stellar labs GALAXY Series Installation And Operating Manual

Custom fireplace program, co-linear direct vent gas fireplaces

Hide thumbs

Also See for GALAXY Series:

- Installation and operating manual (50 pages) ,

- Installation and operating manual (52 pages)

Table of Contents

Advertisement

Quick Links

www.stellarhearth.com

Custom Fireplace Program

Co-linear Direct Vent Gas Fireplaces

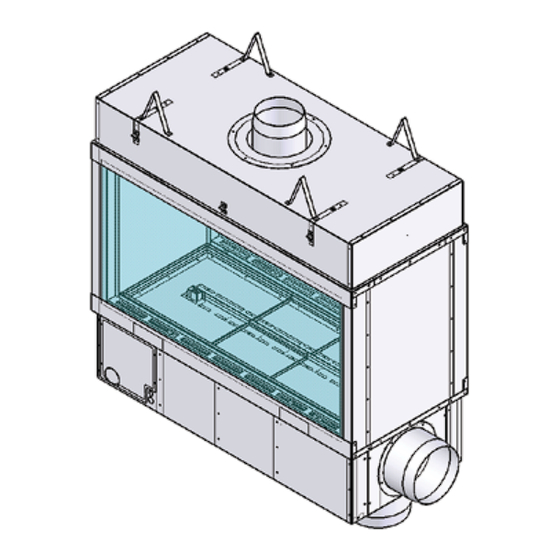

GALAXY SERIES - FOUR SIDED

Installation and Operating Manual

NG & Propane

appliance.

WHAT TO DO IF YOU SMELL GAS

—

TM

Stellar Hearth Products

Installer:

Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

®

Page 1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for stellar labs GALAXY Series

- Page 1 Custom Fireplace Program Co-linear Direct Vent Gas Fireplaces GALAXY SERIES - FOUR SIDED Installation and Operating Manual NG & Propane Installer: Leave this manual with the appliance. Consumer: Retain this manual for future reference. appliance. WHAT TO DO IF YOU SMELL GAS —...

- Page 2 INS_CUST UL REV E Page 2...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Section Description Page Safety Information Venting - Continued A. Safety Icon Designations K. Vertical Terminations B. Important Safety Considerations L. Horizontal Cap Location & Clearances M. Horizontal Terminiation Commonwealth of Massachusetts Requirements N. Powervent & Air-intake Placement Clearances O. -

Page 4: Safety Information

1 - SAFETY INFORMATION A. SAFETY ICON DESIGNATIONS Various safety icons appear throughout this installation manual. Please familiarize yourself with the icons making sure you understand the serious consequences that may occur if ignored or of handling the products inappropriately. IMPORTANT NOTE HOT GLASS WARNING This indicates additional instructions that you should consider... -

Page 5: Commonwealth Of Massachusetts Requirements

For all sidewall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purpos- INSTALLATION OF CARBON MONOXIDE DETECTORS EXEMPTIONS The following equipment is exempt from 248 CMR 5.08 (2) (a) 1 through At time of installation of side wall horizontally vented gas fueled 4:The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented”... -

Page 6: Fireplace Dimensions

3 - SPECIFICATIONS FOUR SIDED DIMENSIONS: INCHES [MILLIMETERS] Finishing Finishing Firebox Top Overall Edge To Overall B-VENT AIR INTAKE Model # Glass Height Depth FLUE COLLAR Width - Front Width - Ends Height Height Center Flue Width Diameter Diameter 20" HIGH GLASS 41-3/4 20-7/8 41-3/4... - Page 7 3 - SPECIFICATIONS 3. FOUR SIDED DIMENSIONS 1/4-20 UNC 1/4-20 UNC B-VENT [305] [305] B-VENT TOP VIEW I, J & K Section 3 (Prepare The Fireplace) [13] 3 [76] FRONT VIEW 3 [76] 3’-7’ 8’ [381] [432] ACCESS PANEL [16] FRONT&...

