Summary of Contents for STACKER S Series

- Page 1 S-Series User Guide © Copyright 2020 STACKER, LLC Minneapolis, MN 55427 http://stacker3d.com STACKER® is the registered trademark of STACKER, LLC . Last Revised: 16 March, 2021...

-

Page 2: Table Of Contents

4. Your First Print 5. Changing Nozzles and Filament Guide Tube Changing Nozzles Changing Filament Guide Tubes 6. Printer Calibration Adjusting First Layer Height Stacker Run Volumetric Calibration S2 and S4 Bed Leveling S4XL Bed Leveling Leveling Nozzles 7. Filament Out Switch 8. -

Page 3: Warnings

1. Warnings Stacker 3D printers are industrial machines that should never be operated around children or left unattended. Careful setup and training is required for optimal results. Read through this entire User Guide and view online resources before attempting to operate your printer. Please note, this printed copy of the User Guide may not be the most up to date version. -

Page 4: Introduction

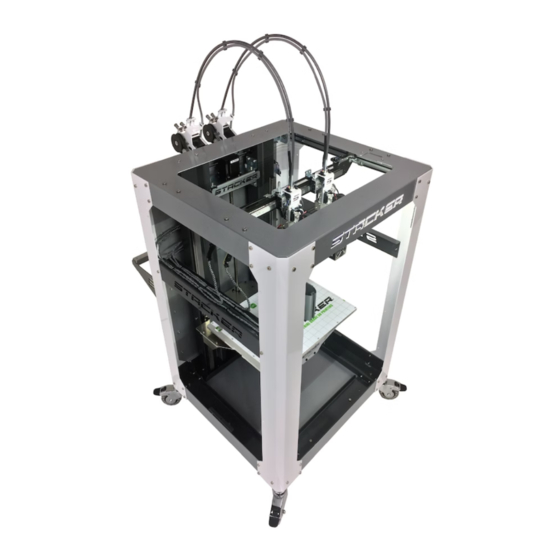

Welcome to STACKER! Our high performance industrial grade 3D printers are capable of producing everything from one-off prototypes to multiple part production runs. To get the most out of your Stacker 3D printer, please read the entire User Guide before attempting to operate your printer. This User Guide should provide all the information necessary to set up and operate your printer. - Page 5 Stacker Printer and have profiles for each Stacker model available on our website . To receive your copy of Simplify3D, please be sure to register your printer and contact sales@ stacker3d.com...

-

Page 6: Printer Specifications

Power Requirements 100-240VAC 8.5AMPS 100-240 VAC 8.5 AMPS 240 VAC 15 AMPS Internal Voltage 24VDC 24VDC 240 VAC Recommended UPS 1500VA/1000w or greater Size Connectivity USB and SD Card Default BAUD Rate 115200 Simplify3D, Stacker RUN Software Included Page 6... - Page 7 3. Unboxing and Assembly Your Stacker printer has been shipped in a wooden crate to protect the printer during transit. Should you ever need to transport the printer or return it to Stacker for warranty service, we recommend keeping both the crate and packaging materials.

-

Page 8: Hardware List

3.1 Hardware List 6-15P/C19 Power Cord (S4XL Only) 5-15P/C19 Power Cord USB Cable SD Card 1.5mm Hex Key 2mm Hex Key 3mm Hex Key 7mm Nut Driver Tube Cutter 0.007”/0.18mm Feeler Gauge 2.5mm Hex Driver Glue Stick 5mm Wrench Filament Drive Cleaning Brush (2) M4 x 10mm screws Filament Rail Brackets –... -

Page 9: Final Printer Assembly

3.2 Final Printer Assembly A. Remove Packaging To protect your printer during shipping, low tack tape and protective film was attached to the printer. You MUST remove all of this packing material before attempting to operate the printer. You will find tape attached to the X-gantry and frame. - Page 10 C. Attach Universal Filament Rail to Rear of the Printer Step 1. Locate the Filament Rail, the two Filament Rail Brackets, and the two M4 x 10mm bolts Step 2. Use the 3mm hex key to carefully remove four M5 x 12mm Socket Head Cap Screws from the rear of the printer frame just below the controller housing.

- Page 11 D. Install Glass Bed The Stacker S series printers include a glass bed. To install the glass bed on the S series, you must first remove all of the packaging material from the glass plate, and then place the glass plate on the aluminum print bed.

- Page 12 The tubes should make a gentle arch when the gantry is homed in the Y axis. F. Connect Power Cords The Stacker S2 and S4 uses one C19 inlet and the Stacker S4- XL uses two C19 inlets. The upper C19 inlet is for the auto switching power supply and will accept 120 to 240 volts of AC power at 47 to 440 Hz.

