Subscribe to Our Youtube Channel

Summary of Contents for TempMaster Omni Premier 25 Ton

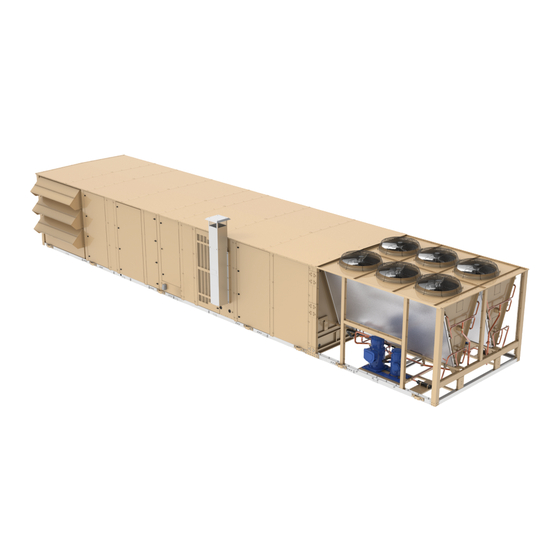

- Page 1 Tempmaster Omni™ Premier 25 Ton ® to 80 Ton Rooftop Units Installation and Maintenance Guide Installation Guide Form Number: 5881373-TIM-421 Issue Date: 2021-04-01 New Release Tempmaster...

- Page 2 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 3: Table Of Contents

Indoor air quality..........18 Control wiring............69 Indoor air quality..........18 Occupancy input..........69 Double wall construction....... 18 Safety switch input.......... 69 Demand control ventilation......18 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 4 Recommandation sur la tuyauterie de gaz..113 Oil analysis..............93 Installation de cheminée de gaz de Condenser and evaporator coils........93 combustion.............. 113 Hot water and steam coils..........94 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 5: Changeability Of This Document

BAS controls points, and hydronic valve specifications are available in the Selection Navigator program. Contact your local sales office or representative for additional unit-specific information. WARNING Cancer and Reproductive Harm — www.P65Warnings.ca.gov. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 6: Nomenclature 25 Ton To 80 Ton Model Number

Digits 1–2: Product brand name Digit 8: Motor control options H: Top return, left OA, front exhaust (no return fan available)* GT: Tempmaster 1: Supply fan variable frequency drive (VFD) J: Left return, right OA, front exhaust Digit 3: Capacity... - Page 7 H: DDP return fan with 1 in. spring isolation J: DDP return fan with 2 in. spring isolation K: DDP return fan, fan with 2 in. spring isolation and seismic restraint Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 8 Y: Touchscreen with MAP with BACnet IP and customer D: 60 Hz terminal board* Note: *Item noted will be available in the future for the 60 ton to 80 ton cabinet. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 9: General

Size (in.) 18–18 18–18 25–25 25–25 30-30 30-30 30-30 Motor size range (min 3–15 3–15 5–20 5–20 5-25 5-40 5-40 to max HP) Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 10 Number of rows/fins 1/23 1/23 1/23 1/23 1/23 1/23 1/23 per in. Size (thickness in in.) Type Microchannel Microchannel Microchannel Microchannel Microchannel Microchannel Microchannel Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 11 750 / 607.5 / 4 1000 / 810 / 4 (input/output/stages) 750 / 607.5 / 4 1,250 / 1012.5 / 6 1500 / 1215 / 6 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 12 24 x 24 / 20 x 24 W in.) 12 x 20 / 12 x 24 Bag filters Total filter face area 29.33 40.00 53.02 (sq. ft.) Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 13 24 x 24 / 12 x 24 24 x 24 / 20 x 24 Rigid W in.) filters Total filter face area 27.11 38.00 53.02 (sq. ft.) Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 14 4. Modulating or staged gas heat 11. Collapsible rain hoods 5. Condenser maintenance safety tie-off 12. Exhaust or return fan 6. Condenser fans 13. Final filter 7. Scroll compressors Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 15: Introduction

A complete range of heating and cooling options are provided to meet today’s customers’ requirements. The unit has also been thoughtfully The Tempmaster® Omni™ Premier rooftop units are designed to include several features that reduce a single package with cooling only or cooling with service and installation time. -

Page 16: Compressor Circuiting

Sound travels through the supply air duct path, hence it needs particular attention. Contact Optional factory installed compressor sound Tempmaster Application Engineering for application blankets can help to further reduce sound radiated specific requirements. from the compressor. In applications such as... -

Page 17: Double Sloped Stainless Steel Drain Pan

DDP supply and markings for the field to drill holes either through return fan. the base or side of the unit. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 18: Fan Spring Isolation

