Advertisement

Quick Links

Engineering Specification, Installation, Operation and Maintenance

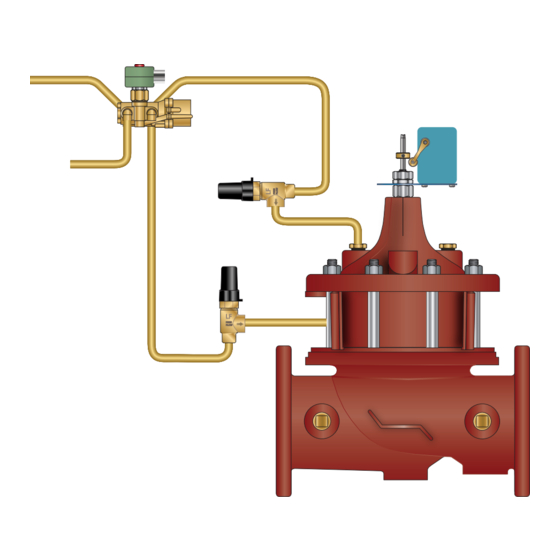

Series LF985GD / LF685GD

Deep Well Pump Control Valve

Sizes: 6" to 24"

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

WARNING

!

Local building or plumbing codes may require modifica-

tions to the information provided. You are required to

consult the local building and plumbing codes prior

to installation. If the information provided here is not

consistent with local building or plumbing codes, the

local codes should be followed. This product must be

installed by a licensed contractor in accordance with

local codes and ordinances.

WARNING

!

Need for Periodic Inspection/Maintenance: This product

must be tested periodically in compliance with local codes,

but at least once per year or more as service conditions

warrant. All products must be retested once maintenance

has been performed. Corrosive water conditions and/or

unauthorized adjustments or repair could render the product

ineffective for the service intended. Regular checking and

cleaning of the product's internal and external components

helps assure maximum life and proper product function.

NOTICE

For Australia and New Zealand: Pipeline strainers should be

installed between the upstream shutoff valve and the inlet of

the backflow preventer.

It's important that this device be tested periodically in compli-

ance with local codes, but at least once per year or more as

service conditions warrant. If installed on a fire sprinkler system,

all mechanical checks, such as alarm checks and backflow

preventers, should be flow tested and inspected internally in

accordance with NFPA 13 and NFPA 25.

Watts product specifications in U.S. customary units and metric are ap prox i mate and are pro vid ed for ref er ence only. For precise mea sure ments, please contact

Watts Tech ni cal Ser vice. Watts re serves the right to change or modify prod uct de sign, con struc tion, spec i fi ca tions, or ma te ri als with out prior notice and without

in cur ring any ob li ga tion to make such chang es and mod i fi ca tions on Watts prod ucts previously or sub se quent ly sold.

Submittal Package

Table of Contents

Basic Valves

Standard

Optional Components

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ACV Maintenance Schedule

LF985GD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . 18

ES-A-ACV-LF985GD

FLOW

CLOSES VALVE

OPENS VALVE

Page

. . . . . . . . . . . . . . . . 14

Advertisement

Summary of Contents for Watts AMES LF985GD Series

-

Page 1: Table Of Contents

Watts product specifications in U.S. customary units and metric are ap prox i mate and are pro vid ed for ref er ence only. For precise mea sure ments, please contact Watts Tech ni cal Ser vice. Watts re serves the right to change or modify prod uct de sign, con struc tion, spec i fi ca tions, or ma te ri als with out prior notice and without... -

Page 2: Engineering Specifications

When the valve reaches the full open position, the limit switch is actuated, turning the pump off. ES-A-ACV-LF985GD 2115 © 2021 Watts... - Page 3 Grooved End = 400psi (27.6 bar) Operating Temperature Buna-N: 160°F (71°C) Maximum EPDM: 300°F (140°C) Maximum Viton™: 250°F (121°C) Maximum Epoxy Coating**: 225°F (107°C) Maximum ** Valves can be provided without internal epoxy coating consult factory ES-A-ACV-LF985GD 2115 © 2021 Watts...

-

Page 4: Acv Schematic

• The C Factor of a value is the flow rate in US GPM at 60°F that will • For sizing questions including cavitation analysis consult Watts cause a 1psi drop in pressure. with system details. • factor can be used in the following equations to determine Flow (Q) and Pressure Drop (∆P):... - Page 5 ***Note: 6 inch and smaller valves, Seat Ring is threaded NOTICE Installation: If unit is installed in any orientation other than horizontal (cover up) OR extreme space constraints exist, consult customer service prior to or at the time of order. ES-A-ACV-LF985GD 2115 © 2021 Watts...