-

Page 13: Uninterruptible Power Supply (Ups)

The lower C19 inlet is only present on the S4-XL and powers the heat bed. We recommend powering the bed with 240v AC. If you power the lower C19 inlet with less than 240v (e.g., 208v or 120v), the bed will still function, but it will not heat as quickly or or get as hot. - Page 14 USB port on your computer. B. Power Up Printer. The Stacker S4 and S2 have one power switch, and the Stacker S4-XL has two power switches. On the S4-XL, be sure to turn on both power switches. The printer will will not operate properly if only one of the power switches is turned on.

- Page 15 Step 2. Preheat the print bed and hot end. Every filament has an optimal extruding temperature. Most filament manufactures provide a recommended extrusion temperature range, check the label on the filament spool or the manufacture's website for the suggested range. In this example, we have selected to use I-BEAM IMPACT PLA filament for our test print.

- Page 16 Stacker. If you continue pushing by hand, you will eventually see your filament extrude from the nozzle. Step 5. Secure the Filament Idler Assembly.. Close the assembly by hand while securing the Filament Idler Bolt in a position to prevent the assembly from opening.

- Page 17 Step 6. Secure Additional Heads For Copy Mode Print (Optional). If you are p rin ting with mult ip le heads using cop y mode atta ch the e xtra head s to the X a xis be lt. Posit ion the additional heads so the the y don 't p rint on top of each othe r, addit iona lly make sure la st head doesn't run into the f rame of the prin ter.

- Page 18 Step 9. Watch Your Test Print. While your print is running, watch for any problems with the printer. Although the printer was calibrated prior to shipping, calibration can sometimes be thrown off during shipping. If the printer is not performing adequately, calibration may be necessary to improve print quality.

-

Page 19: Changing Nozzles

Changing Nozzles Your Stacker print comes with 0.4mm nozzle preinstalled, the S4 and S4XL have four nozzles and the S2 has two nozzles. We recommend experimenting with different nozzle sizes after you become familiar with the operation of your printer. Changing your nozzle size can increase print speeds (with larger nozzle sizes) or improve the fine detail of your prints (with smaller nozzle sizes). - Page 20 Lastly, use the wire brush included with the accessories kit or a dry cloth to wipe any melted filament from the nozzle and underside of the heater block. NOTE, THE NOZZLE IS HOT! PROTECT YOURSELF FROM GETTING BURNED! You will want to thoroughly remove all the filament from underneath the hot end.

- Page 21 Step 5. Remove Old Nozzle. To loosen the nozzle from the heat sink, use a 5mm open end wrench to turn the nozzle counterclockwise. Once you loosen the nozzle with the wrench, you can turn it with your fingers until it is removed. Step 6.

-

Page 22: Printer Calibration

Slide the tube into the new nozzle, then screw the nozzle into the heat sink with your fingers. Use the 5mm open end wrench to secure the nozzle, DO NOT OVER TIGHTEN! Just turn the nozzle until it is snug. Step 7. - Page 23 The feeler gauge in the accessories kit is a good starting point. Use the gauge to adjust the gap between the nozzle and the bed. When sliding the feeler gauge between the nozzle tip and the bed, you should feel a small amount of friction from the nozzle tip. If there is no friction, then the nozzle is too high, and if you are unable to slip the gauge between the nozzle and the bed, then the nozzle is too close to the bed.

-

Page 24: Stacker Run

6.2 Stacker RUN To assist with printer calibration, it is necessary to download and install Stacker RUN software which is available for free on our website. Stacker RUN software is an enhanced version of Repetier Host customized for using Stacker printers. -

Page 25: Volumetric Calibration

Stacker RUN. When all other software has been closed on your computer, click the Connect button located in the upper left corner of Stacker RUN. A drop down menu will allow you to select the four or two head model. - Page 26 Step 1. Connect to Stacker RUN and Preheat the Extruder. Open Stacker RUN and connect to your printer. Once connected, preheat your extruder to the filament’s required temperature.

- Page 27 115mm of filament because we only measure 6mm of filament remaining. Step 6. Change the EEPROM Steps Per mm: Open your EEPROM window in Stacker RUN by pressing Alt+E or select “Firmware EEPROM Configuration” under the Config menu to see your current E-STEPS for each extruder.

- Page 28 Stacker nozzles use a system of small machined dots around the tip for identification purposes. Be sure to enter the correct nozzle size in your slicing software. Stacker’s standard nozzle size is 0.40mm, also called a 040 nozzle, and these were per-installed on your printer.

