the below information for a standard connection of a one-ring stiffener (CTS-4006XX) to a two-ring stiffener (CTS-4074XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) One-ring stiffener (CTS-4006XX) Two-ring stiffener (CTS-4074XX) Splice (CTS-4035XX) -

Page 65: Two-Ring Stiffener (15-18 Ga.) To A Two-Ring Stiffener (15-18 Ga.)

Chapter 6: Stiffeners Two-Ring Stiffener (15-18 Ga.) to a Two-Ring Stiffener (15-18 Ga.) Refer to the below information when connecting a two-ring stiffener (CTS-4004XX) to a two-ring stiffener (CTS-4004XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) Two-ring stiffener (CTS-4004XX) Splice (CTS-4035XX) Completed assembly NOTE: Two-post stiffeners shown. -

Page 66: Two-Ring Stiffener (8-14 Ga.) To A Two-Ring Stiffener (2-6 Ga.)

Chapter 6: Stiffeners Two-Ring Stiffener (8-14 Ga.) to a Two-Ring Stiffener (2-6 Ga.) Refer to the below information when connecting a two-ring stiffener (CTS-4074XX) to a two-ring stiffener (CTS-4002XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) Two-ring stiffener (CTS-4002XX) Two-ring stiffener (CTS-4074XX) Splice (CTS-4073XX) Completed assembly... -

Page 67: Two-Ring Stiffener (8-14 Ga.) To A Base Stiffener (10-14 Ga.)

Chapter 6: Stiffeners Two-Ring Stiffener (8-14 Ga.) to a Base Stiffener (10-14 Ga.) Refer to the below information when connecting a two-ring stiffener (CTS-4074XX) to a base stiffener (CTS-4038XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) Two-ring stiffener (CTS-4074XX) Splice (CTS-4035XX) Base stiffener (CTS-4038XX) Completed assembly... -

Page 68: Two-Ring Stiffener (15-18 Ga.) To A Base Stiffener (10-14 Ga.)

Chapter 6: Stiffeners Two-Ring Stiffener (15-18 Ga.) to a Base Stiffener (10-14 Ga.) Refer to the below information when connecting a two-ring stiffener (CTS-4004XX) to a base stiffener (CTS-4038XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) Two-ring stiffener (CTS-4004XX) Splice (CTS-4035XX) Base stiffener (CTS-4038XX) Completed assembly... -

Page 69: Laminated Stiffeners (2 Ga.) With Inserts (10-12 Ga.)

Chapter 6: Stiffeners Laminated Stiffeners (2 Ga.) with Inserts (10-12 Ga.) Refer to the below information when connecting a laminated stiffener (CTS-4008XX) to an insert (CTS-4010XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) Laminated stiffener (CTS-4008XX) Insert (CTS-4010XX) Completed assembly NOTE: Two-post stiffeners shown. -

Page 70: Base Stiffener (10-16 Ga.) To A Base Boot

Chapter 6: Stiffeners Base Stiffener (10-16 Ga.) to a Base Boot Refer to the below information when connecting a base stiffener (CTS-4038XX) to a base boot (CTS-4046XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) Base stiffener (CTS-4038XX) Base boot (CTS-4046XX) Completed assembly NOTE: Two-post stiffeners shown. -

Page 71: Laminated Base Stiffener (2 Ga.) With Insert (2+10 To 2+12 Ga.) To A Base Boot

Chapter 6: Stiffeners Laminated Base Stiffener (2 Ga.) with Insert (2+10 to 2+12 Ga.) to a Base Boot Refer to the below information when connecting a laminated base stiffener with insert (CTS-4034XX and CTS-4037XX) to a base boot (CTS-4045XX or CTS-4048XX). M10 x 25 flange bolt (S-10782) M10 flange nut (S-10784) Laminated base stiffener (CTS-4034XX) -

Page 72: 12-Bolt Pattern Laminated Stiffeners With Insert

Chapter 6: Stiffeners 12-Bolt Pattern Laminated Stiffeners with Insert Refer to the below information when connecting two 12-bolt pattern laminated stiffeners (CTS-4041XX) with inserts (CTS-4042XX). M10 x 25 flange bolt (S-10782) Insert (CTS-4042XX) M10 flange nut (S-10784) Completed assembly Laminated stiffener (CTS-4041XX) NOTE: Two-post stiffeners shown. -

Page 73: 12-Bolt Pattern Laminated Stiffener To Laminated Base Stiffener With Inserts To A Base Boot

Chapter 6: Stiffeners 12-Bolt Pattern Laminated Stiffener to Laminated Base Stiffener with Inserts to a Base Boot Refer to the below information when connecting a 12-bolt pattern laminated stiffener (CTS-4041XX) and a laminated base stiffener (CTS-4042XX) with inserts (CTS-4039XX and CTS-4040XX) to a base boot (CTS-4049XX). -

Page 74: 12-Bolt Pattern Laminated Stiffener To Laminated Base Stiffener With Inserts To A Base Boot

Chapter 6: Stiffeners 12-Bolt Pattern Laminated Stiffener to Laminated Base Stiffener with Inserts to a Base Boot Refer to the below information when connecting a 12–bolt pattern laminated stiffener (CTS-4041XX) and a laminated base stiffener (CTS-4050XX) with inserts (CTS-4042XX and CTS-4051XX) to a base boot (CTS-4045XX or CTS-4048XX). -

Page 75: Chapter 7 Door Assemblies

Door Assemblies Topics Covered in this Chapter ▪ General Information ▪ Door Assembly Instructions (NCWT0803) ▪ Door Assembly Instructions (NCWT0637) General Information Two Ring Doors for Various Bin Heights The two ring door used for each bin depends upon the number of rings. Refer to the below table to identify the door used with each bin height. -

Page 76: Door Assembly Instructions (Ncwt0803)

Chapter 7: Door Assemblies Door Assembly Instructions (NCWT0803) Two Ring Door Layout Figure 7-1 Two ring door placement (NCWT0803) Door assembly Short door sheet Special door sheet Standard sidewall sheet Left notch door sheet Left door sheet Right notch door sheet Right door sheet PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin... - Page 77 Chapter 7: Door Assemblies Installing the Door Weldment The two ring door is installed in the last two rings, after all the other rings have been assembled and lifted. There are notched door sheets (66 and 67), short door sheet (71), left and right door sheets (78 and 79) and special door sheet (72) that must be installed around the door weldments (31 and 33) to ensure the correct installation.

