Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Yanmar SD25

- Page 1 OPERATION MANUAL SAIL-DRIVE SD25 English...

- Page 2 We reserve the right to make any change at any time without notice. Yanmar and are registered trademarks of YANMAR CO., LTD. in Japan, the United States and/or other countries. All Rights Reserved:...

-

Page 3: Table Of Contents

Fitting a Fixed Propeller (2-Blade) ..... 17 Lubricating Oil ............18 Lubricating Oil Chart .......... 18 For SD25 (Except if coupled with the 1GM10C) .. 18 Filling with Lubricating Oil ........19 Checking The Instrument Panel Alarm System ..20... - Page 4 Periodic Maintenance Procedures......32 After Initial 50 Hours of Operation...... 32 Every 100 Hours of Operation......33 Every 250 Hours of Operation......34 Every Year ............34 Every 2000 Hours of Operation......35 Every 5 Years............. 36 Specifications..............37 SD25 Operation Manual...

-

Page 5: Introduction

INTRODUCTION This Operation Manual describes Sail-Drive Model SD25. For engine handling and operation, refer to the respective operation manuals for Engine Models 1GM10C, 2YM15, 3YM20, 3YM30 and 3YM30AE. However, instructions for the marine gear box are not necessary as they are included. - Page 6 INTRODUCTION This Page Intentionally Left Blank SD25 Operation Manual...

-

Page 7: Safety

SAFETY Yanmar considers safety of great DANGER importance and recommends that anyone that comes into close contact with its Indicates a hazardous situation which, products, such as those who install, if not avoided, will result in death or operate, maintain or service Yanmar serious injury. -

Page 8: Safety Precautions

• Safety signs and labels are additional maintenance. reminders for safe operating and maintenance techniques. • See your authorized Yanmar marine dealer or distributor for additional training. Crush Hazard • Never stand under a hoisted Sail-Drive. -

Page 9: During Operation And Maintenance

• Always stop the engine before you begin to service the Sail-Drive and secure the propeller so it will not turn. Alcohol and Drug Hazard Never operate the engine while under the influence of alcohol or drugs or when feeling ill. SD25 Operation Manual... - Page 10 Sail-Drive. Sudden Movement Hazard • Always keep the electrical connectors Always stop the engine before and terminals clean. Check the beginning service. electrical harnesses for cracks, abrasions, and damaged or corroded connectors. SD25 Operation Manual...

- Page 11 • Modification will impair the safety and performance of the product and shorten product life. • Modifications to the design, safety or limiting features will void the warranty. SD25 Operation Manual...

- Page 12 Never attempt to modify the Sail-Drive’s design or safety features. Failure to comply may impair the marine gear’s safety and performance characteristics and shorten the Sail-Drive’s life. Any alterations to this Sail-Drive may affect the warranty coverage of your Sail-Drive. SD25 Operation Manual...

-

Page 13: Product Overview

• Comply with and follow all lubrication Sail-Drive oil levels frequently. and maintenance instructions and recommendations; and Dealer/Distributor Responsibilities • Have an authorized Yanmar dealer/distributor perform periodic In general, a dealer’s responsibilities to the checkups. customer include predelivery inspection and preparation such as:... -

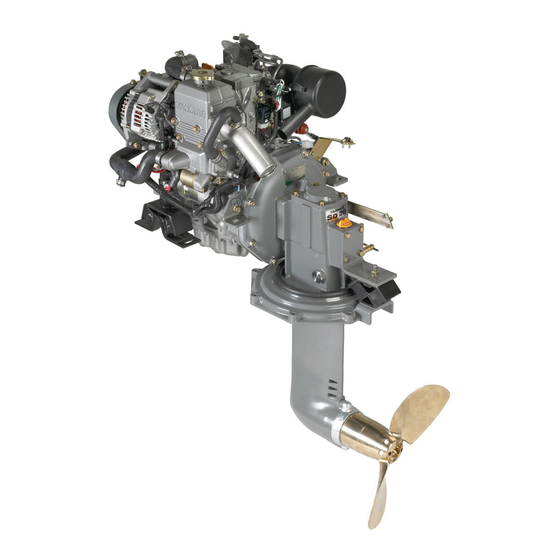

Page 14: Component Identification

PRODUCT OVERVIEW COMPONENT IDENTIFICATION K0006440 1 – Dipstick 5 – Propeller 6 – Seawater inlet 2 – Upper gear case 7 – Flexible mount 3 – Lower gear case 4 – Lubricating oil drain plug Figure 1 SD25 Operation Manual... -

