Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Okolab CO2-O2-UNIT-BL

- Page 1 CO2-O2-UNIT-BL [0-10; 0-1] Gas Controller Manual IST2180_REV01 SV 2.2.5...

- Page 2 This page was left Blank...

-

Page 3: Table Of Contents

SAFETY NOTES ..................................3 SUPPLIED EQUIPMENT ................................5 GAS SUPPLIED REQUIREMENTS ............................6 COMPATIBILITY ..................................6 EQUIPMENT DESCRIPTION ..............................8 INSTALLATION ..................................10 CO2-O2-UNIT-BL [0-10; 0-1] ............................ 10 ETTING UP CO2-O2-UNIT-BL [0-10; 0-1] ............18 OW TO ASSEMBLE WITH A CONTROLLER USER INTERFACE .................................. - Page 4 FIGURE LIST ..................................55 MANUAL REVISION TABLE ............................56...

-

Page 5: Preface

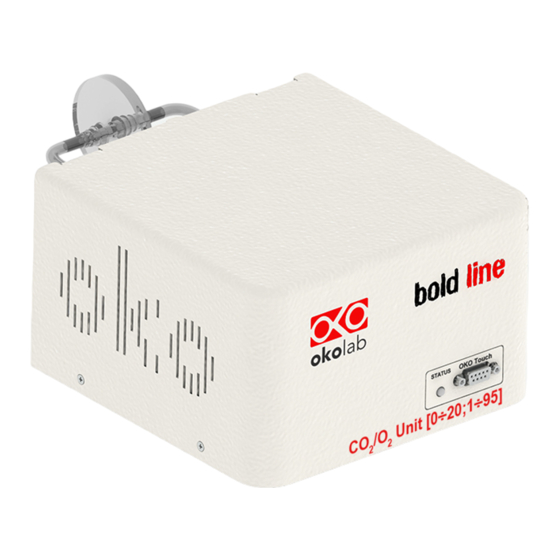

Preface CO2-O2-UNIT-BL [0-10; 0-1] is a Digital CO2/O2 Controller that mixes CO2, N2 and Air to the desired concentration in the CO2 range 0-10% and O2 range 0-1%. It features a long life Non Dispersive Infrared (NDIR) dual wave length CO2 detector and a O2 electrochemical sensor to ensure a high accuracy on the gas composition and a flow rate sensor to regulate output flow rate. -

Page 6: Symbol Description

Symbol description This paragraph describes the symbols used in this manual and on the product label. Symbols used in this manual The following symbols identify important information to note: CAUTION or WARNING: this symbol warns you about the risk of electrical shock. CAUTION or WARNING or IMPORTANT: this symbol warns you of circumstances or practices that can affect the functionality of the instrument. -

Page 7: Safety Notes

Safety Notes In order to achieve maximum performance and to ensure proper operation of your new equipment, please read carefully the following safety notes and the instructions. If you have any question, please contact Okolab. − The equipment must only be used as intended and as described in this Manual. - Page 8 We reserve the right to make technical variations. IN NO EVENT SHALL OKOLAB S.R.L. BE LIABLE FOR ANY DIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY NATURE, OR LOSSES OR EXPENSES RESULTING FROM ANY DEFECTIVE PRODUCT OR THE USE...

-

Page 9: Supplied Equipment

TUBE-A (x3). Rigid tubes, Polyurethane 3m long 6mm OD each. Use TUBE-A to connect N2, Air and CO2 supply to the corresponding input ports (N2, Air and CO2) on the rear panel of the CO2-O2-UNIT-BL [0-10; 0-1]. Pressure Gauge for CO2/N2 + regulator + assembly stirrup (x2). Install pressure gauge between the pure CO2 /N2 supply pressure regulator and the corresponding CO2/N2 input port on the rear panel of CO2-O2- UNIT-BL [0-10;... -

Page 10: Gas Supplied Requirements

Air. Air must be available at 1.4 barg (20.3 psig), with a connector for 6mm OD rigid tube. Note ► An alternative to the compressed air, OKO-AIR-PUMP-BL allows to use background Air. Compatibility CO2-O2-UNIT-BL [0-10; 0-1] is compatible with: • OKO-TOUCH (required), including: −... - Page 11 • DATA-LOG. Software used to log, view, and store data from a PC. It may be used to change parameters of the controllers via PC. Data can be exported in .xlsx format. Figure 3. DATA LOG software. • SM-BL Smart Box. To store data, to operate the controllers via web/smartphone/tablet and to allow remote assistance for service.

