Summary of Contents for Fidelity Electronics C-10 Series

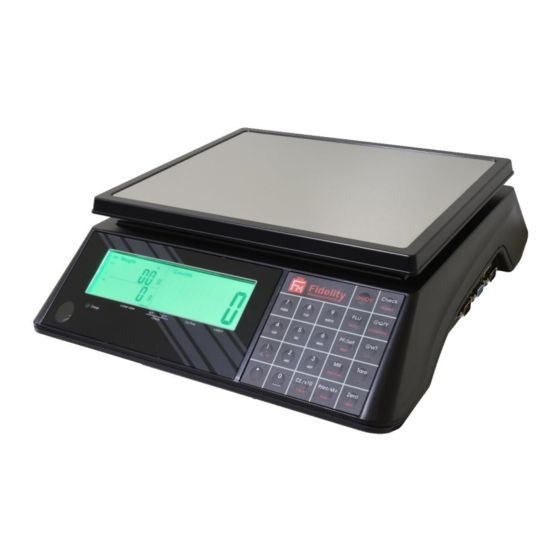

- Page 1 C-10 Series Configurable Counting Scales Operation Manual (Full Version) PLEASE READ THIS MANUAL VERY CAREFULLY BEFORE OPERATING THIS INSTRUMENT Specifications subject to change without prior notice V126 January 2021...

-

Page 3: Table Of Contents

Content Cautions ................................9 1. Reminders..............................9 1.1 Metrological Legislation .......................... 9 1.2 Seal & Serial Number ..........................9 1.3 Warm Up Time ............................9 1.4 Placing the Instrument ..........................9 2. Specifications ............................. 10 3. Panel and Keys ............................11 3.1 Key Board Description ...........................11 3.2 Display Panel Description ........................ - Page 4 8.4 Android and iOS APP ..........................29 8.4.1 Settings when Using App via WIFI Connection ................29 8.4.2 Settings when Using App via Bluetooth Connection ............... 29 9. Basic Operation............................29 9.1 Power Instrument On and Off ....................... 29 9.2 Power on Countdown Process ......................29 9.3 Operator number ..........................

- Page 5 10.5.1 Memory accumulation settings ..................... 35 10.5.2 Manual accumulation ........................35 10.5.3 Automatic accumulation........................ 35 10.5.4 When data is accumulated to memory..................35 10.5.5 Memory recall and clearance......................36 10.5.6 Dual platform accumulation rules ....................36 11. Quick PLUs .............................. 37 11.1 Unit Weight Quick PLU ........................

- Page 6 12.2.1 By Instrument keyboard........................ 41 12.2.2 By Execution Command ....................... 42 12.3 Clear Customized Setting PLU ......................42 12.3.1 By Instrument keyboard........................ 42 12.3.2 By Execution Command ....................... 42 12.4 Quit Current Customized Setting PLU Effect ..................42 13. Data Output Protocols & Formats ......................42 13.1 PC Output Protocols ...........................

- Page 7 E.1 Customized Lab 2 Output Format Variants Table .................. 57 E.2 Edit Customized Lab 2 Print Output Format ..................58 Appendix F: - Lab 3 Output Formats ......................59 Appendix G: - Lab 4 Output Format ....................... 60 Lab 4 Output Format Illustration ......................... 60 Appendix H: - Lab 5 Output Format ........................

- Page 8 Appendix S - Quick PLU Reading Commands ....................88 Appendix T: - Customized Operation Settings PLU Saving Commands ............90 T.1 Command Description Table ......................... 90 T.2 Parameter Description Table ......................... 91 Appendix U: Customized Operation Settings PLU Reading Commands ............93 U.1 Command Description Table ........................

