MEMOLUB HPS User Manual

Hide thumbs

Also See for HPS:

- Installation instructions (4 pages) ,

- Quick instructions (2 pages) ,

- Instructions (2 pages)

Summary of Contents for MEMOLUB HPS

- Page 1 ® MEMOLUB User’s Guide PLI, Power Lube Injection 1509 Rapids Drive Phone: (800) 635-8170 P .O. Box 044051 Fax: (262) 637-4090 Racine, WI 53404 www.memolub.com Represented By: Revised: November 2005...

-

Page 2: Table Of Contents

..............................8 ESCRIPTION .............................. 9 ORKS ® MEMOLUB ........................9 ETROFITTING A ® THE MEMOLUB HPS WITH EXTERNAL POWER CONTROL OR SUPPLY ........9 ® MEMOLUB EPC V ........................9 ERSION ® MEMOLUB EPS: 4.5VDC, 12VDC & 24VDC P ..............10 OWERED ®... - Page 3 NSTALLATION NSTRUCTIONS MEMOLUB® HPS has a 2-year limited warranty for replacement due to defects in material and labor. Not responsible for consequential damages beyond replacement or refund of amount paid. MEMOLUB is a registered trademark of MEMOLUB International, s.a. © 2003 PLI, LLC.

-

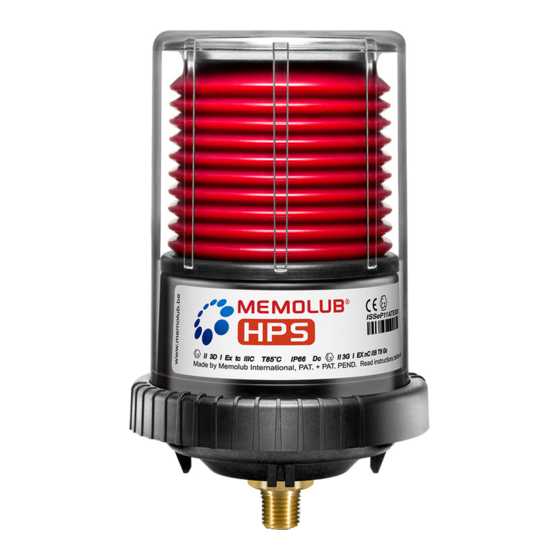

Page 4: The Memolub ® Hps

The MEMOLUB HPS is an automatic, self-contained, electro-mechanical lubricator. The "HPS" in its name stands for High Pressure System. It ejects grease or oil under programmable control at an output pressure of 350psi. There are three available models: Cartridge Capacity... -

Page 5: The Memo

The MEMO regulates the rate of grease output of the ® MEMOLUB HPS. It consists of a brass adapter, a black plastic timing-ring holder, and three plastic timing rings (one white, one red, and one black). The MEMO is permanently fitted onto the bearing or other component, and all ®... -

Page 6: The Lubricator Body

The output settings are shown on two pages in the Appendix titled “Basic Program Settings” and “Fine Tuning Your Lubrication Program”. ® When the MEMOLUB HPS lubricator is shipped, all three timing rings are seated in the plastic holder. To remove them, just use a small screwdriver. The Lubricator Body 1.3.1 Description... -

Page 7: Lubricant Cartridges And Battery Packs

The MEMOLUB EX is the same self-contained, battery powered lubricator as the ® MEMOLUB HPS model with a modified enclosure rated for limited hazardous locations. This version is identified by the black motor base housing (see Appendix for EX Ratings). ®... -

Page 8: The Multi-Point Lubrication System

® Using a MEMOLUB distribution block, the MEMOLUB HPS Multi-Point System can service from 2 to 12 lubrication points. The distribution block is completely sealed to keep out airborne contaminants, dust, and dirt, and works on the principal of piston valves. During operation, a series of pistons inside the block is actuated by the flow of lubricant from the ®... -

Page 9: Coupler Bridging Elements

® On occasion it may be desired to retrofit a previously-purchased MEMOLUB lubricator into a multi-point system, or change the number of outlet ports in a multi-point system that was previously installed. When this occurs, individual distribution blocks and coupler bridging elements are available from PLI. -

Page 10: Etrofitting Amemolub

Retrofitting a MEMOLUB ® A MEMOLUB HPS can be retrofit in the field to a 2- point Splitter-MEMO. Retrofitting is accomplished by removing the black timing ring holder from the brass fitting of the MEMO and placing it on the Splitter- MEMO. -

Page 11: The Memolub ® Eps: 4.5Vdc, 12Vdc & 24Vdc Powered

MEMOLUB HPS except when the MEMO is fitted ® with all three timing rings (white, red, and black). In this case, the MEMOLUB will complete approximately 10 continuous cycles each time power is supplied, before resuming its normal programming. -

