Summary of Contents for Flintec TR2 Series

- Page 1 TR2 Catalogue User Manual 0089002 User Manual TR2 Catalogue V1.0 March 2019 Page 1 of 43...

-

Page 2: Table Of Contents

First connection - Connecting TR2 to a PC ................. 12 8.1. Installing drivers ........................13 Password-protected Commands ..................13 10. Calibrate the TR2 with a PC running FDC (Flintec Device Configurator) ......14 10.1. Start up the FDC ......................15 10.2. - Page 3 Execute Command - Calibrate System Zero ............25 12.5. Connect PC to TR2 using PCAN-USB ................25 12.6. Using Flintec Device Configurator (FDC) and TR2 CAN ..........25 12.6.1. TR2 CAN Tabs ......................26 12.7. FDC CAN Terminal ......................27 12.8.

-

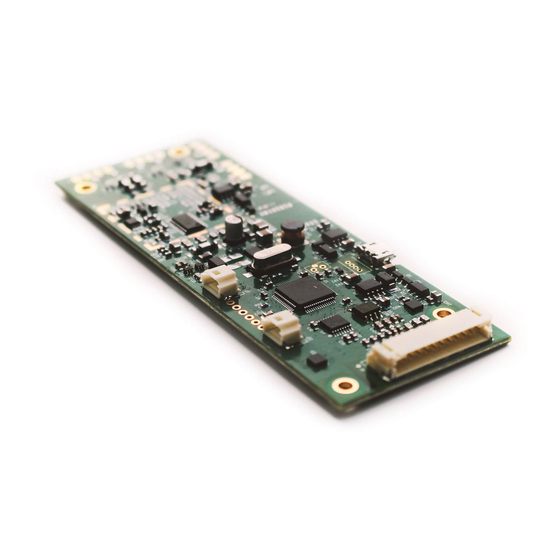

Page 4: Tr2 Catalogue

There are two variants, to cater for different supply voltages: TR2-A (5V) and TR2-B (10-24V). Setup of the module is simple using a terminal emulation program or FDC application software (available from Flintec.com). 1.2. Key features • CAN Interface •... -

Page 5: Disclaimer

Flintec reserves the right to revise this manual and alter its content without notification at any time. Neither Flintec nor its affiliates shall be liable to the purchaser of this product or third parties for damages, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with Flintec operating and maintenance instructions. -

Page 6: Safety Instructions

ALWAYS DISCONNECT this equipment from the power source before cleaning or performing maintenance. CALL Flintec for parts, information, and service. WARNING: Only permit qualified personnel to service this equipment. Exercise care when making checks, tests and adjustments that must be made with power on. -

Page 7: Specifications

5 Hz to 50 Hz Calibration Test weights or load-cell simulator Digital Filtering None / 8 or 32 Moving Average / Flintec Baby Scale Weighing Functions Zero; Gross; Tare; Net; Filter; Zero-tracking etc. Programmable Parameters Stability criteria, zero range, initial zero, min/max weight... -

Page 8: References

125 x 45mm 3. References Title Doc. Number Rev. TR2 Catalogue Text-Based Communications Specification 0084789.docm TR2 Catalogue CAN Bus Communications Specification 0087289.docm TR2 Catalogue I2C Bus Communications Specification 0087552.docm Flintec Device Configurator (FDC) Quick Start Guide. 0088642.docm Page 8 of 43... -

Page 9: Tr2-A And Tr2-B Hardware Differences

TR2 Catalogue User Manual 0089002 4. TR2-A and TR2-B Hardware differences The only difference between TR2-A and TR2-B is the supply voltage required. • TR2-A requires 5V • TR2-B requires 10V to 24V A resistor fitted to the board can be interrogated by the software to determine if it’s a TR2-A or TR2- B configuration. -

Page 10: Power, Rs232 And Can (J6)

TR2 Catalogue User Manual 0089002 Connect the input using the colour coding for load-cell connections: J8, J9, J10 and J11 Load-Cell Function Pin-Out Excitation+. Excitation-. Signal+. Signal-. Figure 2- 4-Wire Connection 5.2. Power, RS232 and CAN (J6) The power supply depends on the model. RS232 and CAN interfaces are available through this connector. -

