Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Volpi Tecno Energia PAGURO 2000

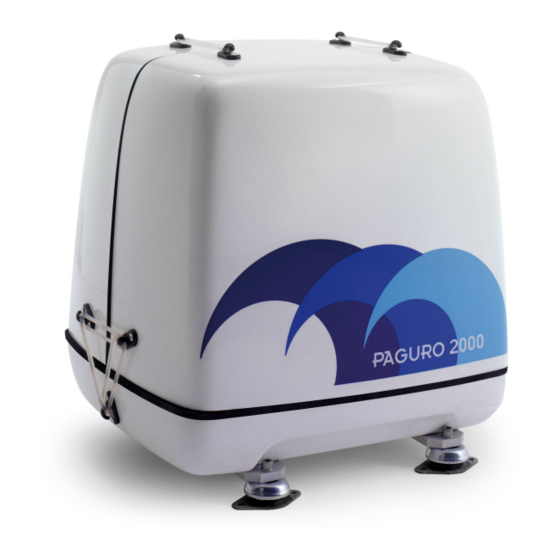

- Page 1 OWNERS MANUAL PAGURO 2000 MARINE DIESEL GENERATOR...

- Page 2 OWNERS MANUAL PAGURO 2000...

-

Page 3: General Informations

So there is not the need to waste a large room in your boat, and even if the chosen place is away from the centre line of the boat, the reduced weight of the PAGURO will not influence the stability. TECHNICAL SPECIFICATION AND PERFORMANCES PAGURO 2000 Diesel engine maker Yanmar Italy S.p.a. Yanmar L48 Engine type / cylinders n. - Page 4 IF YOU OR ANYONE ELSE EXPERIENCE ANY OF THESE SYMPTOMS GET OUT INTO THE FRESH AIR IMMEDIATELY. If symptoms persist, seek medical attention. Shut down the unit and do not restart unit until it has been inspected and repaired. PAGURO 2000...

-

Page 5: Safety Instructions

Steam can cause injury or death! Extinguishers rated ABC by the NFPA are appropriate for all applications encountered in this environment. - In case of an engine overheat, allow the engine to cool before touching the engine or checking the coolant. PAGURO 2000... - Page 6 Muscular twitching Sulfuric acid in batteries can cause severe injury Dizziness or death! Intense headache Throbbing in temples Weakness and sleepiness - When servicing the battery or checking the electrolyte level, wear rubber gloves, a rubber apron, and eye PAGURO 2000...

- Page 7 - Make sure all attaching hardware is properly tightened. Keep the protective shields and guards in their respective places at all times. - Do not check fluid levels while the engine is operating. PAGURO 2000...

- Page 8 The undersigned declares that the generator model: Code Model AP02023050M0 PAGURO 2000 Corresponds to the requirements of the following EEC Directives: 89/392/EEC (as amended by the Directive 91/368/EEC and 93/44/EEC) 89/336/EEC (as amended by the Directive 92/31/EEC) 73/23/EEC (as amended by 93/68/EEC)

-

Page 9: Table Of Contents

12 VOLT DC CONTROL CIRCUIT ……………………………………………………………………………………………………………………………….. BATTERY (Battery Care, Checking the service Battery) ……………………………………………………………………………………………… ELECTRICAL SCHEME ………………………………………………………………………………………………………………………………………………... 12. GENERATOR INFORMATION ……………………………………………………………………………………………………………………………….. GENERATOR MAINTENANCE ……………………………………………………………………………………………………………………………….. 13. GENERATOR TROUBLESHOOTING ………………………………………………………………………………………………………………. 14. SHORE POWER TRANSFER SWITCH ………………………………………………………………………………………………………………. 15. LAY UP AND RECOMISSIONING ……………………………………………………………………………………………………………………………….. PAGURO 2000... -

Page 10: Introductions / Recomissionings

Consult the siphon-break manufacturer for a proper maintenance schedule. EXHAUST SYSTEM The exhaust hose must be certified for marine use. The system must be designed to prevent water from entering the exhaust under any sea conditions and at any angle of the vessel’s use. PAGURO 2000... -