-

Page 9: Cautions

Cautions The instrument is not an explosion proof device. The instrument is not a water proof device. Do not open the instrument, no user serviceable parts inside. Always contact your dealer for service. Do not place this instrument in where shock, excessive vibration or extremes of temperature (before or after installation) exist. -

Page 10: Specifications

2. Specifications Model Capacity (Max) Readability (d) C10-3000L 3000g 0.1g 30,000 C10-6000L 6000g 0.2g 30,000 C10-15KL 15kg 0.5g 30,000 C10-30KL 30kg 30,000 C10-6000M 6000g 0.1g 60,000 C10-15KM 15kg 0.2g 75,000 C10-30KM 30kg 0.5g 60,000 C10-10KH 10kg 0.1g 100,000 C10-20KH 20kg 0.2g 100,000 Platter... -

Page 11: Panel And Keys

3. Panel and Keys 3.1 Key Board Description Function Description Description Normal Operation Internal Function Setting Starting inputting Lo and Hi limit under current checking condition (in [Check] Quick access to label settings. terms of weight or quantity). [On/Off] Power instrument on or off. Quit without saving and power off. - Page 12 Long press = Save current operation parameters to Customized Setting PLU Numeric value + [@WT] = To introduce unit weight. Long press = To save current unit weight entry to quick PLU. [@WT] Nil. [@WT] + [Check] = Start inputting Lo and Hi limit in terms of weight.

-

Page 13: Display Panel Description

3.2 Display Panel Description Name Description LCD2 LCD display panel #2. Weight value is displayed here. (When under dual weighing range/interval mode) Visible when this Indicator instrument is operating at the first weighing range (W (When under dual weighing range/interval mode) Visible when this Indicator instrument is operating in the second weighing range (W (When under dual platform configuration) Visible when current /... -

Page 14: Meaning Of Platform No. In This Manual

3.3 Meaning of Platform No. in this Manual P1 = the built-in platform of this instrument. P2 = the external platform connected to this instrument. PA = P1+P2. 4. Connection Points 4.1 Connection Pins & Plugs Name Description External power adaptor (DC12V, 1A center positive) is plugged in here. -

Page 15: P2 Load Cell Connector Pin Assignment Table

4.2 P2 Load Cell Connector Pin Assignment Table Notes Pin # Pin Assignment Excitation +ve Apply both the 4/6 wire load cell Remote Sense +ve jumpers on external platform input board when 4-wire load cell is used. Excitation -ve ... -

Page 16: Power Adaptor, Built-In Batteries And Recharging

5. Power Adaptor, Built-In Batteries and Recharging 5.1 Power Adaptor Always use the power adaptor supplied together with this instrument to avoid un -recoverable damages to this instrument. 5.2 Before Plugging in Power Adaptor to Electricity Grid Double check if the input voltage marked on adaptor data matches with the electricity grid. If not, do not plug in and contact your dealer immediately. -

Page 17: Internal Function Settings

6. Internal Function Settings 6.1 About Internal Function Table To enable this instrument to meet and to give the best performance under various application requirements and demands, a set of internal functions are built-in. Most internal function comes with various parameters to meet various application demands and preference. These internal functions are classified into 2 categories: - •... -

Page 18: Internal Function Table

6.5 Internal Function Table Parameters / Note Description Default = Press [Print/M+] to set offset value to zero when unloaded. Then add load on the platform to observe the span value of load applied. • LCD2 represents the million digits of the AD value. •... - Page 19 System (F7~F36) ** No Initialization • Press [PF/Set] to shift between No and YES and press [Print/M+] to confirm. • If YES is selected, press [1] when “SURE?” is displayed. Instrument shows Done when initialization is completed. Auto Power Off Setting ** 5 Other Notes: -...

- Page 20 d. Then press [Zero] to quit or [Print/M+] to save and continue with AD conversion speed setting. 5 AD conversion speed parameters (15 ~ 120 time per second) are available. Press [PF/Set] or [MR] to select: - ** 15 times per second. b.