Page 15: Galvanic Corrosion

Galvanic corrode Sail-Drive components. isolators and isolation transformers are also available from the aftermarket (not supplied by Yanmar). The Galvanic isolator is a device that is installed in series with the (AC) grounding (GREEN) conductor of the shore-power cable to... -

Page 16: Shore Power

Galvanic isolators are Sail-Drive. available from the aftermarket (not supplied by Yanmar) to block these currents while still providing a path to ground for dangerous shock currents. Failure to use the correct anode material... -

Page 17: Underwater Drive Coating

• Never paint over drain holes, sacrificial anodes, or other items specified by the sacrificial anode Manufacturer. Contact your authorized Yanmar Marine dealer or distributor for assistance. Galvanic corrosion damage, normal maintenance and consumable parts are not covered by the Yanmar Limited Warranty. SD25 Operation Manual... - Page 18 PRODUCT OVERVIEW This Page Intentionally Left Blank SD25 Operation Manual...

-

Page 19: Before You Operate

This section of the Operation Manual describes propeller selection, propeller fitting, lubricating oil specifications and how to replenish them. It also describes the daily instrument panel and remote-control device checks. Before you operate the Sail-Drive, review the Safety section on page 3. SD25 Operation Manual... -

Page 20: Propeller Selection

16.5 in. 3YM30AE 16 in. 16.5 in. Make sure the propeller (fixed or folding) has a rubber bushing. If a propeller is used without a rubber bushing, the shaft, bearing and gears of the Sail-Drive will be damaged. SD25 Operation Manual... -

Page 21: Fitting A Fixed Propeller (2-Blade)

■ Locking procedure for fixed propeller nut (optional) When tightening the nut to 60 to 70 N·m (44 to 52 lb-ft) torque for the SD25, move the shift lever to ahead and hold the crankshaft V-pulley clamp nut with a wrench to stop the propeller rotating. -

Page 22: Lubricating Oil

Use only oil of quality GL-4 or GL-5 in the API service, and SAE No. 90 or 80W-90. (Except model SD25 1GM10C). Use only oil of quality CC or greater in the API service, and SAE No. 10W-30. (Applicable model: SD25 1GM10C). For SD25 (Except if coupled with the 1GM10C) Supplier Brand name API service SAE No. -

Page 23: Filling With Lubricating Oil

1 – Oil supply port 2 – Oil capacity nameplate Figure 3 It takes about 10 minutes to fill up the Sail-Drive with lubricating oil. Check the oil level 15 minutes after adding the specified quantity of oil. SD25 Operation Manual... -

Page 24: Checking The Instrument Panel Alarm System

6 – Battery low charge alarm lamp 7 – Alarm buzzer 7 – LCD (Hour meter) 8 – Start switch (Push button) 8 – Start switch 9 – Stop switch Figure 4 10 – Glow switch 11 – Power switch Figure 5 SD25 Operation Manual... - Page 25 (3, Figure 6) and (4, Figure 6) sounds the warning buzzer and lights the rubber seal lamp on the instrument panel. If this happens, stop the engine and under sail, quickly return to the nearest port for repairs. SD25 Operation Manual...

-

Page 26: Daily Checks

Drain cooling water and close cooling water cock after operation. See Engine Cooling Water on page 26. If any problem is noted during the visual check, the necessary corrective action should be taken before you operate the engine. SD25 Operation Manual... -

Page 27: Sail-Drive Operation

SAIL-DRIVE OPERATION Before you operate the Sail-Drive, read the following safety information and review the Safety section on page 3. SD25 Operation Manual... -

Page 28: Remote Control Device Check

Confirm that the operation lever of the Sail-Drive moves smoothly to AHEAD, ASTERN and NEUTRAL. Because the Sail-Drive SD25 uses a dog clutch, the clutch is not engaged unless the operation lever is moved to the NEUTRAL position. When sailing, set the remote control lever in neutral. - Page 29 5 – Cable clamp 6 – Remote control cable 6 – Remote control cable 7 – Ahead stop 7 – Pivot 8 – Neutral position Figure 3 9 – Astern stop 10 – Spring joint Figure 2 SD25 Operation Manual...

