Summary of Contents for AC Air Technology AC TRACKTECH T1X4

- Page 1 MODEL: AC TRACKTECH T1X4 Instruction Manual 95582 Rev. A World’s First Portable, Remote-Control Aircraft Tugs...

-

Page 2: Table Of Contents

1. Components Table of Contents 1. Components ...............3 1-1 Components in the Box .................3 1-2 Tug Components ...................4 1-3 Spare Parts ...................5 1-4 Track Tools ....................6 1-5 On-Board Parts Box ................8 2. Start Up Guide ..............9 2-1 Remote Control Operation ..............9 2-2 Operating the Tug ................ -

Page 3: Components

1. Components 1. Components 1-1 Components in the Box Booster Plate Foam Stand (Part of tug shipping foam) Radio Transmitter Battery Tray Radio Charger Tug Charger Owners Manual Spare Parts Bag... -

Page 4: Tug Components

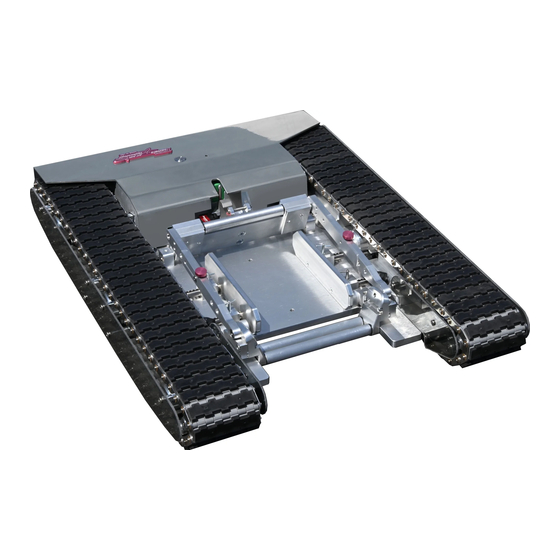

1. Components 1. Components 1-2 Tug Components Rear Cradle Gate Wheel Cradle Ramp Power Switch Tug Charging Port Left Rail-Track Assembly Cradle Release Lever Electronics Cover Electronics Mainplate Assembly Right Rail-Track Assembly Cradle Mainplate Assembly... -

Page 5: Spare Parts

1. Components 1-3 Spare Parts Spare Track Parts Retainer Clips Pins Links Treads Track Install Tools Fuses 4 Amp Light Fuse 10 Amp Circuit Board Fuse Retainer Clip Tool... -

Page 6: Track Tools

1. Components 1-4 Track Tools The track tools are used to assist in the installation of new tracks. This section is intended to show how the tools are used only. A detailed instruction guide is provided when purchasing new tracks. Refer to that instruction guide when installing new tracks. - Page 7 The Track Pin Tools are used to assist in the installation of new tracks when the they are too tight making it diffi cult to align the pin holes. Insert the track pin tools on the inside and outside adjacent pins to the missing pin hole.

-

Page 8: On-Board Parts Box

1. Components 1-5 On-Board Parts Box The On-Board Parts Box contains spare track links, clips, and tools to quickly replace or repair tracks. It also includes cradle shims and mounting screws to lift the wheel cradle ramp away from the ground. When the ground is very uneven the wheel cradle ramp may hit the ground preventing the aircraft from loading.These components are located on-board the tug, underneath the electronics cover. -

Page 9: Start Up Guide

1. Components 2. Start Up Guide 2-1 Remote Control Operation Power Indicator Control Stick 3 Speed Toggle Light Switch Latch Switch Charging I ndicator ON/OFF Switch Charging Jack Lanyard Anchor Note: The 3 Speed Toggle ranges from fast, to moderate, to slow. When operating the tug at slow speed it may be neccessary to switch to the moderate or fast speed mode on the toggle when turning. - Page 10 2. To drive the tug, move the control stick in the desired direction. Forward Left Right Reverse Reverse Right Left Forward Warning: The control stick on the remote controller is very sensitive and will cause the tug to move if it is moved accidentally. Turn OFF the remote controller when not in use.