- Page 21 Off = Check Mode Disable when value is less than zero. ** On = Absolute value, all negative values will be deemed and checked as positive ones. UART (Comport) Setting 4 UARTs (UART 0, 1, 2, 3) are available. Refer to operation manual for more setting details. Machine ID and Group Machine ID Group Number...

- Page 22 Near Zero Value ** 20d or 20d Near Zero value is useful for dynamic weight check applications to bypass unnecessary Lo alarm during uploading and unloading process. Notes: - • Value entered valid only when Check function is activated. • Near zero weight value can be any value between 20d and Lo limit.

- Page 23 • ZEro = [Zero] • tAre = [Tare] • Print = [Print/M+] • ACC-Mr = [MR] • CLEAr = [CE/x10] • P.F.= Shift among P1, P2 and PA. • Set = Access internal function setting mode (F1~F36). Setting procedures: - 1.

- Page 24 • If Custom is selected, follow the below procedures for report content detail settings. 6. Press [MR] or [PF/Set] until the preferred report content detail parameter appears on LCD3 and press [Print/M+]. Below parameters are available. • oP.Code (Operator No.) •...

- Page 25 Notes: - • Select On to enable that search criteria. • Select Off to disable that search criteria. 4. Name of the next search criteria name is displayed on LCD2. 5. Repeat above steps 2 and 3 for all other search criteria until instrument displays Report on LCD2. Instrument is now in report output date duration setting status.

-

Page 26: Recommended Setting Procedures For User

7. Recommended Setting Procedures for User 1. Power off instrument and remove power adaptor. 2. Complete connection with external platform (P2). 3. Complete all hardware connection with peripheral. 4. Apply power adaptor and power on. 5. Go to F1 and check internal count value. Verify connection with weighing platform(s) is correctly done, by applying and removing loads from weighing platform. -

Page 27: Parameters Table For Pc & Command & Scanner

Setting procedures 1. Go to F16 and press [Print/M+]. 2. Name of the current UART # appears on LCD2. 3. Press [PF/Set] until the UART # (UART 0 ~ 3) appears on LCD2 and press [Print/M+]. 4. Press [PF/Set] or [MR] until the preferred transmission type appears on LCD3 and press [Print/M+] to set data communication types. - Page 28 Accumulation Default = On Note B Check Control Off / On ■ ■ ■ ■ Note C Default = Off Stability Control Yes / No ■ ■ ■ ■ Note D Default = Yes Minimum Output 10 ~ 20d in 11 steps ■...

-

Page 29: Android And Ios App

8.4 Android and iOS APP Android and iOS App are available to work with this instrument: - • For Android App: - Visit Google Play and search for aConnect. • For iOS App: - Visit Apple App Store and search for FMDirect. These Apps support both Bluetooth and WIFI connection. -

Page 30: Operator Number

6. At this point, depends on internal function number F28 setting, instrument may ask for operator number input. If this is the case: - • Input 4-digit operator number, or • Press [CE/x10] to skip operator number 7. And press [Print/M+] to enter. 8. -

Page 31: Manual Zero

9.8 Manual Zero If zero weight cannot be obtained when unloaded, press [Zero]. Zero Indicator lights up when instrument is at zero weight status. 9.9 Tare Functions 9.9.1 Manual and automatic tare This instrument is equipped with the below various tare functions. These functions can be selected in F12. a. -

Page 32: Expiry Date

9.11 Expiry Date This instrument supports expiry date output. Once expiry duration (in term of number of day) is entered in internal function F36, instrument will convert the duration entered into expiry date. Expiry date can be recalled for other purposes. 9.12 Print a Customer &... -

Page 33: Sampling Method

10.1.2 Sampling method This method is used when the unit weight is not known. Procedures: - 1. Apply samples with known quantity on weighing platform. 2. Enter quantity through numeric keys and press [@QTY]. 3. Calculation unit weight is then displayed on LCD3. 10.1.3 Employ the last unit weight when power on To employ this function, set F35 = On. -