Page 11: Micro Usb Socket (J4)

TR2 Catalogue User Manual 0089002 5.3. Micro USB Socket (J4) The USB connection has 2 functions depending on jumper J2:- 5.3.1. Normal Operation – USB-CDC (Communications Device Class) J2 not made – The USB port functions as a USB-CDC device and appears to the PC as a Serial Com Port (in Device Manager –... -

Page 12: Tr2 Serial Rs232

TR2 Catalogue User Manual 0089002 6. TR2 Serial RS232 Please note: There is comprehensive coverage of text-based serial comms in document:- 0084789.docm - TR2 Catalogue Text-Based Communications Specification 6.1. The basics • TR2 can communicate over RS232 at a fixed baud-rate of 115200, 8 data bits, No Parity and 1 stop bit. -

Page 13: Installing Drivers

For CAN you can use your preferred CAN controller. The PCAN-USB is quoted here as it is the only CAN device that will work with the Flintec Device Configurator App (FDC). The easiest connection is by USB-CDC as it uses a standard cable. -

Page 14: Calibrate The Tr2 With A Pc Running Fdc (Flintec Device Configurator)

10. Calibrate the TR2 with a PC running FDC (Flintec Device Configurator) The Flintec Device Configurator is an application that allows the user to set-up and calibrate the TR2 with a user-friendly graphical user interface (GUI). Whether connected to the TR2 by R232, USB-CDC or CAN the GUI looks the same. -

Page 15: Start Up The Fdc

10.1. Start up the FDC The screen shot shows the FDC Connection screen with no connections made. Note: The FDC supports the Flintec EM100 as well as the TR2. Figure 3 - FDC started and TR2 Catalog tab selected Page 15 of 43... -

Page 16: Connect To The Tr2 Using Comport Or Usb-Cdc

TR2 Catalogue User Manual 0089002 10.2. Connect to the TR2 using ComPort or USB-CDC Select the COM Port to which the TR2 is connected and press [Connect] Figure 4 - TR2 connected to FDC • Notice that on connecting to the TR2 the Weighing, Real-Time Chart, TR2 Set-up, Save/Restore Settings and Terminal tabs have become active. -

Page 17: Calibrate The Zero Point

TR2 Catalogue User Manual 0089002 There are some differences, for instance, CAN does not support streaming so the Real-Time Chart is not available. 10.4. Calibrate the Zero Point With the load-cell unloaded (zero load), check the [Enable Calibration] checkbox to enable the Calibration controls. -

Page 18: Calibrate The Gain / Span Point

TR2 Catalogue User Manual 0089002 10.5. Calibrate the Gain / Span Point Enter 2000 in the [2. Enter the Span / Gain weight for calibration] and place a 2000g weight on the load-cell. Press the [3. Calibrate Gain / Span Point] to set this as the span. Figure 6- Calibration done and successfully saved With Zero and Span calibration done press the [4. -

Page 19: Set The Minimum And Maximum Limits

TR2 Catalogue User Manual 0089002 10.6. Set the Minimum and Maximum limits This is not part of the calibration but if you wish to restrict the weighing range transmitted then enter the following:- • [Minimum Output CI] = -20 • [Maximum Output CI] = 2020 •... - Page 20 TR2 Catalogue User Manual 0089002 Figure 8 – Weighing tab showing load-cell with 2020g - reading still valid Figure 9 – Weighing tab showing load-cell with weight >2020g - returns Over status Page 20 of 43...

-

Page 21: Calibrate The Tr2 Manually Using Terminal

TR2 Catalogue User Manual 0089002 11. Calibrate the TR2 manually using Terminal When performing the previous calibration, the FDC hides all of what is going on “under the bonnet”. Here we are going to use a Terminal and the text-based commands to perform the same calibration. Though PC Terminal programs such as HyperTerm, TeraTerm and PuTTY can do the job the FDC has a handy ‘Terminal’... -