Page 11: Installation

8. Raw water inlet and outlet (through exhaust system). 9. Oil fill and oil drain hose. 10. Electrical connections. 11. Maintenance and service accessibility. 12. Accessories. Refer to the following illustration for the generator's overall dimensions. Generator dimensions Inverter dimensions PAGURO 2000... -

Page 12: External Connections

The locations of the external connections are shown on the following illustration. The various lines should be of the specified gauges/diameters, not only to avoid loosening or leakage, but also because using the correct sizes will prevent unnecessary gaps in the sound-shield that could emit noise. External connections DIAMETERS: PAGURO 2000 Water inlet: 19 mm Exhaust system: 40 mm Fuel in:... -

Page 13: Location And Mountings

NOTE: Even if a fuel filter is contained in the capsule, it is necessary to install an external water/fuel separator. PAGURO 2000... -

Page 14: Exhaust System

Water-exhaust separator: it is possible to reduce the noise of the exhaust line installing a water-exhaust separator as per the following images. In this case, the exhaust gas output is separated from the water output, so that the typical plash of the water (of the traditional exhaust lines) is eliminated. PAGURO 2000... -

Page 15: Raw Water Cooling System (Siphon Break, Raw Water Intake)

CAUTION: Failure to use a siphon-break when the external shock absorbers are located at or below the waterline will result in raw water damage to the engine and possible flooding of the boat. PAGURO 2000... -

Page 16: Inverter Installation

(one of the 2 studs located on the starter where is already foreseen a metallic loop) Please refer to the electrical scheme of this manual. The generator's battery charger will charge its starting battery only (8A max) PAGURO 2000... -

Page 17: Main Output Voltage (230 V Ac)

A manual switch (shore / generator) or an automatic switch (shore / generator) must be provided. Both the lines or at least the generator line only, have to be protected with a thermo-switch, fitted on the main board panel. For your PAGURO choose a: 230V 50cyc. PAGURO 2000 PAGURO 2000... -

Page 18: Control Panel

≈ 290 gr Electronic protection IP65 Electronic protection - connectors IP65 Operating temperature -10 – 60 °C Feeding 8 / 30 V DC Consumption ≈ 122 mA + Pre alternator exitation Display LCD graphical 128x64 white backlight Buttons PAGURO 2000... - Page 19 8 PIN 15 MT 24 PIN 8A e 4C BATTERY POSISTIVE BROWN FUEL SHUT-OFF VALVE GRAY STARTING MOTOR GREEN SENSORS (TEMP. / PRES.) BLACK BATTERY NEGATIVE YELLOW PREHEATING WHITE LOAD INDICATOR BLUE GENERATOR RUNNING AUTOMATIC STARTING (ON REQUEST) DIMENSIONS: PAGURO 2000...

- Page 20 ALARM LED Alarm DISPLAY LCD: The remote control panel is a device to start, stop and manage the generator. As soon it is fed, for few second the display shown the VTE logo, then appears according the following picture. PAGURO 2000...

- Page 21 PAGURO STARTING AND STOPPING: GENERATORS WITHOUT PREHEATING (PAGURO 2000 / 3 SY / 3000 / 4 SY / 4000 / 5000 / 12500): To start push and keep pushed START button up to the generators is started. To stop push and release STOP button.