Page 34: Check Types And Target

Check functions accept various values value and targets for P1 and P2. Settings for P1 and P2 are independent to each other. 10.4.1 Check types and target Below 2 types of check target are available. • Quantity Check: - Check target = quantity value •... -

Page 35: Check Function Priority Rules For Dual Platform (Pa) Operation

10.4.4 Check Function priority rules for dual platform (PA) operation Instrument follows the below priority rule numbers to determine the Lo and Hi check limits for dual platform (PA) operation. The platform with larger capacity. The platform with larger division value. P1 when both platforms have the identical capacity and division settings. -

Page 36: Memory Recall And Clearance

10.5.5 Memory recall and clearance To recall memory, press [MR] to recall total accumulated summary. • Number of accumulations is displayed on LCD3. • Total accumulated weight is displayed on LCD2. • Total accumulated piece number is displayed on LCD1. At this point, press [Zero] to return to operation or press [CE/x10] to clear memory. -

Page 37: Quick Plus

11. Quick PLUs This instrument is equipped with 10 quick PLUs for each for the below. Some of these quick PLUs may accept various values for P1 and P2. If it is the case, settings for P1 and P2 are independent to each other. Unit weight Quantity check limit (Quick PLU settings for P1 and P2 are independent to each other) Weight check limit (Quick PLU settings for P1 and P2 are independent to each other) -

Page 38: Recall Quantity Check Limit From Quick Plu

11.2.2 Recall quantity check limit from quick PLU Procedures: - If more than one weighing platform is used, shift to the preferred platform. During normal operation status, press [Qty] then [Check] then [PLU] Instrument displays Recall on LCD1. Press the preferred quick PLU number (0~9) and press [Print/M+]. Instrument displays the recalled Lo and high quantity limit then returns to operation status. -

Page 39: Recall Preset Tare Value From Quick Plu

11.4.2 Recall preset tare value from quick PLU Procedures: - If more than one weighing platform is used, shift to the preferred platform. During normal operation status, press [0] and press [Tare]. Instrument displays Recall on LCD1. Press the preferred quick PLU number (0~9) and press [Print/M+]. Instrument displays tare value recalled on LCD3 then returns to operation status. -

Page 40: Applying Blank Product Code And Product Description

11.5.4 Applying blank product code and product description To apply blank customer code and customer description: - During normal operation status, long press numeric number key 0. Press [PF/Set] or [MR] until P Code appears on LCD1 and press [Print/M+]. Instrument displays PLU = 00 on LCD3. -

Page 41: Applying Blank Customer Code And Customer Description

11.6.4 Applying blank customer code and customer description To apply blank customer code and customer description: - During normal operation status, long press numeric number key 0. Press [PF/Set] or [MR] until C Code appears on LCD1 and press [Print/M+]. Instrument displays PLU = 00 on LCD3. -

Page 42: By Execution Command

At this point, Customized Setting Indicator appears and selected operation settings/parameters are recalled and in effect. 12.2.2 By Execution Command Refer to paragraph M.3 on Appendix M for how to execute and recall a Customized Settings PLU. 12.3 Clear Customized Setting PLU 12.3.1 By Instrument keyboard If more than one weighing platform is used, shift to the preferred platform # (under which the log PLU is save) by pressing [PF/Set]. -

Page 43: Lab 2 Customized Output Format

• Lab 5 Output Format (Appendix H) 13.2.2 Lab 2 Customized Output Format This instrument supports customized Lab 2 output format. Refer to Appendix E for details. 13.2.3 Label Printing This instrument supports the following label printer models: - • LP50 by Datecs (www.datecs.bg/en) •... -

Page 44: Define When A Transaction Data Is Saved To Alibi Memory

Alibi Management Report Structure Illustration Table 14.2 Define when a Transaction Data is saved to Alibi memory It is important to define first the timing at when the data of a transaction is saved to Alibi memory during system setup. To do so, go to F71 (supervisor password may be needed) and select the preferred parameter. -

