Table of Contents

Advertisement

Quick Links

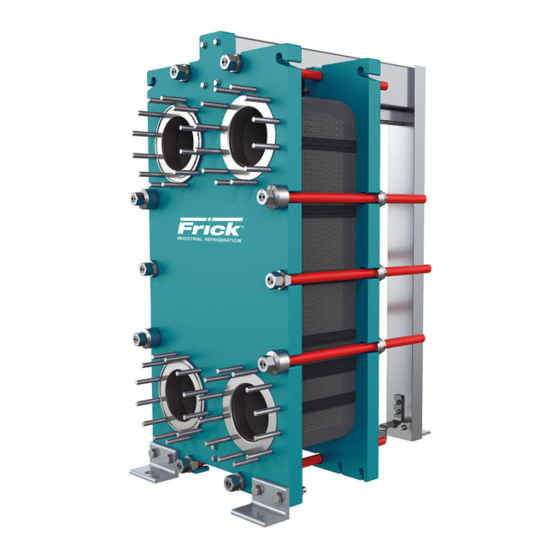

LaZerWeld II Plate Heat Exchangers

LZWII-2M, LZWII-4B, LZWII-4E, LZWII-6B,

LZWII-8K, LZWII-8B, and LZWII-12M

This manual contains rigging, assembly, start-up, and maintenance

instructions. Read thoroughly before beginning installation. Failure

to follow these instructions may result in personal injury or death,

damage to the unit, or improper operation.

Check www.FrickCold.com for the latest version of this publication.

Form 190.210-IOM (FEB 2020)

INSTALLATION–OPERATION–MAINTENANCE

File:

SERVICE MANUAL–Section 070

Replaces:

NOTHING

Dist:

3, 3a, 3b, 3c

Advertisement

Table of Contents

Summary of Contents for Frick LZWII-2M

- Page 1 NOTHING Dist: 3, 3a, 3b, 3c LaZerWeld II Plate Heat Exchangers LZWII-2M, LZWII-4B, LZWII-4E, LZWII-6B, LZWII-8K, LZWII-8B, and LZWII-12M This manual contains rigging, assembly, start-up, and maintenance instructions. Read thoroughly before beginning installation. Failure to follow these instructions may result in personal injury or death, damage to the unit, or improper operation.

-

Page 2: Table Of Contents

190.210-IOM (FEB 20) LAZERWELD II PLATE HEAT EXCHANGER Page 2 INSTALLATION - OPERATION - MAINTENANCE Contents General Information Operation Preface ................3 Start-up ................11 Safety considerations ............3 Unit in operation ............. 12 Warranty conditions ............3 Shut-down ..............12 Advice ................ -

Page 3: General Information

INSTALLATION - OPERATION - MAINTENANCE Page 3 General Information ENVIRONMENTAL COMPLIANCE FRICK endeavours to perform its own operations as cleanly and efficiently as possible, and to take environmental PREFACE aspects into consideration when developing, designing, This manual provides information needed to install, oper- manufacturing, servicing, and marketing its products. - Page 4 190.210-IOM (FEB 20) LAZERWELD II PLATE HEAT EXCHANGER Page 4 INSTALLATION - OPERATION - MAINTENANCE Figure 1: LZWII main components Distance sheets Port hole with stud Carrying bar bolt connections Bolt protection Supporting column Pressure plate Tightening bolts Flanged pipe connection Frame plate Guiding bar Plate pack...

-

Page 5: Nameplate

If the operat- ing temperatures as specified on the assembly drawing are to be exceeded, consult the supplier. Figure 3: Nameplate FRICK Sales Order No. Tag No. (Optional) Material No. FOR PARTS, SERVICE AND AFTER MARKET ASSISTANCE... -

Page 6: Identification Of Plate Side

190.210-IOM (FEB 20) LAZERWELD II PLATE HEAT EXCHANGER Page 6 INSTALLATION - OPERATION - MAINTENANCE Figure 4: Cassette arrangement forming the plate pack End cassette I End single plate Channel cassettes End cassette II End single plate Two plates which form the welded channel inside the cassette (red) -

Page 7: Installation

LAZERWELD II PLATE HEAT EXCHANGER 190.210-IOM (FEB 20) INSTALLATION Page 7 Figure 5: Shut-off valve and elbow location Installation BEFORE INSTALLING Elbow NOTICE Before start-up, check that all tightening bolts are firmly tightened and that you use the correct mea- surements of the plate pack. -

