Table of Contents

Advertisement

Quick Links

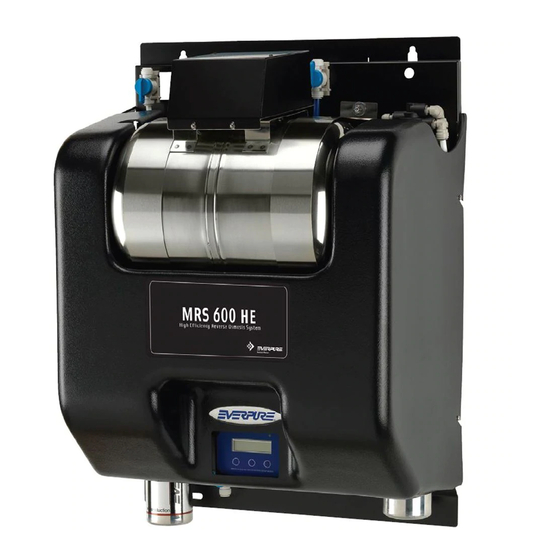

IntroductIon

The Everpure ENVI-RO™ Mineral Reduction System is a pre-

engineered, pre-assembled Reverse Osmosis (RO) system designed

to provide high purity water for multiple applications, such as

premium espresso, coffee, blended beverages and steam, to name a

few. It combines a number of water treatment technologies into one

easy to install package. The system provides superior protection

against taste and odor causing contaminants while removing dirt,

particulates and dissolved solids that can foul or scale equipment.

Initial System Production

Water production depends on supply water pressure and temperature.

See PERFORMANCE section (page 8) for normalized production.

Influent Water characteristics

The following table lists the allowable operating range of various

water properties within which the ENVI-RO™ will function

properly.

Total Dissolved Solids (TDS)

pH

Chlorine

1

Chloramines

Turbidity

Iron

1

Reverse osmosis membrane filter used in this system will be damaged by chlorine. An

activated carbon filter should be provided with this system to protect the reverse osmosis

membrane from chlorine attack. Influent chlorine should not exceed 3 mg/I.

the system consists of 5 major components:

1.

2SR-BW Water Conditioning cartridge

2.

Dual-Head booster pump

3.

MR-600 Reverse Osmosis (RO) membrane cartridge.

4.

6-Gallon RO Water Storage Tank

5.

Control System with Power Supply

The 2SR-BW Water Conditioning cartridge contains media that

reduces the scaling tendency of hard water minerals found in many

water supplies, extending RO membrane life.

The Dual-Head booster pump increases the inlet pressure to

maintain consistent permeate production, plus eliminates back-

pressure on the permeate output. This innovative approach to both

boosting and eliminating back-pressure allows for maximum system

efficiency.

The MR-600 RO membrane cartridge contains a semi-permeable

reverse osmosis membrane. Here, most dissolved impurities are

separated from the water and flushed down the drain. The water

that is able to pass through the membrane, which is very low in

dissolved impurities, is referred to as permeate, RO water, or

product water.

Once the RO water is produced, it is stored in the 6-Gallon RO Water

Storage Tank. This tank serves two key functions; 1) It acts as a

buffer between the system and the connected equipment, providing

ample volumes of water instantaneously, 2) It reduces the on-off

cycling of the RO system, which produces better quality water, and

prolongs the system's life.

Printed in U.S.A.

0-1,000 ppm (0-1,000 mg/I)

5-10

0-3 ppm (0-3 mg/I)

0-3 ppm (0-3 mg/I)

0-1 NTU

0-1 ppm (0-1 mg/I)

Installation and Operation Guide

ENVI-RO™ High Efficiency Reverse Osmosis System

Mineral Reduction System For Foodservice Applications

oPeratIng SPecIfIcatIonS

•

Dynamic Operating Pressure: 25-80 psi (1.7-5.5 bar)

•

Static Operating Pressure: 100 psi (6.9 bar)

•

Operating Temperature 40-100°F (4.4-37.8°C)

•

Connections

Inlet/Outlet: 3/8-inch OD tube (John Guest© Push-in)

Concentrate: 3/8-inch OD tube (John Guest© Push-in)

Electrical: 115 volt AC / 60 Hz / 1 Phase

Ampere:

Stand-by: 0.2

Flush:

Run/Fill:

Branch Circuit Protection: 15 or 20 AMP Ground Fault Protected

Pre-Installation checklist

1.

Can

the unit be mounted within a reasonable distance of the

water supply and drain facilities?

2.

Is

there an un-switched 115 VAC GFIC (ground fault interrupter

circuit) protected receptacle available for powering the system?

3.

Is

there adequate clearance and support to install the unit

and permit access for maintenance? The total system weight

will vary based on model and storage tank selected. See

specification table for approximate operating weights.

4.