Page 45: Output And Settings For Alibi Memory & Management Report

14.3 Output and Settings for Alibi Memory & Management Report Complete both 2 procedures below to output management report. 1. Define report output comport and report content in F33. Refer to F33 of Internal Function Table on paragraph 6 for details. Avoid assigning RS485 for report output unless Machine ID (set in F18) is = blank. -

Page 46: Change To Different Input Target

15.2 Change to Different Input Target Once an input target barcode is scanned (e.g. product code), instrument will assume all following barcode scanning is for the same input type (i.e. product code) unless a different input target will be scanned. 15.3 More about Customer / Product Code &... -

Page 47: System Message & Error Code

17. System Message & Error Code 17.1 System Message Table Message Description --oL-- Overload (Gross weight is more than Max plus 9d). bAt.Lo Battery level low. Major system error detected. Power off instrument and remove power adaptor HALT immediately. Then check load cell connection and system power status. •... -

Page 48: Daily Care & Maintenance

Err 28 Maximum accumulation limit is exceeded Err 29 Standard deviation data exceed memory size (300 transactions) Err 30 Working mode (Operation mode AP or STA or AP&STA) Err 31 WAN Setting Err 32 Network Protocol Setting Err 33 LAN Setting Err 34 Cannot access to command mode of WIFI module Err 35... -

Page 49: Appendix A: - Pre-Defined Pc Output Protocols

Appendix A: - Pre-Defined PC Output Protocols A.1 Data Abbreviation Table Data Code Description Comma Polarity Sign Positive = space. Negative = minus (-) Polarity Sign Positive = 0. Negative = minus (-) 7 digits ADC value with lead space Gross/Net •... -

Page 50: Output Formats Tables

A.2 Output Formats Tables Protocol 0 Output Format Position Data Protocol 1 Output Format Position Data Protocol 2 Output Format Position Data Field 1 (Net Weight) Field 2 (Tare Weight) Protocol 3 Output Format Position Data Protocol 4 Output Format Position Data Protocol 5 Output Format... - Page 51 Protocol 6 Output Format Position Data Protocol 7 Output Format Position Data Protocol 8 Output Format Position Data Protocol 9 Output Format Position Data...

-

Page 52: Appendix B: - Customized Pc Output Protocol

Appendix B: - Customized PC Output Protocol This instrument supports customized PC output protocol. Under this mode: - • 2 data separation types • 7 control codes, and • 26 different transaction data are available from instrument. B.1 Customized PC Output Protocol Setting Procedures 1. -

Page 53: Customized Pc Output Content Table

B.2 Customized PC Output Content Table Symbol Explanations Nature No. of Digit Remarks CoMMA Comma Data Separator Select either one SemiCo Semi Colon Cr LF HEX Code 0D 0A HEX code 0D HEX code 0A Control Code HEX code 01 Hex code 02 Hex code 03 ... - Page 54 Op Code Operator Number 0000 ~ 9999, **** = None P Code Product Code 1 ~ 18 Blank = not entered P-Desc Product Description 1 ~ 30 Blank = not entered C Code Customer Code 1~ 18 Blank = not entered C-Desc Product Description 1 ~ 30...

-

Page 55: Appendix C: - Lab 1 Output Formats

Appendix C: - Lab 1 Output Formats Lab 1 Print Format When Lab 1 is selected, output in default format will be generated with printed data is sent. No header will be generated when line number is set = 00. See below table for print format and explanations. -

Page 56: Appendix D: - Standard Lab 2 Output Format

Appendix D: - Standard Lab 2 Output Format Standard Lab 2 Output Format Illustration Table Time of Output Time 12:24:18 Date of Output Date 2018/8/19 Accumulate Sequence No. Platform No. Platform # Customer Code Name Product Code Customer Code Description Line for Customer Description Product Code Pcode... -

