Table of Contents

Advertisement

INSTALLATION INSTRUCTIONS

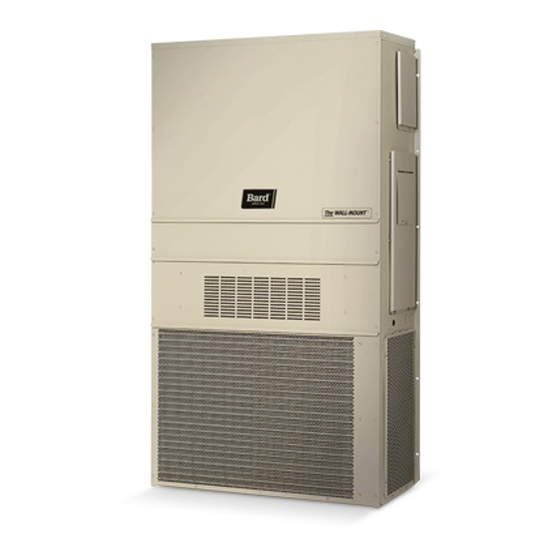

WALL MOUNTED

PACKAGE HEAT PUMPS

Standard & Dehumidification

T30S1

T36S1

T42S1

T48S1

T60S1

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

MODELS

T30S1D

T36S1D

T42S1D

T48S1D

T60S1D

Manual :

2100-547D

Supersedes:

2100-547C

File:

Tab 17

Date:

08-13-14

Page

1 of 26

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the T30S1 and is the answer not in the manual?

Questions and answers