Table of Contents

Advertisement

Quick Links

INSTALLATION, MAINTENANCE,

Visit our Web site at www.paccarwinch.com for the most comprehensive collection of winch, hoist, and drive

information on the Internet. Most publications and specification sheets are available for downloading.

LIT2718 R2

PB243

April 2017

Printe d in USA

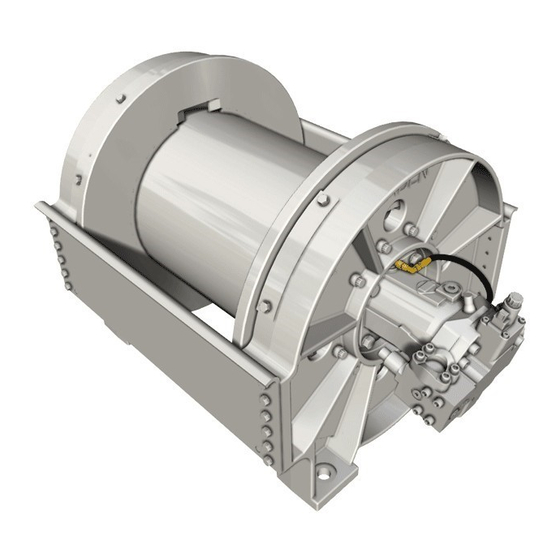

CH330 and CH400

HYDRAULIC WINCH

AND SERVICE MANUAL

WRITE HOIST SERIAL NUMBER BELOW

First 2 numbers indicate

year manufactured

For serial number location see page 4

1

CH330

CH400

©2017 PACCAR Inc.

All rights reserved

Advertisement

Table of Contents

Need help?

Do you have a question about the CH330 and is the answer not in the manual?

Questions and answers