- Page 78 Chapter 7: Door Assemblies 3. The second door is installed to the other side of the bin (opposite side of the previously installed door). 4. Install the door at the same time as you install the second ring from the bottom. The door consists of outer frame weldment (31), jamb plate weldments (32 and 46), inner frame weldment (33), seal weldment (36), upper cover (37), top inner door panel (34), bottom inner door panel (35), outer cover assembly (59), base stiffeners (60) and door stiffeners (61).

- Page 79 Chapter 7: Door Assemblies Assembling the Jamb Plates Assemble the left jamb plate weldment (32) and right jamb plate weldment (46) between the outer door frame weldment (31) and the inner door frame weldment (33) using 7/16" x 2-1/2" flange bolts (1), 7/16"...

- Page 80 Chapter 7: Door Assemblies Installing the Seal Weldment Install the seal weldment (36) to the top of the door frame weldments (31 and 33) using 3/8" x 1" HHCS bolts (14), special washers (22) and 3/8" hex nuts (24). NOTE: Refer to note in Installing the Door Weldment, page 77 for details on the specific order in which these parts must be assembled.

- Page 81 Chapter 7: Door Assemblies Installing the Door Frames to the Sidewall 1. Position the jamb plate weldments (32 and 46) to the inside of the sidewall with outer door frame weldment (31) to the outside of the bin. 2. Place the corrugated sealing strip (69) between the outer and inner edges of the sidewall to jamb plate weldments (32 and 46) connection.

- Page 82 Chapter 7: Door Assemblies 4. Install the jamb plate weldments (32 and 46) to the inside of the sidewall using M12 x 60 flange bolts (3) and M12 flange nuts (80). NOTE: The seal weldment (36) at the top must be installed to the inside of the sidewall. Remember to apply rope caulk (68) around the bolt holes between the seal weldment (36) and the sidewall .

- Page 83 Chapter 7: Door Assemblies Installing the Door Stiffeners 1. Position the door stiffeners (61) under the base stiffener (60) on top of the outer door frame weldment (31) and install using 3/4" x 5" HHTB bolts (4), 3/4" flat washers (16), 3/4" square washers (17) and 3/4"...

- Page 84 Chapter 7: Door Assemblies Installing the Bearing Pins The bearing pins (38) are used to align the inside panels correctly with the door frame weldment. Install eight bearing pins (38) to the inner door frame weldment (33) using 5/16" x 1-1/2" HHCS bolts (5), 5/16"...

- Page 85 Chapter 7: Door Assemblies Installing the Latch Bar Holders The door latch bar (39) holders are used to secure the inner doors tightly against the door frame weldment. 1. Install eight 1/2" x 1-1/4" HHTB bolts (6) and 1/2" flange nuts (29) to fill in the holes inside of the outer door frame weldment (31).

- Page 86 Chapter 7: Door Assemblies Assembling the Top and Bottom Inner Doors The inner doors assemble in the same way. Make sure the hinge side of the panels are oriented correctly before starting the assembly. 1. Assemble the latch bars (43) to a set of the right and left latches (42 and 45) using four 5/16" x 1" MS screws (9) and 5/16"...

- Page 87 Chapter 7: Door Assemblies Figure 7-11 Assembling the top and bottom inner doors 5/16" x 1" flange bolt with sealing washer 40 Inside/outside hinge weldment (NCWT0018) (S-10260) 5/16" x 1" MS screw with sealing washer 41 Door reinforcement angle (NCWT0917) (S-10633) 18 5/16"...

- Page 88 Chapter 7: Door Assemblies Installing the Inside Door Panels IMPORTANT: The inner door panels (34 and 35) must seat on the bearing pins and lock over latch bar holders for the door panels to close correctly. DO NOT fill the bin until the door panels have been installed correctly.

- Page 89 Chapter 7: Door Assemblies Assembling the Outer Door The outer door must be assembled before it can be installed to the column weldments. 1. Attach the middle reinforcement channel (51) at the same time as the hold-back plate (74) to the middle of the outer door cover (48) using six 5/16"...

- Page 90 Chapter 7: Door Assemblies Installing the Outer Door 1. Fill all open holes on the inside of the column weldments with 3/8" x 1" bin bolts. 2. Install the outer door cover angles (53) to the outside of the outer door frame weldment (31) using eight 5/16"...

- Page 91 Chapter 7: Door Assemblies 4. Install the cover hinge weldments (55) to the outside of the right outer door cover angle (53) using four 5/16" x 1" MS screws (9), 5/16" flat washers (18) and 5/16" flange nuts (28). 5. Install the door latch mounting bracket (54) to the outside of the left outer door cover angle (53) using two 5/16"...

- Page 92 Chapter 7: Door Assemblies 6. Install the top and bottom outer door latches (56 and 57) to the door latch mounting bracket (54) using 5/16" x 3/4" carriage bolts (12), latch bushing (44) and 5/16" flange nuts (28). NOTE: Make sure the holes in the outer door latches (56 and 57) align with the holes in the door latch mounting bracket (54) to allow the door to be locked.

- Page 93 Chapter 7: Door Assemblies 8. Align the cover hinge brackets (50) on the outer door cover assembly (59) with the set of cover hinge weldments (55) and install using two 3/8" x 4-1/2" HHCS bolts (10), 3/8" flat washer (15) and 3/8"...