Page 12: The Memolub 24Vdc Plc Controlled Version

+ Brown White ® • Length and type of wire to use between MEMOLUB EPS and transformer: AWG 20 (Cross section 2 x 0.5mm²) – 16 feet (5 meters) or less AWG 18 (Cross section 2 x 1.0mm²) – 33 feet (10 meters) ®... -

Page 13: Accessories

Only tubes rated at a minimum working pressure of 580psi should be used. Polyamide ® tubes (air) are not suitable for use with the MEMOLUB HPS. Keep in mind that a tube’s pressure resistance diminishes with increased temperature. The following table lists the appropriate tubing for a particular ambient temperature range: ®... -

Page 14: Table Of Recommended Pipe And Tubing Lengths

When in ® doubt, consult your tube supplier, your MEMOLUB distributor, or PLI. PLI offers tubing of various materials and diameters. This tubing is sold empty (up to 100 feet) or pre-filled with the lubricant of your choice (up to 30 feet). -

Page 15: Installation

Installing the MEMO Before installing the MEMO on the bearing, the user should manually lubricate the ® component with the same grease as the one contained in the MEMOLUB . Caution: Not ® all lubricants are compatible. When in doubt, contact PLI, your MEMOLUB distributor, or your lubricant supplier. - Page 16 • Prime the MEMOLUB HPS (if necessary) with a hand grease gun. This ® step is required only if the MEMOLUB was permitted to operate without a cartridge in place or operate with an empty cartridge. Do this by placing the outlet of the hand grease gun on the inlet ®...

-

Page 17: Installing An Oil Cartridge

® a few seconds. The MEMOLUB HPS will then go through an ejection cycle. This will confirm that electronics, mechanics and batteries are okay. It is important that this be done only with a ®... -

Page 18: Mounting The Memolub ® Hps Onto The Memo

HPS from the MEMO approximately one turn and then screw it back down (hand-tight). If the unit is working properly, it will immediately complete one ® ejection cycle. If, due to a noisy environment, it is not possible to hear the MEMOLUB ® HPS functioning during this test, unscrew the MEMOLUB HPS completely from the MEMO, go to a quieter location, and follow the instructions in Section 6.5. -

Page 19: Remote Installation

1/4” (6mm) and should not exceed 40 feet in length when the ambient temperature is 68°F or higher and when using a lubricant with a base-oil viscosity of ® 100cSt (refer to table in Section 5.2). When in doubt, consult PLI or your MEMOLUB distributor. Mounting with the 2-Point Splitter (Splitter- MEMO) The Splitter-MEMO must be mounted with tubing of 1/4”... -

Page 20: No Lubricant Is Coming Out Of The Memolub Hps

No lubricant is coming out of the MEMOLUB ® If the MEMOLUB HPS does function, and no grease comes out of the unit when doing a manual test, consider the following: • Is there a lubricant cartridge installed? If not, recharge the unit with a cartridge as described in Section 6.3. -

Page 21: Lubricant Does Not Get To The Application

Lubricant does not get to the application ® If the MEMOLUB HPS does function and empty correctly, however no lubricant is getting into the component: a) Tubing is damaged and should be replaced. b) A fitting is not correctly screwed in or the seal may be missing. -

Page 22: Appendix

APPENDIX ® MEMOLUB HPS User’s Guide Page PLI, LLC 21 of 39... -

Page 23: Memolub ® Hps Specifications

• Mining Equipment • Production Equipment of All Kinds PLI, PLI,LLC * P.O. Box 044051 * 1509 Rapids Drive * Racine, WI 53404 Telephone: 800-635-8170 * Fax: 262-637-4090 Power Lube Injection ® MEMOLUB HPS User’s Guide Page PLI, LLC 22 of 39... -

Page 24: Drawing

® MEMOLUB Dimension Drawing HPSDIM-1030 Copyright © PLI, LLC All rights reserved ® MEMOLUB HPS STANDARD - MEGA - GIGA 3.380 3.380 3.41 3.41 (86mm) (86mm) (87mm) (87mm) L1 L2 3.41 3.41 4.000 4.000 (87mm) (87mm) (102mm) (102mm) 4.000 4.000... -

Page 25: Basic Program Settings

MEMO is screwed into the bearing and remains there unless it is decided to ® change the output rate. The MEMOLUB Lubricator is then screwed onto the MEMO. This turns the lubricator on to eject lubricant at the rate of output programmed. -

Page 26: Fine Tuning Your Lubrication Program

*We recommend that Battery Packs and Lubricant Cartridges be changed at no more than 12 month intervals **Ejection cycle every 16 hours / *** Ejection cycle every other day MEMOLUB® HPS User’s Guide MEMOLUB® HPS User’s Guide Page 25 of 39... -

Page 27: Nformation

MPS4PGIN-0103-PG2 How to order your complete Multi-point Lubrication System A complete MEMOLUB® MPS (Multi-Point System) can be ordered by using the quick coding below. Simply replace the “X’s” with the code corresponding to your selection in the sub-menus. Additional installation parts and nylon tubing (empty or pre-filled with lubricant) are also available. - Page 28 Model 480 Mega MEMOLUB MEMOLUB Standard Model 240 Model 120 MEMOLUB MEMOLUB MEMOLUB MPS-05 MPS-04 MPS-06 MEMOLUB MEMOLUB MEMOLUB MPS-07 MPS-08 MPS-09 MEMOLUB MEMOLUB MEMOLUB MPS-10 MPS-11 MPS-12 MEMOLUB MEMOLUB MEMOLUB MEMOLUB® HPS User's Guide Page 27 of 39 PLI, LLC...