-

Page 12: Equipment Description

Gas Output. Push to fit Input connector for 6 mm O.D. rigid tubing to supply mixed gas to the user system. Power Input. OKO-AIR-PUMP-BL connector. Leave unplugged if CO2-O2-UNIT-BL [0-10; 0-1] is not equipped with OKO- AIR-PUMP-BL. HM-ACTIVE connector. Leave unplugged if CO2-O2-UNIT-BL [0-10; 0-1] is not equipped with HM-ACTIVE. - Page 13 Figure 5. Gas Controller Rear Panel Overview. Figure 6 illustrates CO2-O2-UNIT-BL [0-10; 0-1] left panel: Oxygen Analyzer includes the O2 sensor. Oxygen Analyzer – Gas input connector. Push to fit connector (4 mm OD rigid tube) for mixed gas input to O2 Sensor.

-

Page 14: Installation

Install the supplied pressure gauge between the CO2 supply and CO2-O2-UNIT-BL [0-10; 0-1]. Install the supplied pressure gauge between the N2 supply and CO2-O2-UNIT-BL [0-10; 0-1]. Follow the arrow on the rear of the pressure gauge for the correct Gas In-Out (see Figure 7). - Page 15 CO2-O2-UNIT-BL [0-10; 0-1] gas sensors. Connect the TUBE-CB with the Filter In and Filter Out connectors on the rear panel of CO2-O2-UNIT-BL [0-10; 0-1] (1, 2 in Figure 5 and Figure 10). Make sure the Filter In label side of the filter is always connected to Filter In connector on the rear panel of CO2-O2-UNIT-BL [0-10;...

- Page 16 Figure 11. How to connect (a) and disconnect (b) tubings from push to fit connectors. Before disconnecting any of tubing connected to CO2-O2-UNIT-BL [0-10; 0-1], make sure there is no residual pressure by adjusting the pressure gauges upstream of the system and the tanks.

- Page 17 Tip ► Make sure to push the tubes all the way into the connectors thus avoiding any gas leak. ORING O2 SENSOR Figure 12. O2 Sensor installation. Figure 13 shows the connections between the N2, Air and CO2 tanks and the respective connectors on the rear panel of CO2-O2-UNIT-BL [0-10; 0-1].

- Page 18 TUBE-A NOT supplied Figure 13. N2, Air and CO2 tanks connections to the back panel of CO2-O2-UNIT-BL [0-10; 0-1]. Tip ► If you have ordered OKO-AIR-PUMP-BL, connect TUBE-B between the OKO-AIR-PUMP-BL and the connector labeled Air on the rear panel of CO2-O2-UNIT-BL [0-10; 0-1] (see Figure 14).

- Page 19 Connect one end of the TUBE-C to the push to fit connector of the port labeled “Gas output” on the rear panel of CO2-O2-UNIT-BL [0-10; 0-1] and the other side of the TUBE-C to your device, as shown in Figure 15.

- Page 20 Note ► If you purchased CO2-O2-UNIT-BL [0-10; 0-1] with H301-T-UNIT-BL-PLUS and HM-ACTIVE use the supplied TUBE-C to connect the CO2-O2-UNIT-BL [0-10; 0-1] gas output to the to the port labeled “Gas Input” on the Humidity Sensor Lid of HM-ACTIVE (see Figure 17). Connect the Heated Based cable of HM-ACTIVE to the port labeled “H.M.”...

- Page 21 4) on the front of CO2-O2-UNIT-BL [0-10; 0-1] will turn green. 10. Once the system has been initialized the Status LED on the front of CO2-O2-UNIT-BL [0-10; 0-1] will stop blinking and will turn steadily on. The Homepage will appear on the touch screen, the color of the Status Indicator (see 1 in Figure 22 and Figure 25) on the gas tab will be yellow at the start.