-

Page 8: Gas & Electric Access Dimensions (3', 4', 5', 6 & 7')

3 - SPECIFICATIONS PILOT SIDE VIEW BACK SIDE VIEW ELECTRIC 3" GAS 3" GAS 2X 2 27/32" 1 1/2" 1 25/32" 1 1/2" 2X 1 19/32" 2 3/4" 2 7/32" 3 7/32" 5 3/8" 2 7/32" 11 1/8" ELECTRIC 2X 5 13/32" FRONT VIEW 2X 2 29/32"... -

Page 9: Gas & Electric Access Dimensions (8')

3 - SPECIFICATIONS PILOT SIDE VIEW BACK SIDE VIEW ELECTRIC 3" GAS 3" GAS 2X 2 27/32" 2X 1 19/32" 2X 11 3/16" 1 25/32" 1 1/2" 2X 2 7/32" 1 11/16" 2 3/4" ELECTRIC 3 1/4" 5 13/32" 2X 2 7/32" FRONT VIEW 2 29/32"... -

Page 10: Installation Overview

3 - SPECIFICATIONS C. SPECIFICATIONS Propane Model # DESCRIPTION B-VENT REG PV IN-LINE PV BTU’S ORIFICE ORIFICE 3-4S-X-GL X = ANY HEIGHT 8" 10" RS012 RSIF160 40,000 (2X) #43 (2X) #55 4-4S-X-GL X = ANY HEIGHT 8” 10” RS012 RSIF160 60,000 (3X) #43 (3X) #55... -

Page 11: Clearances

3 - SPECIFICATIONS F. CLEARANCES From unit left & right sides 1" 25mm Unit top to ceiling 6" 152mm Unit side to adjacent sidewall 1" 25mm CLEARANCES SHOWN ARE MINIMUM TO COMBUSTIBLES Figure 3F NON-COMBUSTIBLE FRAMING AND FINISHING MATERIALS ALLOWED RIGHT UP TO THE FIREPLACE. 1/2”... - Page 12 CAUTION: FIREPLACE IS NOT LOAD-BEARING. NOTE: OTHER CLEARANCES APPLY. ALL CLEARANCES MUST BE MAINTAINED. A. STANDOFF INSTALLATION LOOSEN SCREW LOOSEN SCREW AND FOLD EACH AND FOLD EACH STANDOFF STANDOFF LOOSENED SCREW LOOSENED SCREW REMOVE REMOVE SECOND SCREW SECOND SCREW PIVOT FOLDED STANDOFF PIVOT FOLDED STANDOFF AND SECURE AND SECURE...

-

Page 13: Shipping Support Brackets

B. SHIPPING SUPPORT BRACKETS The temporary support brackets are not shipped in place on the Galaxy Four Sided Series and you will be required to assemble them at the jobsite to support the hood for installation. Installation instructions on Pages 14-15. Once the hood is properly supported with required threaded rods installed. - Page 14 3 - PREPARE THE FIREPLACE B. SUPPORT BRACKET INSTALLATION STEP 1 STEP 1.1 Attach the four bottom brackets to the base in the STEP 1.2 Attach screws in this area to all four brackets. orientation shown. STEP 2.1 Attach cross beams as shown STEP 2.2 Attach screws on each side of the cross beam INS_CUST UL REV E...

- Page 15 3 - PREPARE THE FIREPLACE B. SUPPORT BRACKET INSTALLATION STEP 3 STEP 3.1 Attach the four top brackets to the cross beams in the STEP 3.2 Attach screws on each side of the cross beam orientation shown STEP 4.1 Carefully place hood on top of the brackets. STEP 4.2 Attach screws in this area on all four brackets.

-

Page 16: Threaded Rods

C. THREADED RODS The Galaxy FOUR SIDED Series requires 4 threaded rods to be placed at the glass-to-glass intersections. Placement of the required threaded rods is at the I & J intersection at the front left and back FOUR SIDEDs notated as REQUIRED I & J locations. Additional locations are provided if your installation needs more support notated as OPTIONAL I, J &... -

Page 17: Threaded Rod Insallation (Example)

For each threaded rod installation 1Threaded Threaded Rod Fender Super Strut or All Thread Washer or Uni-Strut Recommend using loctite • • • is exact all the way around. Use Locktite to secure the nut from from loosening (not shown). •... -

Page 18: Framing & Mantel Requirements

Section 8 (Venting) of this manual. If masonry is to be used (optional), prepare the necessary foundation for the masonry load. When masonry construction is being used, a lintel must be may be used. PANELS INTO THE FIREPLACE. FINISHING MATERIALS MUST NOT OVERLAP THE DIMENSIONS HIGHLIGHTED IN GREEN IN SECTION 2 (DIMENSIONS). -

Page 19: Framing Dimensions

A. FOUR SIDED FRAMING DIMENSIONS IMPORTANT:FIREPLACE IS NOT LOAD-BEARING. 6” [152] MINIMUM COMBUSTIBLE OR NON-COMBUSTIBLE NON-COMBUSTIBLE ZONE BACKING MATERIAL (I.E.SHEETROCK) OPEN AIR SPACE Framing Framing Framing INCHES [MM] Width Height Depth 40-3/4 3-4S-20-GL [1,035] [1,321] [584] 52-3/4 4-4S-20-GL [1,340] [1,321] [584] 64-3/4 5-4S-20-GL... -

