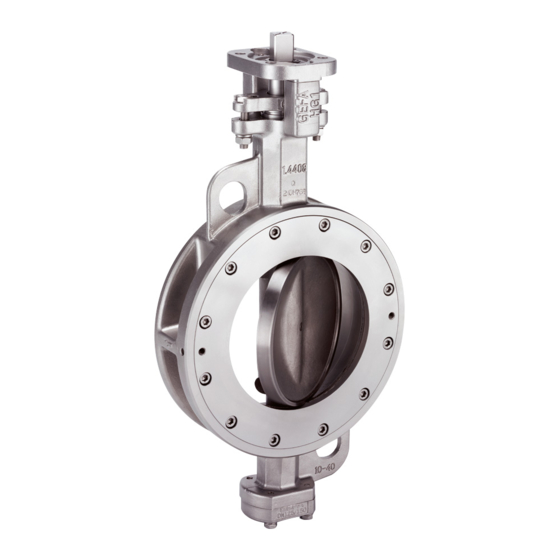

Summary of Contents for Gefa HG1

- Page 1 ARMATURENTECHNIK Original instructions Germaniastraße 28 • D-44379 Dortmund Tel.: +49 (0)231 / 61 00 9-0 • Fax: +49 (0)231 / 61 00 9-80 Internet: www.gefa.com • E-Mail: gefa@gefa.com Version 0 • Dokument-Nr. 74572811...

-

Page 2: Table Of Contents

Table of contents 1 Imprint ................................ 3 2 Safety instruction ............................ 4 2.1 Used information and warning signs...................... 4 2.2 Intended Use ............................ 5 2.3 User ................................ 5 2.4 Improper use............................. 5 2.5 Due diligence of the operator........................ 5 2.6 Product safety............................ 6 2.7 Product-specific dangers .......................... 6 2.8 Outflowing media ............................ 6 2.9 Failure of actuator operating power ...................... 6 2.10 Mounting of actuators .......................... 6 3 Scope of delivery............................ 7... -

Page 3: Imprint

These operating instructions must be available to all users at all times. GEFA Processtechnik GmbH is not liable for unauthorized changes of the device or for improper use. -

Page 4: Safety Instruction

If contradictory identifications occur, speak with the responsible authority. All PPE (personal protective equipment) must be provided by the user of the valve. 4 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 5: Intended Use

Data, diagrams, applications described and only in connection with the components, which are recommended by GEFA Processtechnik GmbH, ap- proved and mentioned in this documentation. The faultless and safe operation of the device requires proper transport, proper storage and installation as well as careful operation and maintenance. -

Page 6: Product Safety

2.6 Product safety The valves of GEFA Processtechnik GmbH correspond to the state of the art and the prescribed safety rules, but nervertheless hazards can occur in connection with valves. The valve may only be operated in proper condi- tion, in the intended area and under consideration of all associated documentation. Any change to the valve may only be made after approval by the manufacturer. -

Page 7: Scope Of Delivery

3 Scope of delivery 3.1 Exploded view DN50-300 (The description of the components can be found at the end of the chapter) 7 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 8: Exploded View Dn350-500

3.2 Exploded view DN350-500 (The description of the components can be found at the end of the chapter) 8 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 9: Exploded View Dn600

3.3 Exploded view DN600 (The description of the components can be found at the end of the chapter) 9 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 10: Bearing Protection And Vacuum Seal Dn50-600 Dn50-600 (Optional)

3.4 Bearing protection and vacuum seal DN50-600 DN50-600 (optional) Vacuum seal Bearing protection Bearing protection (The description of the components can be found at the end of the chapter) 10 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 11: Components High Performance Butterfly Valve Series Hg

1.17 O-ring 1.18 Hexagon screw 1.19 Sealing tape (optional) 1.20 Sealing tape (optional) 1.30 O-ring (optional) 1.31 O-ring (optional) 1.32 O-ring (optional) (See illustrations in this chapter) 11 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 12: Transport And Storage

For valves that are delivered without actuation, the shut-off element is not secured against adjustment. It must be transported in such a way that it can not be opened from the closed position by external influences (eg vibration). 12 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 13: Mounting And Initial Operation

If the exact end position is exceeded, bring the valve back into the open or partly open posi- tion. Then approach the end position again from the open position. 13 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 14: Installation Conditions

(ØDi ≥ ØL + 6 mm). This must be checked before the valve is installed and compared with the space necessary for the valve according to the table. ØL 14 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 15: Installation Position

1.1 x ∆PS (max. differential pressure) or 1.1 x PS (max. operating pressure) with the shut-off element closed, the lower value must be used. Flushing process NOTICE The valve must not be switched during the flushing process. 15 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 16: Mounting Instructions

With thevalve disc completely closed, tighten the flange screws crosswise using the stipulated torque. The tightening torque depends on the seals chosen. > If no specifications are given, the following standard values can be used: Flange screw Torque in Nm 16 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 17: Impermissible Operation

The throttling and control range in an intermediate position with an opening of 0 to 20% is not permissible in the long run, as the flow rate will be excessive high and the valve will be damaged. 17 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 18: Operation

Valves that regularly remain in one position must be operated at regular intervals to ensure their mobility. The valve may only be operated by trained persons who know the operating instructions, understand them and can work in accordance with. 18 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 19: Maintenance And Repair

The valves of GEFA Processtechnik GmbH are as far as possible maintenance-free. However, for operational safety reasons, all valves should nevertheless be checked regularly, for example by assessing the external con- dition and their accessories. -

Page 20: Replacing The Seat

(1.5) *. > *(See chapter 3 "Scope of delivery") 20 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 21: Decommissioning And Disposal

Since the operator of the valve is responsible for a safety rating, it is important to observe and comply with all local and company-standard safety precautions. 21 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 22: Removing Of The Valve

The opening of pneumatic actuators or pneumatic cylinders, which are equipped with a closing or opening spring, is associated with increased risk. It is essential to follow the maintenance and re- pair instructions. Maintenance and repair instructions can be found on www.gefa.com or request them directly from us. -

Page 23: How To Proceed In Case Of Malfunctions

- Check whether the limit switch is defective or misaligned Replace actuator if necessary. Remove and clean the valve, if necessary replace defective parts ac- Valve clogged or damaged cording to the instructions of the manufacturer. 23 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... - Page 24 When returning the product to the manufacturer, enclose the safety data sheet of the media. Furthermore, if ne- cessary, it must be stated which safety measures have to be observed when handling the returned product. 24 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com...

-

Page 25: Annex

After the switching operation has been completed, the position of the hand lever is to be secured by tightening the star knob. 25 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com... -

Page 26: Mounting Of The Hand Lever

If required, push the square adapter (2.5) onto the shaft. If necessary, use the enclosed retaining ring to en- sure that the square adapter will not slip off the shaft (2.4). 26 / 26 Version 0 • Dokument-Nr. 74572811 Internet: www.gefa.com • E-Mail: gefa@gefa.com...

Need help?

Do you have a question about the HG1 and is the answer not in the manual?

Questions and answers