- Page 94 Chapter 7: Door Assemblies 9. Make sure the outer door cover assembly (59) operates smoothly and the slots in the top and bottom door latches (56 and 57) align with the door latch rod (52) to firmly close the door against the frame.

- Page 95 Chapter 7: Door Assemblies Installing the Door Cover Hold-Back 1. Assemble the latch bracket (77) to the adjustment bracket (76) loosely, using two 5/16" x 1" flange bolts (8) and 5/16" hex nuts (73). Make sure each bolt (8) goes through a hole and a slot to allow for sliding adjustment.

- Page 96 Chapter 7: Door Assemblies Parts List Figure 7-20 Two ring door assembly (NCWT0803) parts PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

- Page 97 Chapter 7: Door Assemblies Table 7-2 Two ring door assembly (NCWT0803) parts list Description Description Ref # Part Number Ref # Part Number 7/16" x 2-1/2" flange bolt with Door reinforcement angle S-10134 NCWT0917 sealing washer Inside panel latch - R.H. S-7185 3/8"...

-

Page 98: Door Assembly Instructions (Ncwt0637)

Chapter 7: Door Assemblies Door Assembly Instructions (NCWT0637) Two Ring Door Layout Figure 7-21 Two ring door placement (NCWT0637) Door assembly Standard sidewall sheet Special door sheet Left notch door sheet Right notch door sheet Short door sheet PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin... - Page 99 Chapter 7: Door Assemblies Installing the Door Weldment The two ring door is installed in the last two rings, after all the other rings have been assembled and lifted. There are special door sheet (4), short door sheet (5) and notched door sheets (7 and 8) that must be installed around the jamb plates of the door assembly (3) to ensure the correct installation.

- Page 100 Chapter 7: Door Assemblies Installing the Door Frames to the Sidewall 1. Position the jamb plates of the door assembly (3) to the inside of the sidewall and align the jamb plate holes with the sidewall sheet holes. 2. Place the corrugated sealing strip (10) between the outer and inner edges of the sidewall to jamb plate connection.

- Page 101 Chapter 7: Door Assemblies 4. Using the seal strip of the door assembly (3) as a template, field drill the top row of holes (11) in the sidewall sheet. 5. Install the seal strip of the door assembly (3) to the sidewall using M12 x 60 flange bolts (1) and M12 nuts (2).

- Page 102 NOTES PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 103: Chapter 8 Roof Assembly

Roof Assembly Topics Covered in this Chapter ▪ Attaching the Inside Stiffener to the Top Outside Stiffener ▪ Attaching the Eave Bracket to the Inside Stiffener ▪ Attaching the Eave Angle to the Sidewall Sheet ▪ Connecting the Tension Member to the Eave Bracket ▪... -

Page 104: Attaching The Inside Stiffener To The Top Outside Stiffener

Chapter 8: Roof Assembly Attaching the Inside Stiffener to the Top Outside Stiffener The inside stiffener supports the eave bracket and installed at the same time as the top outside stiffener. The inside stiffeners are only installed at the eave bracket locations in the sidewall sheet. What You Should Know NOTE: Do not tighten the nuts until all the bolts to connect the inside stiffener with sidewall and outside stiffener has been installed. -

Page 105: Attaching The Eave Bracket To The Inside Stiffener

Chapter 8: Roof Assembly Attaching the Eave Bracket to the Inside Stiffener Eave brackets secure the roof rafter to the sidewall. Before You Begin Make sure all the inside stiffeners are installed to the sidewall. 1. Install the eave bracket (23) to the inside stiffener (24) flanges using 3/8" x 1" flange bolts (7) and 3/8"... -

Page 106: Attaching The Eave Angle To The Sidewall Sheet

Chapter 8: Roof Assembly Attaching the Eave Angle to the Sidewall Sheet The eave angle secures the bottom of the roof panels to the bin eave. What You Should Know Each eave angle section will overlap the previously installed eave angle and installed to the inside of the sidewall. - Page 107 Chapter 8: Roof Assembly 4. Install 5/16" x 1" flange bolts (2) and 5/16" flange nuts (19), leaving the end hole open for the next eave angle to be installed. NOTE: The quantity of flange bolts (2) and flange nuts (19) may vary, depending on the sidewall punch pattern.

-

Page 108: Connecting The Tension Member To The Eave Bracket

Chapter 8: Roof Assembly Connecting the Tension Member to the Eave Bracket Tension members are installed to the eave bracket around the inside of the bin. Before You Begin Make sure all the eave brackets and eave angles are installed. What You Should Know IMPORTANT: Install bolts with bolt head on the backside of the eave bracket as shown. -

Page 109: Assembling A Laminated Rafter

Chapter 8: Roof Assembly Assembling a Laminated Rafter A rafter is assembled together with an insert to give additional strength. What You Should Know All the lower rafters are assembled with rafter inserts before attaching the purlin clips and purlins. 1. -

Page 110: Assembling The Rafters

Chapter 8: Roof Assembly Assembling the Rafters What You Should Know For the 135' diameter bins, each rafter will consist of a two piece design and will need to be spliced together with rafter clips before constructing the A-frames. 1. Locate an upper rafter (30) and lower rafter (32), and find the end with series of twelve holes on both the rafters. -

Page 111: Attaching The Center Collar Rafter Clips To The Rafter

Chapter 8: Roof Assembly Attaching the Center Collar Rafter Clips to the Rafter Center collar rafter clips secure the A-frame rafter sections to the center collar. What You Should Know Each roof rafter receives two center collar rafter clips, identified as the left center collar rafter clip (39) and the right center collar rafter clip (40). -

Page 112: About Temperature Cable Brackets And A-Frame Assemblies

GSI is not responsible for the effectiveness or performance of any temperature cable monitoring system or layout. - Page 113 Chapter 8: Roof Assembly Figure 8-9 A-frame installation sequence and temperature cable locations for 135' diameter bin 55.4' radius location 12.3' radius location 32.2' radius location Table 8-1 A-frame installation sequence and temperature cable locations for 135' diameter bin Temp Cable Number A-frame number Rafter Number Radius Location...