Page 57: Appendix E: - Customized Lab 2 Output Format

Appendix E: - Customized Lab 2 Output Format 25 variants + 2 commands (Cr LF and End) are available for customized Lab 2 output format. Refer to the below table for more detail. E.1 Customized Lab 2 Output Format Variants Table Symbol Description Edit finished... -

Page 58: Edit Customized Lab 2 Print Output Format

E.2 Edit Customized Lab 2 Print Output Format Follow the below steps to create customized printout. 1. Go to internal function F22. Press [PF/Set] or [MR] until Custom appears. 2. Press [Print/M+], 3. This instrument displays Line 1 and the last variant or command (refer to paragraph E.1 for details) stored, 4. -

Page 59: Appendix F: - Lab 3 Output Formats

Appendix F: - Lab 3 Output Formats Current working mode and all related data are sent under this mode. Refer to below table for data output format. Semi colon is inserted between data. Lab 3 Output Format Illustration Table Data Output Output Content Data 1 Operator Number... -

Page 60: Appendix G: - Lab 4 Output Format

Appendix G: - Lab 4 Output Format Transaction data is sent in journal output format with quantity and net weight of each individual transaction. Refer to below for details. Lab 4 Output Format Illustration Data Explanation Name Customer Code Customer Code (if entered) Pcode Product Code Product Code (if entered) Opr 8888... -

Page 61: Appendix H: - Lab 5 Output Format

Appendix H: - Lab 5 Output Format Transaction data is sent in journal output format with time and quantity of each individual transaction. Refer to below for details. Lab 5 Output Format Illustration Data Explanation Name Customer Code Customer Code (if entered) Pcode Product Code Product Code (if entered) Opr 8888... -

Page 62: Appendix I: - Tsc Printer Installation, Setup & Label Upload Procedures

Appendix I: - TSC Printer Installation, Setup & Label Upload Procedures I.1 Get the below ready before Printer Installation An appropriate cable to connect printer and computer. This cable usually comes with the printer. If not, contact your printer supplier. Printer installation driver. -

Page 63: Create & Upload Label To Tsc Printer

I.4 Create & Upload Label to TSC Printer I.4.1 Selecting the Correct Edition for Bartender Software 1. To enable label uploading from computer to TSC printer, it is necessary to run Bartender as Automation or Enterprise Automation edition. Procedures as below: - 2. - Page 64 11. Double click on the preferred data source to which variant(s) has/have to add. 12. check the box below External Keyboard, then 13. enter the appropriate command on the Prompt Box (refer to paragraph K.1 for command detail). 14. Select Auto on the Source box under Template Field.

-

Page 65: Appendix J: - Sbarco Printer Installation, Setup & Label Upload Procedures

Appendix J: - Sbarco Printer Installation, Setup & Label Upload Procedures J.1 Get the below ready before Printer Installation An appropriate cable to connect printer and computer. This cable usually comes with the printer. If not, contact your printer supplier. A serial cable to connect printer and this instrument. -

Page 66: Create & Upload Label To Sbarco Printer

J.3 Create & Upload Label to Sbarco Printer 1. Run BarDrawer. Click File and then New. 2. On Printer Driver Selection page: - a. click on the preferred printer driver, then b. select Make Form under Type, then click Finished. 3. - Page 67 7. On Save Form page: - a. make sure that the Form name is correct, then b. Click Save 8. On Select Store Media page: - a. select Printer, then b. select Printer’s Flash ROM, then c. click OK...

-

Page 68: Appendix K: - Label Programming, Illustration & Samples

Appendix K: - Label Programming, Illustration & Samples Prompt commands, information description, working mode and suggested length on label are listed on the below table. K.1 Label Prompt Command Table Prompt Command Suggested Description Length Sbarco LP50 & TSC DATE Date TIME Time... - Page 69 cwnt6 Current Net Weight in 6-digit integer CQTY Quantity cqty6 Quantity in 6-digit integer AVGW Unit Weight avgw6 Unit Weight in 6-digit integer CWNT Current Animal Weight cwnt6 Current Animal Weight in 6-digit integer ASEQ Accumulation Sequence No. Accumulation Sequence No. in 6-digit aseq6 integer AWGS...