Page 22: Manual Calibration Breakdown

TR2 Catalogue User Manual 0089002 11.1. Manual calibration breakdown Here is a breakdown of the screenshot Command Response Description Load-cell unloaded (Zero) PW 632111<CR> Password – needed to allow calibration CE<CR> E+00595 Get Calibration counter = 595 CZ<CR> Calibrate System Zero (Zero Point) CW 2000<CR>... -

Page 23: Tr2 Can

TR2 Catalogue User Manual 0089002 12. TR2 CAN 12.1. TR2 CAN Overview • TR2 works to CAN 2.0B standard and uses 29-bit identifiers for all communications. Default speed = 500 kbps • Only one TR2 can be on the bus. (The CAN ID is treated as a command and not an address.) •... -

Page 24: Can Command Breakdown

TR2 Catalogue User Manual 0089002 10000005 [0][1] Status Bytes Function Byte [0] = System Status 0x01 Measurement is stable (no motion). 0x02 Zero action performed. 0x04 Tare is active. 0x08 TR2 is in calibration mode. 0x10 Gravity compensation is active. 0x20 0x40 TR2 warm-up is in progress. -

Page 25: Execute Command - Calibrate System Zero

CAN communication between PC and TR2 has been successfully achieved using the PCAN-USB adaptor from PEAK-Systems. Details on how to set up this adaptor and install the FDC program can be found in document:- 0088642.docm - Flintec Device Configurator (FDC) Quick Start Guide. Before going any further ensure:- •... -

Page 26: Tr2 Can Tabs

TR2 Catalogue User Manual 0089002 Figure 11- TR2 selected for CAN operation Note: To connect another TR2 using CAN would require another PCAN-USB adaptor. 12.6.1. TR2 CAN Tabs Once connected the Weighing, TR2 Set-up, Save/Restore Settings and Terminal tabs are active. If you are familiar with using TR2 over Serial you will notice that apart from the Terminal tab, all the controls on the tabs are the same and the GUI is very familiar. -

Page 27: Fdc Can Terminal

TR2 Catalogue User Manual 0089002 12.7. FDC CAN Terminal Whilst it is easy to set up and calibrate the TR2 from the TR2 Set-up tab, we are going to use the TR2 CAN Terminal tab to calibrate the TR2. The reason for this is so the user can get a good idea of the data that goes back and fore. Not all TR2 users are going to use the TR2 connected to a PC or require the FDC for their project. -

Page 28: Manually Calibrate Tr2 Over Can

TR2 Catalogue User Manual 0089002 12.8. Manually calibrate TR2 over CAN This is similar to what was done earlier in the document where we used the Serial Terminal to manually calibrate the TR2 with a 2000g weight. The steps of this exercise will be: •... -

Page 29: Decode The Commands, Data And Response

TR2 Catalogue User Manual 0089002 12.8.2. Decode the commands, data and response This shows the commands, data and response recorded in the screenshot and their meaning. Command Response Description Load-cell unloaded (Zero) 1000040 2F A5 09 00 100000005 09 00 Cmd = Set Password = 0x09A52F (632111 decimal) Resp = In Cal Mode, Stable, No errors. -

Page 30: Using Pcan-View

TR2 Catalogue User Manual 0089002 12.9. Using PCAN-View If you decide to use the PCAN-USB adaptor from PEAK-Systems, then it is useful to know about their PCAN-View PC application for doing lower level work or debugging. We’ve used PCAN-View in 2 scenarios:- 1. -

Page 31: Read Command 0X10000006 - Get Calibration Counter

TR2 Catalogue User Manual 0089002 • Write command – 0x1000040 - Set Calibration Mode Register (Password) • Execute command – 0x10000087 - Calibrate System Zero We are going to send these commands from FDC to TR2 and allow PCAN-View to record the data. The screenshots below show the command/data transmitted and the command/data received. -

Page 32: Tr2 I2C

TR2 Catalogue User Manual 0089002 13. TR2 I2C See document 0087552.docm - TR2 Catalogue I2C Bus Communications Specification for a fuller description of using TR2 over I2C. 13.1. TR2 I2C Overview • The TR2 will operate in slave mode, meaning that the master ECU will define the clock speed, though it is assumed that this will be around 20 kHz. -