- Page 114 Chapter 8: Roof Assembly Table 8-1 A-frame installation sequence and temperature cable locations for 135' diameter bin (cont'd.) Temp Cable Number Radius Location A-frame number Rafter Number 12.3' 55.4' 32.2' — — 32.2' — — — — 55.4' 55.4' 32.2' 55.4' 32.2' —...

- Page 115 Chapter 8: Roof Assembly Table 8-1 A-frame installation sequence and temperature cable locations for 135' diameter bin (cont'd.) Temp Cable Number Radius Location A-frame number Rafter Number 32.2' — — 32.2' 12.3' 55.4' NOTE: A-frames labeled as “A1” through “A9” have X-bracing and are installed first. A-frames labeled as “A10”...

-

Page 116: Assembling The Temperature Cable Bracket

Chapter 8: Roof Assembly Assembling the Temperature Cable Bracket The temperature cable brackets are installed to the roof rafters and support the temperature cables. Before You Begin Determine the correct location of the temperature cable brackets within the A-frame Assembly. See About Temperature Cable Brackets and A-Frame Assemblies, page 112. - Page 117 Chapter 8: Roof Assembly 3. Install a quick link (130) to each temperature cable bracket (143) to support the temperature cables. IMPORTANT: Do not attach weights to the temperature cables; secure the bottom of cables to the floor with light twine. No roof rafter shall support more than one cable. Figure 8-11 Installing the supplier quick link to the temperature cable bracket Supplier quick link Temperature cable bracket...

-

Page 118: Attachment Locations Of Purlins To Rafters

Chapter 8: Roof Assembly Attachment Locations of Purlins to Rafters Purlins are horizontal members between the rafters that give support to the roof structure. The length of the purlin determines its location on the A-frame assembly. The below image represents a completely assembled A-frame section with X-bracing installed. For more information, see the following sections: Assembling the Purlin Number 8, page 119,... -

Page 119: Assembling The Purlin Number 8

Chapter 8: Roof Assembly Assembling the Purlin Number 8 Purlin number 8 is located eighth from the eave. Before You Begin Place two roof rafters on the ground with roof panel holes facing up. Some A-frame assemblies will have X-bracing installed and will be placed at specific locations around the roof. Determine if X-bracing is being installed and note those steps in this procedure. - Page 120 Chapter 8: Roof Assembly 7. Install a 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17), securing the X-braces (85 and 86) together where they cross. 8. Tighten all the hardware to the recommended torque specifications. See Bolt Torque Specifications, page Figure 8-14 Assembling the purlin 8 and X-bracings to the A-frame assembly 1/2"...

-

Page 121: Assembling The Purlin Number 7

Chapter 8: Roof Assembly Assembling the Purlin Number 7 Purlin number 7 is located seventh from the eave. Before You Begin Place two roof rafters on the ground with roof panel holes facing up. Some A-frame assemblies will have X-bracing installed and will be placed at specific locations around the roof. Determine if X-bracing is being installed and note those steps in this procedure. - Page 122 Chapter 8: Roof Assembly 7. Install a 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17), securing the X-braces (87 and 88) together where they cross. 8. Tighten all the hardware to the recommended torque specifications. See Bolt Torque Specifications, page Figure 8-15 Assembling the purlin 7 and X-bracings to the A-frame assembly 1/2"...

-

Page 123: Assembling The Purlin Number 6

Chapter 8: Roof Assembly Assembling the Purlin Number 6 Purlin number 6 is located sixth from the eave. Before You Begin Place two roof rafters on the ground with roof panel holes facing up. Some A-frame assemblies will have X-bracing installed and will be placed at specific locations around the roof. Determine if X-bracing is being installed and note those steps in this procedure. - Page 124 Chapter 8: Roof Assembly 7. Install a 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17), securing the X-braces (89 and 90) together where they cross. 8. Tighten all the hardware to the recommended torque specifications. See Bolt Torque Specifications, page Figure 8-16 Assembling the purlin 6 and X-bracings to the A-frame assembly 1/2"...

-

Page 125: Assembling The Purlin Number 5

Chapter 8: Roof Assembly Assembling the Purlin Number 5 Purlin number 5 is located fifth from the eave. Before You Begin Place two roof rafters on the ground with roof panel holes facing up. Some A-frame assemblies will have X-bracing installed and will be placed at specific locations around the roof. Determine if X-bracing is being installed and note those steps in this procedure. - Page 126 Chapter 8: Roof Assembly 7. Install a 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17), securing the X-braces (91 and 92) together where they cross. 8. Tighten all the hardware to the recommended torque specifications. See Bolt Torque Specifications, page Figure 8-17 Assembling the purlin 5 and X-bracings to the A-frame assembly 1/2"...

-

Page 127: Assembling The Purlin Number 4

Chapter 8: Roof Assembly Assembling the Purlin Number 4 Purlin number 4 is located fourth from the eave. Before You Begin Place two roof rafters on the ground with roof panel holes facing up. Some A-frame assemblies will have X-bracing installed and will be placed at specific locations around the roof. Determine if X-bracing is being installed and note those steps in this procedure. - Page 128 Chapter 8: Roof Assembly 7. Install a 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17), securing the X-braces (93 and 94) together where they cross. 8. Tighten all the hardware to the recommended torque specifications. See Bolt Torque Specifications, page Figure 8-18 Assembling the purlin 4 and X-bracings to the A-frame assembly 1/2"...