Page 20: Mantel Requirements

8' units. Notes About TV Placement: WARNING! Risk of Fire A mantel is not required if you are placing a TV above the opening. 12" [305] minimum clearance COMBUSTIBLE OR NON-COMBUSTIBLE requirement for placement of a TV above BACKING MATERIAL (I.E. SHEETROCK) the opening if NOT using a mantel. -

Page 21: Mantel Requirements

8' units. Notes About TV Placement: WARNING! Risk of Fire A mantel is not required if you are placing a TV above the opening. 12" [305] minimum clearance COMBUSTIBLE FRAMING requirement for placement of a TV above COMBUSTIBLE OR NON-COMBUSTIBLE the opening if NOT using a mantel. -

Page 22: Glass Frame Assembly

6 - GLASS FRAME ASSEMBLY A. GLASS FRAME ASSEMBLY IDENTIFICATION GLASS GLASS Upper Groove Quality Suction Cup LOWER FILLER STRIP SITS OVER GLASS CLIPS LOWER FILLER STRIP SITS OVER GLASS CLIPS Lower Groove GLASS CLIP GLASS CLIP Figure 6B.1 Figure 6A THE INSTRUCTIONS EXACTLY WHEN REMOVING AND INSTALLING GLASS FRAME ASSEMBLY. -

Page 23: Install Glass Frame Assembly/Glass Edge Protectors

6 - GLASS FRAME ASSEMBLY B. INSTALL GLASS FRAME ASSEMBLY IMPORTANT: PLASTIC GLASS EDGE PROTECTORS U-Shaped See Figure 6B.2 Edge Protector Inner Glass Unwrap the panes of glass carefully making sure to protect the edges. Apply the suction cups to the inner glass assembly, following instructions included with the suction cups. - Page 24 7 - GAS LINE SPECIFICATIONS GAS LINE CONNECTION Propane 11.0 inches W.C. 7.0 inches W.C. MINIMUM INLET GAS PRESSURE (recommended) (recommended) MAXIMUM INLET GAS PRESSURE 14.0 inches W.C. 10.0 inches W.C. MANIFOLD PRESSURE (HI) 10.0 inches W.C. 3.5 inches W.C. ORIFICE SIZE in Section 2.C in Section 2.C...

-

Page 25: Venting

8 - VENTING STOP: MAINTAIN ALL CLEARANCES AS STATED IN THIS INSTALLATION MANUAL. Figure 7 A. APPROVED VENTING OUTSIDE STANDARD IN-LINE Model # DESCRIPTION B-VENT POWERVENT POWERVENTV 3-4S-X-GL X = ANY HEIGHT 8" 10" RS012 RSIF160 4-4S-X-GL X = ANY HEIGHT 8”... -

Page 26: Chimney Collar Dimensions

8 - VENTING D. RS SERIES POWERVENT SPECIFICATIONS A power vent (RS-12 & RS014) is approved for use with this appliance. It is crucial that all B-Vent pipe and elbow joints, and the longitudinal seam are sealed using a high temperature RTV Silicone and/or foil tape. MODEL Axial vane Axial vane... - Page 27 8 - VENTING F. RSIF SERIES POWERVENT SPECIFICATIONS An in-line power vent (RSIF160 or RSIF180 is approved for use with this appliance. It is crucial that all B-Vent pipe and elbow joints, and the longitudi- nal seam are sealed using a high temperature RTV Silicone and/or foil tape. 2.37 in.

-

Page 28: In-Line Powervent Preparations - Rsif 180

D. IN-LINE POWERVENT PREPARATIONS Perform the following steps when installing the RSIF180 on 6', 7' & 8' models. 1. Attach the provided 10 inch B-Vent collar to the intake side of the powervent. The intake side is located opposite the fan motor as shown in Figure 8G.1. -

Page 29: Horizontal Vent System Clearance

8 - VENTING ALL APPROVED VENTING BOTTOM SIDES 8 - VENTING connected to the pressure switch. (Figure 8E) Take care to keep the end of the tube clean. mounted in the center of the Page 29 16400-7806 G4S REV F... -

Page 30: Vertical Terminations

8 - VENTING K. VERTICAL TERMINATIONS • • NO SUBSTITUTION IS ACCEPTABLE. • • DO NOT use an additional speed control on this powervent. • You must use the included Capacitor. • DO NOT RECESS TERMINATION KIT INTO OUTSIDE BUILDING MATERIALS - i.e.: brick, stone, siding, etc. If necessary, extend framing so that termination kit will be exposed once building materials are installed. - Page 31 8 - VENTING Inside Corner Outside Corner Recessed Location A = Combustible 24” (609.6mm) F = Combustible 6” (152mm) = Non-combustible 12” (304.8mm) = Non-combustible 6” (152mm) Balcony Balcony C = Clearance from corner in with perpendicular side wall with no side wall recessed location = Combustible 24”...