-

Page 22: How To Assemble Co2-O2-Unit-Bl [0-10; 0-1] With A Bold Line Tcontroller

Figure 20. CO2-O2-UNIT-BL [0-10; 0-1] and H301-T-UNIT-BL-PLUS. CO2-O2-UNIT-BL [0-10; 0-1] must stack on top of the Bold Line T controller by lining up the bus ports located on the top and bottom surface of each unit. When the units are properly connected the Temperature and CO2/O2 parameters will appear on the OKO-TOUCH Touch Screen interface Home page. - Page 23 Figure 21. CO2-O2-UNIT-BL [0-10; 0-1] and H301-T-UNIT-BL PLUS on stock. If you have CO2-O2-UNIT-BL [0-10; 0-1] and a Bold Line T controller, it is essential to read both this manual and the Bold Line T controller User Manual to familiarize yourself with the...

-

Page 24: User Interface

8. Settings. Press here to access system options and settings. 9. Home. To open the homepage. 10. Product info. Press here to know generic info about CO2-O2-UNIT-BL [0-20; 1-95] and running time. Tip ►The OKO-TOUCH is pre-set at 6% CO and 1% O 9.1.1... - Page 25 24 b) to save or Cancel to undo. Tip ►After any change in the Setpoint value, CO2-O2-UNIT-BL [0-10; 0-1] enters into a transient regime, the Status Indicator and the TOP LED (see Figure 25) turn yellow (see paragraph 9.1.2). During the transient...

-

Page 26: Controller Status: Colours Led And Meaning

Setpoint change. The system is working properly, it is not in alarm and no action is needed. As soon as CO2-O2-UNIT-BL [0-10; 0-10] reaches the CO2 and/or O2 composition, CO2-O2-UNIT-BL [0-10; 0-1] Status changes to NORMAL and the color turns GREEN. -

Page 27: Settings

Settings 9.2.1 Press on Settings icon to enter the Settings menu, as shown in the Figure 26 a. Figure 26. Gas Settings (a – b). To enter the Gas Settings Submenu, press the Gas Icon Figure 26 b). Then the page shown in (see Figure 27 appears. - Page 28 Note ► When using Air Pump, the maximum total flow is limited to 0.4 l/min. To connect the Air Pump (OKO-AIR-PUMP-BL) to CO2-O2-UNIT-BL [0-10; 0-1], see Figure 14. In the case you are using OKO-AIR-PUMP-BL please note that it can be turned on/off only via the Touch Screen interface (OKO-TOUCH).

-

Page 29: Calibration

Calibration Menu, as shown in Figure 30. Figure 30. How to reach the Sensor Calibration Submenu (a – b). Note ► Okolab recommends the calibration of O2 Sensor every three weeks. Note ► Okolab recommends the calibration of CO2 Sensor every year. - Page 30 CO2-O2-UNIT-BL [0-10; 0-1] Reading values 5.00% 0.51 % External Gas Meter (not supplied) Figure 32. External Gas Meter Connection. Once you have connected the external gas meter to CO2-O2 Unit-BL [0-10; 0-1], wait until it steadily reads CO2 and O2 values and make sure that the system remains stable over time.

-

Page 31: Sensors (With Calibration Gas)

Gas Tank (Span Gas or N2 tank) connected to the port labeled “N2” on the rear panel of CO2-O2-UNIT-BL [0-10; 0-1], then press the Sensors icon , as shown in Figure 37 a. At this... -

Page 32: View

Figure 37. How to insert the Span Gas Calibration parameters (a – b). 9.2.1.2.2.1 View Press on View icon to visualize the latest calibration. Figure 38.View Sensor calibration status (a – b). 9.2.1.2.2.2 Span Settings Press on Span Settings icon to access to the span gas settings (see Figure 39, a). -

Page 33: Factory Reset

9.2.1.2.2.3 Factory Reset Press on Factory Reset icon (see Figure 40 a) to reset the Gas Calibration to the factory calibration. After clicking, a pop-up message will appear. If you are sure to proceed and restore factory values, press “Reset”, as shown in the Figure 40 b. -

Page 34: Start Zero

Zero Calibration (see Figure 44 a). Note ► Okolab recommends to use N2 with Standard Purity (coded as 5.0). After clicking a pop-up message will appear warning about the pause of the control during the calibration... -

Page 35: Factory Reset

Figure 44. Start Zero calibration (a – b) The Zero Calibration will start after pressing “OK” and the progress bar will appear (see Figure 45 b). Figure 45. Zero calibration running (a – b) 9.2.1.2.3 Factory Reset If you are unsure about the calibration you have just performed or if for any reason you want to reset to the factory calibration, press on Factory Reset icon (see Figure 46 a). - Page 36 to send to your incubator/device. Press the Total flowmeter to set the gas flowrate in the range 0.2÷1.0 l/min using the slider, as shown in Figure 48. Figure 47. Flowrates View (a – b) Figure 48. How to change the total flow rate. When setting the flowrate for values below 0.2 l/min, the warning message “Total Flow not allowed”...

