Table of Contents

Advertisement

Hot wa

ater fired

ModelN

o.

16LJ-

-F11

16LJ-

-F21

16LJ-

-F31

16LJ-

-F51

16LJ-

-F61

16LJ-

-F71

16LJ-

-F81

d type

16LJ-

F12

16LJ-

F22

16LJ-

F32

16LJ-

F52

16LJ-

F62

16LJ-

F72

16LJ-

F82

16LJ-F

F13

16LJ-F1

16LJ-F

F23

16LJ-F2

16LJ-F

F41

16LJ-F4

16LJ-F

F53

16LJ-F

F63

16LJ-F

F73

OPERA

ATION

Abs

sorptio

16LJ-

-F Serie

14

24

42

Or

riginal l

languag

AC

CQA36-002

MANUA

AL

n Chille

er

es

ge

270

Advertisement

Table of Contents

Summary of Contents for Carrier 16LJ-F Series

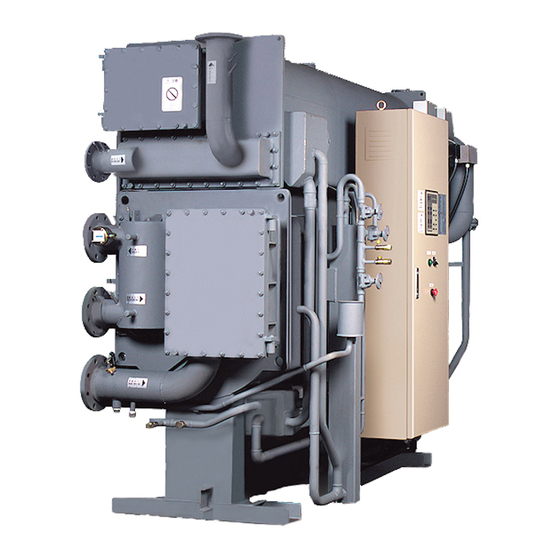

- Page 1 OPERA ATION MANUA sorptio n Chille 16LJ- -F Serie Hot wa ater fired d type ModelN 16LJ- -F11 16LJ- 16LJ-F 16LJ-F1 16LJ- -F21 16LJ- 16LJ-F 16LJ-F2 16LJ- -F31 16LJ- 16LJ-F 16LJ-F4 16LJ- -F51 16LJ- 16LJ-F 16LJ- -F61 16LJ- 16LJ-F 16LJ- -F71 16LJ- 16LJ-F...

- Page 3 Please utilize the Chiller to its optimum performance by following recommended daily maintenance and handling, and periodic service. If you need any information about maintenance contract or any other inquiries, please contact Carrier service agent. DECLARATION OF CONFORMITY < for CE marking model >...

-

Page 4: Table Of Contents

Absorption Chiller Operation Manual ****** ****** Table of Contents 1. SAFETY PRECAUTIONS -------------------------------------------------------------------------------------- 2. OPERATING PRECAUTIONS -------------------------------------------------------------------------------- 2-1. PRECAUTIONS WITHIN 1 HOUR AFTER THE CHILLER STOP -------------------------- 2-2. PRECAUTIONS AFTER THE CHILLER SHUTDOWN ---------------------------------------- 2-3. CONTROL PROCEDURES FOR AUXILIARY EQUIPMENTS ------------------------------- 2-3 2-4. -

Page 5: Safety Precautions

1. SAFETY PRECAUTIONS To avoid harm to the operator and others, and to protect own asset, be sure to follow the instructions and requirements on safety described in this manual. We explain about a harm or damage if a chiller is used with mistaken usage ignoring these precautions. Failure to observe this instruction must result in serious injury or death. - Page 6 WARNING TURN OFF THE BREAKER BEFORE DO NOT TOUCH THE PARTS INSIDE THE CLEANING AND CHECKING CONTROL PANEL DO NOT TOUCH THE CONTROL PANEL Always turn off the breaker before SWITCH WITH WET HANDS cleaning and checking the cooling tower fan, water pumps, or others Do not touch the parts inside the linking to the chiller, to provide control panel to avoid electric shock.

- Page 7 DO NOT OPERATE COOLING WATER PUMP WIRE EACH INTERLOCK WITHIN 1 HOUR AFTER CHILLER STOPS COMPLETELY Be sure to wire the interlock for There is a possibility of chilled water Must be chilled water pump, cooling water freezing by the remaining cooling pump and ventilation fun.

- Page 8 CAUTION DO NOT PLACE HEAVY OBJECTS ON THE DO NOT CLIMB UP THE CHILLER CHILLER OR THE CONTROL PANEL Do not climb up the chiller to avoid Do not place heavy objects on the nasty fall. chiller or the control panel to avoid possible injury caused by falling.