-

Page 129: Assembling The Purlin Number 3

Chapter 8: Roof Assembly Assembling the Purlin Number 3 Purlin number 3 is located third from the eave. Before You Begin Place two roof rafters on the ground with roof panel holes facing up. Some A-frame assemblies will have X-bracing installed and will be placed at specific locations around the roof. Determine if X-bracing is being installed and note those steps in this procedure. - Page 130 Chapter 8: Roof Assembly 7. Install a 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17), securing the X-braces (95 and 96) together where they cross. 8. Tighten all the hardware to the recommended torque specifications. See Bolt Torque Specifications, page Figure 8-19 Assembling the purlin 3 and X-bracings to the A-frame assembly 1/2"...

-

Page 131: Assembling The Purlin Number 2

Chapter 8: Roof Assembly Assembling the Purlin Number 2 Purlin number 2 is located second from the eave. Before You Begin Place two roof rafters on the ground with roof panel holes facing up. Some A-frame assemblies will have X-bracing installed and will be placed at specific locations around the roof. Determine if X-bracing is being installed and note those steps in this procedure. - Page 132 Chapter 8: Roof Assembly 7. Install a 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17), securing the X-braces (97 and 98) together where they cross. 8. Tighten all the hardware to the recommended torque specifications. See Bolt Torque Specifications, page Figure 8-20 Assembling the purlin 2 and X-bracings to the A-frame assembly 1/2"...

-

Page 133: Assembling The Purlin Number 1

Chapter 8: Roof Assembly Assembling the Purlin Number 1 Purlin number 1 is located closest to the eave. Before You Begin Place two roof rafters on the ground with roof panel holes facing up. Some A-frame assemblies will have X-bracing installed and will be placed at specific locations around the roof. Determine if X-bracing is being installed and note those steps in this procedure. - Page 134 Chapter 8: Roof Assembly 7. Install a 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17), securing the X-braces (99 and 100) together where they cross. 8. Tighten all the hardware to the recommended torque specifications. See Bolt Torque Specifications, page Figure 8-21 Assembling the purlin 1 and X-bracings to the A-frame assembly 1/2"...

-

Page 135: Assembling A Double A-Frame

Chapter 8: Roof Assembly Assembling a Double A-Frame To achieve the required spacing between each A-frame, a double A-frame need to be assembled on the ground before lifting and installing into place as one assembly. Before You Begin The double A-frame assembly will consist of three assembled roof rafters, purlin clips, and purlins. There are also two different purlin clips, a left purlin clip (63) and a right purlin clip (64). - Page 136 Chapter 8: Roof Assembly Figure 8-23 Double A-frame assembly exploded view 1/2" x 1-3/4" flange bolt (S-10252) Right purlin clip (CTR-0949) 1/2" flange nut (S-10253) Roof rafter Left purlin clip (CTR-0975) Purlin Right purlin clip (CTR-1005) Assembled A-frame Left purlin clip (CTR-0976) Weight of an Assembled Double A-frame 135' Double A-frame assembly Approximate Weight...

-

Page 137: Assembling The Outer Center Collar

Chapter 8: Roof Assembly Assembling the Outer Center Collar Each A-frame section is assembled to the center collar at the top. The outer center collar assembly is a two piece design and will need to be spliced together with splice plates before installing the lower stand-off support brackets. -

Page 138: Assembling The Lower Stand-Off Bracket To The Outer Center Collar

Chapter 8: Roof Assembly Assembling the Lower Stand-Off Bracket to the Outer Center Collar There will be eight lower stand-off support brackets that are needs to be assembled to the outer center collar before it is lifted onto the roof with the center pole. Before You Begin Make sure that the outer center collar is secured properly on the stands or suitable blocks. -

Page 139: Center Collar Placement

Chapter 8: Roof Assembly Center Collar Placement The following figure gives the approximate height needed to install the center collar. With one sidewall ring in place, use the center support and position the center collar at the height specified, measuring from the bottom of the center collar to the bottom of the sidewall sheet as shown. If additional rings are required for construction purposes, add 44"... -

Page 140: Guidelines For Assembling And Lifting The A-Frame Rafter Sections

Chapter 8: Roof Assembly Guidelines for Assembling and Lifting the A-Frame Rafter Sections The roof is assembled in sections and referred to as A-frame sections. Each A-frame section is assembled on the ground and lifted into place. IMPORTANT: Do not drill additional holes in purlins. Install the flange bolts and nuts based on the number of holes in the purlins. - Page 141 Chapter 8: Roof Assembly All lifting should be performed by a certified crane operator with prior bin construction experience. Never lift during windy conditions. DANGER General Guidelines: • Construct the A-frame sections on flat ground or blocking. • Install the temperature cable brackets at the same time you assemble the A-frame sections. •...

-

Page 142: Attaching The A-Frame To The Center Collar

Chapter 8: Roof Assembly Attaching the A-Frame to the Center Collar The upper portion of the A-frame assembly must be installed to the center collar, so that it supports the center collar and the main roof structure. Before You Begin Make sure the center collar is assembled and secured to the center support pole. -

Page 143: Attaching The A-Frame To The Eave Bracket

Chapter 8: Roof Assembly Attaching the A-Frame to the Eave Bracket The bottom end of the rafters in the A-frame must be installed to the eave brackets. 1. Lower the A-frame assembly (133) along the side of the eave bracket (23) and align with the proper holes. -

Page 144: Assembling The Roof Panel Clips

Chapter 8: Roof Assembly Assembling the Roof Panel Clips The roof panel clips provide support to the roof panels at the peak and are installed nearest to the center collar. Before You Begin Make sure all the rafter assemblies are installed and secured to both the center collar and eave bracket. What You Should Know Roof panel clips are installed between the two rafter assemblies. -

Page 145: Installing The Intermediate Purlins

Chapter 8: Roof Assembly Installing the Intermediate Purlins Intermediate purlins must be installed to connect each A-frame assembly together. The intermediate purlins connecting each A-frame assembly have six holes on each side to secure them with the purlin clips. Before You Begin All A-frame assemblies must be installed and secured to both the center collar and the eave brackets. -