-

Page 22: Preparation For Initial Start-Up

This precaution will prevent damage caused by unanticipated operation of the AC machinery will prevent a cold engine from stalling. PAGURO 2000... -

Page 23: Starting/Stopping Procedure

Disregarding this fact and not maintaining the proper oil level may lead to overfilling, causing overheating and the possibility of engine runway. After shutdown, carefully inspect the generator. Check for possible leaks from all the connections inside the sound-shield. PAGURO 2000... -

Page 24: Break-In Procedure

Disregarding this fact and not maintaining the proper oil level may lead to overfilling, causing overheating and the possibility of engine runway. After shutdown, carefully inspect the generator. Check for possible leaks from all the connections inside the sound-shield. PAGURO 2000... -

Page 25: Maintenance Schedule

Remove the filter and take it to the appropriate collection site; replace with original filter type. FUEL FILTER REPLACEMENT – EVERY 250 H Remove the filter and take it to the appropriate collection site; replace with original filter type; loosen the filter support screw and breathe. PAGURO 2000... - Page 26 This operation must be performed by authorized personnel trained on the product. PARTIAL OVERHAUL – EVERY 2500 H This operation must be performed by authorized personnel trained on the product. TOTAL OVERHAUL – EVERY 5000 H This operation must be performed by authorized personnel trained on the product. PAGURO 2000...

-

Page 27: Exhaust System

Prevent this from happening by closing the raw supply through-hull shutoff, draining the exhaust muffler, and correcting the cause of the excessive engine cranking. Remember that engine damage resulting from raw water entry is not covered by warranty. PAGURO 2000... -

Page 28: Cooling System

If the engine temperature gauge ever shows higher than normal reading, the cause may be that silt, leaves or grass may have been caught up in the strainer, slowing the flow of raw water through the cooling system. PAGURO 2000... -

Page 29: Lubrication System

NOTE: do not replace the plug on the manual oil pump- out until after the new oil has been added and its level has been checked. This will allow the operator to pump out any excess oil in case of overfill. PAGURO 2000... -

Page 30: Adding New Oil

Make sure proper ventilation exist whenever servicing fuel system components. FUEL FILTER The frequency of a fuel filter change depends on the degree of contamination of the fuel, however it should be performed according the engine manufacturer manual. PAGURO 2000... -

Page 31: Fuel Supply Line

While the likelihood of having to service the system at sea is slim, the possibility does exist. Therefore, we recommend that banjo washers, injector seat washers and a fuel filter be carried on board at all times. Purchase needed spare parts from your PAGURO 2000... -

Page 32: Engine Troubleshooting

OWNERS MANUAL local Volpi Tecno Energia dealer or distributor. If a leak should develop at a banjo washer that cannot be corrected by a simple tightening of the fitting, replace the sealing washer with a replacement found in the hardware kit for your model. -

Page 33: Dc Electrical System

If not, there is a problem in the service battery charging circuit by checking the wiring and connections, the solenoid, isolator, battery switch, and the battery itself. A 5 amp fuse located in the control box protects the battery charging circuits. No panel lights means a blown fuse. PAGURO 2000... -

Page 34: Electrical Scheme

OWNERS MANUAL PAGURO 2000... -

Page 35: Generator Information

Proper no load voltage Low loaded engine speed. Dirty fuel filter; replace. but low voltage under Overload. Check the load indicator. load Loose contacts. Check connections. Unstable voltage Uneven rotation. Check for uniform rotation speed (dirty fuel filter). PAGURO 2000... -

Page 36: Shore Power Transfer Switch

Both the lines or at least the generator line only, have to be protected with a magneto thermo safety switch, fitted on the main board panel. For your PAGURO choose a: 230V 50cyc. PAGURO 2000 PAGURO 2000... -

Page 37: Lay Up And Recomissioning

Lubrication and cleaning of the starter drive pinion is advisable. Make sure the battery connections are shut off before attempting to remove the starter. Take care in properly replacing any electrical connections removed from the starter. SPARE PARTS PAGURO 2000... - Page 38 Do not smoke or allow an open flame near the battery being serviced. Shut off all electrical equipment in the vicinity to prevent electrical arcing during servicing. 2. Start the engine in accordance with the procedures described in the PREPARATIONS FOR INITIAL START-UP section of this manual. PAGURO 2000...

- Page 39 OWNERS MANUAL PAGURO 2000...

- Page 40 OWNERS MANUAL PAGURO 2000...

Need help?

Do you have a question about the PAGURO 2000 and is the answer not in the manual?

Questions and answers