Cascade G Series Operator's Manual

Rotators

Hide thumbs

Also See for G Series:

- Installation instructions manual (34 pages) ,

- Service manual (38 pages) ,

- User manual (16 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Cascade G Series

- Page 1 PERATOR’S GUIDE G D E G, D & E-Series Rotators...

-

Page 2: Table Of Contents

ONTENTS Introduction End User Please Notice Attachments Daily Inspection Fork Installation WARNING Rated capacity of the truck/attachmen Attachments Operation combination is a responsibility of the orginal truck manufacturer and may be Safety Rules less than shown on the attachment nameplate.Consult the truck nameplate. Load Handling CAUTION: Do not operate this attachment unless... -

Page 3: Introduction

NTRODUCTION — — — Rotators-Cascade Rotators are available in a wide variety of types designed to handle a wide variety of loads. 30E Rotators About this Guide-The information in this Guide is intended to simplify operator understanding about effiective and safe carton Clamp use and operation. -

Page 4: End User Please Notice

ND USER PLEASE NOTICE 86-592-6512500 86-592-6512531 - 3 -... - Page 5 ND USER PLEASE NOTICE The daily inspection and periodic maintenance is very important for ensuring the normal performance and durable service life of the forklift attachment. For details, please refer to Cascade Xiamen Forklift Attachment User Manual Service Manual .

-

Page 6: Attachments Daily Inspection

AILY INSPECTION Check items each day.Report problems to your supervisor.See the Service Manual for maintenance and repair procedures. Upper hook engagement Cylinders and Hoses for leaks Safety decals & nameplates Lower hook engagement Fasteners Forks - 5-... -

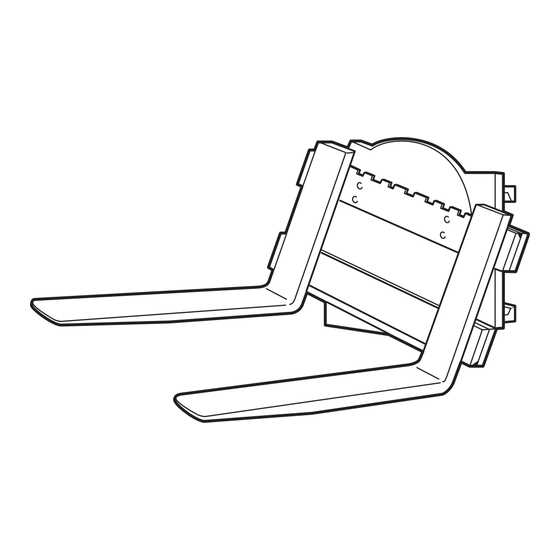

Page 7: Fork Installation

ORK INSTALLATION POSITON,LOCK FORKS Position fork Engage spring lock Release spring lock Remove fork keeper Install fork keeper CAUTION:Pin must be Fork bar engaged in notch. WARNGING:Handle fork with care to avoid pinching fingers or dropping on feet. Forks must have third hook when used on Rotators. -

Page 8: Attachments Operation

TTACHMENT INSPECTION Rotate Counterclockwise(CCW) Rotate clockwise(CW) Tilt Forward Hoist down AUXILIARY VALVE FUNCTIONS Hoist up Tilt back - 7 -... -

Page 9: Safety Rules

AFETY RULES No rides No reaching through mast No standing under load With load Tilt Raise 8 cm (3 in.) No load RAMPS Traveling empty Motor off,park,lower load - 8 -... - Page 10 AFETY RULES No parking on ramp No turning on ramp Watch clearances TRAFFIC STOP Observe Stop Workers Slow for two-way Sound horn,slow Sound horn,slow traffic at intersection at corner Wet floors Bumps Dips - 9 -...

-

Page 11: Load Handling

OAD HANDLING Top of load must not extend above frame. Do not rotate in immediate vicinity of other people LOAD WEIGHT Rotate elevated loads slowly Captive fork slots required. Load weight must not exceed combined truck/attachment capacity(see truck nameplate). Fast rotation affect truck Lotal fork capacity(LH+RH fork) must stability... -

Page 12: Spare Parts List

PARE PARTS LIST Rotator Group When Ordering replace parts, please consult us and provide the Attachment Model or Serial No.stamped on the nameplate. - 11 -... - Page 13 PARE PARTS LIST Fork Bar Group Mounting Group When Ordering replace parts, please consult us and provide the Attachment Model or Serial No.stamped on the nameplate. - 12 -...

- Page 14 PARE PARTS LIST Mounting Group When Ordering replace parts, please consult us and provide the Attachment Model or Serial No.stamped on the nameplate. - 13 -...