(DCV). film transistor (TFT) with multitouch capacitive touchscreen and 1280 × 800 resolution is also available to order factory installed or to field install. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 19: Smoke Control

Split ship Filtration Tempmaster Omni Premier 60 ton to 80 ton units The unit is configured for various types of draw- are provided with a split ship option, to meet through and final filtration options to meet the specific applications. -

Page 20: Service Valves And Sight Glasses

RTUToolKit app and QR code tools needed. Tempmaster believes in empowering our customers Condenser safety tie-off with all unit-specific information at all times, even on the roof. Download the RTUToolKit app, available... - Page 21 * Standard sensors and transducers. All other sensors and transducers listed are optional. Actual sensor locations and availability may vary based on the unit configuration and options ordered. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

-

Page 22: Safety Considerations

If you cannot reach your gas supplier, call the fire department.Installation and service must be performed by a qualified installer, service agency, or the gas supplier. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 23: Limitations

If the gas • Variable Air Volume for Tempmaster Omni valve is subjected to a pressure greater than 0.5 psig or 13.5 iwg, it must be replaced. The furnace must Premier Rooftop Units Application Guide... -

Page 24: Installation

Clearances and locations Long term storage • Tempmaster offers an optional roof curb that When a unit(s) is stored for an extended period of is specially designed for the Omni™ Premier time, conduct a visual inspection of the entire unit unit footprint. - Page 25 • For additional information on roof curbs, intakes. refer to the Roof Curbs for Tempmaster Omni™ Premier Units Application Guide (5553808-TAD). Proper service clearances must be maintained around the perimeter of the unit. This will allow for...

-

Page 26: Rigging And Handling

As part of the submittal data a unit specific rigging and handling instructions document with lifting lug drawing is available. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 27 Failure to do so could result in damage to the unit or injury to personnel. Figure 5: Warning label on the unit Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 28 Figure 7: Lifting load angles Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

- Page 29 Note: The roof curb, wood nailer, and gasket are factory provided. All other illustrated items (insulation, flashing felts, and so on) must be field supplied. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

-

Page 30: Weights And Unit Dimensions

Supply fan and 7.5 HP 208-230/460 V TEFC Supply fan and 10 HP 208-230/460 V TEFC Supply fan and 15 HP 208-230/460 V TEFC 1044 1044 1044 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 31 Belt driven exhaust/return fan 5 HP Motor 575 V ODP Belt driven exhaust/return fan 7.5 HP Motor 575 V ODP Belt driven exhaust/return fan 10 HP Motor 575 V ODP Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

- Page 32 Top or right discharge • Discharge filters, humidifier or sound attenuator, or blank post-evaporator section • Requires discharge plenum. Discharge can be bottom, left, right, or top Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 33: Dimensions

16. For cooling only units with no post-evaporator blank, a 55 in. supply fan section length is available. All other units have a 74 in. supply fan section. Dimensions Figure 11: Rooftop unit component locations Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®... - Page 34 Bottom return, right OA, side exhaust 86.63 51.36 31.94 59.92 19.26 21.00 7.00 17.17 Bottom return, right OA, front exhaust 86.63 51.36 31.94 59.92 19.26 21.00 7.00 17.17 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 35 SU with heat, small post-evap blank, DP (B, L, R, T) 379.40 55.00 96.05 112.50 2.50 SU with heat, large post-evap blank, DP (B, L, R, T) 421.40 55.00 96.05 112.50 2.50 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 36 77.00 273.09 30.13 9.53 77.00 SU with heat, large post-evap blank, DP (B, L, R, T) 315.09 30.13 9.53 77.00 315.09 30.13 9.53 77.00 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 37 47.04 350.56 28.21 4.65 47.04 SU with heat, large post-evap blank, DP (B, L, R, T) 392.56 28.21 4.65 47.04 392.56 28.21 4.65 47.04 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 38 17.17 exhaust Bottom return, left OA, front 13.76 37.63 41.51 11.71 46.77 14.46 4.10 17.17 13.76 37.63 72.99 4.18 31.13 23.40 4.10 17.17 exhaust Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 39 SU with heat, small post-evap blank, DP (B, L, R, T) 412.20 70.00 96.05 123.00 2.50 SU with heat, large post-evap blank, DP (B, L, R, T) 454.20 70.00 96.05 123.00 2.50 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 40 77.00 365.09 30.13 9.53 77.00 SU with heat, large post-evap blank, DP (B, L, R, T) 407.09 30.13 9.53 77.00 407.09 30.13 9.53 77.00 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 41 SU = Standard Unit, DP = Discharge Plenum, B = Bottom Discharge, L = Left Discharge, R = Right Discharge, T = Top Discharge. Dimensions are ± 1 in.. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

