Table of Contents

Advertisement

Quick Links

Start-up

Operation

Maintenance

Accessories

We manufacture in

Germany

USER'S MANUAL

Carefully read these instructions before starting

and using your grapples!

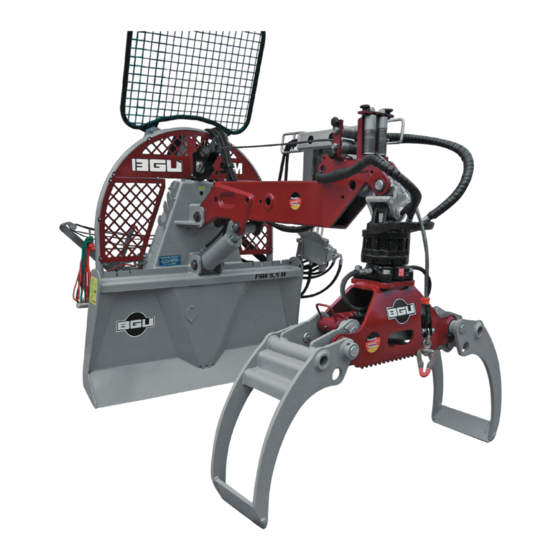

Logging Grapples

Attachment

HRZ Kombi Anbau

Südharzer Maschinenbau GmbH

Helmestraße 94 ∙ 99734 Nordhausen/Harz

Zentrale:

Internet: www.bgu-maschinen.de

e-mail: info@bgu-maschinen.de

03631/6297-0 -111

Advertisement

Table of Contents

Summary of Contents for BGU HRZ Kombi Anbau

- Page 1 USER‘S MANUAL Carefully read these instructions before starting and using your grapples! Logging Grapples Attachment Start-up Operation HRZ Kombi Anbau Maintenance Accessories We manufacture in Germany Südharzer Maschinenbau GmbH Helmestraße 94 ∙ 99734 Nordhausen/Harz Zentrale: 03631/6297-0 -111 Internet: www.bgu-maschinen.de...

-

Page 2: Table Of Contents

CONTENTS Contents Introduction 1.1 About the manual 1.2 Delivery and transport claims Safety pictograms and warning labels Safety 3.1 General safety rules and occupational safety Operation Mandatory application field Attaching the grapple arm to an implement Start-up Hydraulic system Repairs and maintenance Services to be provided at 10 hour operation intervals Handling and Transportation 8. -

Page 3: Introduction

INTRODUCTION Dear customer,thank you very much for your trust and preference in buying this loader! 1.1 About the manual Please take time to read this manual and learn to how operate and maintain the splitter safely. For your easier reading this manual is laid out in several sections. The sections are progressively numbered 1 through 14 and listed on the “contents”... - Page 4 de on the delivery bill. All transport damages must be notified within latest 2 days from de- livery. Therefore delivery must be collected and inspected within this term. Later claims will be disregarded. In case of assumed but not vi- sually clear transport damages make sure to mark the following sen- tence on the delivery bill: „„Reserved delivery due to assumed transportation damages.“...

-

Page 5: Safety Pictograms And Warning Labels

5. 10. Production label „Product identification“ This label shows the company details of the manufacturer and the Südharzer Maschinenbau GmbH main machine technical data. Helmestr.94 99734 Nordhausen Bezeichnung: Holzrückezange - Anbau Maschinentyp: HRZ Kombi - Anbau Maschinennr: Bj. 13 „BGU-Maschinen“ Manufacturer's logo... - Page 6 Safety pictogram „Do not infringe the dange- rous zone“ Avoid standing in the dangerous zone between the tractor and the log loader. Safety pictogram „Danger Pinch Point“ Keep hands away from this danger zone till all moving parts have come to a complete stop. Safety pictogram „Caution : operating zone“...

-

Page 7: Safety

SAFETY RULES Strictly perform installation, set-up, maintenance, cleaning and transportation with the unit switched off and all moving parts firmly secured against accidental operation. Immedia- tely disconnect power off the machine in case of any eventual faults or troubles. The user shall strictly comply with these operation, set-up, mainte- nance, repair and trouble-shooting instructions in order to assure safe operation and avoid damages to the equipment. - Page 8 • When you pull/hand timber always keep in mind that lurching or other sudden, flicking movements of a suspended/pulled load may oc- cur due to timber flexibility and bounciness. Mind for the safety of your fellow workers safety and take due measu- res to keep the work area free from other thirds and obstacles.