-

Page 15: Periodic Maintenance

ERIODIC MAINTENANCE WARNING: After completing any service procedure, always test the atachment through ve complete cycles. First test empty, then test with a load to make sure the attachment operates correctly before returning it to the job. Rotator Bearing Assembly Ball Race Grease Fitting (A) Rotator Drive End Rotator Drive... - Page 16 ERIODIC MAINTENANCE 100-Hour Maintenance Every time the lift truck is serviced or every 100 hours of truck operation, whichever comes rst, complete the following maintenance procedures: Check for loose or missing bolts, worn or damaged hoses, and hydraulic leaks. Check that fork locking pins and end bar keepers are installed and functional.

- Page 17 ERIODIC MAINTENANCE TB183 Check sample of bearing capscrews for proper torque 684597 (30E) 672946 (100D, X100D, value. See Technical Bulletin TB183 or Service Manual 120D,150D) 6089468 (45G-100G) 684597 (30E) or Service Manual 672946 (100D, X100D, 120D, 150D) or Service Manual 6073955 (45G–100G) for checking and replacement procedures.

- Page 18 656300) SAE 90 wt AGMA If necessary, ll with Cascade Rotator Drive Lubricant, 6 EP Part No. 656300, or SAE 90 wt. gear lube (AGMA 'mild' 6 EP Gear Oil). Replace plug. Inspect forks, carriage bars and frame for cracks and wear.

- Page 19 Manual 6089468 for service. Fill thr 656300) SAE 90 wt AGMA to the end cover level hole. Use Cascade Rotator Drive 6 EP Lubricant, Part No. 656300, or SAE 90 wt. gear lube (AGMA 'mild' 6 EP Gear Oil). Replace plug.

- Page 20 ERIODIC MAINTENANCE 2000 2000-Hour Maintenance 2000 1000 After each 2000 hours of truck operation, in addition to the 100, 500 and 1000-hour maintenance, perform the following procedures: TB183 rotation bearing capscrews for proper torque 684597 (30E) 672946 (100D, X100D, value. See Technical Bulletin TB183 or Service Manual 120D,150D) 6089468 (45G-100G) 684597 (30E) or Service Manual 672946 (100D, X100D,...

- Page 21 ERIODIC MAINTENANCE 2000 Fork Inspection – After 2000 hours of truck operation, forks in use shall be inspected at intervals of not more than 12 months (for single shift operations) or whenever any defect or permanent deformation is detected. Severe applications will require more frequent inspection. Fork inspection shall be carried out by trained personnel to detect any damage that might impair safe use.

-

Page 22: Safe Operation And Maintenance

AFE OPERATION AND MAINTENANCE (OSHA REGULATIONS) OSHA OSHA1910. 178) 警告: OSHA1910.178 ANSI B56.1-1969 (5i) (5ii) (a)(2) (5iii) (a)(2) 1972 2 15 ANST ANSI B156.1-1969 - 21 -... - Page 23 AFE OPERATION AND MAINTENANCE (OSHA REGULATIONS) (10) (7i) 10º (7iii) - 22 -...

- Page 24 AFE OPERATION AND MAINTENANCE (OSHA REGULATIONS) WARNING:The safe operation and maintenance of industrial Standard for Powered Industrial Trucks, Part II,ANSI B56.1- trucks is regulated by Occupational Safety and Health(OSHA) 1969",except for vehicles intended primarily for earth moving or regulations 1910.178 and American National Standards over -the-road hauling.

- Page 25 AFE OPERATION AND MAINTENANCE (OSHA REGULATIONS) (6) A safe distance shall be maintained from the edge of ramps or load engaging means elevated shall be prohibited except to platforms while on any elevated dock or platform or freight pick up a load.An elevated load shall not be tilted forward car.Trucks shall not be used for opening or closing freight doors.

-

Page 26: Warranty

ARRANTY “ ” “ ” 4000 1000 “ ” - 25 -... - Page 27 ARRANTY 40088 57315 2013 9 24 Version No.: Cascade Xiamen 2013 - 26 -...

- Page 28 1000 hours of operation, whichever terminates first alternatively. Within the policy, "Warranty" means Cascade Xiamen will repair or replace, at its option, any part that a Cascade Xiamen itself or .authorized inspection reveals to be defective in materials or workmanship.

- Page 29 ON THE FACE OF CASCADE XIAMEN'S ORDER ACKNOWLEDGEMENT. If the end user customer would like to know more about Cascade Xiamen product or the relevant aspects of installation and service, please firstly consult with the forklift truck OEM or its Dealer who sold the product.

- Page 30 Cascade Xiamen Forklift Truck Attachment Co., Ltd 361026 No.668 Yangguang Road, Haicang, Xiamen, Fujian ,361026 P.R China /Tel: 0592-6512570 /Fax: 0592-6512571 Cascade Xiamen reserves the rights to make change without notice. 1210976R3 xm cn 05/2015...

Need help?

Do you have a question about the G Series and is the answer not in the manual?

Questions and answers