-

Page 30: Engine Cooling Water

K0005447 1 – Cooling water cock 4 – Hose clamp 5 – Seawater inlet 2 – Cooling water hose 3 – To cooling water pump Figure 4 SD25 Operation Manual... -

Page 31: Periodic Maintenance

Before you perform maintenance on the Sail-Drive, read the following safety information and review the Safety section on page 3. This section of the Operation Manual describes the procedures for proper care and maintenance of the Sail-Drive. SD25 Operation Manual... -

Page 32: Tightening Fasteners

10.8 ± 1.0 25.5 ± 2.9 49.0 ± 4.9 88.3 ± 9.8 137.0 ± 9.8 226.0 ± 9.8 kgf·m 1.1 ± 0.1 2.6 ± 0.3 5.0 ± 0.5 9.0 ± 1.0 14.0 ± 1.5 23.0 ± 2.0 SD25 Operation Manual... -

Page 33: Periodic Maintenance

Failure to perform periodic maintenance will shorten the life of the Sail-Drive. ■ Yanmar replacement parts Yanmar recommends that you use genuine Yanmar parts when replacement parts are needed. Genuine replacement parts help ensure long Sail-Drive life. ■ Tools required Before you start any periodic maintenance procedure, make sure you have the tools you need to perform all of the required tasks. -

Page 34: Periodic Maintenance Table

PERIODIC MAINTENANCE PERIODIC MAINTENANCE TABLE : Replace ●: Contact your authorized Yanmar Marine dealer or distributor : Check or Clean Periodic maintenance interval Daily 50 hours Every Every Every System Item (See Daily Every Every 5 2000 Checks on... -

Page 35: When The Vessel Is Out Of The Water, Perform The Following

Follow the manufacturer’s directions for surface preparation and application. K0005464 Contact your authorized Yanmar Marine 1 – Lower gear case dealer or distributor for assistance. 2 – Seawater inlet Inspecting the Anode... -

Page 36: Periodic Maintenance Procedures

Figure 2 from the drive unit immediately after ■ Inspecting and replacing the operation. clutch shifter See your authorized Yanmar dealer or Replacing oil distributor for procedure. Refer to Filling with Lubricating Oil on page SD25 Operation Manual... -

Page 37: Every 100 Hours Of Operation

To inspect and replace the anode on calculated for the Sail-Drive. Changing the the lower gear case, the vessel must be material of the propeller may require removed from the water. additional anodes to be installed on the Sail-Drive. SD25 Operation Manual... -

Page 38: Every 250 Hours Of Operation

• Inspecting remote control device ■ Inspecting and replacing the • Repairing case coating clutch shifter • Inspecting rubber diaphragm seal See your authorized Yanmar dealer or ring distributor for procedure. • Inspecting seal sensor • Inspecting and/or replacing the flexible mount ■... -

Page 39: Every 2000 Hours Of Operation

■ Replacing the flexible mount Replace if clearance is less than 1 mm See your authorized Yanmar dealer or (1, Figure 4). See your authorized Yanmar distributor for procedure. Flexible Mount Marine dealer or distributor for procedure. must be replaced every 2000 hours. -

Page 40: Every 5 Years

PERIODIC MAINTENANCE Every 5 Years Perform the following maintenance every 5 years of operation. • Replacing rubber diaphragm seal ring ■ Replacing rubber diaphragm seal ring To replace, consult your Yanmar Marine dealer. SD25 Operation Manual... -

Page 41: Specifications

15.3 kW (20.8 hp)/3600 min 3YM30 3YM30AE 21.3 kW (29 hp)/3600 min 21.3 kW (29 hp)/3200 min Note: • A propeller with rubber bushing must be used in all SD series Sail-Drives. • 1 hp metric = 0.7355 kW SD25 Operation Manual... - Page 42 SPECIFICATIONS This Page Intentionally Left Blank SD25 Operation Manual...

- Page 43 Yanmar Engine (Shanghai) Co., Ltd. 10F, E-Block Poly Plaza, No.18 Dongfang Road Pudong Shanghai, China P.R.C. 200120 Phone: +86-21-6880-5090 Fax: +86-21-6880-8090 OPERATION MANUAL SD25 1st edition: June 2014 Issued by: YANMAR CO., LTD. Marine Operations Business Edited by: YANMAR TECHNICAL SERVICE CO., LTD.

- Page 44 0ASDM-EN0030 http://yanmar.com...

Need help?

Do you have a question about the SD25 and is the answer not in the manual?

Questions and answers