- Page 6 2600 1180 1051 43 1105 3300 1497 41 3/8 Grooved End Dimensions Valve Globe Grooved Cover To Center Angle Grooved Angle Grooved Port Size Port Size Port Size Shipping Weights* Size (npt) (npt) (npt) lbs. kgs. ES-A-ACV-LF985GD 2115 © 2021 Watts...

- Page 7 However, brass solenoids may be used as a replacement component in a lead free Watts ACV main valve, as the wetted surface of a lead free Watts ACV main valve including installed brass solenoids contains less than 0.25% of lead by weight.

- Page 8 * The wetted surface of this product contacted by consumable water contains less than 0.25% of lead by weight. Parts List Item Description Limit Switch Bracket Stem Trip collar Set Screw Wiper Ring* O-Ring* Guide O-Ring* Polypak* Locknut Body Coupling *Included in Repair Kit ES-A-ACV-LF985GD 2115 © 2021 Watts...

- Page 9 Lead Free Brass FLOW Needle: Stainless Steel (304) Elastomers: Buna-N (standard) Internal Threads * The wetted surface of this product contacted by consumable water FLOW contains less than 0.25% of lead by weight. FLOW External Threads FLOW ES-A-ACV-LF985GD 2115 © 2021 Watts...

- Page 10 * The wetted surface of this product contacted by consumable water contains less than 0.25% of lead by weight. Dimensions SIZE DIMENSIONS WEIGHT lbs. kgs. 0.77 11/16 11/16 11/16 11/16 0.77 0.77 5/16 5/16 0.77 ES-A-ACV-LF985GD 2115 © 2021 Watts...

- Page 11 -40°F - 400°F Temp Rating: * The wetted surface of this product contacted by consumable water contains less than 0.25% of lead by weight. Size Dimensions Weight lbs. 13/16 7/16 13/16 7/16 13/16 7/16 15/16 5/16 ES-A-ACV-LF985GD 2115 © 2021 Watts...

- Page 12 * The wetted surface of this product contacted by consumable water contains less than 0.25% of lead by weight. Parts List Item Description Limit Switch Bracket Stem Trip collar Set Screw Wiper Ring* O-Ring* Guide O-Ring* Polypak* Locknut Body Coupling *Included in Repair Kit ES-A-ACV-LF985GD 2115 © 2021 Watts...

-

Page 13: Installation, Operation And Maintenance

Valve Servicing Dimensions FLOW FLOW FLOW FLOW The following tables detail the recommended minimum valve servicing dimensions. Globe Size (in) 21/2 A (in) B (in) Angle Size (in) 2 1/2 C (in) D (in) ES-A-ACV-LF985GD 2115 © 2021 Watts... -

Page 14: Commissioning The Deep Well Pump Control

Operation Operation STEP 3 De-energize the solenoid prior to initial pump start. STEP 4 Energize the solenoid at pump start to close the main valve, checking that the main valve closes. Figure 1 4-Way Solenoid ES-A-ACV-LF985GD 2115 © 2021 Watts... - Page 15 At valve full open position deep well pump will stop. Adjust limit switch collar to final position to ensure positive actuation of limit switch electrical contact, if necessary, by sliding up/down to loca- tion (See Figure 3). Figure 3 Limit Switch in Open Position ES-A-ACV-LF985GD 2115 © 2021 Watts...

-

Page 16: Troubleshooting Guide

Automatic Control Valve Maintenance Schedule To ensure peak performance and longevity of your automatic con- • Annual Maintenance trol valve, Watts/Ames recommends following the below – Conduct monthly & quarterly inspections. standard maintenance schedule. – Inspect & clean all strainers. - Page 17 Check voltage at the solenoid Should be performed by actuate connection, insuring that it has licensed electrician the minimum of 85% of the coils rated voltage. Manual operated is engaged Turn manual operator counter- clockwise to disengage ES-A-ACV-LF985GD 2115 © 2021 Watts...

-

Page 18: Valve Disassembly Instructions

Size (in) 2 1/2 0677-21 0677-22 0677-23 0677-24 0677-25 0677-26 Consult Factory 0677-28 0677-29 0677-30 Table 3: Reduced Port Valve (600GD/600AD) Repair Kits Size (in) 20 & 24 0677-21 0677-23 0677-24 0677-25 0677-26 0677-27 0677-28 0677-30 ES-A-ACV-LF985GD 2115 © 2021 Watts... - Page 19 USA: Backflow T: (978) 689-6066 • F: (978) 975-8350 • AmesFireWater.com USA: Control Valves T: (713) 943-0688 • F: (713) 944-9445 • AmesFireWater.com Canada: T: (888) 208-8927 • F: (905) 481-2316 • AmesFireWater.ca Latin America: T: (52) 55-4122-0138 • AmesFireWater.com ES-A-ACV-LF985GD 2115 © 2021 Watts...

Need help?

Do you have a question about the AMES LF985GD Series and is the answer not in the manual?

Questions and answers