- Page 42 Dimension set Left return, right OA, front exhaust 50.78 66.05 7.67 33.23 23.08 11.27 13.93 Left return, no OA, no EA 50.78 66.05 7.67 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 43 For units that are shipped split, please contact your local sales office or use the Selection Navigator to get the individual air handler and condenser unit lengths. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

- Page 44 Left return, right OA, front exhaust 5.09 50.78 66.05 7.67 38.08 20.58 11.27 13.93 Left return, no OA, no EA 5.09 50.78 66.05 7.67 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 45 For units that are shipped split, please contact your local sales office or use the Selection Navigator to get the individual air handler and condenser unit lengths. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

- Page 46 Empty Empty Empty Humidifier Humidifier Air blender Sound attenuator Sound attenuator Final filter Final filter Sound attenuator and final filter Sound attenuator and humidifier Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 47: Roof Curb Dimensions

451.40 84.38 DP (B, L, R, T) SU with heat, large post-evap blank, 425.90 96.05 421.40 91.55 493.40 84.38 DP (B, L, R, T) Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 48 91.32 DP (B, L, R, T) SU with heat, large post-evap blank, 441.40 96.05 436.90 91.55 87.30 524.20 91.32 DP (B, L, R, T) Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 49 DP = Discharge Plenum, B = Bottom, L = Left, R = Right, T = Top Figure 17: 25 ton to 50 ton roof curbs: left bottom return opening and bottom supply opening without Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

- Page 50 SU with heat, small post-evap blank, DP (B, L, R, T) 9.35 51.00 33.73 7.27 30.13 77.00 SU with heat, large post-evap blank, DP (B, L, R, T) 9.35 51.00 33.73 7.27 30.13 77.00 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 51 Right, RAL = RA Left, SA = Supply Air SU = Standard Unit, DP = Discharge Plenum, B = Bottom, L = Left, R = Right, T = Top Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

- Page 52 96.05 302.90 91.55 72.00 374.90 11.41 SU with heat, large post-evap blank, DP (B, L, R, T) 349.40 96.05 344.90 91.55 72.00 416.90 11.41 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 53 96.05 320.40 91.55 87.30 407.70 11.41 SU with heat, large post-evap blank, DP (B, L, R, T) 366.90 96.05 362.40 91.55 87.30 449.70 11.41 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 54 SU with heat, large post-evap blank, DP (B, L, R, T) 72.99 37.63 7.27 30.13 77.00 Figure 19: 60 ton to 80 ton roof curbs left bottom return opening and bottom supply opening without Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 55 (B, L, R) with basic eco SU with small post-evap blank, DP 48.6 77.9 56.9 17.2 30.0 74.0 (B, L, R) with standard eco Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 56 DP (B, L, R) with basic eco SU with heat, small post-evap blank, 397.9 113.0 393.3 108.49 125.2 518.5 11.4 DP (B, L, R) with standard eco Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 57 AHU = Air Handling Unit, LG = Length, WD = Width, Cond = Condenser, RA = Return Air, RAR = RA Right, RAL = RA Left, SA = Supply Air SU = Standard Unit, DP = Discharge Plenum, B = Bottom, L = Left Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

- Page 58 DP (B, L, R) with basic eco SU with heat, small post-evap blank, 359.4 113.0 354.8 108.49 97.2 452.0 11.4 DP (B, L, R) with standard eco Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 59 (B, L, R) with basic eco SU with small post-evap blank, DP 344.9 113.0 340.3 108.49 125.2 465.5 11.4 (B, L, R) with standard eco Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 60 For the 60 ton to 80 ton units, the basic economizer is available with the barometric damper. The standard economizer is available with the exhaust/return fan. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®...

-

Page 61: Submittal Data

NEC Class 1 and comply termination point must be copper conductor only. with applicable local codes. Aluminum wire cannot be connected to the incoming power termination point. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 62: Electrical Service Sizing