-

Page 32: Powervent & Air-Intake Placement Clearances

8 - VENTING N. POWERVENT AND AIR-INTAKE PLACEMENT CLEARANCES RS SERIES POWERVENT X = Intake X = Intake PV = Vent PV = Vent 0” 0” P.V. 0” 36” 24” 9” 9” 9” Minimum Clearance Using an In-Line Powevent Minimum Clearance Using a RS Series Powervent Intake Placed Below Vent = 24”... - Page 33 8 - VENTING O. VERTICAL VENT CAP LOCATION AND CLEARANCES ROOF PITCH 1.83 24” MIN (610MM) 24” MIN* (610MM) * = 24” TO A COMBUSTIBLE SIDE WALL 12” TO A NON-COMBUSTIBLE SIDE WALL IMPORTANT: ALL DIMENSIONS ARE FROM THE EDGE OF THE CAP Figure 8O Page 33 16400-7806 G4S REV F...

- Page 34 8 - VENTING P. ROOF TERMINATION CAP INSTALLATION - WITH AND WITHOUT DAMPER Roof Termination Without POWERVENT Optional Mechanical Damper MOUNTING BRACKETS OR DRILL MOUNTING HOLES TO MATCH BASE INSULATION PAD MUST BE CUT IN CENTER TO ACCOMMODATE VENT SIZE STEEL CHIMNEY ADAPTER Figure 8P.1 Roof Termination With...

- Page 35 8 - VENTING Wall Termination Without Optional Mechanical Damper FRAMING: DRILL 1/4” HOLES TO MATCH POWER VENT BASE INSULATION PAD MUST BE CUT IN CENTER TO ACCOMMODATE VENT SIZE USE APPROPRIATE HEAVY DUTY FASTENERS TO SECURE POWER VENT Wall Termination With Optional Mechanical Damper OPTIONAL MECHANICAL FLUE DAMPER...

- Page 36 8 - VENTING R. OUTDOOR AIR INTAKE Vent runs utilizing 10 inch rigid metal pipe may be 110 feet with 11 elbows. We recommend insulating the intake air duct or using UL Failure to do so will result in higher operating temperatures. WARNING! Risk of Fire! DO NOT draw intake air from an attic or crawl space.

- Page 37 8 - VENTING Figure 8T.1 Complete Installation Instructions Provided In The PDS-1 Box Figure 8T.3 Figure 8T.6 Page 37 16400-7806 G4S REV F...

- Page 38 OPTIONAL UNIVERSAL EXHAUST IN AIR-INTAKE LOUVER MODEL UNITS LOUVER-8 3', 4' & 5' Exhaust and Air-Intake LOUVER-10 6' & 7' Exhaust and Air-Intake LOUVER-12 Air-Intake ONLY This kit is an optional method of terminating the fresh air and/or exhaust for the appliance. Exhaust terminations must be installed with an FOLLOW COMPLETE inline powervent.

- Page 39 A. ELECTRIC - AT INSTALL Figure 1A Powervent Voltage Chart Supply Voltage Chart (N/L1) To light the fireplace: Activate the switch. The fireplace has a pre and post timer, set at the factory for 30 seconds. The powervent will start after the switch is activated. The flame will not turn on for 30-60 seconds after switch is activated and the powervent will run for 30 seconds after it has been shut off.

- Page 40 B. ELECTRIC - SERVICE & TROUBLESHOOTING INS_CUST UL REV E Page 40...

- Page 41 Page 41 16400-7806 G4S REV F...

- Page 42 GROUND - LOCATE THE GREEN WIRE CLUSTER CONNECT THE GREEN WIRE TAIL TO BUILDING GROUND Terminals 7 & 8 INS_CUST UL REV E Page 42...

- Page 43 OPTIONAL Flue Damper Connection OPTIONAL TERMINALS 9 & 10 FLUE DAMPER CONNECTION TERMINAL #9 IS THE NEUTRAL CONNECTION FOR THE DAMPER MOTOR. BLACK WIRE TERMINAL #10 IS THE HOT CONNECTION FOR THE DAMPER MOTOR. RED WIRE THIS IS LOW VOLTAGE AND EXTERNAL POWER MUST NOT BE APPLIED 24 VAC DAMPER MOTOR - RED NEUTRAL DAMPER MOTOR - BLACK...

