Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Franklin Fueling Systems UPP PIPING

- Page 1 PIPING ® INSTALLATION GUIDE...

-

Page 2: Table Of Contents

CONTENTS INTRODUCTION ............................1 LEGAL NOTICES ..........................1 CONTACT INFORMATION ........................1 CONVENTIONS ........................... 1 SAFETY ............................... 1 SITE PREPARATION ..........................2 UNDERGROUND FUEL PIPE SYSTEMS ....................3 UNDERGROUND FUEL PIPE CONSTRUCTION ................. 4 TRANSIT, OFF-LOADING, AND STORAGE ....................5 STORAGE ON SITE .......................... -

Page 3: Introduction

Copyright © 2021 Franklin Fueling Systems, LLC, Madison, WI 53718. All world rights reserved. No part of this publication may be stored in a retrieval system, transmitted, or reproduced in any way, including, but not limited to, photocopy, photograph, magnetic, or other record, without the prior written permission of Franklin Fueling Systems. -

Page 4: Site Preparation

WARNING: Always secure the work area from moving vehicles. The equipment in this manual is usually mounted underground, so reduced visibility puts service personnel working on it in danger from moving vehicles that enter the work area. To help prevent this safety hazard, secure the area by using a service truck (or some other vehicle) to block access to the work area. -

Page 5: Underground Fuel Pipe Systems

• 4 markers (2 metallic, 2 black) • 1 lb lint-free rags • 1 box of nitrile gloves • Emery cloth for FEB preparations (EMRY) • Cellophane wrap • Spray bottles • Hand scrapers (SCR.HAR) • EF1 Welder - Properly inspected, with a inspection sticker dated within the past 3 years, and, if applicable, a step up transformer (EF1-230V, pt# 408032001). -

Page 6: Underground Fuel Pipe Construction

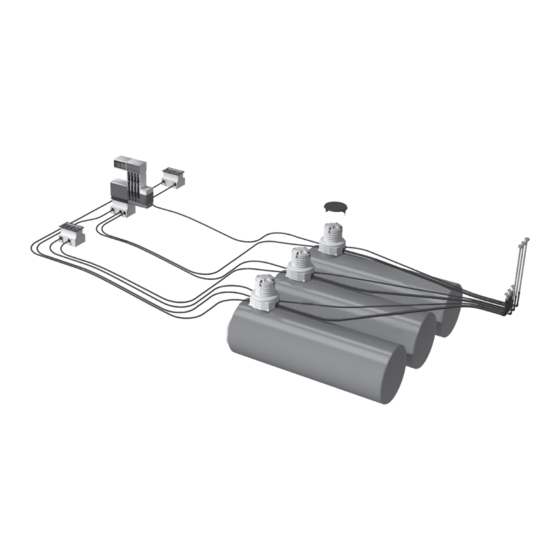

Several types of UPP underground fuel pipe are available for different applications and to meet various ® engineering and legal requirements: • Primary pipe can be used as a fuel-proof liner for product, suction, pressure, vapor vent, and fill lines. •... -

Page 7: Transit, Off-Loading, And Storage

TRANSIT, OFF-LOADING, AND STORAGE Although UPP polyethylene pipe and fittings are extremely hard wearing and resilient, it is important to handle ® and store them with care to prevent scuffing or gouging. Any damaged pipes may need to be rejected and not installed. -

Page 8: Uncoiling Pipe

UNCOILING PIPE CUTTING STRAPS Coil Weights Coiled pipe is delivered with four straps that secure the coil. The coil has a “tail” section that protrudes outside of the coil circumference: • The “tail” must be secured to a stable anchor point with rope or other means before you can start uncoiling. -

Page 9: Pipe Burial Guidelines

WARNING: The pipe can straighten with considerable force. Take care when releasing pipe from the coil and secure the straightened pipe. Let the pipe rest in its uncoiled state for about eight hours. High ambient temperatures can reduce this “layout” time and low temperatures may increase it. - Page 10 300mm (12") 150mm (6") 150mm (6") 150mm (6") 150mm (6") • When laying duct onto a concrete base a 150 mm (6") thick bed of compacted sand should be laid on the concrete, below the duct. (The minimum amount of sand should be 50 mm (2") of compacted sand) •...

- Page 11 Bend radius Center of pipe's arc NOTE: Refer to Table 3 for allowable bend radius of UPP Pipe. ® NOTE: Completion Records—On completion of UPP installation make an “as constructed” drawing showing ® the exact location of all below ground lines. It is also recommended that, in addition, a photographic record is preserved.

-

Page 12: Pressure Testing

NOTE: Both ends of the tape should be grounded during installation. Ends of Tape Must be Grounded at Sumps Earthing Rod When using a detection tool, the near end of the detectable tape should be disconnected from the grounding point to allow the red cable from the transmitter to be connected to the tape and the black cable from the transmitter to be connected to the grounding point. -

Page 13: Recommended Pipe Test Procedure

WARNING: Pipe-work should be disconnected (isolated) from underground storage tank prior to commencing tightness testing. WARNING: Any water used for testing should be disposed of through the oil / water separator or by a specialist contractor and in accordance with any local environmental health and safety requirements and regulations. WARNING: There are two recommended tightness test methods for UPP primary pipe-work: hydrostatic ®... - Page 14 HYDROSTATIC TESTING GRAPH Maintain 145 PSI (10 bar) for 30 minutes 145 (10) 130.5 (9) 116 (8) 101.5 (7) 87 (6) 72.5 (5) 58 (4) 43.5 (3) 29 (2) drop to 43.5 PSI (3 bar) for 90 minutes To Pass Test Pressure Must remain at 43.5 PSI (3 bar) or above 14.5 (1) 30 0 2 4 6 8 10 15 20 25 30 Conditioning Time (mins)

- Page 15 NOTE: FFS recommends that you perform the test at constant temperature. • Record any faults on this Sump Inspection Register and have the fault(s) corrected at the time found. • You can download this form (part number 408001011) from the FFS website at www.franklinfueling.com. •...

- Page 16 408001016 r7...

Need help?

Do you have a question about the UPP PIPING and is the answer not in the manual?

Questions and answers