208 to 230 V / 3 Ph / 60 Hz 460 V / 3 Ph / 60 Hz 575 V / 3 Ph / 60 Hz Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®... - Page 63 48.1 24.7 22.4 80 ton 48.1 24.7 22.4 67.3 32.7 26.3 Note: * 208 VA to 230 VA are based on 230 V operation. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 64 24.7 22.4 48.1 24.7 22.4 70 ton 44.2 22.4 18.6 48.1 24.7 22.4 48.1 24.7 22.4 80 ton 48.1 24.7 22.4 48.1 24.7 22.4 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 65 Low ambient 70 ton 47.8 22.2 14.6 to 80 ton configurations Note: * 208 VA to 230 VA are based on 230 V operation. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 66 208-230/3/60* 460/3/60 575/3/60 20.4 12.5 17.8 14.2 Supply fan motor ** 23.5 19.1 24.5 20.4 Return/exhaust fan motor 12.5 10.0 17.8 14.2 23.5 19.1 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 67 Nominal voltage Motor HP 208-230/3/60* 460/3/60 575/3/60 13.9 25.4 18.1 14.6 Supply fan motor ** 19.2 13.9 Return/exhaust fan motor 25.4 18.1 14.6 19.2 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 68 1250 MBH 2.76 1.38 1.10 1500 MBH 2.76 1.38 1.10 Crankcase heater 90 W UV lights Internal lights (per light) 0.05 0.03 0.02 Note: Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 69: Control Wiring

• The unit can have an optional customer terminal board (see Figure 23 for field wiring). Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 70: Options Board

The options board is factory installed if the terminals. For their locations and descriptions, unit is ordered with a specific option that requires this board. refer to the Tempmaster Omni Premier 25 ™ Ton to 80 Ton Rooftop Units R-410A Start-Up and •... - Page 71 MB = Main Board, CB1 = Condenser Board 1, CB2 = Condenser Board 2, OB = Options Board, CTB = Customer Terminal Board Figure 23: Field wiring to CTB Figure 24: Field wiring to OB Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 72: Display Panel

29). Assemble the panel in the desired location by re-installing the 3 brackets and 12 screws using the pre-drilled holes (see Figure 31). For VFD field parameter settings, refer to Tempmaster Omni Premier 25 Ton to 80 Ton Rooftop ™ Tempmaster Omni™... - Page 73 11.34 30 ton Lower Not an Available Option Upper Not an Available Option 40 ton to Center 15.02 19.21 50 ton Lower 26.22 8.01 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 74: Reset Switch

ON unless this switch has been enabled. The display remains ON when the unit enable switch is turned OFF. See Figure 26 and Figure 27 for location. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 75: Uv Light Reset Switch

Refer to the instructions provided with the Locations of the probe can vary greatly with outdoor pressure reference for proper each building type. installation. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 76: Outside Air Temperature Sensor

If the gas valve is subjected to pressure greater than 0.5 psig or 13.5 iwg, it must be replaced. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®... -

Page 77: Gas Connection

1,150 • When required by local codes, a manual shut- 1,050 off valve must be installed outside of the unit. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 78: Flue Gas Chimney Installation

Drain pan Hot water coil Hollow grommet • The factory installed hot water coil is located in the discharge air section of the unit. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 79 See Figure W32. See Figure 37. Figure 37: Hot water/steam heating valve output Figure 38: Hot water piping schematic Figure 39: Steam piping schematic Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 80: Steam Coil

See Figure 41. Return air and discharge air humidity sensors are provided to maintain zone/return air humidity. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 81: Ductwork

HVAC system. They should NOT be sized to match the dimensions of the duct connections at the unit. Figure 42: Air duct configurations Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 82: Discharge Panel

(60 ton to 80 ton) (Figure 44) and panel using the six or eight panel cleats and screws cleats that hold the discharge panel in place removed in step 1. (Figure 43). Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 83: Air Hoods

Attach each side hood piece to its hood top using the shipped loose screws. Repeat steps 2 and 3 for the remaining hood tops and their side hood pieces. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 84: Exhaust Air Hood

Always replace filters with the same MERV rating, size, and quantity that were originally installed in the factory. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 85: Ultraviolet Lights

See Figure 48 for proper sizing of condensate trap. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 86: Fan Tie-Downs

Figure 56. • H must be at least 1 + fan total static pressure. Figure 49: 25 ton to 50 ton supply fan tie-down bolts Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 87 Figure 50: 60 ton to 80 ton supply fan tie-down bolts Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 88 Figure 51: 25 ton to 80 ton front/side exhaust fan tie-down bolts Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 89 Figure 52: 25 ton to 50 ton front/left/right return fan Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

- Page 90 OA down bolts, right OA Remove bolt from each corner (four total) of the fan skid, as shown in Figure 56. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 91: Start-Up And Operation

For information regarding system start-up, sequences of operation, the BACnet points list, and ® the faults list, refer to the Tempmaster Omni Premier ™ 25 Ton to 80 Ton Rooftop Units R-410A Start-Up and Operation Guide (5881376-TSG-A) that shipped with the unit. -