-

Page 9: Operating Precautions

2. OPERAING PRECAUTIONS (1) Stop timing of auxiliary equipments During the dilution cycle operation of the Chiller, the chilled water pump (both the primary side and the secondary side) and air handling unit must be operated for the necessary time. The Chiller has a little cooling capacity even if it is in the dilution cycle operation. -

Page 10: Precautions Within 1 Hour After The Chiller Stop

2-1. PRECAUTIONS WITHIN 1 HOUR AFTER THE CHILLER STOP (1) Never operate the cooling water pump within 1 hour after the chiller stop. Otherwise, there is a possibility of chilled water freezing in the evaporator tube. Please operate the cooling water pump automatically by a signal from the chiller. -

Page 11: Control Procedures For Auxiliary Equipments

2-3. CONTROL PROCEDURES FOR AUXILIARY EQUIPMENTS (1) On-off control of the auxiliary equipments such as chilled water pump, cooling water pump, cooling tower fan and hot water pump shall be linked to the absorption chiller operation for the safety of the absorption chiller. - Page 12 Detailed procedure (1) At the start of the chiller “chilled water pump on-off signal” and “hot water pump on-off signal” become ON. (2) Chilled water pump starts in conjunction with the above signal. (3) This makes the answerback signal return to the chiller. (4) The chiller control system confirms if the chilled water flow rate is enough.

-

Page 13: Action In Case Of The Power Failure

After that, restart operation. During purging operation. Immediately close the purge valve completely and turn off the purge pump switch on the control panel. After power returns, restart purging, and contact Carrier service agent. 2-5. NOISE DATA Model : 16LJ-A Noise [dB(A)] 78.1 78.1... -

Page 14: Illustration

3. ILLUS STRATIO 3-1. DET TAIL OF TY YPICAL CHI LLER Coolin ng water inle Chilled d water outle Chilled d water flow switch Chilled d water inlet Purge pump TER HEADE ER SIDE Rupture d disk Control pane Purge unit Heat e exchanger Abso... - Page 15 Hot water ou utlet ondenser Genera ator Hot wa ater inlet oling water o outlet Evapor rator Absorber WATER HE EADER SID E (OPPOSIT Refrigerant b blow valve Absorbent p pump No.1 Refr rigerant pum VAPORATOR R SIDE Note: The p positions or quantity of p parts differ a...

- Page 16 3-2. TYP PICAL CON NTROL PAN CE type Touch p anel Fan, Filter Local sta art/stop stand d-by indication n lamp Term inal block Purge pu ump on-off s witch Term inal block fo powe er supply Operatin ng handle Grou nd terminal Note: The p...

- Page 17 3-3. FLOW WCHART OF F CHILLER A AND FUNCT TION OF EA ACH SECTI ot water control valve DT16 upture disk Cooling wate Inlet 69PR DT15 Purge tank Conden nser Generato riving hot water B valve 69CH Chilled water Cooling g water Outlet Outlet...

- Page 18 The List of sensors SYMBOL NAME Chilled water outlet temperature Cooling water outlet temperature Generator temperature Condenser temperature Chilled water inlet temperature Cooling water inlet temperature DT10 Diluted solution temperature at Absorber outlet DT11 Refrigerant temperature at Evaporator DT12 Cooling water mid temperature DT15 Driving hot water inlet temperature DT16...

-

Page 19: Operating Instructions

4. OPERATING INSTRUCTIONS 4-1. TURN ON THE MAIN CIRCUIT BREAKER Self-diagnostic function starts when the breaker inside the control panel of the Chiller is turned on. After completing the self-diagnosis, the display shows the following. (1) The panel display light up. (2) The touch panel starts the communication with the CPU board. -

Page 20: Description Of Keys And Their Functions

4-2. DESCRIPTION OF KEYS AND THEIR FUNCTIONS 1. Data display area 2. Operation indication lamp :Operation indication lamps light while the chiller, pumps, etc. operate. 3. Stop indication lamp :Stop indication lamps light while the chiller, pumps, etc. stop. 4. Status display area 5. -

Page 21: Operation

4-3. OPERATION 4-3-1. Pre-operation check Check the following items before starting operation. (1) Check of the setting point of the chilled water outlet temperature Make sure that the chilled water outlet temperature is set as specified. As for the indication of set value, please refer to Section 4-4. (2) Check of the hot water line a) Make a daily inspection.(Refer to Section 5.) b) Check that the valve(s) is open. - Page 22 4-3-2. Start operation (1) Local operation mode a) Touch the "LOCAL" and confirm the local indication lamp is on. b) Press the “RUN” button on the control panel, then the local start stand by lamp will be on. c) After the machine starts the operation, the lamp on the RUN button will be on and the local start stand by lamp will be off.

- Page 23 4-3-3. Stop operation (1) Local operation mode a) Press the “STOP” button on the control panel, then the local start/stop stand by lamp will be on. b) After the machine stop the operation, the lamp on the RUN button will be off and the local start/stop stand by lamp will be off.