Page 146: Attaching The Roof Panels

Chapter 8: Roof Assembly Attaching the Roof Panels Roof panels overlap the previous roof panel, giving protection from outside elements. Before You Begin Make sure all A-frame assemblies are installed with intermediate purlins and properly tightened. Pre-determine the manway access location. What You Should Know For adjustment purposes, roof panels will be installed to each rafter first, causing exposed gaps between each roof panel group (see figure below). - Page 147 Chapter 8: Roof Assembly 5. Repeat the procedure to continue installing the lower roof panels (114) with the upper roof panels (116) to each roof rafter, leaving an exposed gap (134) between each set (lower and upper) of installed panels. Figure 8-34 Installing the lower and upper roof panels 5/16"...

- Page 148 Chapter 8: Roof Assembly 6. After the roof panels are installed to the rafters, position a lower roof panel (114) to the immediate left of the previously installed lower panels (114). NOTE: The lower panels (114) must be positioned in the gap below the upper roof panel (116). 7.

- Page 149 Chapter 8: Roof Assembly Figure 8-35 Installing the lower and upper roof panels into exposed gaps 5/16" x 1" flange bolt with sealing washer (S-10260) Rope caulk 5/16" flange nut (S-3611) Exposed gap Lower roof panel (CTR-2035) Upper rib Upper roof panel (CTR-1874) Lower rib Rib cap (CTR-1745) PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

- Page 150 Chapter 8: Roof Assembly 12.Working in a counter-clockwise direction, repeat the procedure to continue to fill in all the exposed gaps (134) using the lower roof panels (114) and the upper roof panels (116) on the roof. 13.Secure the lower roof panels (114) and upper roof panels (116) to the roof panel holes (154) in the purlins (132) 5/16"...

-

Page 151: Installing The Roof Flashing

Chapter 8: Roof Assembly Installing the Roof Flashing The roof flashing will seal the area between the center collar and the roof panels. What You Should Know Each roof flashing section overlaps and bolts together with the previously installed roof flashing section. 1. - Page 152 Chapter 8: Roof Assembly 3. Place a strip of rope caulk (122) along the edge of the installed roof flashing (118) where the next roof flashing (118) will overlap. 4. Align the holes along the edge of the next roof flashing (118) with the previously installed roof flashing holes.

-

Page 153: Assembling The Center Collar Brackets To The Inner Center Collar

Chapter 8: Roof Assembly Assembling the Center Collar Brackets to the Inner Center Collar The inner center collar is a one piece design which connects to the outer center collar with eight center collar channel brackets. Five center collar channel brackets must be assembled to the inner center collar before it is lifted to the roof. -

Page 154: Installing The Inner Center Collar To The Outer Center Collar

Chapter 8: Roof Assembly Installing the Inner Center Collar to the Outer Center Collar 1. Make sure all the holes in the center collar channel brackets (120) are aligned with the holes in the weldments of the outer center collar (45) and install the 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17). - Page 155 Chapter 8: Roof Assembly 2. Install the remaining three center collar channel brackets (120) between the inner center collar (119) and outer center collar (45) using 1/2" x 1-3/4" flange bolt (5) and 1/2" flange nut (17). Figure 8-41 Installing the remaining inner center collar brackets 1/2"...

-

Page 156: Installing The Top Panels

Chapter 8: Roof Assembly Installing the Top Panels The top panels seal the area between the inner center collar and outer center collar. 1. Place a continuous strip of caulk (21) on the mating surfaces of the top panel with the roof flashing (118). - Page 157 Chapter 8: Roof Assembly 2. Align the holes on the first top panel (121) with the holes in the center collar channel brackets (120) and the inner center collar flange (119). 3. Install 3/8" x 1" flange bolts (3) and 3/8" flange nuts (15) only to the holes at one end to secure the first top panel (121) with the center collar channel bracket (120).

- Page 158 Chapter 8: Roof Assembly 4. Place two strips of rope caulk (122) along the edge of the top panel (121) (adjacent to the holes) where the next top panel (121) will overlap. Figure 8-44 Placing tube of caulk on the first top panel Top panel (CTR-1646) Rope caulk (S-4458) PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

- Page 159 Chapter 8: Roof Assembly 5. Align the holes along the edge of the next top panel (121) with the holes of the previously installed top panel (121). 6. Install 3/8" x 1" flange bolts (3) and 3/8" flange nuts (15) to the holes at the overlap, securing the top panels (121) with the center collar channel brackets (120).

-

Page 160: Installing The Upper Stand-Off Support Brackets

Chapter 8: Roof Assembly Installing the Upper Stand-Off Support Brackets Eight upper stand-off support brackets are attached to the top panels and allow support for a conveyor or catwalk system. 1. Locate the eight sets of four holes in the top panels (121), and place a gasket (123) over each set of eight holes, where the upper stand-off support brackets (112) will be installed. -

Page 161: Installing The Center Cap Plate

Chapter 8: Roof Assembly Installing the Center Cap Plate Center cap plate will need to be installed on top of the inner center collar and the top panels. 1. Place a continuous strip of caulk (21) on the mating surface (inside edge of the holes) of the cap plate with the top panels (121). - Page 162 Chapter 8: Roof Assembly 3. Attach the appropriate lifting chain (139) to the hook in the center cap plate (124). 4. Attach the appropriate lifting device (138) to the lifting chain (139). 5. Use the qualified personnel to hoist the center cap plate (124) into place. 6.