-

Page 11: Operating The Tug

1. Components 2. Start Up Guide 2-2 Operating the Tug 1. Before turning on the tug, make sure the tracks and bottom of the tug are free from obstruction. 2. Turn the tug on using the ON/OFF switch. There will be a short series of beeps and then the ON/OFF switch will illuminate red to show the tug is on. - Page 12 6. After lifting the tug off of the ground for any reason or taking it in and out of your air- craft, you must check the sprockets for proper seating along the tracks. If the sprock- et is not properly seated it could result in damage to the track. Check for proper seating and alignment.

-

Page 13: Adjusting The Wheel Cradle

1. Components 2. Start Up Guide 2-3 Adjusting the Wheel Cradle 1. When towing a non-fairing aircraft the front and back cradle gates should be adjusted in the fully extended position. For aircraft with fairings, adjust the cradle gates to the lowest setting. - Page 14 3. Adjust the back gate loosen the 4 fl at head screws on the back of the gate. Then slide the right and left sliders to the desired position. Tighten all 4 of the fl at head screws- Note: It may be easier to remove these screws with the link locking pins removed. Right and Left Sliders Flat Head Screws 4.

- Page 15 5. Place wheel chocks behind the rear tires of plane to ensure the plane does not ro- back. 6. Drive tug under the wheel of the plane until the wheel cradle locks in the upright position. The wheel should be touching the back gate as shown. Wheel touching here...

- Page 16 7. Remove the adjustment pins and push the front side of cradle until it is touching the tire and re-install the pins. If the pins cannot be installed while the front side is touching the tire, move the front side of cradle away from the tire until the pin can be inserted into the next closest hole.

-

Page 17: Adjusting The Tire Guide Spacers

1. Components 2. Start Up Guide 2-4 Adjusting the Tire Guide Spacers Adjustment Pin Tire Guide Spacer 1. If the tire guide spacers are in the widest position and your tire does not fi t or it is too close of a fi t, remove the tire guide spacers and adjustment pins. Widest Postion... - Page 18 2. Adjust the tire guide spacers by removing the adjustment pin and sliding the spacers towards eachother. Ideally the tire guide spacers should move the same distance on each side to keep the tire centered in the cradle. The distance between the tire guide spacers should equal the width of your tire plus one inch maximum.

-

Page 19: Adjusting Track Tension

1. Components 2. Start Up Guide 2-5 Adjusting Track Tension Track tension may need to be adjusted after several hours of use. Follow the instruc- tions below for each track. 1. Remove 6 track cover screws and remove the outside plastic track cover. Track Cover Screws Plastic Track Cover 2. - Page 20 3. Push the rail end forward using a small pry bar to tighten up the track. There should be about a 1/2” of play at the center of the track. Push Rail 1/2” Up and Down Play at Center of Track End Forward 4.

-

Page 21: Loading The Aircraft Wheel

If the issue persists call or e-mail AC Air Technology tech support for further assistance. -

Page 22: Unloading The Airplane Wheel

1. Components 2. Start Up Guide 2-7 Unloading the Airplane Wheel 1. Turn the tug power ON and the radio power ON if not already on. 2. Push the tug slightly forward so the airplane tire puts pressure on the back gate of the cradle. -

Page 23: Lifting The Wheel Cradle Ramp

1. Components 2. Start Up Guide 2-8 Lifting the Wheel Cradle Ramp The cradle shims are used to lift the wheel cradle ramp away from the ground. When traversing over very uneven terrain the wheel cradle ramp may hit the ground and prevent the aircraft from loading onto the tug. - Page 24 2. Install the cradle shims onto the Cradle Front Adjusting Arms. Apply thread-locker to the screws to prevent them from vibrating off . Note the orientation of the shim with respect to the cradle front adjusting arms. There should be a small gap between the cradle front adjusting arm and cradle shim as shown below.

-

Page 25: Setup B: Installing Shims For Occasional Use

Setup B: Installing Shims for Occasional Use 1. The shims and mounting screws (with attached lock washer) are located in the on- board parts box underneath the electronics cover. The electronics cover is held down magnetically, pull the cover to open. Electronics Cover Mounting Screws... - Page 26 2. With the wheel cradle in the “Up” latched position, install the shims onto the tug main- plate threaded holes located near the loading end. Two shims and one mounting screw per side. Wheel Cradle Up Mainplate Threaded Holes 3. Both left and right side shims should be engaged if in the ON position or both sides should be disengaged if in the OFF position to prevent the cradle from twisting.

