Advertisement

1.0 Introduction

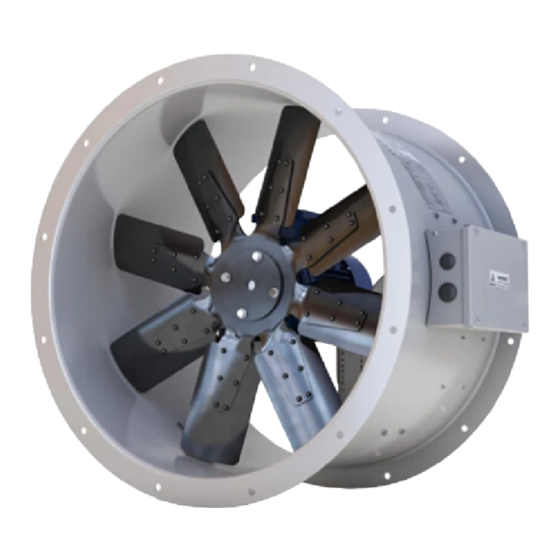

The AXUS SWIFT range of axial flow fans are designed for 'in duct'

applications. Manufactured from galvanised steel, the units are

suitable for indoor or outdoor installation and at any installed

angle.

Available for single and three phase supplies.

Case diameters of 350mm to 1000mm.

Unit codes AXS350 to AXS1000.

Impellers have been selected at blade angle settings matched to

various motor speeds to perform against the design criteria laid down

in our selection catalogue.

Any attempt to adjust or reset impeller blade angles will invalidate

warranty.

For full unit description, dimensional, weight and performance details

refer to the Nuaire product catalogue. A comprehensive range of

ancillaries and silencers are also listed.

2.0 Handling

The fan impeller is carefully balanced and centralised in the fan case,

it is therefore essential that great care is exercised when handling the

unit. Check the weight on the rating plate details before attempting to

lift and always use a spreader as shown (fig. 1), never pass lifting slings

through the impeller (fig. 2).

Figure 1. Correct method of

lifting using a spreader.

nuaire.co.uk

029 2085 8400

AXS

AXUS Swift Circular Long Cased Axial Flow Fans

Installation and Maintenance

Figure 2. The wrong method of

lifting with sling through impeller

can cause case distortion.

3.0 Installation And General Advice

Installation must be carried out by competent personnel, in accordance

with good industry practice, the appropriate authority and in

conformance with all statutory and governing regulations e.g. IEE,

CIBSE, HVCA, ATEX, BSI & EN standards etc.

If the fan is to be installed in a potentially explosive atmosphere it will

have been designed to ATEX directive 2014/34/EU and will incorporate

motors requiring compatible installation wiring direct to the motor

termination box, to complete this installation also follow the guidance

advice of data sheet 671216.

Before commencing installation check that all materials, including

optional ancillaries are available to complete the installation. Every unit

is tested and serialised at works and a test certificate produced, the

details recorded on the fan side rating plate should also be referred to

before handling and installation.

Any damages or deviations should be immediately reported to the

seller/supplier/agent quoting the order and product details from

the product rating plate.

3.1 Mechanical Installation

Rotate the fan impeller by hand to ensure free and smooth rotation and

that no transit or handling damage has occurred, observe the direction

of flow/direction of rotation arrow and ensure that:

All optional accessories such as support brackets, attenuators,

•

inlet cones, guards, flexible connectors etc. are assembled to

the fan.

The optional support brackets are correctly fitted, at any

•

position around the circumference, but suit the installation

plane.

External termination box is accessible to the electrician.

•

When offering the fan to the ducted system that both inlet

•

and outlet connections are perfectly aligned.

In order to ensure performance is as stated, a minimum

•

distance of twice the fan diameter is required between the

appliance and any bends in the ductwork.

3.2 Horizontal on Floor or Supported from Wall etc.

Optional resilient mountings should be attached to the unit mounting

brackets at this stage (fig. 3). If the unit is supported from a wall,

supporting brackets should be used. Position and align the unit with the

ductwork in both horizontal and vertical planes and pack height under

mounting feet if necessary.

Matching attenuators if required; should be fitted to the fan with any

other accessories before installation.

Matching flanges are fixed to the ductwork ends with rivets.

08. 11. 17. Leaflet Number 671645

The EMC Directive

2014/30/EU

The Low Voltage

Directive

2014/35/EU

1

Advertisement

Table of Contents

Summary of Contents for NuAire AXUS SWIFT Series

- Page 1 For full unit description, dimensional, weight and performance details before handling and installation. refer to the Nuaire product catalogue. A comprehensive range of Any damages or deviations should be immediately reported to the ancillaries and silencers are also listed.

- Page 2 If the fan is to be started 3.3 Suspended Horizontally or Vertically direct on line (DOL) to a frequency inverter or Nuaire’s Ecosmart speed A.V. mountings must be arranged so that they are used in compression control the motor must be connected in Delta.

- Page 3 Inverters are configured to suit specific fans and control to the wiring diagram supplied with the unit. In applictions as described on the Customer Order the event of query or uncertainty contact NUAIRE free of charge. directly before any connection is made.

- Page 4 30 metres. Please consult also accommodate the 230V switched live (if used). Nuaire if a longer cable run is needed. The mains supply from the Ecosmart controller to the fan must be • This product must be earthed and always ‘earth’ the appropriately sized, not exceeding 30 metres and must be a screened screened cable at both ends.

- Page 5 50m. If the cable is longer disconnected the fan will over-run for 1 – 60 minutes (see fig. 12). than 12m, Nuaire recommend using screened cable with the screening grounded at one end only (preferably at the inverter end).

-

Page 6: Setting To Work

L to the SL terminal. Unplug all items connected to the ‘Net‘ connectors. Isolation - Before commencing work, make sure that the unit, switched live and Nuaire controls are Switch on the power supply. • electrically isolated from the mains supply. -

Page 7: Maintenance

Clause 14 of our Conditions of Sale. Customers purchasing from Maintenance should be carried out on a regular basis, Nuaire outside of the UK should contact Nuaire International Sales office for recommend three months from commissioning and at least annually further details.

Need help?

Do you have a question about the AXUS SWIFT Series and is the answer not in the manual?

Questions and answers