-

Page 29: Point

The actual volume of lubricant flowing from each output port during the period of one day is controlled by the amount of lubricant that has been programmed to be ejected by the MEMOLUB Lubricator. To program the MEMOLUB to eject the required volume of lubricant for a multi-point application, it is necessary to determine the daily volume of grease required by all of the bearings attached to the system. -

Page 30: 2-Point Splitter Program Settings

Each output strokes ejects .635 cc's of lubricant. This lubricant is divided between the two output ports. The Stroke Limiting Washers used with the Single Point MEMOLUB® to adjust the Volume of output per stroke are NOT used with the MEMOLUB®HPS 2-Point Splitter System. -

Page 31: 2-Point Splitter Dimensions

SPLTIN-0305-PG4 Copyright © 2003 PLI, LLC All Rights Reserved How It Works The Valve Stem is maintained in the upper position by the spring. When the MEMOLUB® HPS ejects lubricant, the MEMOLUB® HPS pump piston simultaneously pushes the Valve Stem downwards. Lubricant flows through the hollow Valve Stem and, as shown in stage 1, out through Outlet 1. -

Page 32: Maintenance Adapter Information

MEMOLUB® Multi-Point Systems ordered as a Plug’n Lube™ system, with tubing that has been pre-filled at the factory, already contains the correct lubricant and does not require filling in the field during installation. -

Page 33: Installation Parts

Bracket for 2 or 3 lubricators 3.75" 12" MLLB-1 MLLBK-1 Power Supply Options (used with the MEMOLUB® EPS lubricators) #OPEPS110AC5V2A2 #OPEPS110AC5V2A EPS Rack Mount Power EPS Plug in Power Connect a 110VAC power supply from your Run the MEMOLUB® EPS lubricator... - Page 34 CA-3S Chain Oil Assembly with 1" Round Stainless Brush OPLBKT-2 Oil brush mounting bracket 2" Flat 1" 5/8" 1" Nylon Round Round Round Nylon Nylon Stainless Steel CA-1 with bracket MEMOLUB® HPS User's Guide Page 33 of 39 PLI, LLC...

-

Page 35: Lubrication

® MEMOLUB HPS Manual Lubrication vs MEMOLUB HPS Automatic Lubrication Typical Manual Lubrication Pattern Relubrication 1) Infrequent 2) Irregular Missing more than one re-lubrication cycle 3) Over Lubricated and a bearing is likely to sustain damage. Regular 4) Under Lubricated... -

Page 36: Memolub® Ex

Lubricant cartridge replacement normally takes less than 1 minute. The MEMOLUB® EX may be used as a single point lubricator, either mounted directly on the bearing or remotely using pipe or flexible tubing. The MEMOLUB® EX can also be used with our progressive distribution block as a multi-point system, lubricating 2 to 12 bearing points, or with the MEMOLUB®... -

Page 37: Memolub® Epc

The 12 inch cable that extends from the bottom of the lubricator serves to interrupt the electric circuit to the drive motor. When the circuit is closed the MEMOLUB® first goes through an output cycle and then proceeds to operate under its own preset program control. When the circuit is opened the lubrication process stops. -

Page 38: Memolub® Eps

Control of the lubrication injection cycles occurs in one of two ways. • The MEMOLUB® EPS is periodically supplied with 4.5 VDC power by a PLC under program control. Lubrication output cycles of the MEMOLUB® can be based upon hours of machine operation, a count of machine cycles or any other desired criteria. -

Page 39: Memolub ® 24Vdc Plc-Controlled

The MEMOLUB 24VDC-PLC is available in three sizes: the Standard (Model 120), the Mega (Model 240), and the Giga (Model 480). Like the HPS model, it is reusable with available replacement lube cartridges. These cartridges are carefully filled at the factory using a precise centrifuging process that eliminates air pockets and contamination. -

Page 40: Nstructions

Oil Cartridges Only SAFETY PRECAUTIONS * Warning: Lower red housing contains a loaded spring. Do not open. * Use only factory pre-filled cartridges and battery packs with MEMOLUB® lubricator. 8. Screw the MEMOLUB® Note: If necessary, prime the HPS lubricator onto the MEMOLUB®...

Need help?

Do you have a question about the HPS and is the answer not in the manual?

Questions and answers