Summary of Contents for Bridgeport HARDINGE TP5260

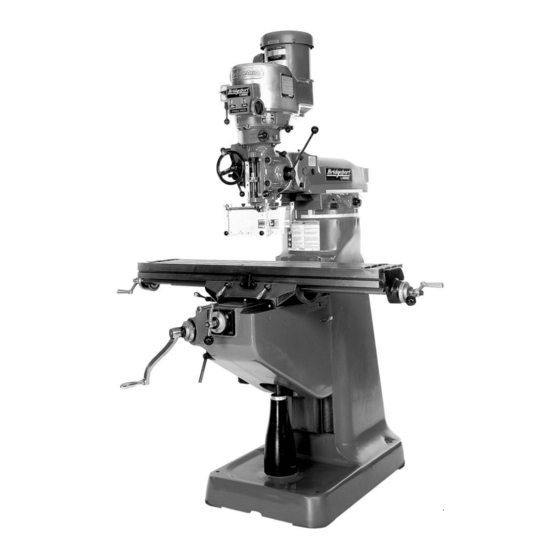

- Page 1 INSTALLATION, OPERATION, MAINTENANCE, AND PARTS LIST SERIES I MILLING MACHINES TP5260 Revised: August 29, 2005 Manual No. M-450 Litho in U.S.A. Part No. M -0009500-0450 June, 2003...

-

Page 2: Chapter 1 - Installation

CHAPTER 1 - INSTALLATION UNCRATING Carefully remove protective crating and skids so that the machine and parts are not marred, scratched or impaired. In the event of damage having occurred during transit, communicate at once with our representative and the transportation company making delivery. SHORTAGES Check shipment carefully against the itemized packing list which is included in the parts box. - Page 3 INSTALLATION If delivery of your machine is made with the milling head in an upside-down position, follow the instructions below to prepare your machine for operation. HANDLES For shipping purposes, the hand cranks are inverted to face the machine. To reverse them, engage the lock mechanism to the saddle and table.

- Page 4 HANDLING Lifting the Machine TP5279 Figure 1.4 - Lifting the Machine - WARNING - BE SURE to use proper sling when lifting. improper lifting could cause seri- ous injury. Note position of ram and table when lifting with sling. Machine should be lifted by placing a sling under the ram as illustrated in Figure 1.4.

- Page 5 FOUNDATION MACHINE TP5280 Figure 1.5 - Tightening Sequence Tightening Sequence Tighten bolts first to 25 lb-ft torque in a diagonal sequence as noted in Figure 1.5, then to 50 lb-ft. Overtightening could cause bind in the quill movement. Placing on Solid Foundation When setting machine on a concrete foundation, it is advisable to use a little grout (thin mortar) to take care of any unevenness in the concrete as well as to provide a solid foundation at all points.

- Page 6 Before securing machine to floor by tightening hold-down bolts, make certain that all four cor- ners are making contact with the floor after ma- chine is leveled. If above condition is not met, it is possible to twist the column and but a bind into ways.

-

Page 7: Machine Power Supply

MACHINE POWER SUPPLY - WARNING - MACHINE MUST be hooked up by a qualified electrician. CONNECTING THE POWER SUPPLY To connect the machine to the plant supply, have a qualified electrician proceed as follows: 1. Check required voltage against power supply to ensure that they are compatible. 2. - Page 8 LUBRICATION Lubrication Instruction Plate Recommended Lubrication Few Drops Twice Daily TP5283 Figure 1.8 - Lubrication Requirements Indicator Lubrication Area Type of Lubrication Way Surfaces and Lead Screws Sunoco Waylube #1180 or equivalent S.A.E. 10 or 10W Light Oil Milling Heads (Spindle Bearings) (None on grease-packed heads) Motor None required.

-

Page 9: Head Controls

INITIAL SETTINGS HEAD CONTROLS Alignment of Head for Fine Work For precision boring or work of that nature, where it is necessary to have the head perfectly square with the table, use method described below. To set head perfectly square with table, adjust ram adapter through vertical adjusting worm shaft with ram adapter on ram. - Page 10 - NOTES - M-450...

Need help?

Do you have a question about the HARDINGE TP5260 and is the answer not in the manual?

Questions and answers