Doe

s the inlet water supply meet the requirements listed below?

a.

A minimum of 25 PSI pressure on a consistent basis

b.

Less than 1,000 ppm of Total Dissolved Solids (TDS)

c.

pH level between 7.0-9.0

d.

Turbidity less than 1 NTU

0.5

2.7

EV3128-25 Rev A SE08

Advertisement

Table of Contents

Summary of Contents for Everpure ENVI-RO

-

Page 1: Operating Specifications

IntroductIon The Everpure ENVI-RO™ Mineral Reduction System is a pre- engineered, pre-assembled Reverse Osmosis (RO) system designed to provide high purity water for multiple applications, such as premium espresso, coffee, blended beverages and steam, to name a few. It combines a number of water treatment technologies into one easy to install package. -

Page 2: Unpacking And Inspection

Lengths of 3/8" tubing have been provided for connecting to the wastewater/drain connection. Supply lines and distribution piping/ tubing are not included. The ENVI-RO™ system is packaged as a complete unit in one carton. At a minimum, you should have the following: Plate mounted processor assembly including: •... - Page 3 Shut-off the supply of water to the existing filtration system, and relieve pressure. Connect a line from the treated water outlet of the filtration system to the inlet of the ENVI-RO system. Connect the appropriate size and type of tubing/piping and associated fittings to the corresponding ENVI-RO outlet connection.

-

Page 4: Control System Operation

SyStem oPeratIon The ENVI-RO system includes a micro-processor based control system that monitors system conditions and controls the system operation. A digital display panel provides operational information and 4 buttons provide operator access. To follow is a list of modes and a description of each function. -

Page 5: Cartridge Installation And Activation

cartrIdge InStallatIon and actIVatIon Remove the outer shrink-wrap and protective cap from the 2SR-BW & MR-600 RO cartridges. Position a bucket under the 2SR -BW cartridge head. Slowly open the Inlet shut-off valve. Apply power to the system by plugging the power cord into the receptacle. - Page 6 table 1 - Recovery & Permeate to Reject Ratio raw (feed) maximum Water recovery 0 - 200 80.0% 201 - 250 77.4% 251 - 300 72.8% 301 - 350 68.3% 351 - 400 63.8% 401 - 450 59.3% 451 - 500 54.7% 501 - 550 50.2%...

-

Page 7: Operation

Once the cartridges have been activated, the storage tank and distribution piping sanitized, the ENVI-RO can be placed into service. During normal operation, the valves on the ENVI-RO should be in the following positions: System inlet and outlet valves – open System by-pass valves –... - Page 8 Operating Weight cartridges and elements Reverse Osmosis Conditioning Cartridge Carbon Post-Filter *Specifications Subject To Change Without Notice. enVI-ro 600 1.5 gpm 0.85 gpm Dependant on: Pressure/volume in storage, line sizes Dependant on: Pressure/volume in storage 60–100 psi (4.1-6.9 bar) 90% minimum...

-

Page 9: Maintenance Section

maIntenance SectIon Performance Log outlet flow drain flow test date (ml/min) (ml/min) noteS: Inlet Steamer Pressure/ Inlet tdS outlet tdS temp (psi/°f) (ppm) (ppm) coffee outlet tdS (ppm) % reduction... -

Page 10: Troubleshooting Guide

troubleSHootIng guIde Problem Possible cause Insufficient product water a. Pre-filtration system restriction. during normal operating periods. SR cartridge plugged. RO cartridge plugged. Insufficient system inlet pressure. e. Incorrect storage tank pre-charge. Insufficient product water Refer to problem 1. volume during peak periods. System rated output low for application. -

Page 11: Replacement Parts

Check Valve, 3/8” EV312840 Check Valve, 1/4” rePlacement cartrIdgeS Part no. deScrIPtIon EV962714 Cartridge, 2SR-BW EV962713 Cartridge, MR-600 Contact your local Everpure Dealer for replacement and spare parts. Part no. deScrIPtIon EV312827 EV312828 EV312829 EV312830 EV312831 EV312832 EV312833 Part no. -

Page 12: Maintenance

The ENVI-RO requires very little maintenance. Regular cartridge replacement is the only normal requirement, and a very important one. In typical service, the cartridge change-out schedules are as listed below. every 6 months - replace the Sr cartridge: •... -

Page 13: Top View

figure 7. Dimensional Drawing Top View Side View Front View 13.6" 346 23" 583 16" 32"... - Page 14 figure 8. General Installation Arrangement...

- Page 15 noteS:...

- Page 16 1040 Muirfield Drive • Hanover Park, Illinois 60133 • 800.323.7873 Printed in U.S.A. technical Service 800.942.1153 www.everpure.com EV3128-25 Rev A - SE08...

Need help?

Do you have a question about the ENVI-RO and is the answer not in the manual?

Questions and answers