Page 8: Raising

190.210-IOM (FEB 20) LAZERWELD II PLATE HEAT EXCHANGER Page 8 INSTALLATION Figure 7: Lifting divice for LZWII-2M and LZWII-4B Figure 10: Lifting divice for LZWII-12M Figure 8: Lifting divice for LZWII-6B RAISING This instruction is valid when raising the LZWII after delivery. -

Page 9: Connecting To The System

LAZERWELD II PLATE HEAT EXCHANGER 190.210-IOM (FEB 20) INSTALLATION Page 9 CONNECTING TO THE SYSTEM 3. Position the LZWII on the timber posts. Remove sealing blind covers from the port holes before connecting the piping system. When connecting the piping system, make sure the pipes do not subject the LZWII to stress or strain. - Page 10 190.210-IOM (FEB 20) LAZERWELD II PLATE HEAT EXCHANGER Page 10 INSTALLATION This page is intentionally left blank...

-

Page 11: Operation

LAZERWELD II PLATE HEAT EXCHANGER 190.210-IOM (FEB 20) OPERATION Page 11 Operation 2. Check that the valve is closed between the pump and the unit controlling the system flow rate. START-UP Closed During start-up, check that no visible leakages appear from the plate pack, valves, or piping system. -

Page 12: Unit In Operation

190.210-IOM (FEB 20) LAZERWELD II PLATE HEAT EXCHANGER Page 12 OPERATION 6. When all air is expelled, close the air vent. Closed 7. Repeat steps 1 to 6 for the second media. UNIT IN OPERATION Make adjustments of flow rates slowly in order to protect the system against sudden and extreme variations of tem- perature and pressure. -

Page 13: Maintenance

NOTICE NOTICE Before opening the PHE check the warranty condi- tions. If in any doubt, contact a FRICK sales repre- If cleaning in place, use modulating or soft pumps to sentative. See Warranty conditions. avoid high flow rates and pressure shocks. - Page 14 5. Measure and note the dimension A. 2. Brush the threads of the bolts clean, using a steel wire brush or the FRICK thread cleaner. Lubricate the threads with a thin layer of grease, such as Gleitmo 800 Lubriplate or equivalent.

-

Page 15: Manual Cleaning Of Opened Units

Cassettes do not need to be removed from the PHE during cleaning. Note: For manual cleaning of heat exchangers in refriger- ant services, contact your FRICK representative 8. Open the plate pack by letting the pressure plate glide on the carrying bar. -

Page 16: Deposits Not Removable With Water And Brush

Cassettes must be removed from the PHE during cleaning. Before opening the LZWII check the warranty condi- WARNING tions. If in any doubt, contact a FRICK sales repre- sentative. See Warranty conditions. Use proper protective equipment, such as safety boots, safety gloves and eye protection, when using 2. -

Page 17: Adhesive Tape

Before opening the LZWII check warranty terms and brush or thread cleaner. Lubricate the threads with a conditions. If in doubt, contact your FRICK sales rep- thin layer of grease, such as Gleitmo 800 Lubriplate or resentative. See Warranty conditions. -

Page 18: Max Tightening Torque

190.210-IOM (FEB 20) LAZERWELD II PLATE HEAT EXCHANGER Page 18 MAINTENANCE b. After that, bolts are tightened alternately and diago- nally. Check the dimension A during tightening at the positions of the bolts that are being used. 5. If the cassettes are correctly assembled, the edges form a honeycomb pattern, see picture below. -

Page 19: Pressure Test After Maintenance

• Inspect the washers. STORAGE OF THE LZWII • When fully tightened, ensure the bolts are all equally FRICK delivers the LZWII ready to be put into service upon tensioned. arrival if nothing else has been agreed. However, keep the heat exchanger in the packing box until installation. -

Page 20: Taken Out Of Service

190.210-IOM (FEB 20) LAZERWELD II PLATE HEAT EXCHANGER Page 20 MAINTENANCE Taken out of service If, for any reason, the LZWII is shut down and taken out of service for a long period of time, follow the same instruc- tions as in the previous section Indoor Storage. Before putting into storage, perform the following actions: •... - Page 21 LAZERWELD II PLATE HEAT EXCHANGER 190.210-IOM (FEB 20) MAINTENANCE Page 21 Notes...

- Page 22 JOHNSON CONTROLS Supersedes: NOTHING 100 Cumberland Valley Avenue Subject to change without notice Waynesboro, PA 17268-1206 USA Published in USA • 02/20 • PDF Phone: 717-762-2121 • FAX: 717-762-8624 www.johnsoncontrols.com/FRICK © 2020 Johnson Controls Int’l PLC - ALL RIGHTS RESERVED...

Need help?

Do you have a question about the LZWII-2M and is the answer not in the manual?

Questions and answers