- Page 44 OPTIONAL Flue Damper Connection OPTIONAL NOTE: OPTIONAL IF A DAMPER IS NOT USED TERMINALS 11 AND 12 HAVE A JUMPER ACROSS THEM NOTE: RED IS NOT USED AND SHOULD BE SAFELY CAPPED INS_CUST UL REV E Page 44...

- Page 45 FOLLOW THE INSTRUCTIONS INCLUDED WITH THE SWITCH. Page 45 16400-7806 G4S REV F...

- Page 46 11 - FINISHING PANELS INTO THE FIREPLACE. FINISHING MATERIALS MUST NOT OVERLAP THE DIMENSIONS HIGHLIGHTED IN GREEN ON NOTE: DO NOT MORE INFORMATION. Figure 11A.1 D - COMBUSTIBLE OR NON-COMBUSTIBLE BACKER MATERIAL (I.E. SHEETROCK) C - COMBUSTIBLE OR NON-COMBUSTIBLE FINISHING MATERIAL COMBUSTIBLE FRAMING E - COMBUSTIBLE MANTEL...

- Page 47 11 - FINISHING PANELS INTO THE FIREPLACE. FINISHING MATERIALS MUST NOT OVERLAP THE DIMENSIONS HIGHLIGHTED IN GREEN ON NOTE: DO NOT NOTE: REFER TO MORE INFORMATION. D - COMBUSTIBLE OR NON-COMBUSTIBLE BACKER MATERIAL (I.E. SHEETROCK) C - COMBUSTIBLE FINISHING MATERIAL B - NON-COMBUSTIBLE BACKER CEMENT BOARD E - COMBUSTIBLE...

- Page 48 FOR YOUR SAFETY - READ BEFORE LIGHTING This appliance needs fresh air for safe operation and must be installed so there are provisions for adequate combustion and ventilation air. It is important to make sure the termination cap remains unobstructed at all times from snow, ice, leaves or other debris. •...

- Page 49 B. IF THE FIREPLACE DOES NOT LIGHT accumulated information on front cover and on previous page of the installation manual. If you don't smell gas, go to next step. or the gas supplier. disappear after several minutes. Page 49 16400-7806 G4S REV F...

- Page 50 13 - PRESSURE TESTING INLET PRESSURE TEST The valve has an allen-plug on the inlet and outlet. Check for leaks. CAUTION: A LOW PRESSURE READING CAN CAUSE DELAYED IGNITION A. INSTALLING THE MEDIA Figure 13A Place the supplied glass media into the base tray. Cover the base evenly.

- Page 51 VALVE AND ELECTRICAL ACCESS A. VENT SYSTEM • • INSTALLATION. • B. GLASS CLEANING & REPLACEMENT See Section 6 for glass installation and removal instructions. • • • • DO NOT SUBSTITUTE MATERIALS. • NOTE: IN CASE OF CHIPPED OR BROKEN GLASS CAUTION: LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS.

- Page 52 C. REPLACEMENT PARTS LIST PART PART NUMBER PART PART NUMBER Gas Valve Pilot Vacuum Switch Propane Conversion Kit LPK-FDN PART PART NUMBER PART PART NUMBER 8 Inch Exhaust Collar Collar LED Controller LED Remote Control Suction Cup INS_CUST UL REV E Page 52...

- Page 53 C. REPLACEMENT PARTS LIST Between Glass - Sides Between Glass - Ends MODEL Page 53 16400-7806 G4S REV F...

- Page 54 Hearth & Home Technologies LIMITED LIFETIME WARRANTY Hearth & Home Technologies, on behalf of its hearth brands (“HHT”), extends the following warranty for HHT gas, wood, pellet, coal and electric hearth appliances that are purchased from an HHT authorized dealer. WARRANTY COVERAGE: HHT warrants to the original owner of the HHT appliance at the site of installation, and to any transferee taking ownership of the appliance at the site of installation within two years following the date of original purchase, that the HHT appliance...

- Page 55 WARRANTY CONDITIONS: • This warranty only covers HHT appliances that are purchased through an HHT authorized dealer or distributor. A list of HHT authorized dealers is available on the HHT branded websites. • This warranty is only valid while the HHT appliance remains at the site of original installation. •...

Need help?

Do you have a question about the GALAXY Series and is the answer not in the manual?

Questions and answers