-

Page 163: Installing The Flashing Lock

Chapter 8: Roof Assembly Installing the Flashing Lock The flashing lock will need to be installed to secure the roof flashing and the top panel. 1. Position the flashing lock (125) under the roof flashing (118), aligning with the holes in the top panel (121) from the underside of the roof. - Page 164 NOTES PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 165: Chapter 9 Bin Accessories

Bin Accessories Topics Covered in this Chapter ▪ Installing the Roof Ladder Steps ▪ Roof Ring Placement (Optional) ▪ Installing the Roof Ring ▪ Installation of the Peak–To–Exhauster Ladder Kit ▪ Preparation for the Roof Exhauster Installation ▪ Assembling the Roof Exhauster ▪... -

Page 166: Installing The Roof Ladder Steps

Chapter 9: Bin Accessories Installing the Roof Ladder Steps Roof ladder steps will allow access to the manway access and peak. What You Should Know Each eave-to-peak ladder step differs with the diameter of each bin. When installing the ladder steps, always start from the eave and work up towards the peak, installing the longer steps first at the eave and the shorter steps later at the peak. - Page 167 Chapter 9: Bin Accessories Use the following table as a guide for the location of each ladder step (rung). Table 9-1 Ladder Rung Placement Chart Bin Diameter Location 105' 135' ↑ LS-260-3 Bin Peak LS-260-3 LS-260-4 LS-260-5 LS-260-6 LS-260-6 LS-260-7 LS-260-8 LS-260-3 LS-260-9...

-

Page 168: Roof Ring Placement (Optional)

Chapter 9: Bin Accessories Roof Ring Placement (Optional) The roof ring is a tubular ring bolted to the exterior of the roof. The placement location and quantity of roof ring kits vary with the diameter of the each bin. The exhauster roof ring (84) on the 135' bin will be installed in the thirty-second (32 ) roof panel rib hole from the eave. -

Page 169: Installing The Roof Ring

Chapter 9: Bin Accessories Installing the Roof Ring Quantity and part numbers of roof ring kits vary with the placing location and with the size of each bin. The following procedure will be similar for each kit. What You Should Know The roof ring and threaded stud may become dislocated from each other during high winds or when the inside pressure of the bin is too high. - Page 170 Chapter 9: Bin Accessories 5. Locate a threaded stud (19) and install two stud nuts (12) evenly and to the center of the threaded stud (19). 6. Install the threaded stud (19) with stud nuts (12) to the end of the installed roof ring section (43). NOTE: Install the threaded stud (19) to the side where the next roof ring section (43) will be installed.

-

Page 171: Installation Of The Peak-To-Exhauster Ladder Kit

Chapter 9: Bin Accessories Installation of the Peak–To–Exhauster Ladder Kit Before installing the roof exhauster, install the peak-to-exhauster ladder kit onto the roof to have access to the roof exhauster. Before You Begin Determine the location of the roof exhauster. What You Should Know This procedure is to install the peak-to-exhauster ladder kit onto the roof. - Page 172 Chapter 9: Bin Accessories Table 9-2 Peak-to-Exhauster Ladder Rung Kit Chart Bin Diameter Location 105' 135' LS-260-3 ↑ Bin Peak LS-260-3 LS-260-4 LS-260-5 LS-260-6 LS-260-6 LS-260-7 LS-260-3 LS-260-4 LS-260-5 LS-260-6 LS-260-4 LS-260-7 Bolt Hole Count LS-260-5 LS-260-8 Located on the Roof Rib LS-260-6 LS-260-7 LS-260-8...

-

Page 173: Preparation For The Roof Exhauster Installation

Chapter 9: Bin Accessories Preparation for the Roof Exhauster Installation Using the roof exhauster mounting plate, some preparations are required for the roof panels to which the roof exhauster mounting plate will be installed. Before You Begin Determine the location of the roof exhauster and set aside the roof panels that the roof exhauster mounting plate will span. - Page 174 Chapter 9: Bin Accessories 4. Bend the tabs (79) downward approximately 90 degrees on the roof exhauster mounting plate (75) to conform with the roof panel (77). NOTE: Bend the tabs (79) on the ground and adjust as necessary once on the roof. 5.

-

Page 175: Assembling The Roof Exhauster

Chapter 9: Bin Accessories Assembling the Roof Exhauster Assembly of the roof exhauster is done prior to installing onto the roof. 1. Apply a strip of tube caulk (81) along the mating surface of the roof exhauster hood (80) and the exhauster mounting plate (75). -

Page 176: Installing The Roof Exhauster Assembly

Chapter 9: Bin Accessories Installing the Roof Exhauster Assembly To install the roof exhauster assembly, it is necessary to replace one of the roof flashing with exhauster flashing. Before You Begin IMPORTANT: Determine the location of the roof exhauster and remove the existing roof flashing panel at this location. - Page 177 Chapter 9: Bin Accessories Figure 9-9 Installing the roof exhauster assembly 5/16" x 1" flange bolt with sealing washer (S-10260) Sealing caulk 5/16" flange nut (S-3611) Roof exhauster assembly Roof exhauster flashing (CTR-2133) PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

- Page 178 Chapter 9: Bin Accessories 7. When the roof exhauster assembly (83) is installed, apply sealing caulk (82) as shown by arrows, sealing the roof exhauster assembly (83) to the roof. Figure 9-10 Sealing caulk location Sealing caulk Roof exhauster assembly PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 179: Installing The Manway Cover

(not shown) are present on the underside of the manway cover (27). If not, contact GSI for the decals and install to the underside of the manway cover (27). NOTE: Suffocation/flighting and entrapment hazard decals replacement part numbers: •... - Page 180 Chapter 9: Bin Accessories Figure 9-11 Installing the manway cover 5/16" x 1" flange bolt with sealing washer 5/16" x 4" hex bolt (S-855) (S-10260) Hinge base (MW-303) 5/16" hex nut (S-396) Manway latch/hasp assembly Hinge leaf (MW-304) (MW-311) Manway cover (MW-301D) Manway sill (CTR-1985) Silicone sealant (NOTE: Factory applied) Latch (MW-306)