-

Page 70: K2. Label Programming Illustration

K2. Label programming Illustration K.2.1 Label Illustration for LP50 & TSC K.2.2 Label Illustration for Sbarco K.3 Sample Labels Label files of the above samples (size = 50 x 80mm) with prompt commands are available for download at: - https://www.fi-measurement.com/resource/driversnsoftwares... -

Page 71: Quick Access To Label Settings

K.4 Quick Access to Label Settings If label printer (TSC or LP50) is selected, follow the below procedures to access quick label settings during operation. Enter F1, then press [Check], Instrument displays number of copy to generate each time. Press [PF/Set] or [MR] until the preferred parameter appears then press [Print/M+] to save. -

Page 72: Appendix L: - Keyboard Command

Appendix L: - Keyboard Command Keyboard command format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Letters KB, followed by c. Letter shown on below illustration diagram (keyboard commands are case sensitive), followed by d. -

Page 73: Appendix M: - Execution Commands

Appendix M: - Execution Commands Execution command format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Command code as shown on below table (all commands are case sensitive), followed by c. End String # “number sign” (Hex code 23). Notes: - ... -

Page 74: Command Description Table (Report Related)

M.2 Command Description Table (Report Related) Command Format Command Definition Parameter Description Start Command Parameter & String Code End String Search Criteria Output all data in Alibi memory. RPTA ;d1;d2;d3;d4# d1 = Operator number 0000~9999. Blank = all. Output data of today in Alibi RPTD ;d1;d2;d3;d4# ... -

Page 75: Appendix N: - System Parameter & Operation Entry Setting Commands

Appendix N: - System Parameter & Operation Entry Setting Commands System parameter & operation entry setting command format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Command code as shown on below table (all commands are case sensitive), followed by c. - Page 76 Command Format Parameter Command Definition Parameter Description Start Command Code & String (Note A) End String Speed d2 = AD Conversion Speed (015/030/060/120) M = Off, A = Auto, 00 ~ 99 = Continuous tare (in term of Set Auto Tare Function F012 ;d1# 1/10 second)

- Page 77 Command Format Parameter Command Definition Parameter Description Start Command Code & String (Note A) End String Set Unit weight before Power Off F035 ;d1# 0 = Off, 1 = On d1 =1~18-digit Customer Code. Blank = nothing Set Customer Code and Description CCDE ;d1;d2# d2 = 1~30 Customer Code Description.

-

Page 78: Appendix O: - System Parameter Reading Commands

Appendix O: - System Parameter Reading Commands System parameter reading command format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Command code as shown on below table (all commands are case sensitive), followed by c. - Page 79 Command Format Start Command Definition Parameter Output Parameter Description Strin Command Code String = exact power off time Read Brightness and Color d1 = Brightness (01~99) F008 d1;d2 Ratio d2 =Color Ratio (01~99) Read Totalization of Platform F009 0 = Off (disable) 1 = On (Enable) P1 &...

- Page 80 Command Format Start Command Definition Parameter Output Parameter Description Strin Command Code String Read Calibration & d1= Calibration Count Parameter Counts and F029 d1;d2;d3 d2 = Parameter Set Count Pointer Value d3 = Pointer Value Read Allow Letters and Symbols for Customer &...

-

Page 81: Appendix P: - Operation Entry Reading Commands

Appendix P: - Operation Entry Reading Commands Operation entry reading command format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Command code as shown on below table (all commands are case sensitive), followed by c. - Page 82 Command Format Command Definition Parameter Output Parameter Description Start Command Code String String Read Date Value DATE 8-digit date value Read Expiry Duration F036 0 ~ 9999 (Day) Read Time Value TIME 8-digit time value Read Week Value WEEK 6-digit time value Read Expiry Date EXPY 8 digits.