-

Page 27: Charging The Tug

1. Components 2. Start Up Guide 2-9 Charging the Tug 1. Before charging your tug, the remote controller and tug should both be turned OFF. Charging Jack Charging Indicator Light 2. The charging indicator LED should light up red once the charger is connected prop- erly. -

Page 28: Charging The Remote Controller

1. Components 2. Start Up Guide 2-10 Charging the Remote Controller WARNING: Only use the supplied charger to charge the controller when using the supplied batteries or the following: - 1200mAh to 2200 mAh Ni-MH or Ni-Cd ‘AA’ Rechargeable Batteries Using the remote control charger with alkaline batteries installed can damage the con- troller. -

Page 29: Replacing The Remote Control Batteries

2. Start-Up Guide 2-11 Replacing the Remote Control Batteries 1. Before changing the remote control batteries, the remote controller and tug should be turned OFF. 2. Remove 2 screws on the back cover of the remote controller then remove the back cover. - Page 30 4A. Replace the batteries by purchasing a new shrink wrapped Note: A shrink wrapped battery pack can battery pack from AC Air Technology be purchused from AC Air Techology to or installing the supplied battery tray replace the installed battery tray. To use a and purchasing 6 rechargable ‘AA’...

-

Page 31: Stowable Feature

3. Stowable Feature 3-1 Disassemble Tug 1. With the wheel cradle in (up) locked position, lift the front-end of the tug and slide the provided foam stand underneath the tug. The foam stand has the following di- menisons, 19” x 11” x 2-1/4”. It is stored in the shipping box, foam packaging) (1) Lift from here Foam stand should sit centered on the tug, aligned to the back of the electronics main-... - Page 32 3. With one hand, apply pressure upward on the bottom, center, of the rail-track as- sembly to relieve pressure off the rail-track assembly lock pin. Turn the quarter-turn fasteners (90 degrees), 2 per side. The quarter-turn fasteners should be easy to turn once the pressure is off...

- Page 33 5. Manually unlatch the wheel cradle and place it in (down) loading position. 6. With the cover open, hold the electronics mainplate assembly by the handles. Slight- ly tilt the assembly forward and slide it to the right until the connection tabs are in the unlocked position.

- Page 34 7. Lift the electronics mainplate assembly straight up. Always use both handles when- maneuvering the electronics mainplate assembly. Lift up Note: Weight per subassembly 25 lb 25 lb 25 lb 20 lb...

-

Page 35: Reassemble Tug

3. Stowable Feature 3-2 Reassemble tug 1. Place the cradle mainplate assembly on top of the foam stand. The foam stand has the following dimenisons, 19” x 11” x 2-1/4”. It is stored in the shipping box, foam packaging 2. Manually unlatch the wheel cradle and place it in (down) loading position. Foam stand Cradle mainplate assembly Wheel cradle in... - Page 36 4. Slightly tilt the electronics mainplate assembly forward and slide it to the left until the connection tabs are in the locked position. Check the latch and cam for proper seating. (2) Slide left Keep cover open (1) Slightly tilt the electronics mainplate assembly forward Tabs in unlocked position...

- Page 37 5. Align the shaft teeth, rotate the motor by hand if the teeth are not engaging correctly. 6. Align the quarter-turn lock pin fasteners with its respective receptacle. 7. Apply pressure upwards on the bottom, center of the rail-track assembly and press the quarter-turn fastener down into the receptacle.

-

Page 38: Troubleshooting

The troubleshooting guide is divided into three sections: Tug, Remote Controller, Wheel Cradle. Refer to the images and descriptions below as they are mentioned throughout the text. Servo Speed Control Latch Mechanism Radio Receiver For technical support call or email AC Air Technology (855) 884-7222 info@acairtechnology.com... -

Page 42: Warranty

In no event shall the liability of AC Air Technology exceed the individual price of the product on which liability is asserted. AC Air Technology has no control of the set up, ap- plication, use, modifi cation, or misuse of this product, thus no liability shall be assumed or ac- cepted for any resulting damage or injury.

Need help?

Do you have a question about the AC TRACKTECH T1X4 and is the answer not in the manual?

Questions and answers