Summary of Contents for Quick MC2 X13 DC

- Page 1 REV 001A MARCH 2020 ANTI-ROLL GYRO STABILIZER INSTALLATION AND USE MANUAL page 3...

- Page 2 PAGE INTENTIONALLY BLANK...

-

Page 3: Installation And Use Manual

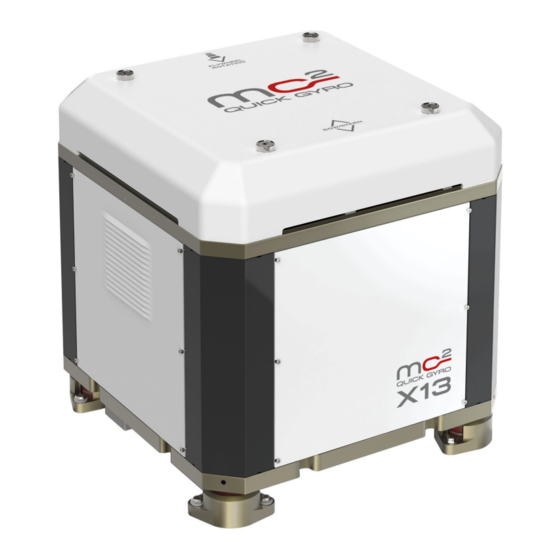

In case of discordance or errors in translation between the translated version and the original text in the Italian language, reference will be made to the Italian text. INSTALLATION AND USE MANUAL QUICK MC²X13_DC - REV001A... - Page 4 HOW A QUICK GYRO STABILIZER IS MADE Quick MC2 gyro stabilizer has been designed for all typesof boats, with the goal of improving on board comfort level by redu- cing the roll amplitude in presence of waves.

- Page 5 ROLL ACCELERATION ROLL CORNER WIDTH ROLL FREQUENCY ROLL ACCELERATION Speed return of the initial boat position ROLL FREQUENCY: Number of oscillations over time ROLL CORNER WIDTH: Inclination value of the boat's axis INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 6 PAGE INTENTIONALLY BLANK...

- Page 7 Pag. 33 11 - Scrapping and Disposing Pag. 34 11.0 - Scrapping Pag. 34 11.1 - Disposing Pag. 35 12 - Accessories Pag. 36 Remote Control Pag. 36 Remote Control Accessories Pag. 36 INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

-

Page 8: Information About The Product

The MC series stabilizers are compact and functional. Quick MC²X13 is useful and effective to improve comfort on board, but it does not eliminate the risks deriving from harsh atmospheric conditions. 1.1 - Main features •... - Page 9 1 - Information about the product 1.3 Dimensions 590 (23 1.4 Dimensions with base plate (optional) 610 (24 INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 10 Connector cable CAN T 5P F/F/F J3 RC Extension cable CAN BUS 12 m Terminator RC REMOTE CONTROL MC touch 5" - IP66 CAN BUS adapter cable (1 m / 3,28 ft) INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

-

Page 11: Supplied Parts

2 - Supplied parts X13 Quick gyro stabilizer is equipped with all the parts needed for its installation. ² 2.0 - Package contains the following parts 1 Pre-wired MC X13 Gyro stabilizer ² 4 Eye bolts for MC X13 stabilizer lifting ²... -

Page 12: General Information

® 3.0 - General information Quick stabilizers have been designed for fixed installations in a protected space. Taking into account the wide range of hulls and types of boats, the installer shall be responsible for building a solid base that makes the stabilizer an integral part of the boat structure. - Page 13 • Do NOT use solvents or fuels to clean the appliance. • Do NOT remove the safety labels on the equipment. WARNING: THIS OPERATION MUST BE CARRIED OUT BY QUICK AUTHORIZED PERSONNEL ONLY. REMOVING THE COVERS AND SEALS WILL VOID THE QUICK WARRANTY.

-

Page 14: Personal Protection Equipment (Ppe)

On the stabilizer will be applied stickers/labels that report dangers and attention to be taken for the correct use. Label pictogram Description Notes DANGER DANGER OF CRUSHING HANDS AND FEET DANGER RISK OF ROLLOVERING CRUSHING CAUTION MOVING AND ROTATING EQUIPMENT INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A... - Page 15 The direction of rotation of the flywheel is indicated by the label on stabilizer cover 4.6 - Air output The label will indicate the stabilizer air outlet area during operation. AIR OUTPUT INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

-

Page 16: Handling And Transportation

• Do not scratch or cut on the painted finish that protects the stabilizer. 5.1 - Crate Removal 1. Remove the top cover of the crate. 2. Remove the side panels of the crate. INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A... - Page 17 4. Lift the stabilizer, and remove the screws from the wood base on which the stabilizer is fixed. NEVER LIFT THE STABILIZER INTO THE CONDITION IN EXAMPLE 5. INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

-

Page 18: Environmental Requirements

The installation of the stabilizer must be carried out with the value of the inclination of the plane of the hull of ± 2 degrees with respect to the water line. water line INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A... - Page 19 Free choice of the position DANGER ROTATING PARTS! in the area available HULL TYPE ROUND BILGE The bottom area of the hull is recommended DANGER Free choice of the position ROTATING PARTS! in the area available INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 20 FLYWHEEL ROTATION: of the flywheel is indicated by Hourly or counterclockwise bound to the verse of stabilizer assembly the label on stabilizer cover HULL TYPE HARD CHINE LIMIT LONGITUDINAL HULL TYPE ROUND BILGE INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