-

Page 83: Appendix Q: - Operation Result Reading Commands

Appendix Q: - Operation Result Reading Commands Operation result reading command format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Command code as shown on below table (all commands are case sensitive), followed by c. - Page 84 Command Format Parameter Command Definition Parameter Description Start Command Code Output String (Note D) String Read Accumulated Gross Weight R0 or R1 or R2 or RA AWGS 8 digits including decimal (if any) Read Accumulated Tare Weight R0 or R1 or R2 or RA AWTA 8 digits including decimal (if any) Read Accumulated Net Weight...

- Page 85 Command Format Parameter Command Definition Parameter Description Start Command Code Output String (Note D) String Read Accumulated Net Weight in 6- R0 or R1 or R2 or RA awnt6 6 digit without decimal digit format and without decimal Read Accumulated Qty Value in 6- R0 or R1 or R2 or RA aqty6 6 digit without decimal...

-

Page 86: Appendix R: - Quick Plu Saving Commands

Appendix R: - Quick PLU Saving Commands Quick PLU saving command format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Command code as shown on below table (all commands are case sensitive), followed by c. - Page 87 Command Format Command Definition Parameter Description Start Command Code Parameter & String (Note E) End String • d1 = Customer Code. Maximum 18 characteristics. Asterisk (*), number sign (#) and semi colon not accepted. Blank = Nothing Save Customer Code and Description to CCDE ;d1;d2;d3# ...

-

Page 88: Appendix S - Quick Plu Reading Commands

Appendix S - Quick PLU Reading Commands Quick PLU reading command format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Command code as shown on below table (all commands are case sensitive), followed by c. - Page 89 Remark: If parameter A is entered, instrument sends content by Quick PLU numeric sequence. Note F: - • R1 = command to read content from Quick PLU of P1. • R2 = command to read content from Quick PLU of P2. •...

-

Page 90: Appendix T: - Customized Operation Settings Plu Saving Commands

Appendix T: - Customized Operation Settings PLU Saving Commands Customized operation settings PLU saving commands format as below: - a. Start String * “asterisk” (Hex code 02A), followed by b. Command code as shown on below table (all commands are case sensitive), followed by c. -

Page 91: Parameter Description Table

T.2 Parameter Description Table Parameter # Description Parameter 01 ~ 99 PLU # Maximum 18 characteristics Asterisk (*), number sign (#) and semi colon not accepted. Customer Code Blank = Nothing Maximum 30 characteristics Asterisk (*), number sign (#) and semi colon not accepted. Customer Description Blank = Nothing Maximum 18 characteristics... - Page 92 Parameter # Description Parameter Blank = 0. If Platform # is = PA; enter zero value here. 0 = Normal Date Format 1 = Week Maximum 4 digits (0 ~ 9999) 0 or blank = F4 value Expiry Duration 1 ~ 9999 = No. of day plus F4 value...

-

Page 93: Appendix U: Customized Operation Settings Plu Reading Commands

Appendix U: Customized Operation Settings PLU Reading Commands Customized operation settings PLU reading commands format as below: - Start String * “asterisk” (Hex code 02A), then followed by Command string listed on below table, then followed by Parameters listed on below table. Always insert semi colon (;) in front of each parameter, followed by End String # “number sign”... -

Page 94: Parameter Output Description Table

U.2 Parameter Output Description Table Parameter Output Parameter Description Parameter # P1 = Built-in platform P2 = External platform Platform # PA = P1+P2 01 ~ 99 PLU # 1~18-digit (* or and # will not be accepted). Blank = Nothing Customer Code Maximum 30 characteristics (* and # will not be accepted). - Page 95 Fidelity Measurement Co., Ltd. www.fi-measurement.com e-mail: info@fi-measurement.com...

Need help?

Do you have a question about the C-10 Series and is the answer not in the manual?

Questions and answers