-

Page 37: Gas Cycles

Figure 50. Setting the flowrate at 0.0 l/min. Note ► When using the Air Pump, the gas flowrate is available in the range 0.2÷0.4 l/min. 9.2.1.4 Gas cycles This function allows switching between two different CO2/O2 concentrations. Press the Gas cycle icon to set a gas concentration cycle (see Figure 51 a). - Page 38 Figure 52. CO2 and O2 Concentrations cycles settings (a – b). Figure 53. Set the duration of the Gas Cycle. Once you have adjusted the settings, the Cycle Summary page will be displayed (see Figure 54 a). Press Save As if you want to save the CO2/O2 Cycle program to be recalled for future experiments. Note ►You can save up to 4 different CO2/O2 Cycles programs.

- Page 39 Figure 55. Cycle Start. The cycle will start at the time set. A concentration cycling icon will be displayed on the Homepage as a reminder (see Figure 56). Figure 56. Icon in Homepage during a CO2/O2% cycle. Note ► Trying to change Setpoint or starting a new cycle while a cycle is still running will open the window in Figure 57.

-

Page 40: Status

Status Press the Status icon to check CO2-O2-UNIT-BL [0-10; 0-1] performance (see Figure 58 a). Figure 58. Status page (a – b). Note ► The Status page contains advanced technical data. You may be asked to read these data in case of... -

Page 41: Touch Screen Configuration

9.2.2 Touch Screen configuration Press on Settings icon to enter the Settings menu, as shown in the Figure 59 a. To enter the Touch Screen configuration menu, press on the icon , as shown in Figure 59 b. Figure 59.Touch screen settings (a – b). 9.2.2.1 Touch Screen Options Press the Options icon... -

Page 42: Touch Screen Visual Effects - Icon And Glance Mode

Never, the Top LED will never illuminate, if you select On Alarm, the TOP LED will illuminate only when CO2-O2-UNIT-BL [0-10; 0-1] is in Alarm Status (see paragraph 9.1.2), if you select Always, the TOP LED will always illuminate. -

Page 43: Alarms

Figure 63. Touch screen settings. Date and Time (a – b). 9.2.2.5 Alarms CO2-O2-UNIT-BL [0-10; 0-1] also allows activating visual and audible alarms. To set the alarms specifications, press the Alarms icon (see Figure 64 a), then follow the indications... -

Page 44: Data Logging

9.2.2.6 Data Logging CO2-O2-UNIT-BL [0-10; 0-1] touch screen interface, OKO-TOUCH (see Figure 2), is equipped with on- board memory for data logging and storage. A simple routine allows downloading data to USB drive or to PC. In order to log and then download the logged data, connect a USB drive (not supplied) to OKO-TOUCH, using MINI-USB-OTG cable (provided), as shown in Figure 66. - Page 45 Figure 67 (a) How to enter the setting menu; (b) how to enter the Touch Screen menu. Press on Logging icon (see Figure 68 a) and flag Internal memory in the page that appears (see Figure 68 Tip ► When activating the logging on the internal memory, you can access the Logging page also by pressing the activated logging icon on the Homepage, as shown in Figure 69 Figure 68.

- Page 46 Figure 70. How to set the logging time (a – b). Choose how you want to organize the data when downloaded, by pressing on Day, Week or Month, see Figure 70 a. Tip ►If you select Day, the data will be split in files, each one containing the data of one day. If you select Week, the data will be split in files, each one containing the data of one week.

- Page 47 Note ►The available memory depends on the time interval you have inserted in the Logging page. The default logging Time Interval is 30 seconds. Figure 73. Internal memory status. (a) Logging page settings; (b) Internal log page settings. To download the data, press on To USB or on Erase if you want to delete the data, see Figure 73 b. Figure 74.