-

Page 9: General Safety Rules And Occupational Safety

3.1 General safety rules and occupational safety • Before each new use, check for your tractor operational and road travel safety! • Mind for all safety pictograms and operation labels on your grapple loader. They are all-important for safe operation and travel! •... -

Page 10: Operation

OPERATION 4.1 Mandatory application field Grapple loaders are strictly designed for wood lot owners to pull, hand- le and manipulate timber logs. This grapper loader HRZ Kombi-Anbau has got front cable guide rollers and hydraulic height adjustment provisions. Grapple loaders HRZ Kombi-Anbau are designed for attachment to the logging winches FSW 5,5 M and KS 5.5 H The maximum working pressure of the grapple is 180 bar. -

Page 11: Start-Up

Südharzer Maschinenbau GmbH will accept no liability for the state and conditions of your tractor three-point linkage. Make sure to install the loader so that no damage can occur to the driver‘s cab during off-road travel or with raised hydraulics. Start-up Operating instructions •... -

Page 12: Hydraulic System

HYDRAULIC SYSTEM • DANGER: the hydraulic system operates at very high pressure! • Mind the correct connection of all hydraulic hoses,as you perform branching of the hydraulic cylinders and of the motors! • For due connection of the hydraulic hoses to your tractor hydraulics hydraulics make sure that no pressure is available on both the tractor and the attachment side! •... -

Page 13: Repairs And Maintenance

REPAIRS AND MAINTENANCE Make sure that the machine is fully disconnected and all moving parts are secured before performing any maintenance/repair work on the machine. Immediately disconnect power off the machine in case of any eventual fault or trouble. Before performing any maintenance/repair work on the machine, make sure that the grapples are open wide and securely set on ground with the machine fully disconnected and all moving parts stopped and secured. -

Page 14: Accessories

8. ACCESSORIES Rotator (replacement rotators are supplied with connection hoses) 1400 Nm, 4.5t at 195 bar, Flange 140x140, 4x M16x50 (Fig. 1) Part No. 96255 (25 kg) Rotator (replacement rotators are supplied with connection hoses) 1200 Nm, 4.5t at 230 bar, Flange 140x140, 4x M16x50 Part No. -

Page 15: Technical Data

TECHNICAL SPECIFICATIONS Technical Specifications Unit of Part No. mea- 96247 sure- ment Attaches to any logging winch Tractor power requirements kW/PS from 45/61 Grapples HG 1300 (included) Gripping capacity (opening width) 90-1280 Clamping force Pivotal hanger for grapple rotation 160° Cardan joint fixation Weight Optional rotator... -

Page 16: Disabling And Disposal

10. DISABLING AND DISPOSAL When the machine is fully obsolete and cannot be of any longer use, it should be duly dismounted ahead of discarding. Certain components need deactivation and dismantling in order to assure that no further use is made by other parties and that no worn out parts are recycled for other applications. -

Page 17: Other Areas Of Possible Dangers

DANGER: removing or by-passing inbuilt machine safeties may result into serious operator's personal injuries. 12. LEGAL WARRANTY All BGU machines are covered with warranty terms in accordance with the law. Customers should promptly notify the manufacturer eventual material or production claims on their detection. While asking for warranty ser- vice, customer should show copy of their purchase invoice or receipt. -

Page 18: Spare Parts For Hrz Kombi-Anbau

13. SPARE PARTS FOR HRZ KOMBI-ANBAU Z- Kombi- Anbau... - Page 19 Description HRZ Kombi-Anbau Part Dimensions Pos. 25499 Swivelling extendible arm Joint assembly 22333 Standard bolts, 40-120 22835 55923 M16x35 Hex screw Rotator 56023 22829 Standard bolts, 30-123 M12x30 Hex screw 51478 Grapple 1300 23842 55931 M16x55 Hex screw Shim 51652 Cable guide HRZ Fix-AS 22268 25505...

- Page 20 Grapple pivotal hanger, complete assembly Zangenschwenkwerk, kpl. Stand Juli 2011...

- Page 21 Description, grapple pivotal hanger, com- Dimensions Pos. plete assembly (Part No. 22387) 55803 Tension spring Shaft bushing 22379 Grapple connection 22383 55910 Plain bearing, collar-less M12x35 Hex screw 51479 51163 AM 6x1 Ball lubricator Washer 51650 M12x45 Hex screw 51481 51595 Hex nut Perforated T-plate...

- Page 22 Grapple 1300 Greifer 1300 Stand Juli 2011 Description Grapple 1300 Dimensions Pos. (Part no. 23842) Housing for grapple 130o 24034 Special bolt 40-178 22355 Special bolt 40-60 22356 Hydraulic cylinder 55938 80-40-510-800-290 Small grapple 23851 23846 Large grapple 24035 Parallel guide 51163 AM 6x1 Ball lubricator...

-

Page 23: Ec Statement Of Compliance

Person responsible for the technical documents: Jörg Kernstock (Management) Südharzer Maschinenbau GmbH Helmestraße 94 ∙ 99734 Nordhausen/Harz Service-Tel. 03631/6297-104 ∙ Fax 03631/6297-111 Internet: www.bgu-maschinen.de e-mail: info@bgu-maschinen.de Venue: Nordhausen Jörg Kernstock (Management) Date 13.02.2013 Translation of the original user's manual in German... - Page 24 Subject to changes without prior notice Südharzer Maschinenbau GmbH Helmestraße 94 ∙ 99734 Nordhausen/Harz Form: 922.13.02.2013- Rev. A Service-Tel. 03631/6297-104 ∙ Fax 03631/6297-111 Internet: www.bgu-maschinen.de e-mail: info@bgu-maschinen.de...

Need help?

Do you have a question about the HRZ Kombi Anbau and is the answer not in the manual?

Questions and answers