Page 92: Maintenance

If a system failure occurs due to improper maintenance during the warranty period, Tempmaster is not liable for costs incurred to return the unit to satisfactory operation. Safety You are required to review the... -

Page 93: Periodic Maintenance - Monthly

The driers may have to be changed several times to fully clean the entire system depending on the degree of contamination. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®... -

Page 94: Hot Water And Steam Coils

Inspect the hot water and steam coils for dirt and debris, and clean when necessary using the same procedure as the condenser and evaporator coils. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®... -

Page 95: Periodic Maintenance - 3 Months To 6 Months

Properly clean Replace the grease drain plug. Figure 62: Motor nameplate example Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 96 Weight of grease frame size Bearing oz (grams) Teaspoon Inches 56–140 (90) 6203 0.08 (2.4) 0.15 140 (90) 6205 0.15 (3.9) 180 (100–112) 6206 0.19 (5.0) Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster...

-

Page 97: Fan Bearing Lubrication

The fan data plate (attached to the fan scroll) lists the type of grease that must be used for lubricating Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®... -

Page 98: Condensate Drain

Inspect and flush the trap drain lines when required. Protect the trap drain lines from freezing. Note: The unit must be properly trapped and charged with water before the units are started. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 99: Periodic Maintenance - Yearly

An alignment error must be corrected to avoid bearing and belt failure. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 100: Belts

When the unit shuts down, close the ball valve located after the filter drier and remove power from the unit to prevent the unit from running. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®... -

Page 101: Energy Recovery Wheel

Air class is based on ASHRAE 62.1-2016 classifications. For Class 4, the manufacturer recommends inspecting and cleaning once or twice per year to maintain optimal performance. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 102: Sliding The Erw

Figure 71: Sliding high CFM ERW: Front Sliding the ERW Note: Low and high CFM ERWs can slide a maximum of 26 in. (66 cm) outside the unit. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 103: Remove Wheel Segments

Failure to maintain control of the wheel rotation while removing/installing segments can cause severe injury to hands. Always close and secure retaining latches on wheel segments before rotating the wheel. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 104: Install Wheel Segments

Repeat until all of the remaining wheel segments are installed, ensuring balance throughout the procedure. Apply power to the wheel and confirm proper rotation. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 105: Periodic Maintenance - As Needed

For instructions, refer to the When the oil is acidic, it is Backup Function and Restore Function sections in the strongly recommended to Tempmaster Omni Premier 25 Ton to 80 Ton Rooftop ™ replace both compressors... -

Page 106: Technical Supplement

Figure 75: Bend radius for power wiring Note: This distance is determined by the data in Table 312.6 (A) in the 2017 National Electric Code (NFPA 70). Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 107: Ton To 80 Ton Power Wiring Side Penetration For Slab-Mounted Units

Bore the hole depending on the size of the gland and the size of wire required. Use tight liquid glands (PG) for wires according to UL 60335. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 108: Technical Supplement

Align with holes in base rail. b. Bracket can be mounted either way. Figure 78: Item locations Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 109: Supplément Technique

étapes . Figure 79: Emplacement des composants de l'unité sur le toit Figure 80: Vue de face et de côté de l'unité Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ®... -

Page 110: Les Dégagements

Cela permettra un entretien correct de l'unité ainsi qu'un débit d'air adéquat pour les serpentins du condenseur et l'air de combustion du chauffage à gaz. Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 111: Tuyauterie De Gaz

La pression de gaz maximale autorisée à la connexion de l’unité est de 0,5 jauge de livres par pouce carré (psig ou 13,5 jauge d'eau en pouces (iwg). Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 112: Connexion De Gaz

Reportez-vous à la Figure 82 pour connaître la disposition typique des canalisations de gaz. • Suivez tous les codes locaux lors de l'installation de la conduite d'alimentation en Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... -

Page 113: Recommandation Sur La Tuyauterie De Gaz

Mesures Turndown de gaz (kW) minimum(m3/s) maximale (kW) de gaz (mm) 2.36 10:1 25-30 2.36 20:1 2.36 30:1 20:1 40-50 30:1 50:1 Tempmaster Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide ® Tempmaster... - Page 114 (kW) x 0,81) / (m3/s x 1,085). La température maximale de l'air sortant ne doit pas dépasser 48,8°C. TEMPMASTER® IS A REGISTERED TRADEMARK OF JOHNSON CONTROLS © 2021 Johnson Controls. All rights reserved. Subject to change without notice. 100 JCI Way, York, Pennsylvania USA 17406-8469.

Need help?

Do you have a question about the Omni Premier 25 Ton and is the answer not in the manual?

Questions and answers