-

Page 48: Overview

Okolab engineers you may be asked for some of these data Icon and Glance Mode View CO2-O2-UNIT-BL [0-10; 0-1] features two display modalities: Icon mode and Glance Mode, as shown in Figure 78 a and b. You can swap between the two display modalities by pressing on icon... -

Page 49: Info Page

Press the icon to access the Info Page, as shown in Figure 79. This page contains the information related to the OKO-TOUCH (as shown in Figure 80 a) and to CO2-O2-UNIT-BL [0-10; 0-1] version (as shown in Figure 80 b). -

Page 50: Touch Screen Calibration

10 Touch Screen Calibration Keep pressed the ON/OFF button on OKO TOUCH for 7 seconds to start the Touch Screen Calibration (see Figure 81). While holding the button, the pop-up message shown in Figure 82 a appears. Then tap blue calibration dots until the calibration is complete (see Figure 82 b). -

Page 51: Cleaning & Maintenance

Liquids should not be entered inside CO2-O2-UNIT-BL [0-10; 0-1]. Maintenance − Verify periodically the status of all hoses/tubing. If some hoses/tubing is damaged, contact Okolab to receive assistance. − After 2 years, disconnect all polyurethane tubing, cut the last 1 cm of the tubing and reconnect them. -

Page 52: Appendix: Oxygen Analyzer

12 Appendix: Oxygen Analyzer The Oxygen Analyzer is designed to be mounted on a suitable clip in a general purpose area. It is not suitable for installation in a hazardous area though it may be mounted outdoors if the temperature range does not exceed the 5-45°C for which it is rated. -

Page 53: O2 Sensor Replacement - Procedure

Disconnect the two tubes from the Oxygen Analyzer – Gas input connector and Oxygen Analyzer – has output connector on the left side of CO2-O2-UNIT-BL [0-10; 0-1] (see image 2 in Figure 84), Unscrew the sensor unit cap (see image 3 in Figure 84) being careful not to lose the O ring (see image 4 in Figure 84). - Page 54 O-RING O2-SENSOR Figure 84. O2 Sensor replacement Inspect the sensor unit cavity, and if any sign of moisture clean it out with a Q tip or similar. Make sure that the contact springs inside the sensor unit are intact. Be careful not to snag them with the Q tip. Carefully open the bag using a pair of scissors or a knife.

- Page 55 Carefully replace the cap, making sure that you do not cross thread it, and tighten firmly by hand. Do not over- tighten. 10. Allow the sensor to stabilize for a few minutes and then calibrate it preferably using known fresh air as the calibration gas.

-

Page 56: Support

To contact one of our engineers please write to support@oko-lab.com or contact us through the live chat in www.oko-lab.com. You can request a remote support session anytime. Please, do not hesitate to contact Okolab should you need any further commercial information or technical support. HARDWARE SUPPORT: sibillo@oko-lab.com Phone... -

Page 57: Technical Specifications

14 Technical Specifications CO2-O2-UNIT-BL [0-10; 0-1] – Technical Specifications Range: 0-10% Step size: 0.1% Accuracy: ± 0.1% Sensor: 10 year-life, Non Dispersive InfraRed (NDIR) dual wave length detector Recommended Calibration Interval: 1 year Range: 0 - 1% Step size: 0.1% Accuracy: ±... -

Page 58: Troubleshooting

15 Troubleshooting We have collected in the table below some frequently asked questions, please contact Okolab if you need support. Symptom Probable cause Remedy No power supplied to Unit Power plug is disconnected Connect plug securely Check gas tanks and/or compressed lines... - Page 59 Figure 12. O2 Sensor installation........................................ 13 Figure 13. N2, Air and CO2 tanks connections to the back panel of CO2-O2-UNIT-BL [0-10; 0-1]............14 Figure 14. N2, CO2 and Air Pump connections to the rear panel of CO2-O2-UNIT-BL [0-10; 0-1]............15 Figure 15.

- Page 60 Figure 78. Display modalities. (a) Icon Mode; (b) Glance Mode..........................45 Figure 79. Info page selection........................................45 Figure 80. Info page OKO-Touch (a) and CO2-O2-UNIT-BL [0-10; 0-1] (a - b)....................45 Figure 81. How to enter in Touch Screen Calibration..............................46 Figure 82.

- Page 61 LIMITATION OF LIABILITY: the total liability of Okolab S.r.l. shall not exceed the purchase price of the component upon which liability is based. In NO event shall Okolab S.r.l. be liable for consequential, incidental or special damage.

Need help?

Do you have a question about the CO2-O2-UNIT-BL and is the answer not in the manual?

Questions and answers