-

Page 29: S2 And S4 Bed Leveling

6.4 S2 and S4 Bed Leveling Step 1. Heat the bed. Heat your bed to 55°C, wait until this temp is reached. Step 2. Home the Z Axis. Use the LCD controller to home the Z-axis. Step 3. Position the print heads. Use both hands to push the X/Y gantry to the rear of the print bed as shown below. - Page 30 When you have a small amount of friction on the left side, slide print head number 2 by hand to the far right side of the gantry. Again, use the 0.007”/0.18mm feeler gauge to determine the gap between the nozzle tip and the bed. You should feel slight friction from the nozzle tip as you move the feeler gauge.

- Page 31 Now that the front of the bed is set, slide the gantry to the rear of the bed and repeat step 4. Repeat steps 4 and 5 until the nozzle gap is consistent in all these areas of the bed. Step 6.

-

Page 32: S4Xl Bed Leveling

6.5 S4XL Bed Leveling Due to the size of the S4XL bed there are a few more leveling points and this requires a slightly different leveling sequence. Step 1. Heat the bed. Use the LCD screen to heat the bed to 55°C, wait until this temp is reached. - Page 33 Start by adjusting the left rear leveling screw. Turn the nut driver clockwise or counter- clockwise until the feeler gauge slides beneath the nozzle with a small amount of friction from the nozzle. When you have a small amount of friction on the left side, slide print head number 2 by hand to the far right side of the gantry.

- Page 34 Next, repeat the same process for the middle rear screw. Move head 2 to the middle rear and adjust the screw until you feel the same small friction on the feeler gauge. Move between all three points until the friction feels the same. Step 5.

- Page 35 Step 6. Re adjust the screws. Move the gantry to the back of the printer and use the feeler gauge to verify the gap. Go between all points and make any adjustments needed to get the same level of friction. Next move the gantry to the front and verify those gaps as well.

-

Page 36: Leveling Nozzles

To fix the first layer squish you can adjust the Z min end stop screw. If you don't have enough first layer squish, turn the screw clockwise. If you have to much first layer squish turn the screw counter-clockwise. After adjusting the screw, restart the print and check the first layer squish again. - Page 37 Step 4. Remove the part cooling fan ducts. For each head you want to level remove the fan duct on the side of the print head. Use a 2mm hex key to loosen the two screws holding the duct in place. Set the ducts to the side for now.

-

Page 38: Filament Out Switch

8. Basic Printer Maintenance Other than periodically replacing nozzles, filament guide tubes, and cleaning the glass bed as needed, the basic maintenance required on a Stacker 3D printer is minimal. 8.1 Keep Your Printer Clean Inevitably, from regular use, small bits of filament debris will land on your printer. You must periodically remove this filament debris to protect your printer from damage. -

Page 39: Filament Drive Gears

8.2 Linear Guides The linear rail system on Stacker 3D Printers uses recirculating linear bearings and profile rail guides. For optimal performance, lubrication of these parts is essential. Lubrication promotes smooth operation, minimizes friction and wear along the raceways, dissipates heat, and prevents corrosion. The absence of proper lubrication will eventually lead to machine failure. -

Page 40: Filament Guide Tubes

8.4 Filament Guide Tubes The filament guide tubes on your printer should be inspected after 250 hours of use, and they typically need to be refreshed at a minimum of every 500 hours of use. W hen operating the print heads at temperatures greater than 250°C, you can expect the portion of the filament guide tube inside the nozzle to degrade more rapidly. -

Page 41: Terms And Conditions

TERMS AND CONDITIONS OF SALE & LICENSE As used herein, “Seller” shall mean Stacker, LLC, a Minnesota limited liability company, or any wholly-owned subsidiary of Stacker, LLC. These terms and conditions, and any applicable Seller quotation, sales order acknowledgment and Separate Software License, along with any other documents incorporated by reference in any of the foregoing (hereinafter collectively the “Agreement”), bind the buyer... - Page 42 CANCELLATION: Buyer may cancel its order at any time prior to shipment by providing written notice thereof to Seller and paying Seller liquidated damages in the following amounts: (a) if the order is cancelled within 48 hours of the Buyer’s purchase order date, then an amount equal to five percent (5%) of the total order price;...

- Page 43 licensed to the other party along with the accompanying documentation and a copy of this Agreement, and provided that the other party accepts the terms of this Agreement. If you transfer the Software as permitted herein, you may not retain any copies of the Software for your own use and your license rights under this Agreement are terminated.

- Page 44 12. CONFIDENTIAL INFORMATION. Any information disclosed by Seller to Buyer related to this Agreement, including quotations, pricing, technical information or otherwise, shall be deemed “Confidential Information”. Buyer shall not disclose any Confidential Information to any third parties without Seller’s prior written consent and shall use such Confidential Information only for the purposes reasonably related to the purchase and use of Seller’s Goods.

Need help?

Do you have a question about the S Series and is the answer not in the manual?

Questions and answers