-

Page 24: How To Change The Indication On Data Display

4-4. HOW TO CHANGE THE INDICATION ON DATA DISPLAY 4-4-1. Regular indication The display usually shows as follows. (Display Example) 4-4-2. How to change the indication If you touch key, the indication on the display changes. Data can be displayed in real time. Operation time, on-off times, temperature, set value, alarm informations etc are displayed. - Page 25 Back to main menu Back to main menu Back to main menu...

- Page 26 4-5. HOW TO CHANGE THE SETTING POINT 1. Check the current setting point at "Analog data" . 2. Touch the setting value 3. The setting window will be displayed 4. Set the new set point. 5. Touch 6. After touch the "Set" key , the new set point will be displayed. ( It takes max.

-

Page 27: Maintenance Message

4-6. MAINTENANCE MESSAGE 4-6-1. Function When a trouble which could disturb an efficient operation of the Chiller is predicted, it shows a notice. 4-6-2. How it is shown It is indicated on the data display as follows. Maintenance message Data name Data code H-01 Operate purge pump... -

Page 28: Alarm Indications And Actions To Be Taken

4-7. ALARM INDICATIONS AND ACTIONS TO BE TAKEN 4-7-1. How they are shown When an abnormity is detected, alarm buzzer sounds(option) and the alarm code is shown on the display and the alrm indication lamp will be on. The Chiller stops for safety reasons after a dilution cycle operation. Depending on the kind of the alarm, it stops without a dilution cycle operation. - Page 29 4-7-2. Actions to be taken THE CHILLER ACTION An alarm occurs. Alarm buzzer sounds, and the indication lamp of “STOP” key blinks. Alarm code is shown on the data display. Press the “BUZZER STOP” key on the touch panel. The alarm buzzer stops. Check the content of the alarm and solve the problem.

- Page 30 4-7-3. Content of alarm and setting List of alarm and setting Purpose Display Set point Chilled water Chilled water temperature is too low. C(36.5 F) or below freeze protection Chilled water pump interlock failure Few flow rate of chilled water 50% or below Cooling water temperature is too low.

- Page 31 4-7-4. Locating Alarm and Disposal List of Alarm Indications with their Causes and Remedies in cooling mode alarm Set point Recovery point Action Contact a service agent. Check Chilled water low temp. C or below above 2.5 other alarm with ▲key (36.5 (36.5 Operate the chilled water pump...

-

Page 32: Maintenance

5. MAINTENANCE 5-1. DAILY INSPECTION If you find an abnormal condition, contact a service agent. (1) Abnormal noise of absorbent pump and refrigerant pump. Consult the plant management company for the following items. (2) Cleaning of the cooling tower and the strainer of the cooling water line. (3) Check of the cooling tower condition. - Page 33 Purge tank Upper shell Purge indicatio lamp (green) B valve Lower shell Purge pump on-off switch rge pump Purge unit Open the g gas ballast v valve slightl ly until you c can hear the e exhaust so ound. If you u open it full purge pum mp oil will be...

-

Page 34: Water Treatment

5-2-3. Refrigerant blow down During g a cooling o operation, a little quantity y of absorbe ent could mi x into the re efrigerant. Accumulate amoun nt of the mix xed absorben nt could incr rease by a lo ong-term op peration and result in low wering of the... - Page 35 2. Analysis of water quality Check the water quality of make up water to satisfy the water quality guideline “JRA GL-02-1994”. About the analysis of water quality, contact a water treatment company. 3. Method of water treatment (1) Blow down Manage the recycling water quality to satisfy the water quality guideline “JRA GL-02-1994”.

- Page 36 Water quality standard for chilled water Chilled water line Tendency Circulation Make up Corrosion Scale T=<20C(68F) pH(at 25C(77F)) 6.5 - 8.0 6.0 - 8.0 Electrical conductivity 25C ms/m 40 or less 30 or less Chloride ion 50 or less 50 or less mgCl Sulfuric acid ion 50 or less...

- Page 37 6. Typical water treatment Even if make-up water for cooling water meets the water standards, the water quality gets worse by its concentration, therefore the following water treatment is necessary. To varying degrees, chilled water also requires this treatment. In case of an application of concrete heat storage tank, special attention should be paid to water treatment.

-

Page 38: Recommended Schedule For Maintenance And Replacement Of Main Components

4. Discharge the water from the discharge port on the cooling water inlet. 5. Keep the discharge port open during shut down. (2) Chilled water Keep the evaporator full with the water. (Wet lay up) (3) Hot water Keep the generator full with the water. (Wet lay up) 5-3-3. -

Page 39: Maintenance Contract

6. MAINTENANCE CONTRACT 6-1. ANNUAL MAINTENANCE CONTRACT Periodic inspection and parts replacement is important for safety operation. The inspection work requires a special skill. Please contract our service agent for details. We are not responsible for any troubles that are caused by maintenance service performed by a non-specialist. - Page 40 Manufacturer CARRIER SCS Route de Thil - BP49 01122 MONTLUEL CEDEX, FRANCE...

Need help?

Do you have a question about the 16LJ-F Series and is the answer not in the manual?

Questions and answers