-

Page 21: Installation Procedures

• IMPORTANT: POSITION THE STABILIZER FOLLOWING THE INDICATIONS OF THE DRILLING TEMPLATE. THE STICKER ON THE COVER (FLYWHEEL ROTATION) MUST BE POSITIONED TOWARDS THE STERN OR TOWARDS THE BOW. STERN DANGER ROTATING PARTS! INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A... - Page 22 7.3 - Planarity of installation In the two configurations with base plate (optional) and without base plate, the stabilizer installation must respect the planarity with the relative tolerance values. 3 mm 3 mm 3 mm INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 23 • Tighten gradually in a criss-cross pattern. • Use suitable locking systems. WARNING: Approximately one week after installation, check screws/nuts for proper tightening. Periodically check the tightening of the screws for potential settling adjustments. INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 24 • Tighten gradually in a criss-cross pattern. • Use suitable locking systems. WARNING: Approximately one week after installation, check screws/nuts for proper tightening. Periodically check the tightening of the screws for potential settling adjustments. INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 25 1 - Example of fiberglass support structure with brass plates on a hull with enough space in between the stringers. SADDLE BRASS PLATE EXISTING STRINGERS FIBERGLASS FILLING Min. thickness 18 mm (45/64 in) INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 26 7.7 - Fiberglass Support - Example 2 2 - Example of fiberglass support with brass plates on hull with insufficient space in between the longitudinal stringers. SADDLE BRASS PLATE EXISTING STRINGER FIBERGLASS Min. thickness 18 mm (45/64 in) INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 27 7 - Installation procedures 7.8 - BRACHET - EXAMPLE 3 3 - Example of support structure on a hull with enough space in between the stringers. SUPPORT STRUCTURE Exemple: PLEXUS MA590 BOAT STRUCTURE INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 28 7 - Installation procedures 7.9 - BRACHET - EXAMPLE 4 2 - Example of support structure on a hull with insufficient space in between the longitudinal stringers. SUPPORT STRUCTURE BOAT STRUCTURE INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

-

Page 29: Electrical Connection

Available in sizes 5" graphic display. IP66. * Not supplied 8.1 - Devices dimensions RC REMOTE CONTROL MC 147 (5 136 x 96 (5 * Not supplied. Dimensions in mm (inch) INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A... -

Page 30: Connection Diagram

POWER SUPPLY BATTERY 12 Vdc 12 Vdc FUSE * CIRCUIT BREAKER ** FUSE THE USE OF ONE OF THESE TWO COMPONENTS EXCLUDES THE OTHER. SEE THE "TECHNICAL DATA" TABLE ON PAGE 8 INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A... -

Page 31: Start-Up Instructions

9 - Start-up * Warning: in order to activate Quick warranty, an installation validation and the first start-up (commissioning) must be carried out by Quick authorized personnel only. 9.0 - Introduction This section describes the first start-up of the stabilizer. -

Page 32: Periodic Maintenance Table

10 - Maintenance 10.2 - Periodic Maintenance Periodic maintenance, every 2000 hours, must be performed by personnel authorized by Quick ® The Remote Control alerts, through a window (image below) that periodic maintenance must be performed. The window appears in the middle of the screen. To close, press OK. -

Page 33: Annual Maintenance

10 - Maintenance 10.3 - *Annual Maintenance WARNING: THIS OPERATION MUST BE CARRIED OUT BY QUICK AUTHORIZED PERSONNEL ONLY. REMOVING THE COVERS AND SEALS WILL VOID THE QUICK WARRANTY. STRICTLY OBSERVE ALL PRECAUTIONS INDICATED IN THE MANUAL IN ORDER NOT TO DAMAGE YOURSELF AND THE STABILIZER. - Page 34 - Check all pressurised systems, depressurising them if necessary. - Break down the machine into easily transportable units. The demolition of the machinemust be assigned to companiesspecialized and trained to executethis kind of operations. INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 35 For the elimination of the contaminating substances(plastic materials, lubricating oil and syntethic rubber)respect the prevailing law disposition in the countryof the platform demolition. Specialist waste disposal companies can be engaged to perform these tasks. INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

-

Page 36: Remote Control Accessories

CONNETTOR CABLE CAN 5P F/F FQCNCFF0RC00A00 TERMINATOR CAN M M12 FQTNCANM1200A00 Electrical protection DESCRIPTION CODE 10200 CIRCUIT BREAKER 200A CC FD1020000000A00 TF200 FUSE 200A CNL DIN FVEFF200CNLDA00 TFH6 FUSE HOLDER FUSES CNL/CNN DIN FVEFPTFH6000A00 INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A... - Page 37 PAGE INTENTIONALLY BLANK INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 38 NOTES INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 39 PAGE INTENTIONALLY BLANK INSTALLATION AND USE MANUAL QUICK MC² X13_DC REV001A...

- Page 40 REV 001A MARCH 2020 INSTALLATION AND USE MANUAL ANTI-ROLL GYRO STABILIZERS Product code and serial number QUICK S.p.A. - Via Piangipane, 120/A - 48124 Piangipane (RAVENNA) - ITALY ® Tel. +39.0544.415061 - Fax +39.0544.415047 - www.quickitaly.com - quick@quickitaly.com...

Need help?

Do you have a question about the MC2 X13 DC and is the answer not in the manual?

Questions and answers