-

Page 181: Assembling The Inside Ladder

Chapter 9: Bin Accessories Assembling the Inside Ladder The inside ladder package consists of the ladder, starter brackets, standoff brackets, reinforcement straps and bottom bracket. The ladder should be assembled before installing it to the bin structure. What You Should Know When assembling the ladder sections, ensure all the slip resistant ladder rungs are oriented in the same direction. -

Page 182: Installing The Inside Ladder

Chapter 9: Bin Accessories Installing the Inside Ladder The inside ladder provides manway access from the inside of the bin. What You Should Know Begin by temporarily positioning the ladder assembly (46) directly under the manway roof panel for the correct placement location. - Page 183 Chapter 9: Bin Accessories 4. Field drill 3/8" holes (47) in the sidewall using the bottom hole in each starter brackets (32 and 35) as guides. Install 5/16" x 1" flange bolts (1) and 5/16" flange nuts (10) to the bottom holes. Tighten all the hardware to the recommended torque specifications.

- Page 184 Chapter 9: Bin Accessories Figure 9-14 Installing the ladder brackets and the inside ladder 5/16" x 1" flange bolt with sealing washer (S-10260) Ladder reinforcing strap (LDR-5143) 5/16" x 1" carriage bolt (S-3550) L.H. starter bracket (LDR-4346) 5/16" flange nut (S-3611) Standoff wedge (LDR-4198) R.H.

-

Page 185: Installing The Inside Ladder Bottom Bracket

Chapter 9: Bin Accessories Installing the Inside Ladder Bottom Bracket The ladder bottom bracket keeps the lower portion of the ladder secure. What You Should Know The lower portion of the ladder may need to be cut to fit properly. Field drilling will be required to complete installation. -

Page 186: Guidelines For Installing A Sidedraw System

90° apart. Installation of multiple systems requires approval of GSI. • Sidedraw systems are intended for use with dry, flowable grain. Sidedraws are not to be used for poorly flowing products. This is not unique to GSI bins and flume systems, but is a general rule for such systems. - Page 187 Chapter 9: Bin Accessories Figure 9-16 Installing the sidedraw Required spacing between chute bolt holes (8") Stiffeners Sidewall sheet horizontal seam from base 44" typical bolt hole in the top chute Starting dimension for first chute PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 188: Locating The Chutes

Chapter 9: Bin Accessories Locating the Chutes Use the following procedures to locate the starting position of the first chute. 1. Starting from the top hole in the first sidewall sheet (55), measure down the “starting distance” (51) for the location of the first chute. 2. -

Page 189: Locating The Discharge Opening

Chapter 9: Bin Accessories Locating the Discharge Opening What You Should Know The last bolt hole in the chute should line up with the center of the discharge opening, that is to be cut. With this last bolt hole as reference, it is possible to approximate an opening. 1. -

Page 190: Sidewall Overlap For Sidedraw Weldment

Chapter 9: Bin Accessories Sidewall Overlap for Sidedraw Weldment For proper watershed, make sure that the upper side sheet (62) overlaps on top of the sidedraw weldment plate (60). Figure 9-19 Sidewall overlap ring from the base ring from the base horizontal seam from the base Chute Sidedraw weldment plate... -

Page 191: Caulking For The Sidedraw Weldment

Chapter 9: Bin Accessories Caulking for the Sidedraw Weldment 1. To seal the sidedraw weldment (60) to the sidewall sheets (49), use one strip of caulking (65) on each side of the outer row of bolts. 2. Use the discharge tube weldment as a template to field drill the bolt holes (67) in the sidewall sheet (49). -

Page 192: Wind Ring Quantities

Chapter 9: Bin Accessories Wind Ring Quantities Refer to the below table for the standard and sidewall wind ring quantities based on the bin diameter. Table 9-4 Standard and sidedraw wind ring quantities 2-Post 3-Post Standard wind Sidedraw wind Standard wind Sidedraw wind Rings/Diameter ring quantities... -

Page 193: Installing The Wind Rings

Chapter 9: Bin Accessories Installing the Wind Rings What You Should Know Before installing, determine the bin size, sidewall gauge thickness and height. Use the hardware chart to match the correct bolt length with the correct sidewall gauge thickness when installing the wind ring brackets to the stiffeners. - Page 194 Chapter 9: Bin Accessories Figure 9-22 Installing the wind rings to the upper portion of the stiffener 7/16" x 3-1/4" flange bolt with sealing washer (S-10261) 40 C-clamp (SS-7248) 3/8" x 1" flange bolt (S-7485) 41 Wind ring coupling collar (CTS-1006) 11 3/8"...

-

Page 195: Assembling The Weather Cover For Roller Valve

Chapter 9: Bin Accessories Assembling the Weather Cover for Roller Valve The following instructions are for assembling the weather cover for the roller valve. 1. Install the weather cover kit after the gate has been installed. 2. Apply strip caulking at all the seams where the weather cover plate (42) attaches to the gate (72). 3. - Page 196 NOTES PNEG-54135-2X 135' Diameter EVO-50 Z-Tek 2X Bin...

-

Page 197: Limited Warranty - N.a. Grain Products

12 months from the date of shipment (or, if shipped by vessel, 14 months from the date of arrival at the port of discharge). If, in GSI’s sole judgment, a product is found to have a defect in materials and/or workmanship, GSI will, at its own option and expense, repair or replace the product or refund the purchase price. - Page 198 Authorities having jurisdiction should be consulted before installations are made. 1004 E. Illinois St. Assumption, IL 62510-0020 Phone: 1-217-226-4421 Fax: 1-217-226-4420 www.gsiag.com Copyright © 2022 by The GSI Group, LLC Printed in the USA CN #402127...

Need help?

Do you have a question about the EVO-50 Z-TEK ROOF BINS and is the answer not in the manual?

Questions and answers