Page 33: Engineering Mode

TR2 Catalogue User Manual 0089002 14. Engineering Mode When requesting Net, Gross or Tare Weight the reading is to 1 decimal place, but with the decimal place always set to 0. Therefore a TR2 calibrated to weigh grams with 108.1g on the load-cell will show 108.0. However, if Engineering Mode is activated the decimal place becomes valid, as shown below. -

Page 34: Tr2 Tilt Sensing

TR2 Catalogue User Manual 0089002 15. TR2 Tilt Sensing 15.1. Overview When weighing with a load-cell it is important that the load-cell is kept level so that the reading is accurate. If the load-cell is tilted then the weight registered will not be as accurate. This may not be a problem for small angles of tilt but for larger angles it could give unacceptable readings. -

Page 35: Tilt Commands

TR2 Catalogue User Manual 0089002 In an ideal situation we would see: • X and Y axis showing approx. 0 counts • Z axis is approx. +1023 counts. • PCB now placed upside down. Z axis is approx. -1023 counts. The best way to see the tilt feature in action is using the FDC application on the TR2 Set-up Tab. -

Page 36: Accelerometer - Nxp Mma8452Q

TR2 Catalogue User Manual 0089002 Figure 18- Tilt Sensor with nearest long edge slightly raised This time the X and Z axes are still near their baseline values, but the Y axes has increased by nearly 100 counts. 15.6. Accelerometer – NXP MMA8452Q The accelerometer used on the TR2 is the NXP MMA8452Q. -

Page 37: Tr2 Gravity Compensation

TR2 Catalogue User Manual 0089002 16. TR2 Gravity Compensation 16.1. Overview Gravity Compensation is usually required when a scale is calibrated in one location (say the factory where it was manufactured) and then moved to the customer location. If the gravity values between the factory and customer location are different then the weight seen on the scale maybe higher or lower than expected. -

Page 38: Tr2 Communication Commands

TR2 Catalogue User Manual 0089002 17. TR2 Communication Commands Below are the commands used over Serial (RS232 and USB-CDC), CAN and I2C. They have been extracted from their respective specification documents which are also listed. These documents are well detailed, so the contents are not repeated here. 17.1. - Page 39 TR2 Catalogue User Manual 0089002 Command code W Description ü C Calibration Gravity Value ü C User Gravity Value C Filter Type ü ü C Sample Rate ü C CAN Bus Speed ü C Engineering Mode ü Tilt Sensor Baseline Tilt Sensor Data ü...

-

Page 40: Can Commands

TR2 Catalogue User Manual 0089002 17.2. CAN Commands From document 0087289.docm - TR2 Catalogue CAN Bus Communications Specification Message ID Data Length Description ‘Read’ Messages. The RTR bit will be set. (RTR = Remote Transmit Request) 0x10000000 8 bytes Get TR2 Serial Number (bytes 0 - 7) 0x10000001 8 bytes Get TR2 Serial Number (bytes 8 - 15) - Page 41 TR2 Catalogue User Manual 0089002 Message ID Data Length Description ‘Write’ Messages. The RTR bit will be clear. 0x10000040 4 bytes Set Calibration Mode Register (Password) 0x10000041 2 bytes Set No-Motion Range 0x10000042 2 bytes Set No-Motion Time 0x10000043 2 bytes Set Calibration Gain Weight 0x10000044 4 bytes...

-

Page 42: I2C Commands

TR2 Catalogue User Manual 0089002 17.3. I2C Commands From document 0087552.docm - TR2 Catalogue I2C Bus Communications Specification Command code W Description 0x00 ü Read Serial Number 0x01 ü Read Firmware Version 0x02 ü Read General Status 0x03 ü Read Calibration Counter 0x04 ü... - Page 43 TR2 Catalogue User Manual 0089002 Command code W Description 0x89 Save Calibration Data 0x8A Restore Factory Defaults 0x8B ü Reset Firmware 0xC0 Set No-Motion Range 0xC1 Set No-Motion Time 0xC2 Set Calibration Gain Weight 0xC3 Set User Gravity Value 0xC4 Set Minimum Output Value 0xC5 Set Maximum Output Value...

Need help?

Do you have a question about the TR2 Series and is the answer not in the manual?

Questions and answers